Patents

Literature

35results about How to "Prevent lateral swing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

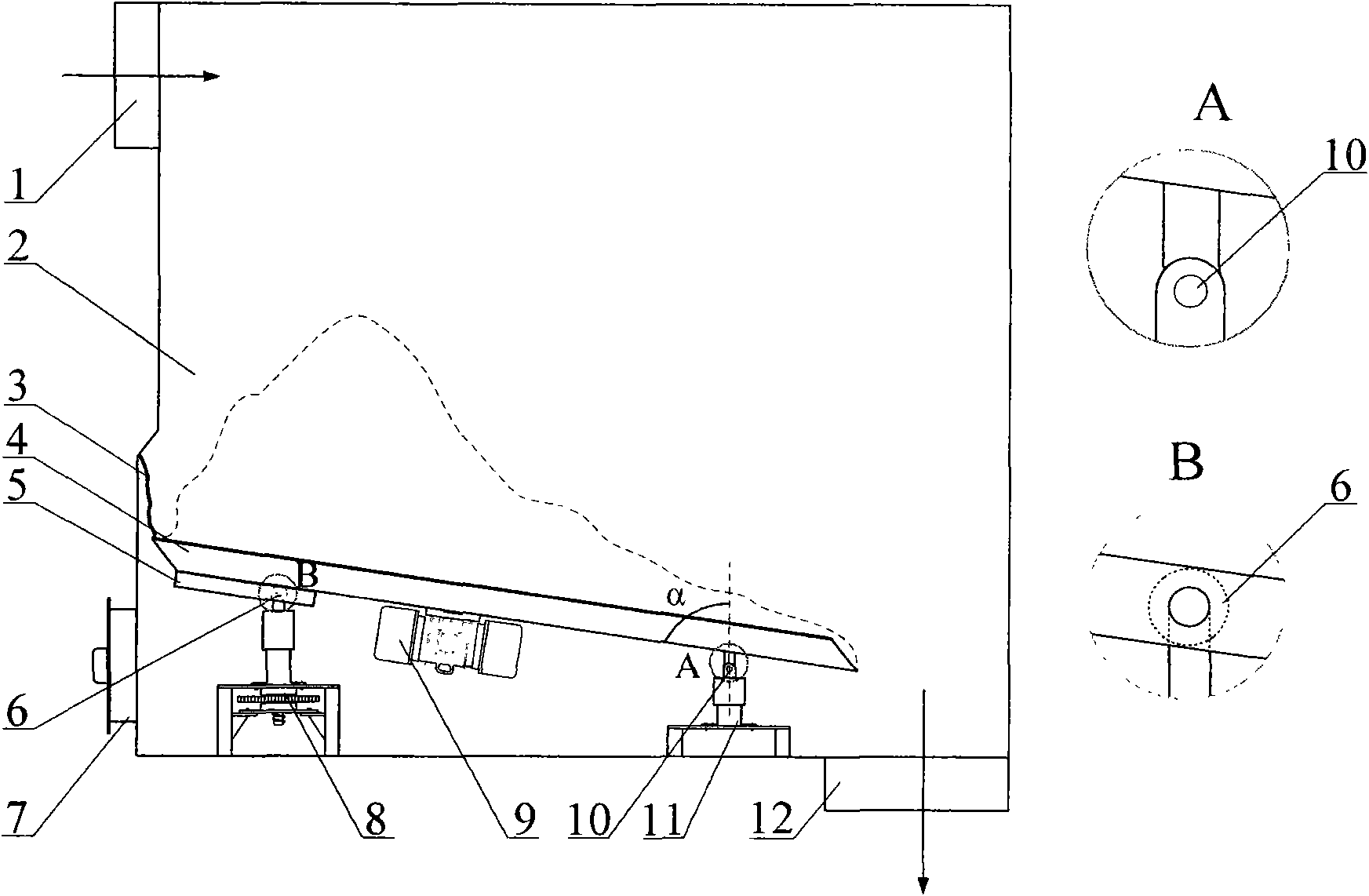

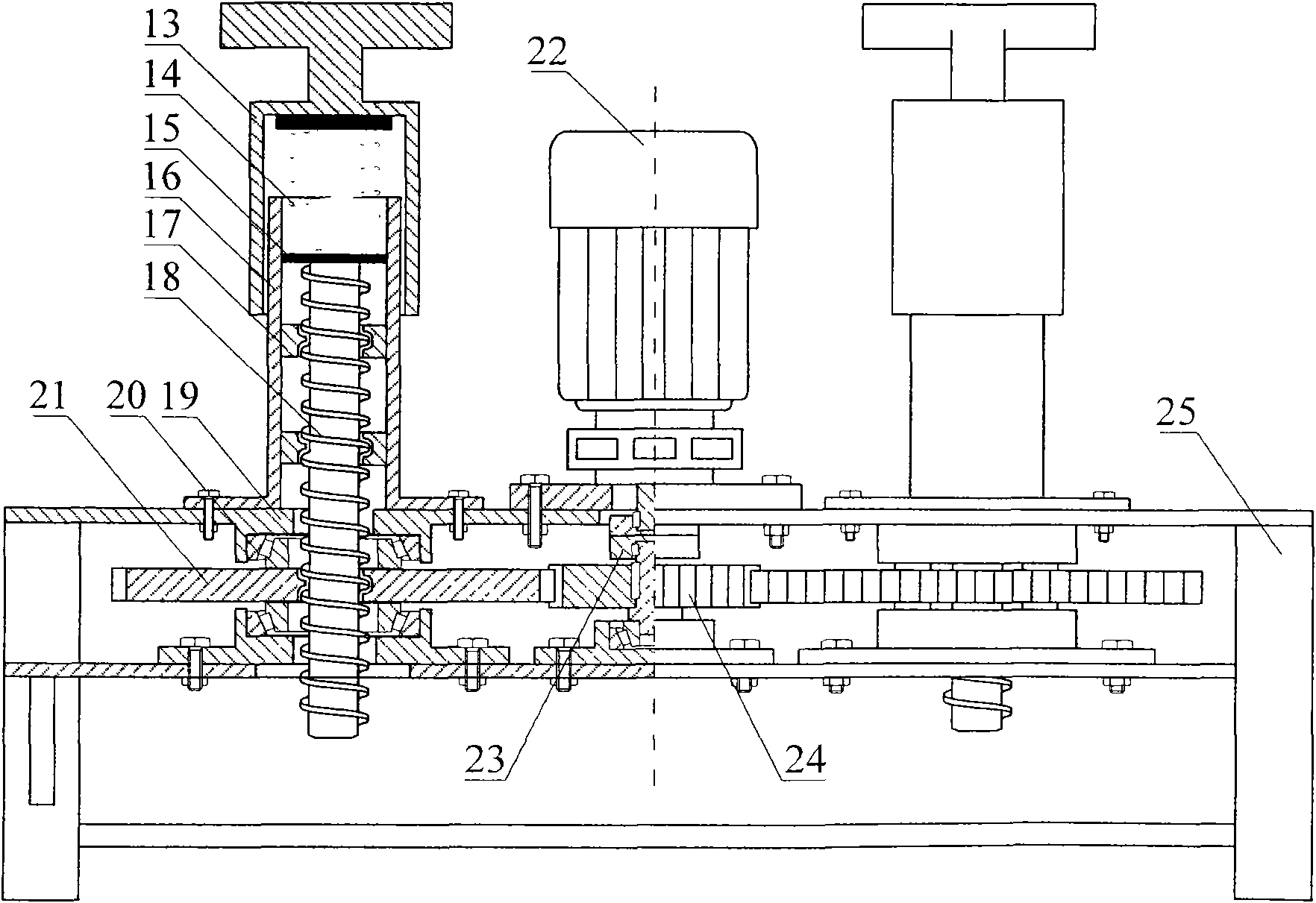

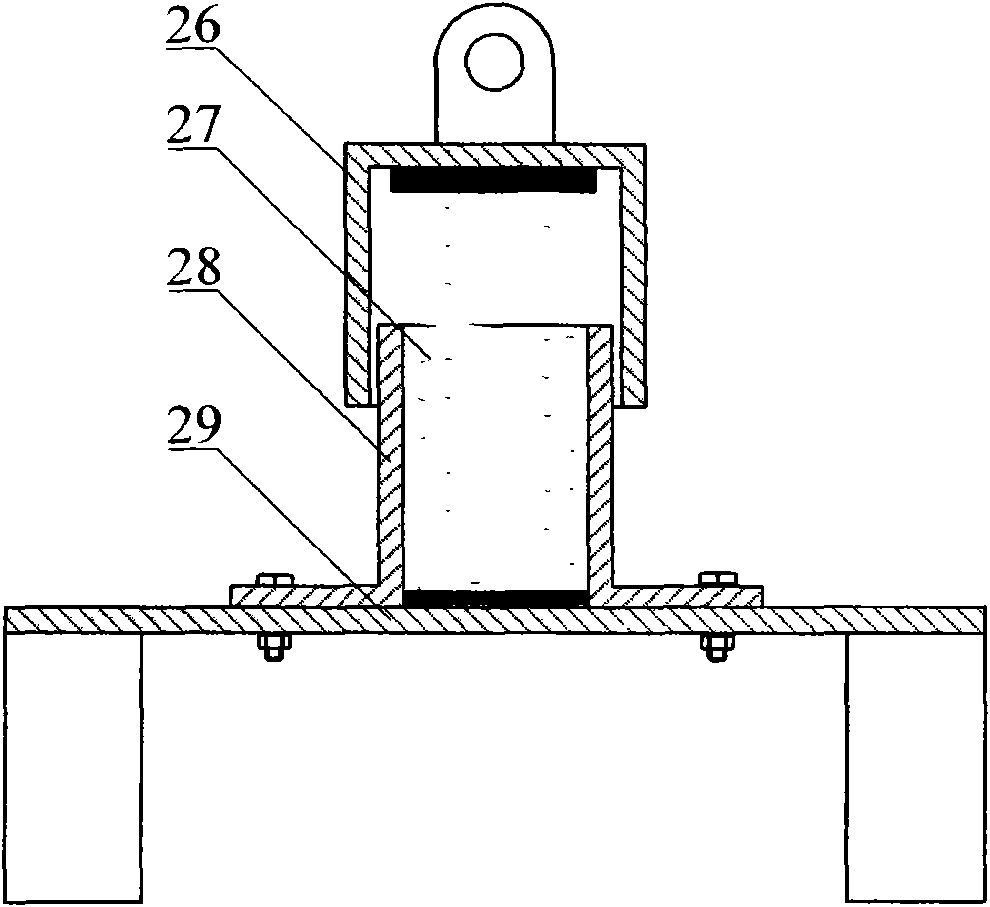

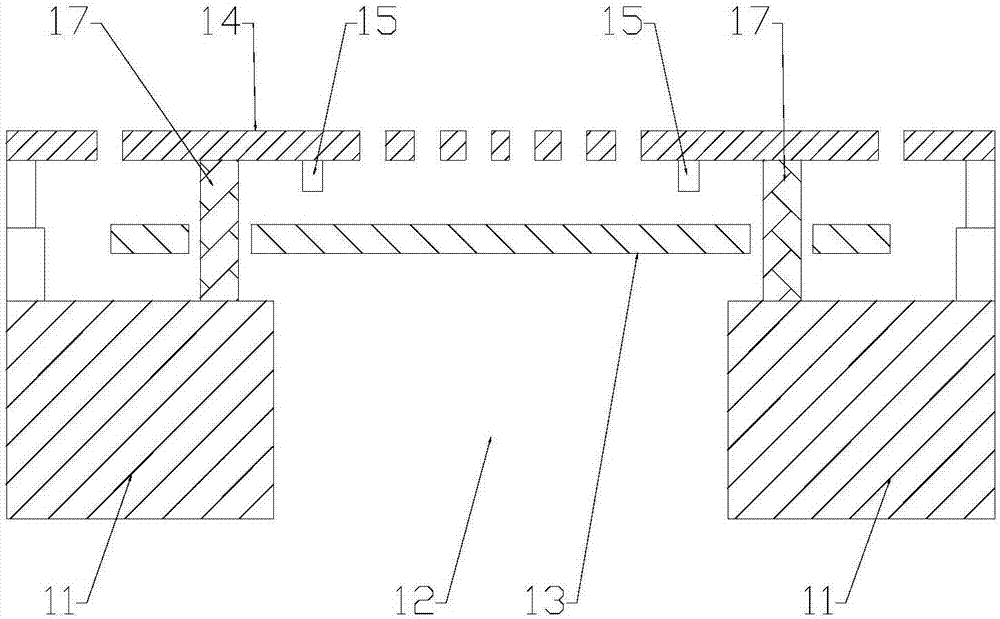

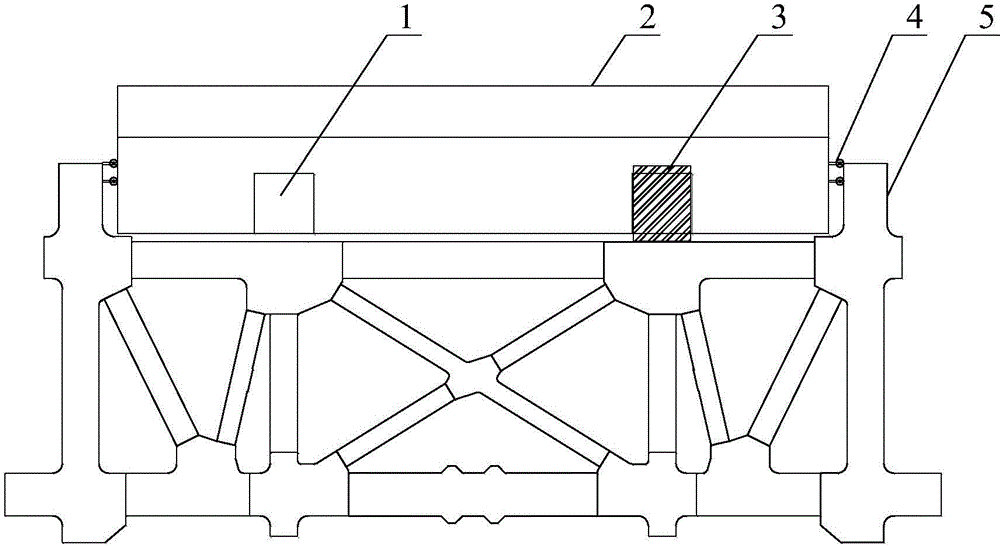

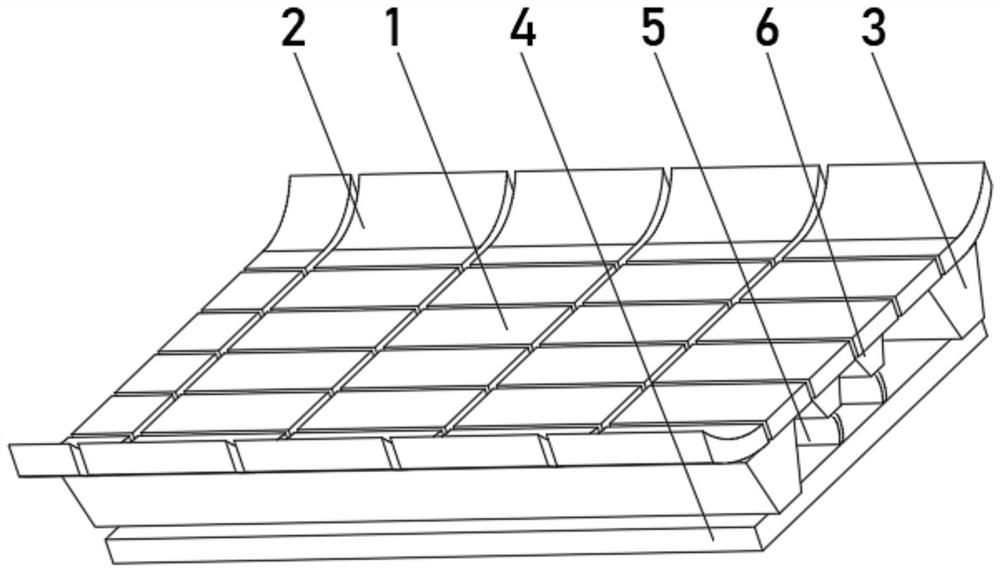

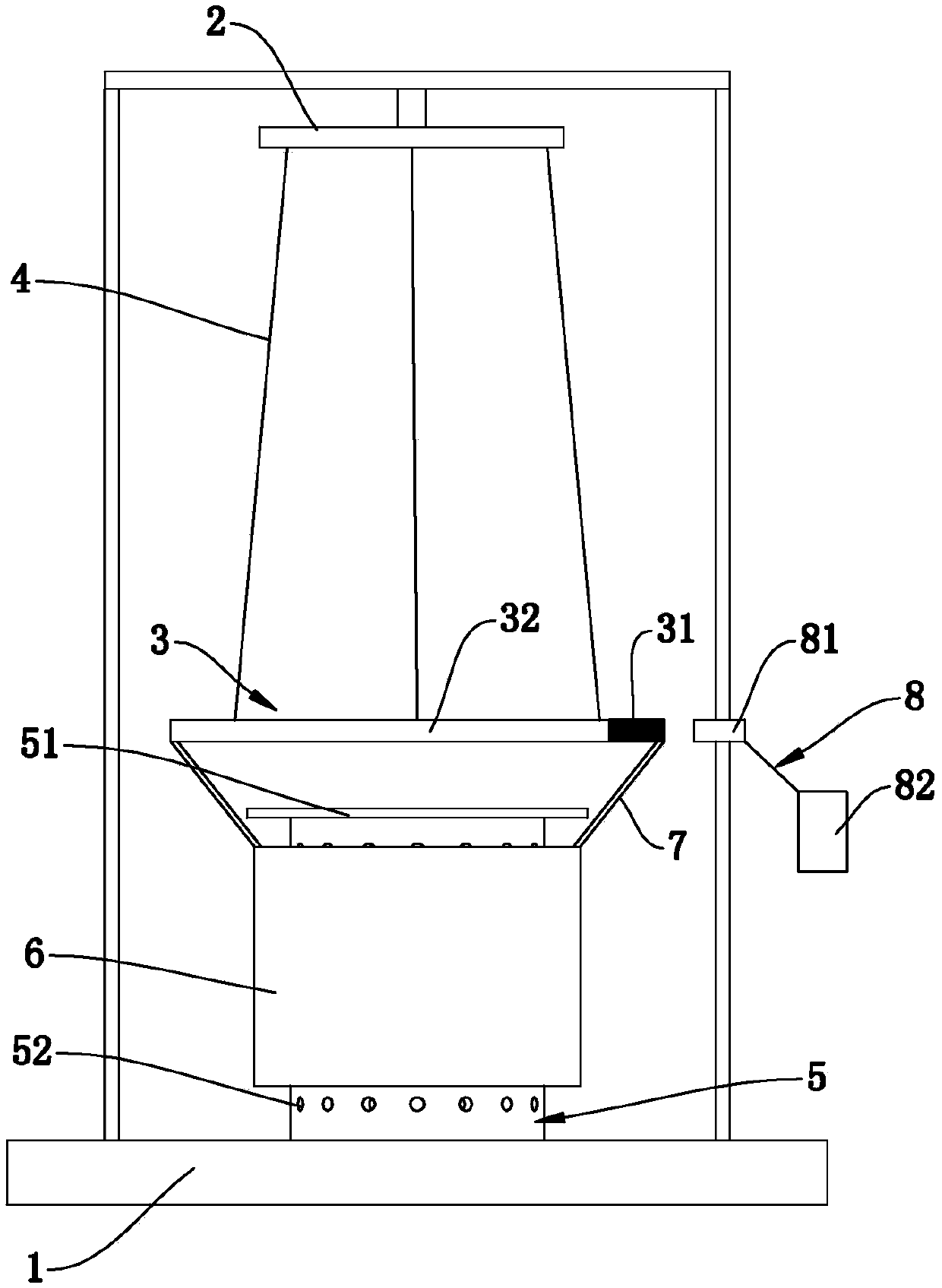

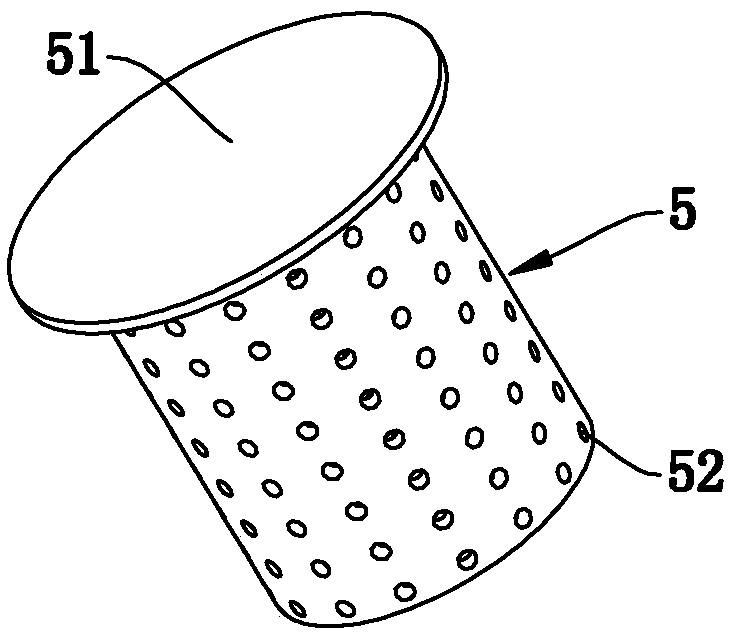

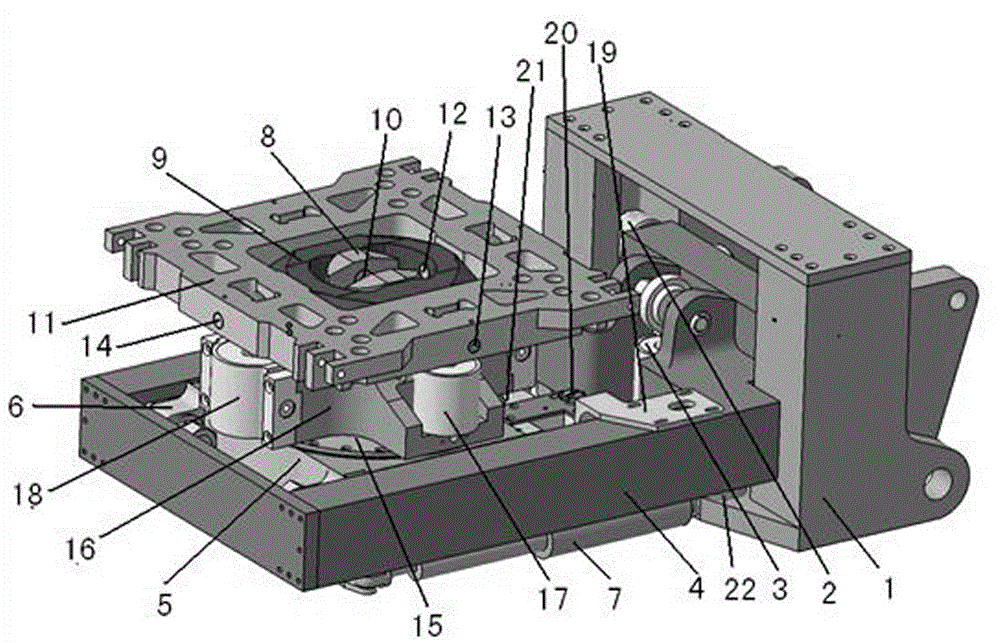

Biomass feed divider with changeable trough obliquity and vibration frequency and amplitude

ActiveCN101613039AContinuous, stable and even distribution of materialsAchieve free rotationLarge containersLoading/unloadingMultiple formsMaterial distribution

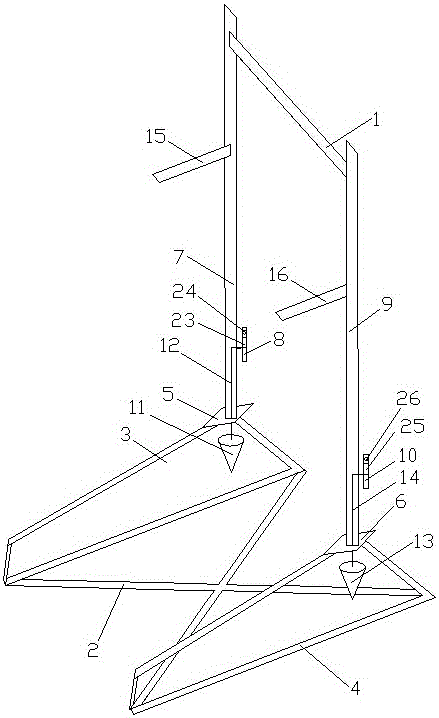

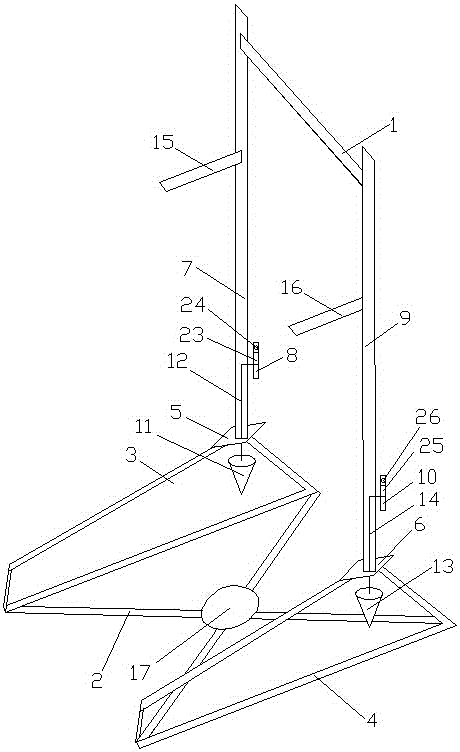

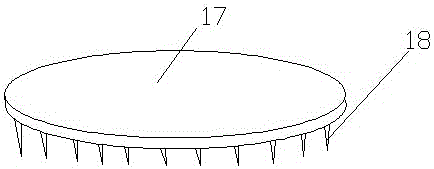

The invention relates to a biomass feed divider with changeable trough obliquity and vibration frequency and amplitude, which realizes continuous, stable and safe feed division by adopting two regulating measures of changing obliquity of a trough and changing vibration frequency and amplitude and by exciting force generated by a vibrating motor (9). The device is formed by arranging one or a plurality of independent distributors in parallel, wherein each distributor mainly comprises a trough body (4), a vibrating motor (9), an elevating (8), a spring supporting mechanism (11) and an auxiliary mechanism; the trough body (4) is supported by the spring supporting mechanism (11) at the front part and the elevating (8) at the rear part, the vibrating motor (9) is arranged in the middle of the bottom of the trough body (4), and the rear part of the trough body (4) is connected with bulkhead by canvas (3). The device integrates material storage and material distribution, is not only suitable for hard biomass but also is suitable for soft biomass, and has lateral expansibility, thereby being convenient to be used together with material equipment of various types.

Owner:SOUTHEAST UNIV

MEMS chip

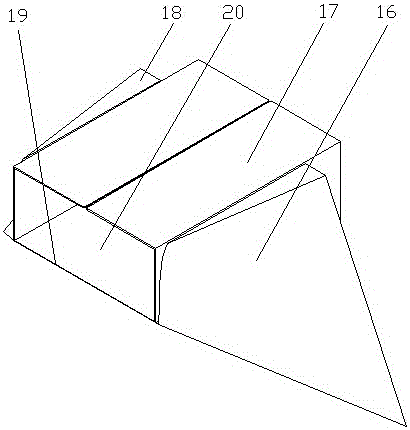

PendingCN107244646APrevent lateral swingAvoid distortionTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEngineeringCapacitor

The invention provides an MEMS chip. The MEMS chip comprises a substrate, and a polar plate supported on the substrate. Containing space is formed between the substrate and the polar plate. The MEMS chip further comprises a sensitive film freely arranged in the containing space, and a capacitor structure is formed by the sensitive film and the polar plate. A limiting column is arranged in the containing space, and the limiting column penetrates through the sensitive film to define the vibrating direction of the sensitive film. According to the MEMS chip, through the arrangement of the limiting column, the sensitive film can vibrate up and down along the limiting column, the limiting column can effectively prevent transverse swinging of the sensitive film in the vibrating process, it is avoided that the sensitive film warps due to too high amplitude, and the service life of the MEMS chip is prolonged.

Owner:GOERTEK MICROELECTRONICS CO LTD

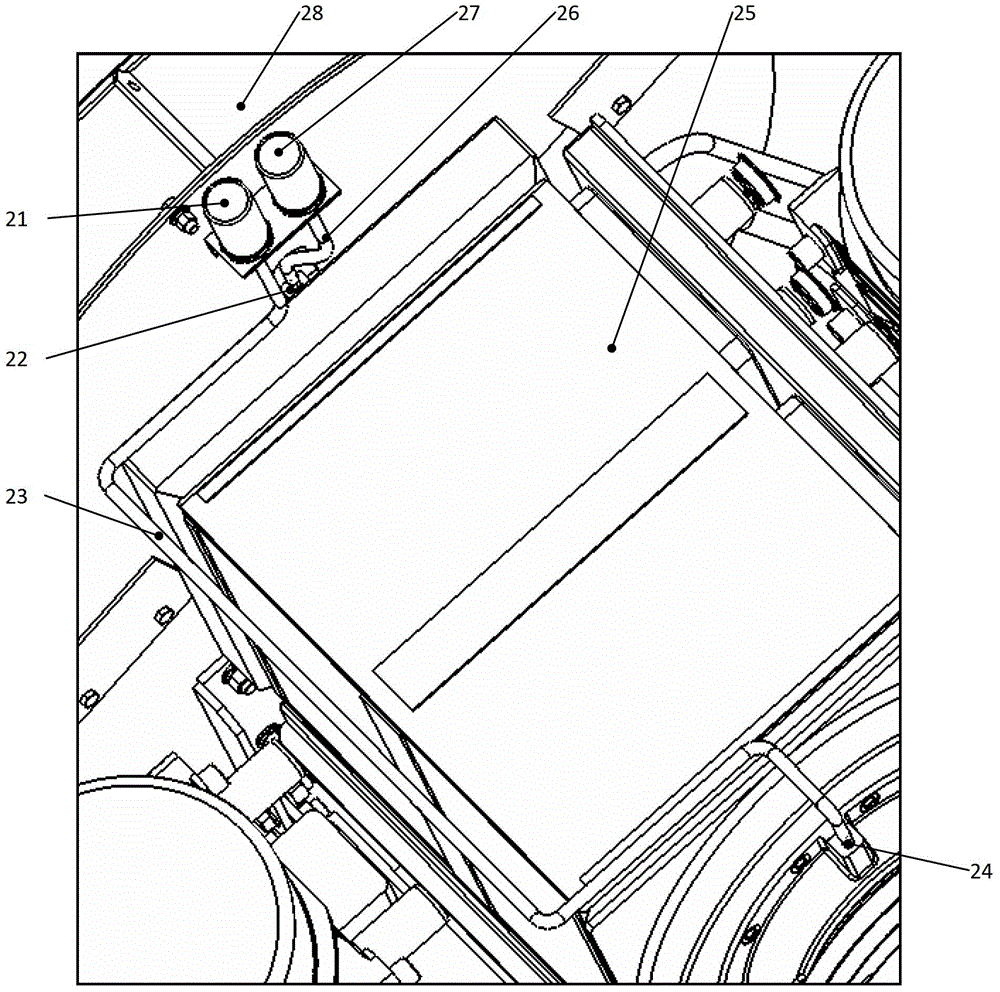

Forming and sealing method for food packaging

ActiveCN104443571AImprove sealing efficiencyImprove continuityWrapper twisting/gatheringEngineeringFood packaging

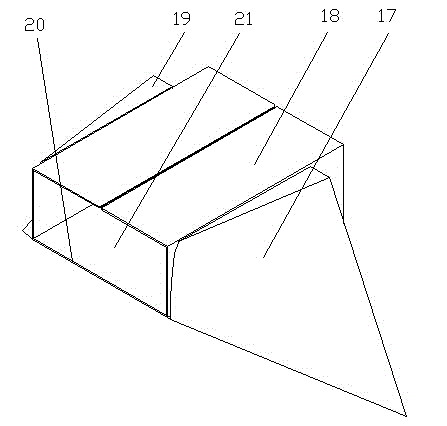

The invention discloses a form-seal method for food packaging. The method sequentially includes the steps of a bag forming process, a vertical sealing process and a transversal sealing process, wherein the bag forming process includes folding an entire roll of packaging film into square film bags through a bag forming unit, the transversal sealing process includes performing corner inserting and heat-sealing to the front ends of the square fill bags filled with food after being vertically sealed, by a knife-sealing corner-inserting unit, cutting the rear ends of the square film bags in advance, then performing corner inserting and heat-sealing to obtain the finished products. During the transversal sealing process, the vertically sealed square film bags can be successively subjected to end corner inserting and sealing by adopting the knife-sealing corner-inserting unit, and thereby the efficiency of forming and sealing of a whole package is improved and the sealing effect is better.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

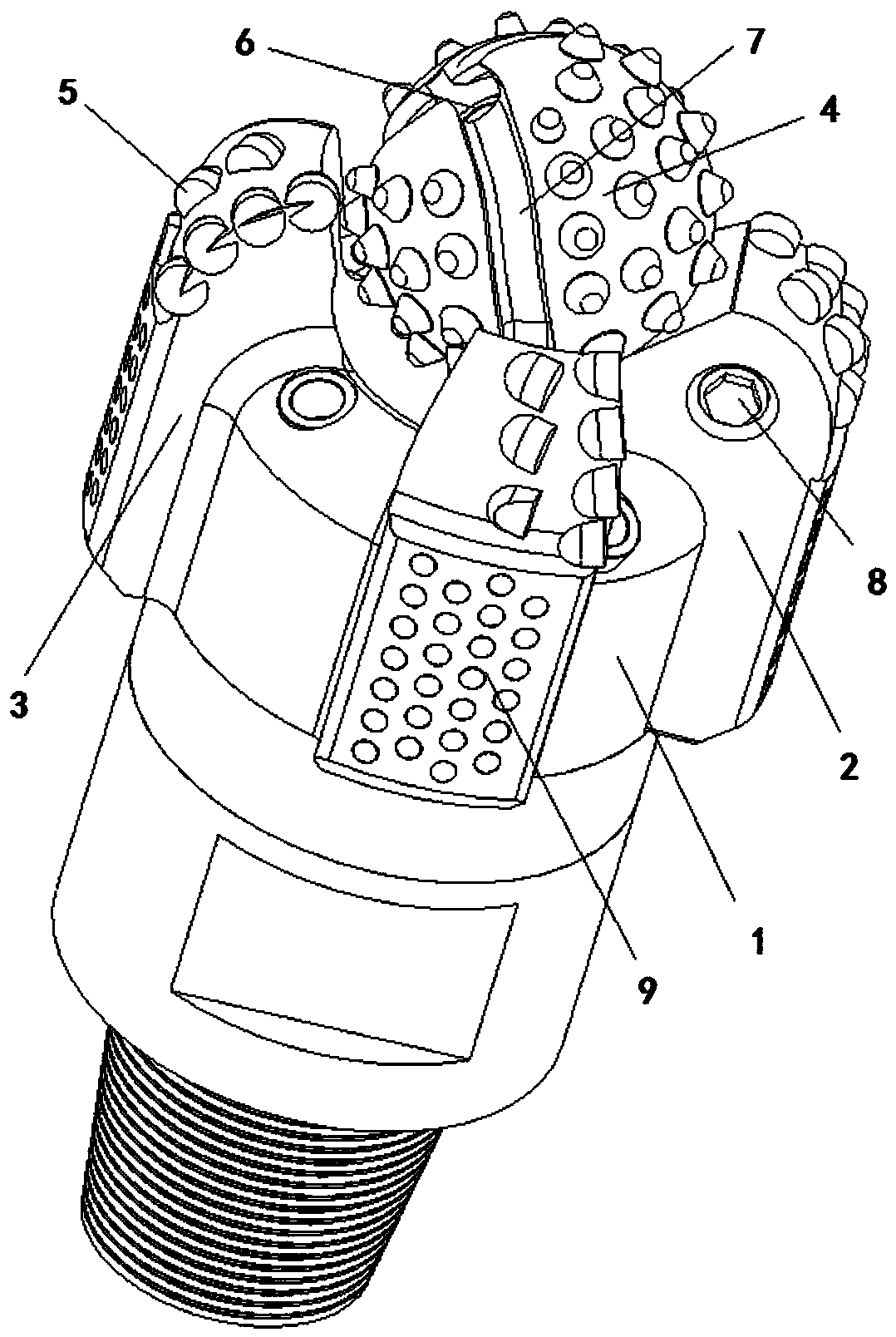

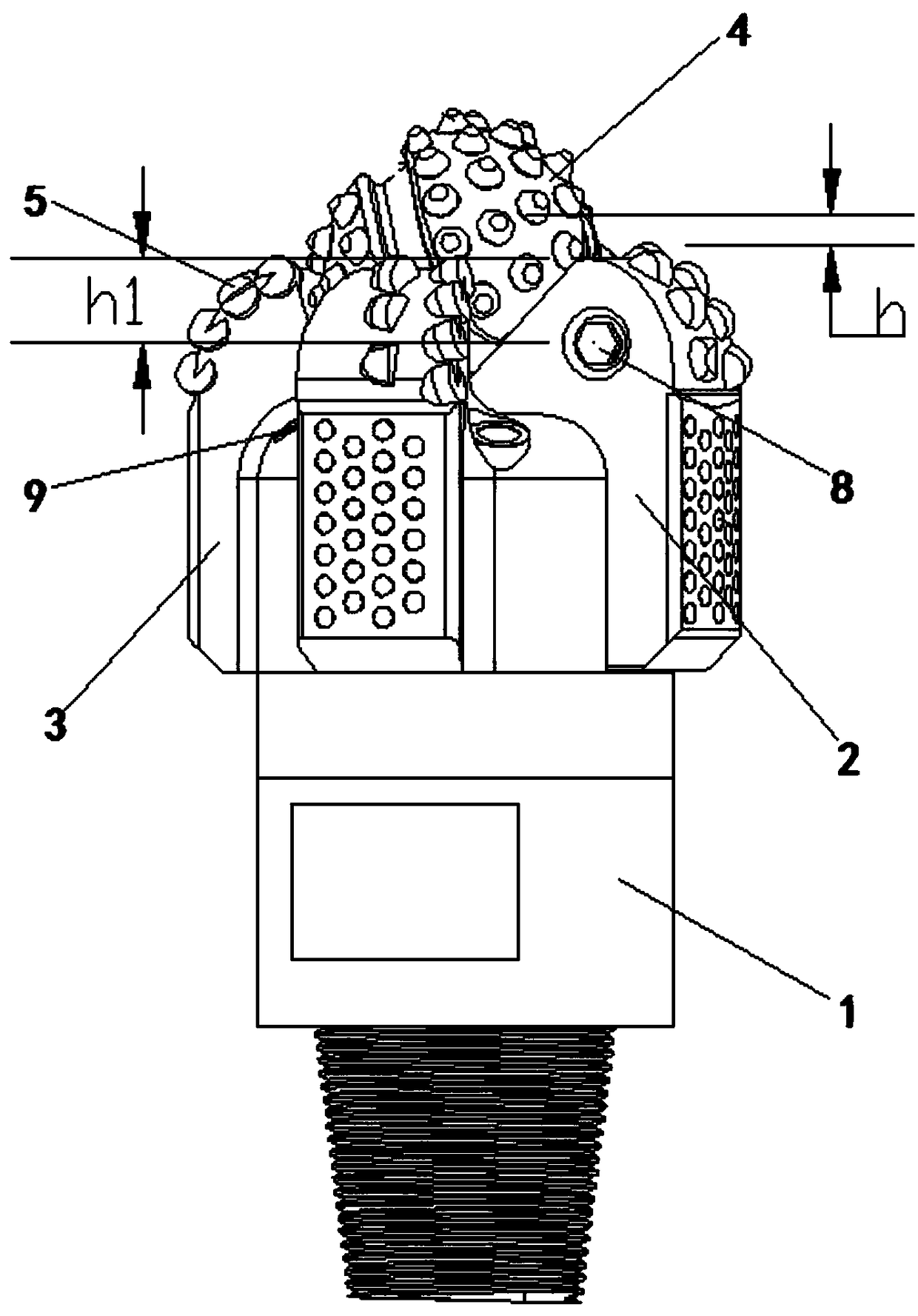

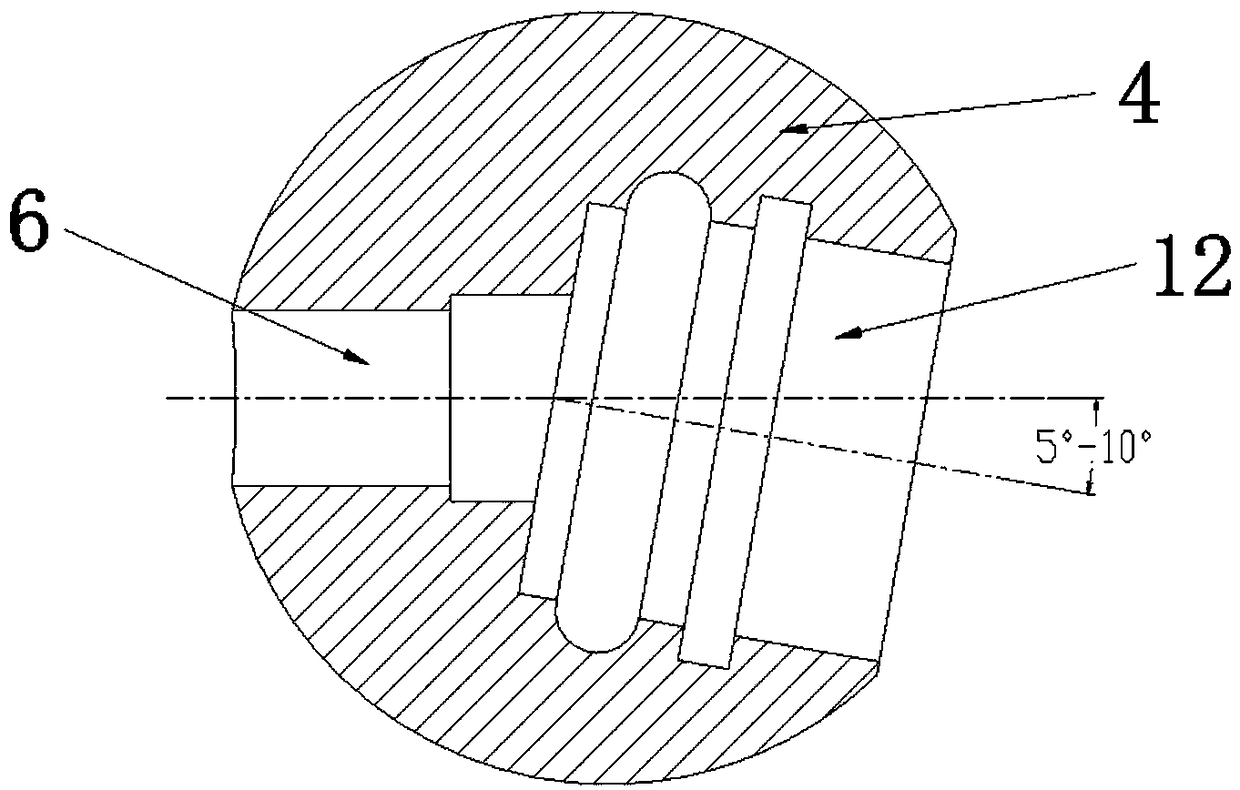

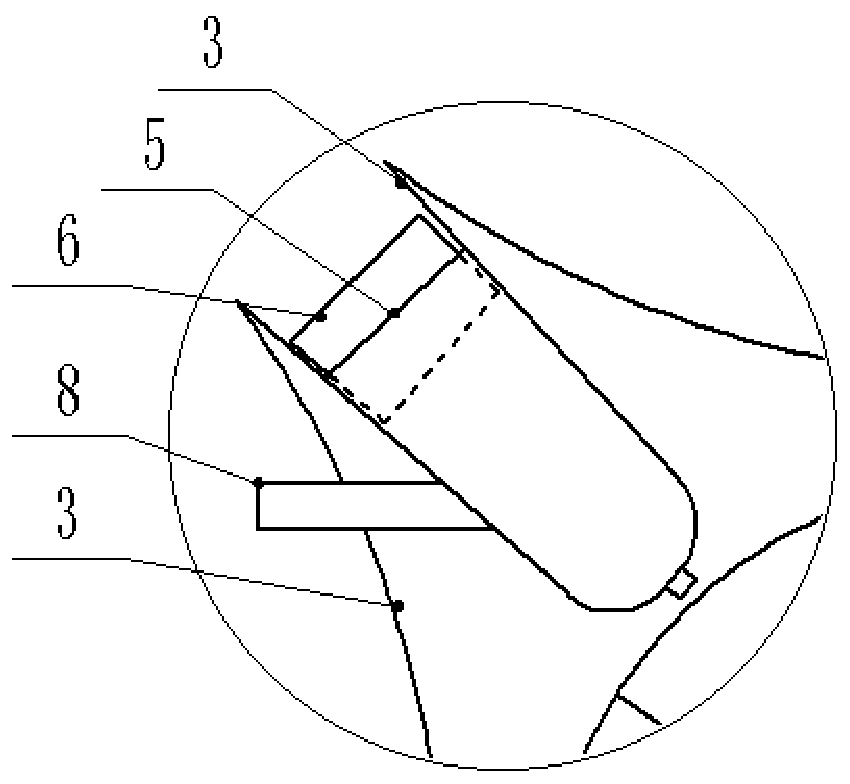

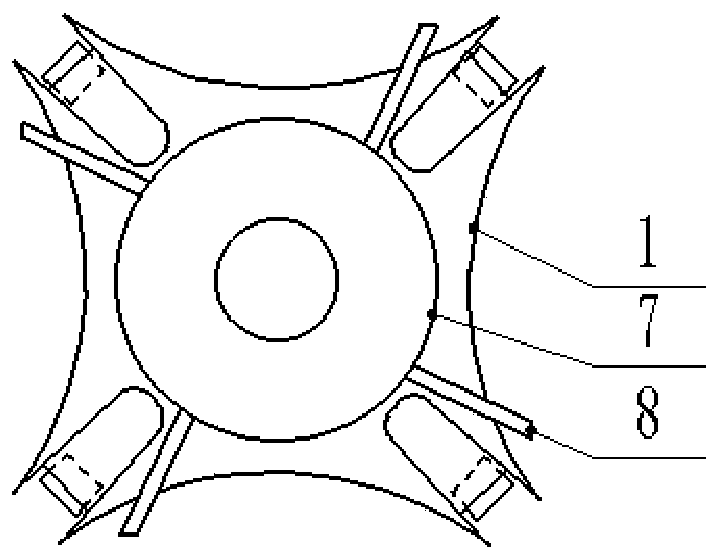

Novel pdc and roller cone composite drill bit

The invention discloses a novel pdc and roller cone composite drill bit. The novel pdc and roller cone composite drill bit comprises a drill bit body, a roller cone palm, a cutting blade, and a spherical roller cone. The spherical roller cone is installed the roller cone palm. The outer sides of the roller cone palm and the cutting blade are provided with pdc cutting teeth and fixed on the drill bit body. The spherical roller cone is positioned above the drill bit body, and a center line of the spherical roller cone is coincided with an axis of the drill bit body. A vertical distance between asphere center position of the spherical roller cone and a highest point of the cutting blade is within a range of 18-29 mm. The side face of the roller cone palm is provided with an oil storage seal.According to the related novel composite drill bit, in a drilling process, a bit pressure is shared by the pdc cutting teeth and the roller cone together, a pressure applied to each tooth is reduced,the wear-resistant capacity of the drill bit is improved, thereby the service life of the whole drill bit is prolonged. In addition, because a position of the oil storage seal is closer to the top ofthe drill bit, a sensitivity of a drill bit lubricating system for sensing a bottom hole pressure is improved, and the drill bit is positioned in the better lubricating environment, so the service life of the drill bit is improved.

Owner:SOUTHWEST PETROLEUM UNIV

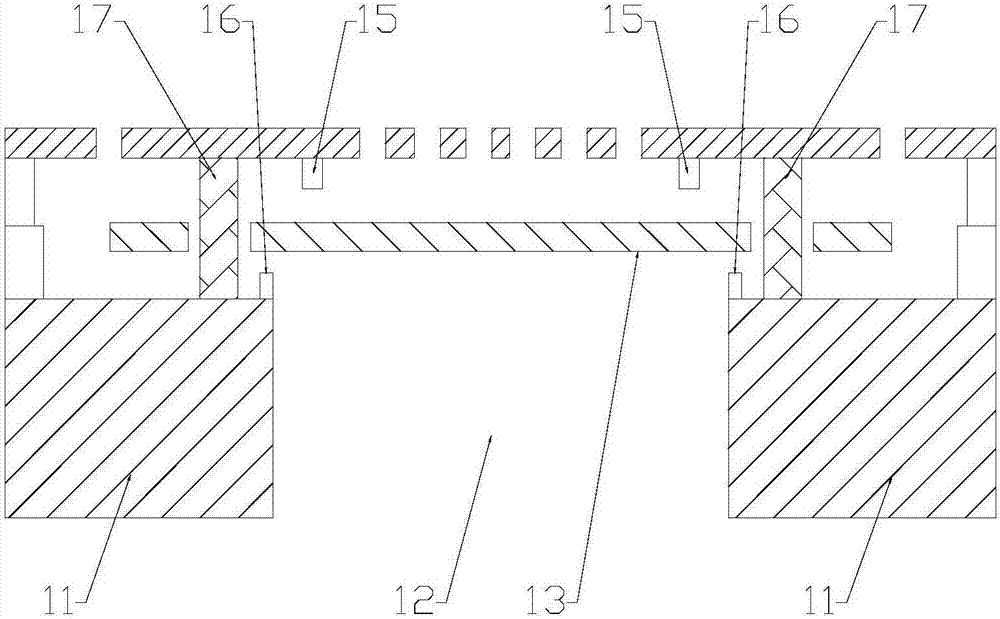

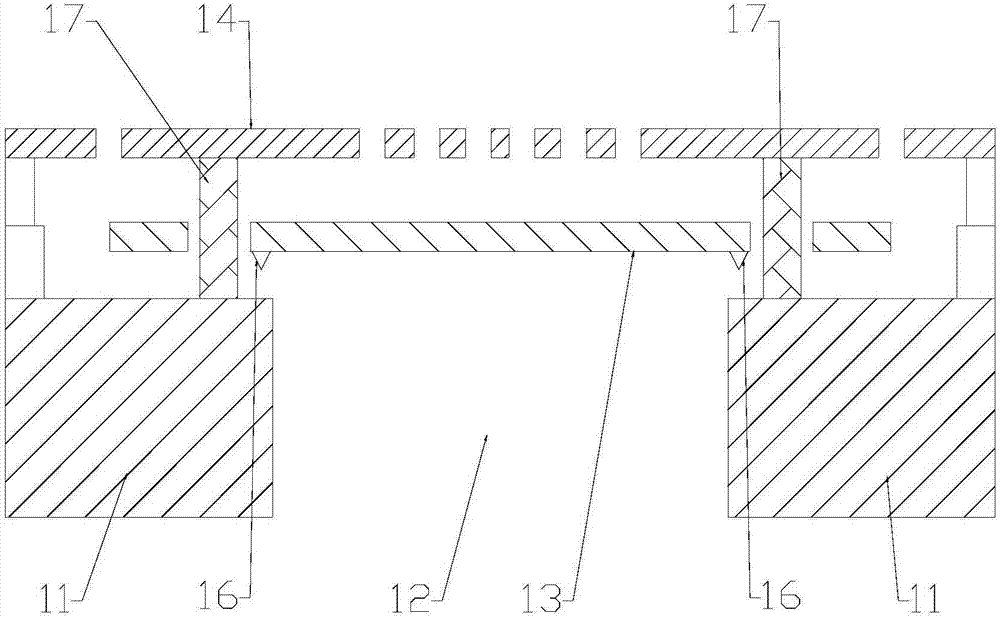

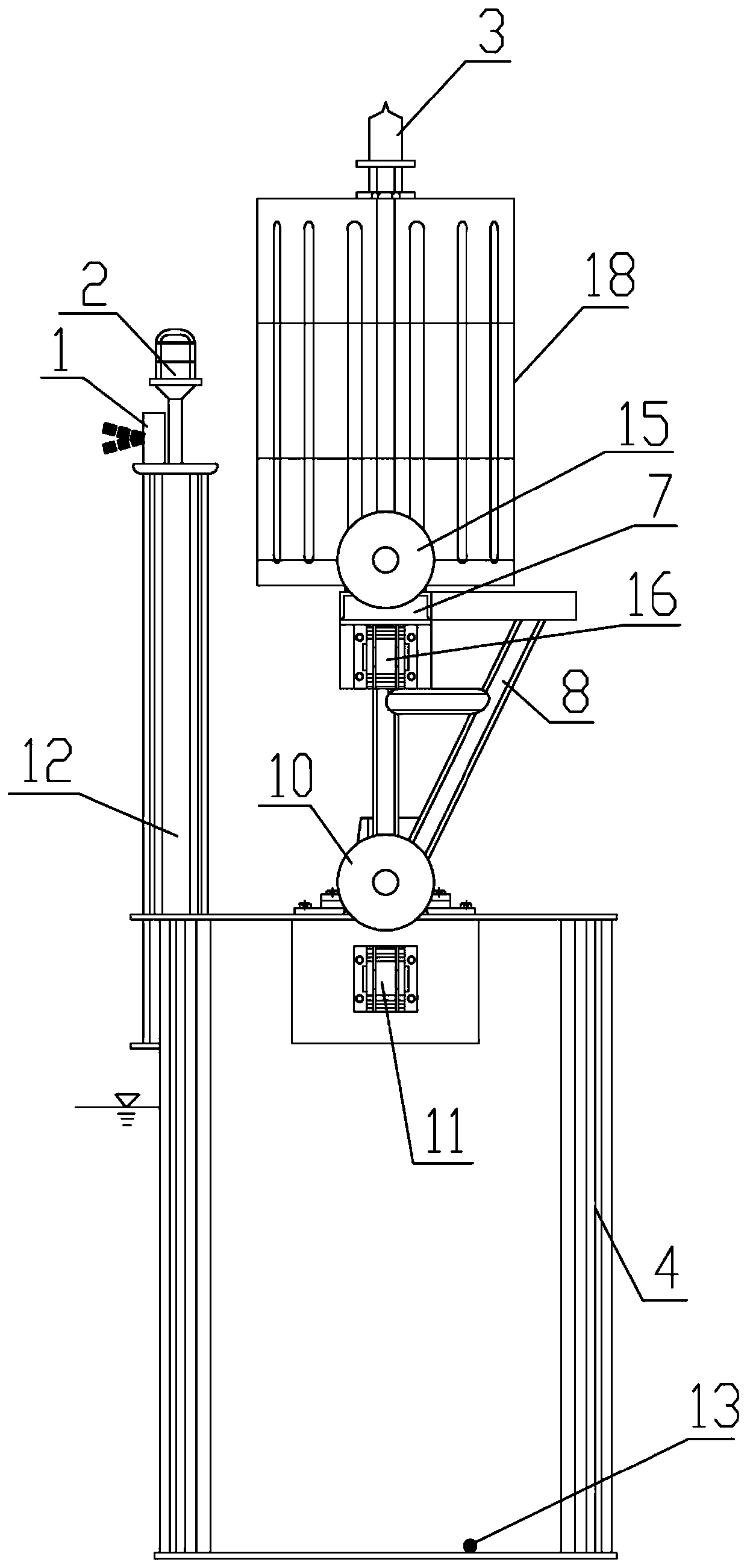

Device and method for closure construction of girder side span of cable-stayed bridge

InactiveCN104631342APrevent lateral swingRealize synchronous scalingCable-stayed bridgeBridge erection/assemblySupporting systemCable stayed

The invention discloses a device and a method for closure construction of a girder side span of a cable-stayed bridge and relates to the field of construction of cable-stayed bridges. The device comprises a cable drawing hanging basket, a pier top support system and a cantilever outrigger, wherein the cable drawing hanging basket is arranged at the bottom of a cast girder, the pier top support system is arranged at the top of a side span closure section pier, and the cantilever outrigger is arranged at the top of the cast girder and above the pier top support system and the cable drawing hanging basket. The cable drawing hanging basket comprises two arc-shaped heads, and a transverse limit fixed pulley is welded on the outer side of each arc-shaped head and fixed on the outer side of the side span closure pier. The pier top support system comprises a first support, a second support, a plurality of first sand boxes and second sand boxes at the top of the side span closure section pier, and the outer portions of the first support and the second support are sleeved with support cover plates. The cast-in-situ section and the cast girder body are freely and synchronously telescopic, and construction cost is reduced.

Owner:THE 5TH ENG MBEC +1

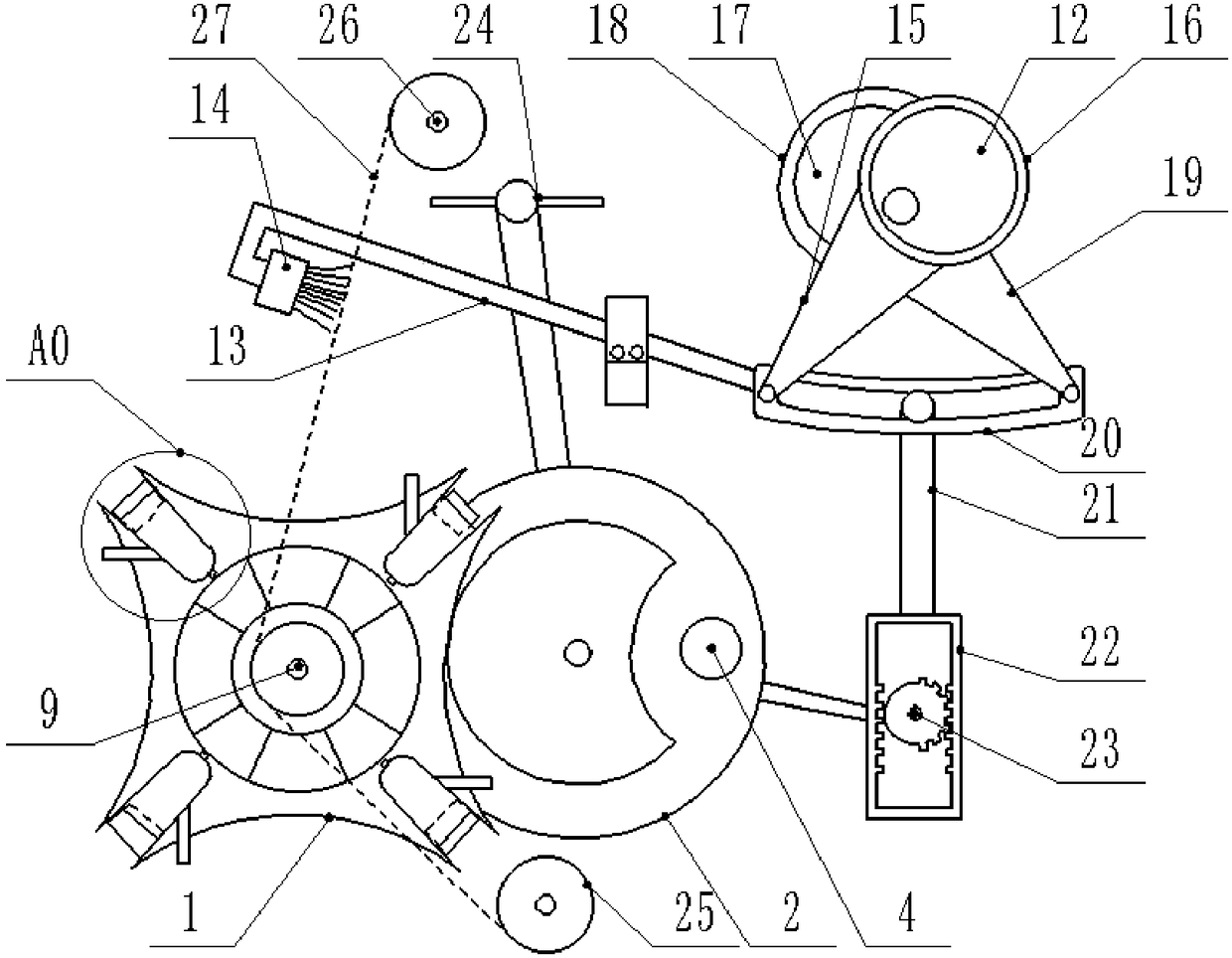

Printing device

The invention relates to the technical field of printing equipment and discloses a printing device. The printing device comprises a printing roller and a grooved wheel mechanism. The grooved wheel mechanism comprises a grooved wheel and a rotating wheel. The end face of the grooved wheel is connected with an ink guide roller, and the ink guide roller is fixed to the printing roller. The ink guideroller is provided with a plurality of ink guide grooves distributed uniformly, an ink cavity communicating with the ink guide grooves is formed in the printing roller, and the outer surface of the printing roller is provided with ink outlet holes communicating with the ink cavity. The grooved wheel is provided with a plurality of clamping grooves, the number of the clamping grooves is equal to the number of the ink guide grooves, an opening of the side portion of each clamping groove is in sliding connection with a sliding plate for sealing the opening, the sliding plates can slide in the radial direction of the grooved wheel, a cavity is formed between each sliding plate and the groove wall of the corresponding clamping groove in an enclosed mode, a piston is connected in each cavity ina sliding mode, a nozzle is connected to the end, close to the circle center of the grooved wheel, of each cavity, a pressure valve is arranged on each nozzle, and each nozzle faces the interior of the corresponding ink guide groove. The rotating wheel is provided with a clamping post. By means of the printing device, the problem that ink liquid in ink grooves is thrown out during ink feeding of existing printing rollers can be solved.

Owner:重庆博创知识产权运营有限公司

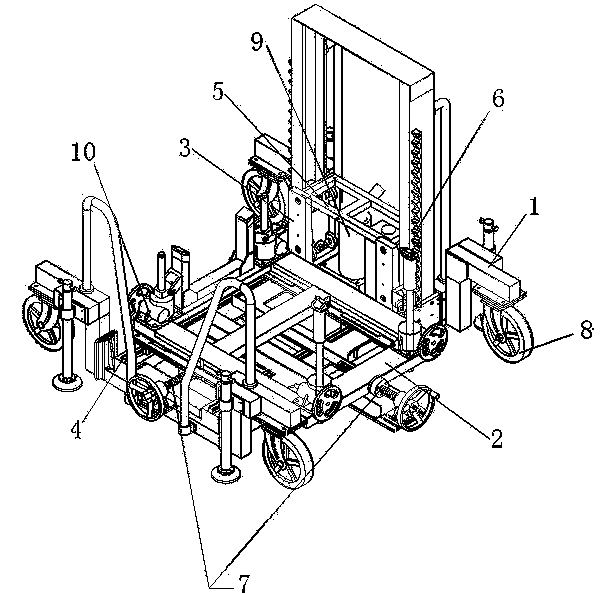

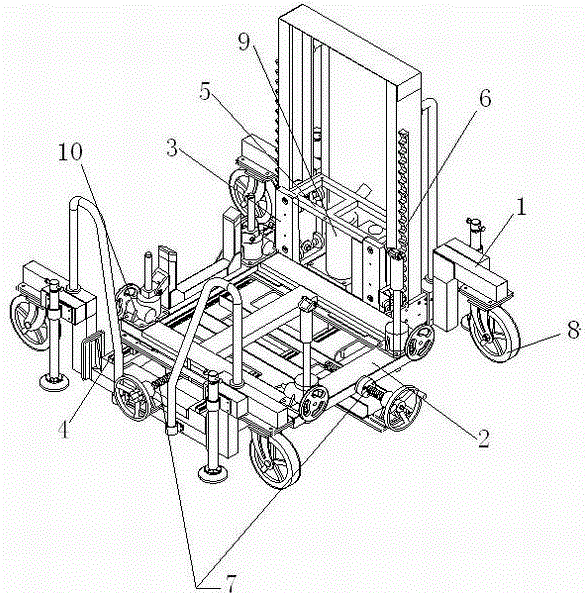

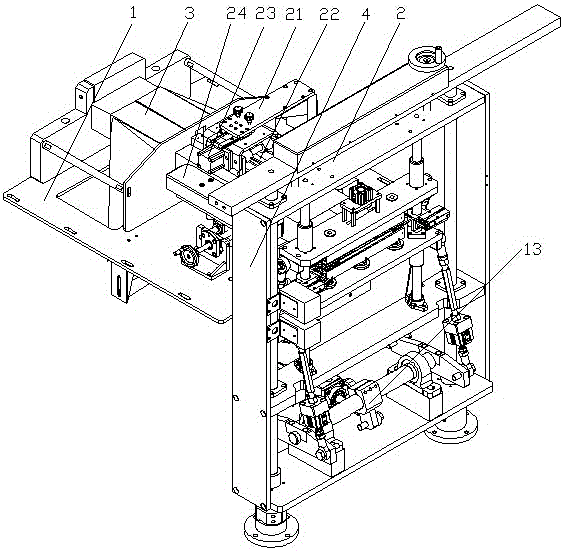

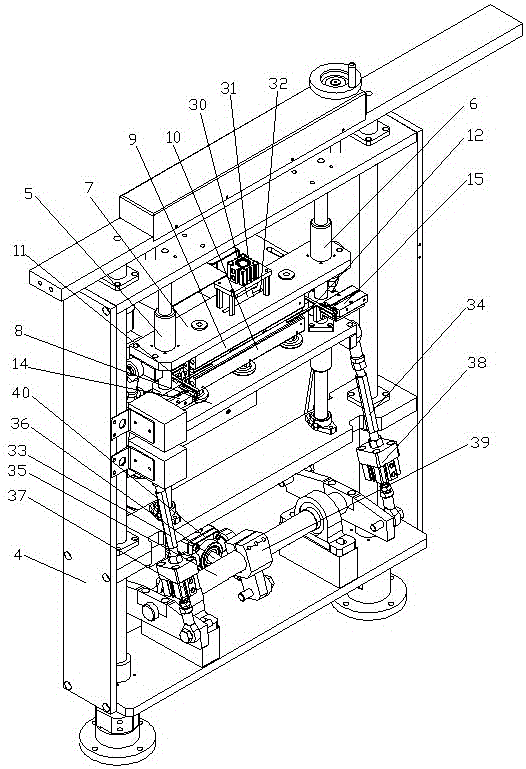

Aircraft engine installing device

ActiveCN103639973APrevent slippingEasily brokenLifting framesMetal-working hand toolsManufacturing technologyLocking mechanism

The invention relates to an aircraft manufacturing technology, belongs to mechanical products and particularly provides an aircraft engine installing device. The aircraft engine installing device comprises a base, a moving bracket, an L-shaped bracket, a guide rail placing assembly, a lifting mechanism, a locking mechanism and adjustable screw rods, wherein the guide rail placing assembly is installed between the L-shaped bracket and the moving bracket. Moving trundles are installed at four ends of the base. The adjustable screw rods are arranged on four sides of the moving bracket. The locking mechanism is used for limiting and fixing the L-shaped bracket and the lifting mechanism. A lifter is installed on the moving bracket. A jack is installed on the base. The aircraft engine installing device jacks up an engine and performs ascending motion by utilizing the ascending hydraulic jack, the jack can be locked by using a check nut and prevented from sliding downward in the event of oil leakage when ascending any height, the problem that a steel wire rope in the prior art is easily broken and corroded during traction motion is solved, and the using safety is improved.

Owner:JIANGXI HONGDU AVIATION IND GRP

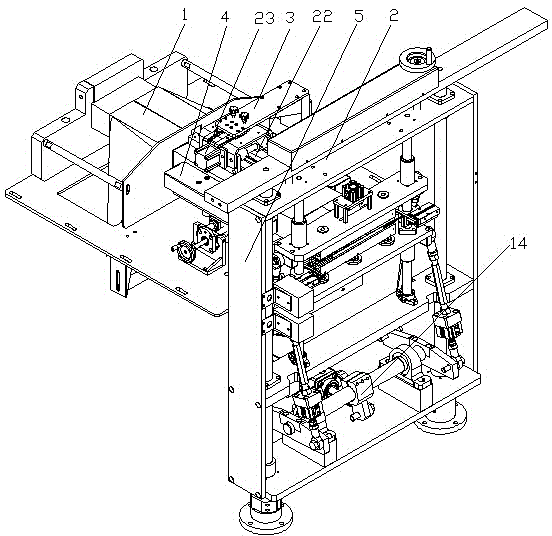

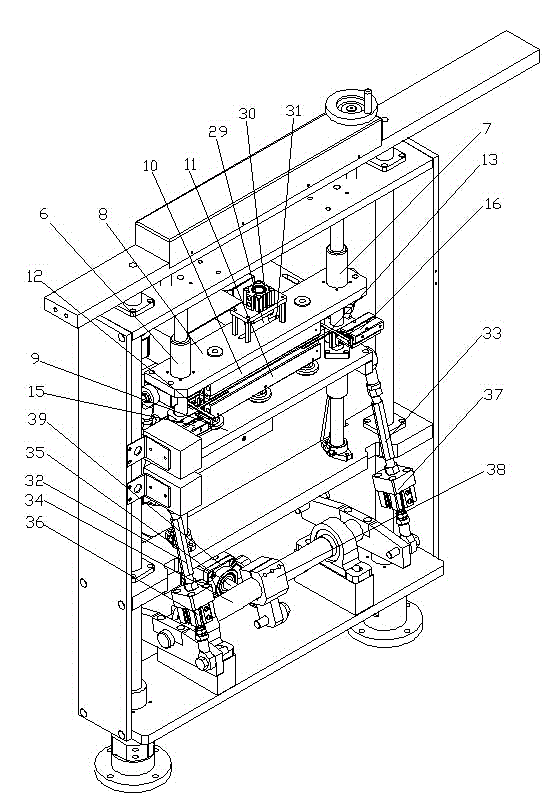

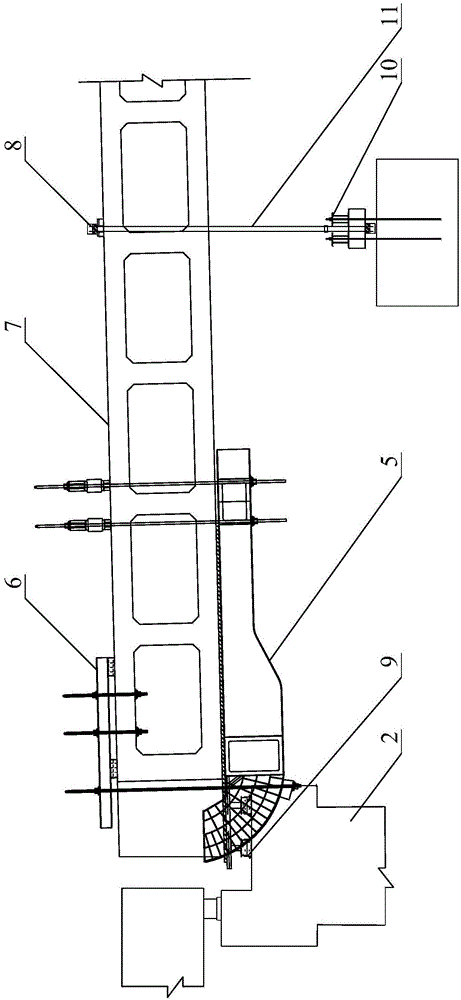

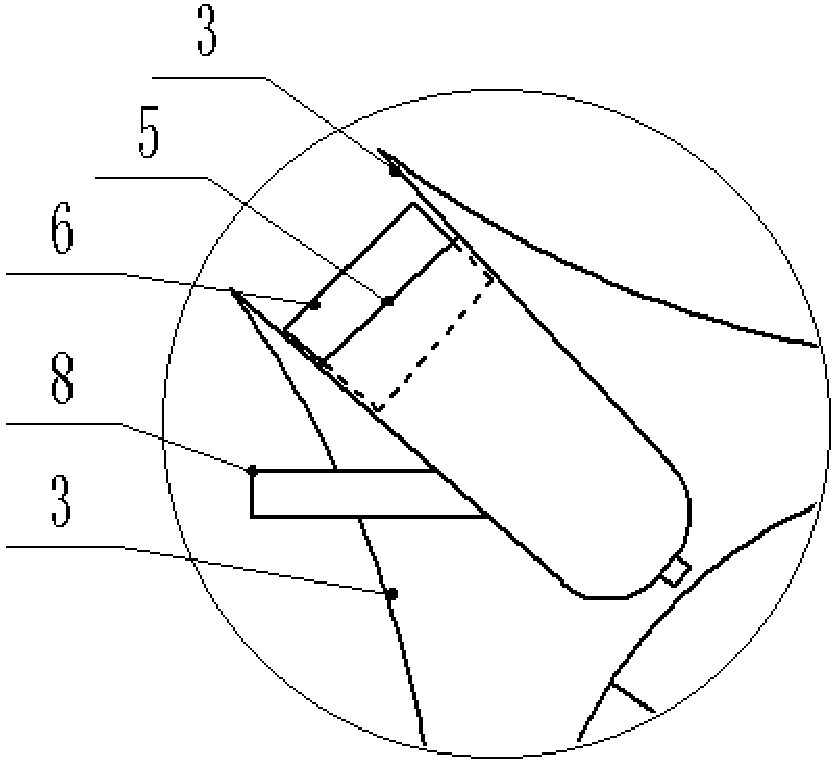

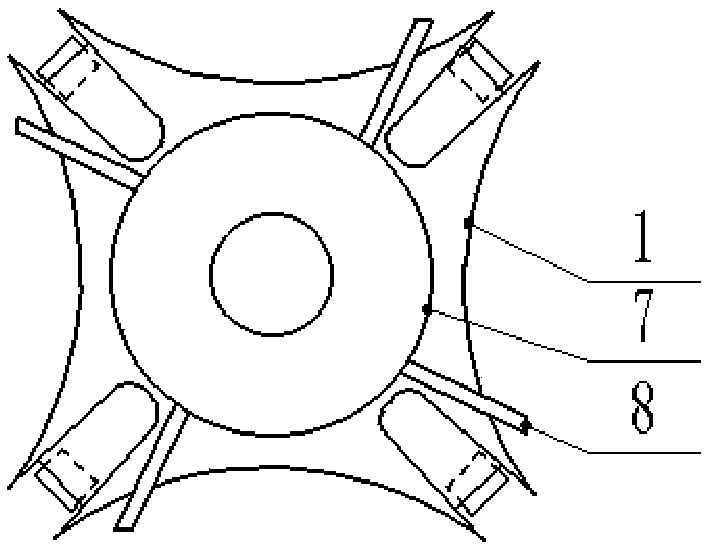

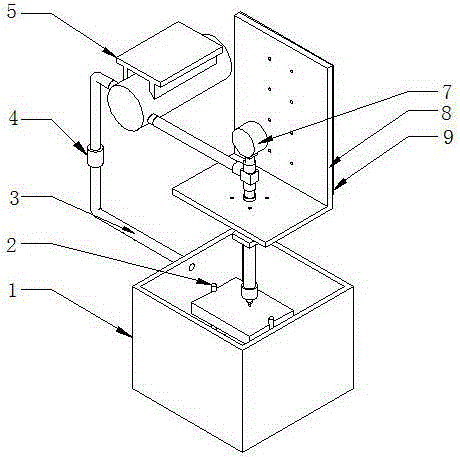

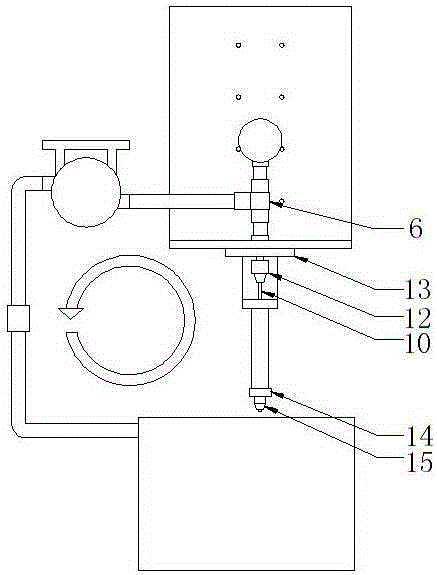

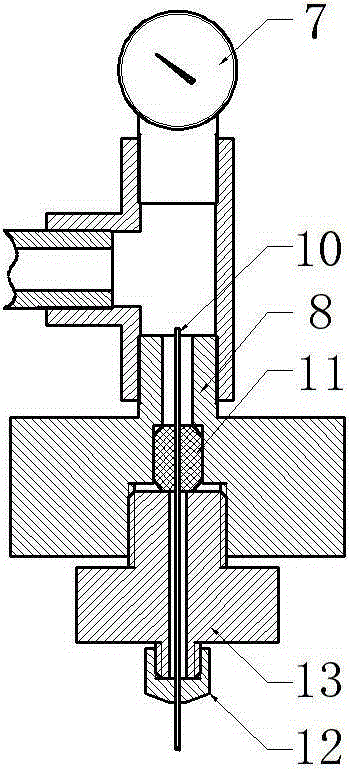

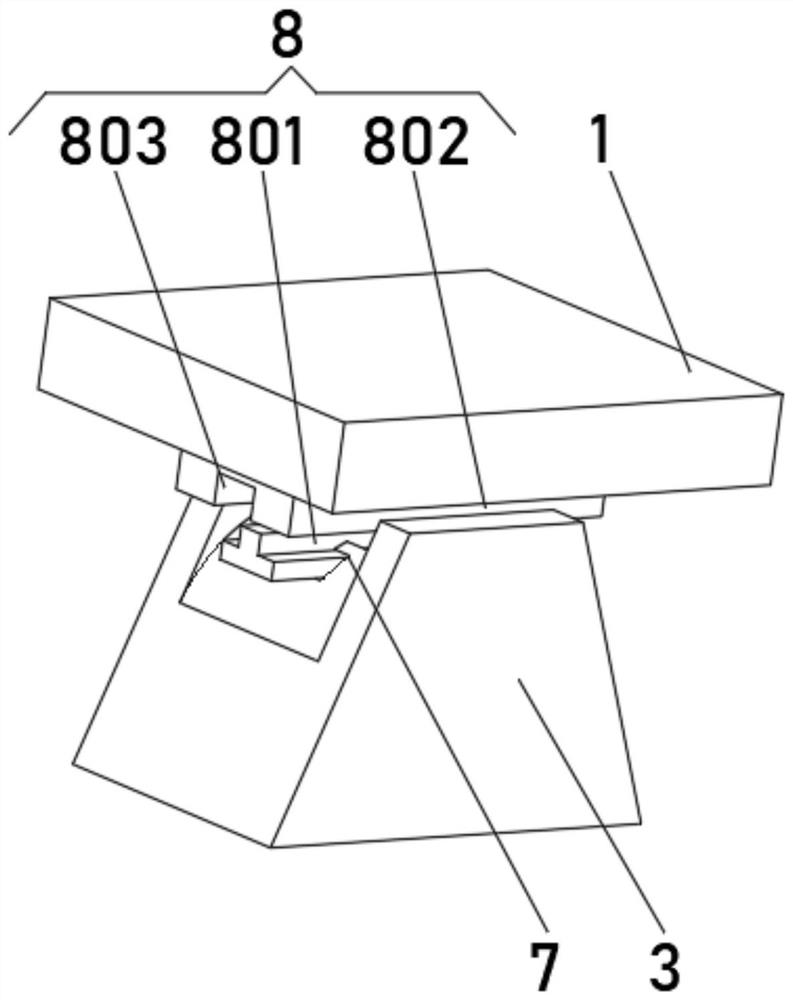

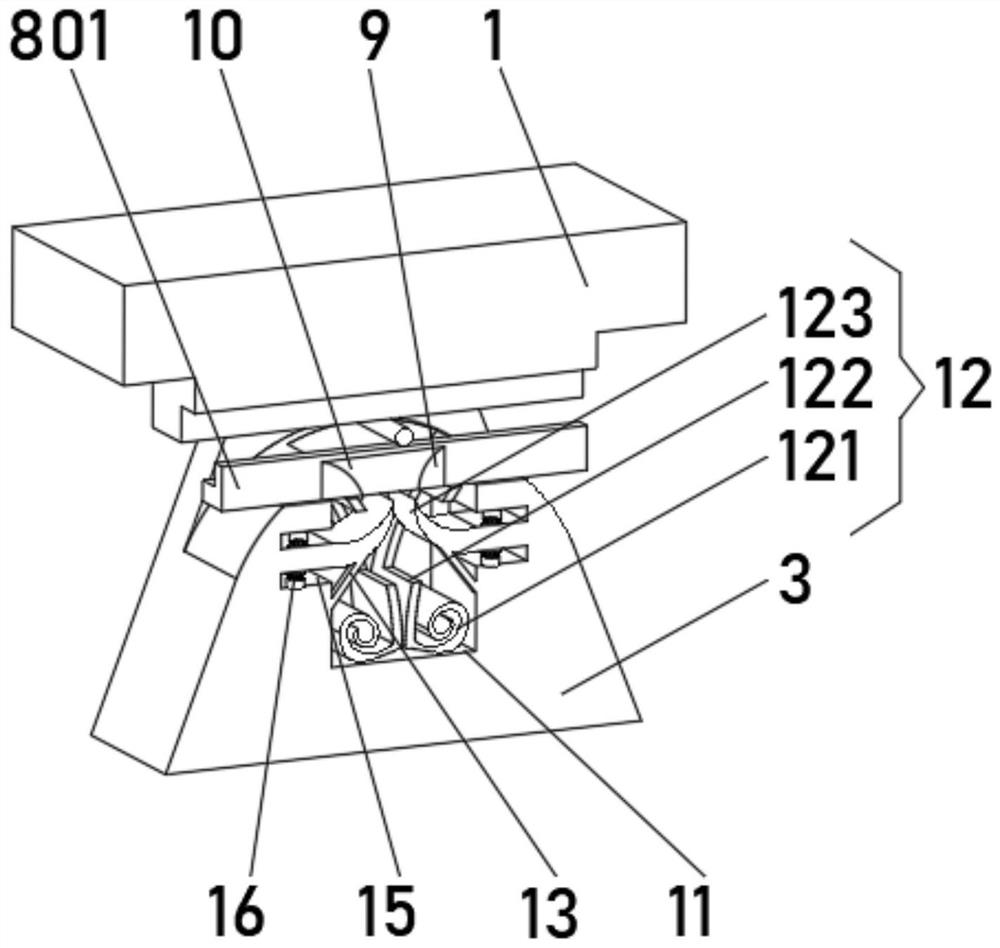

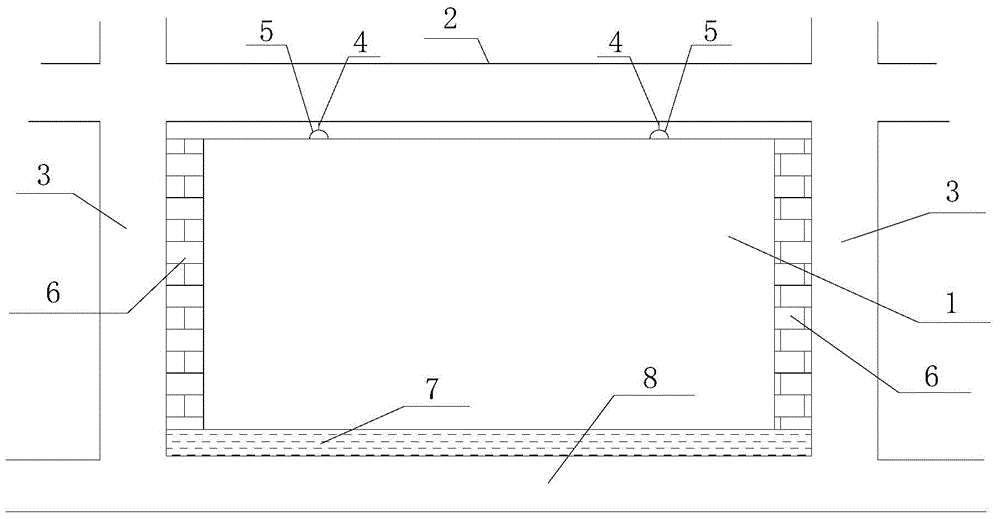

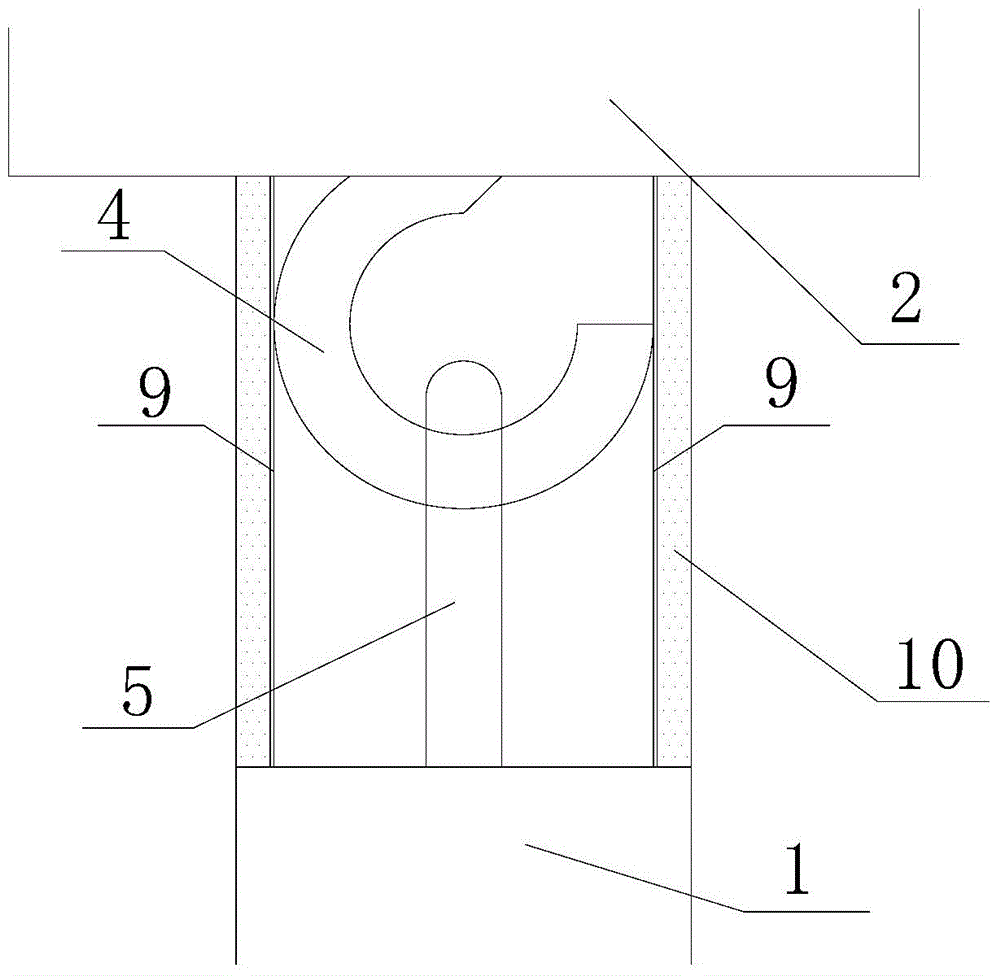

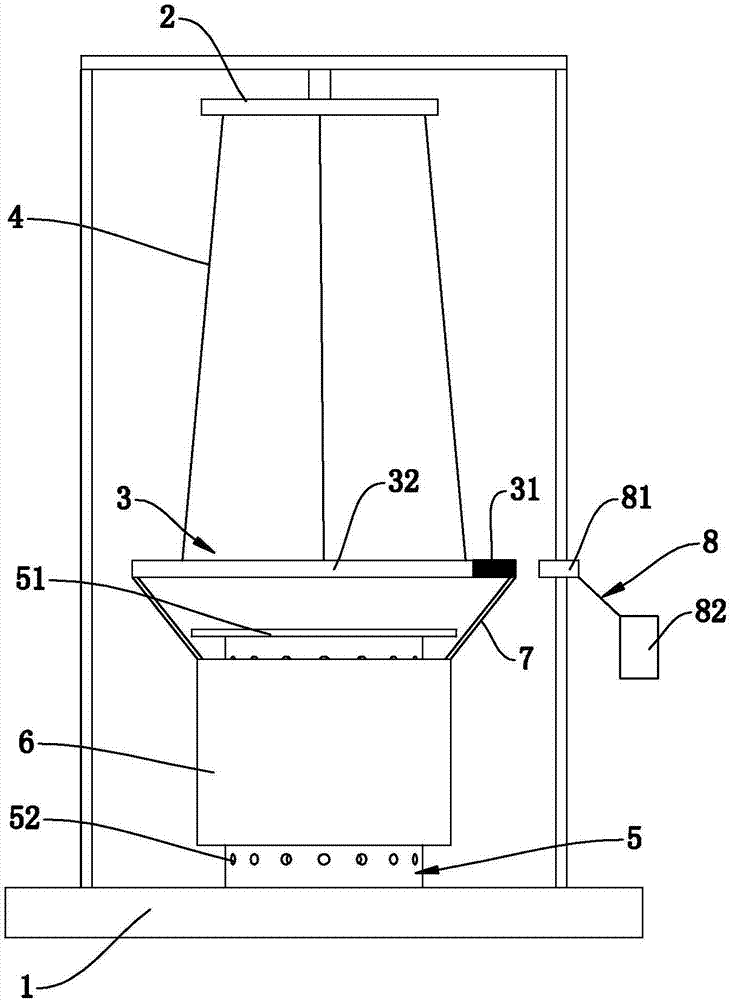

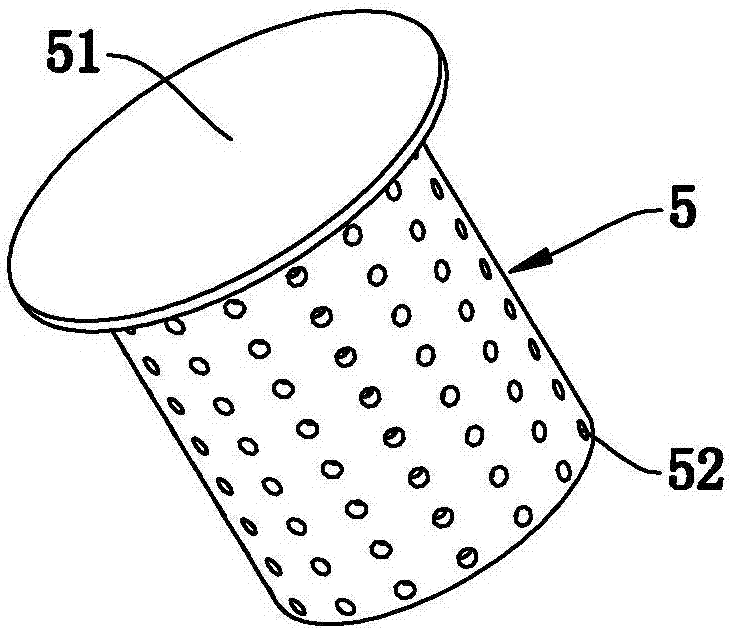

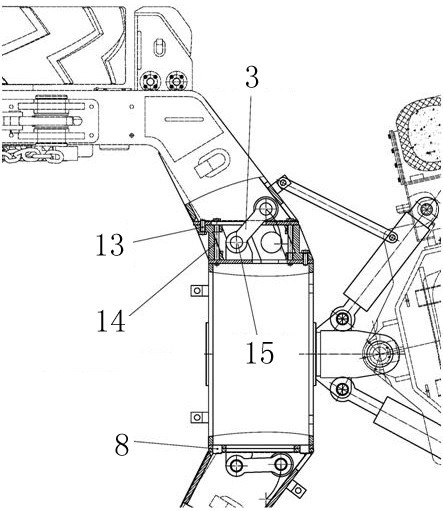

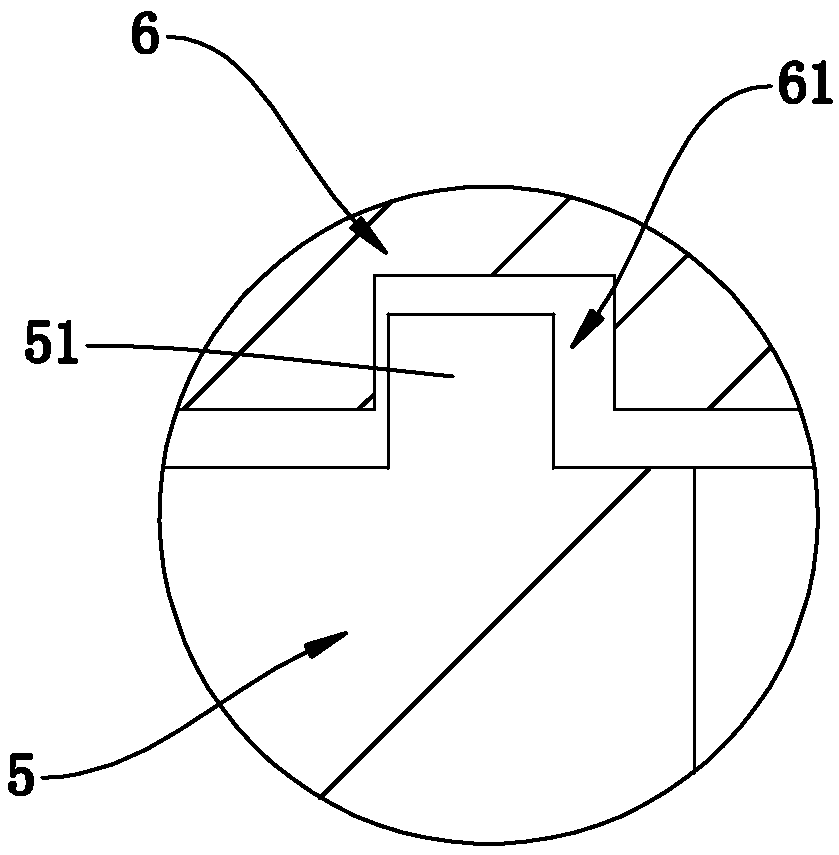

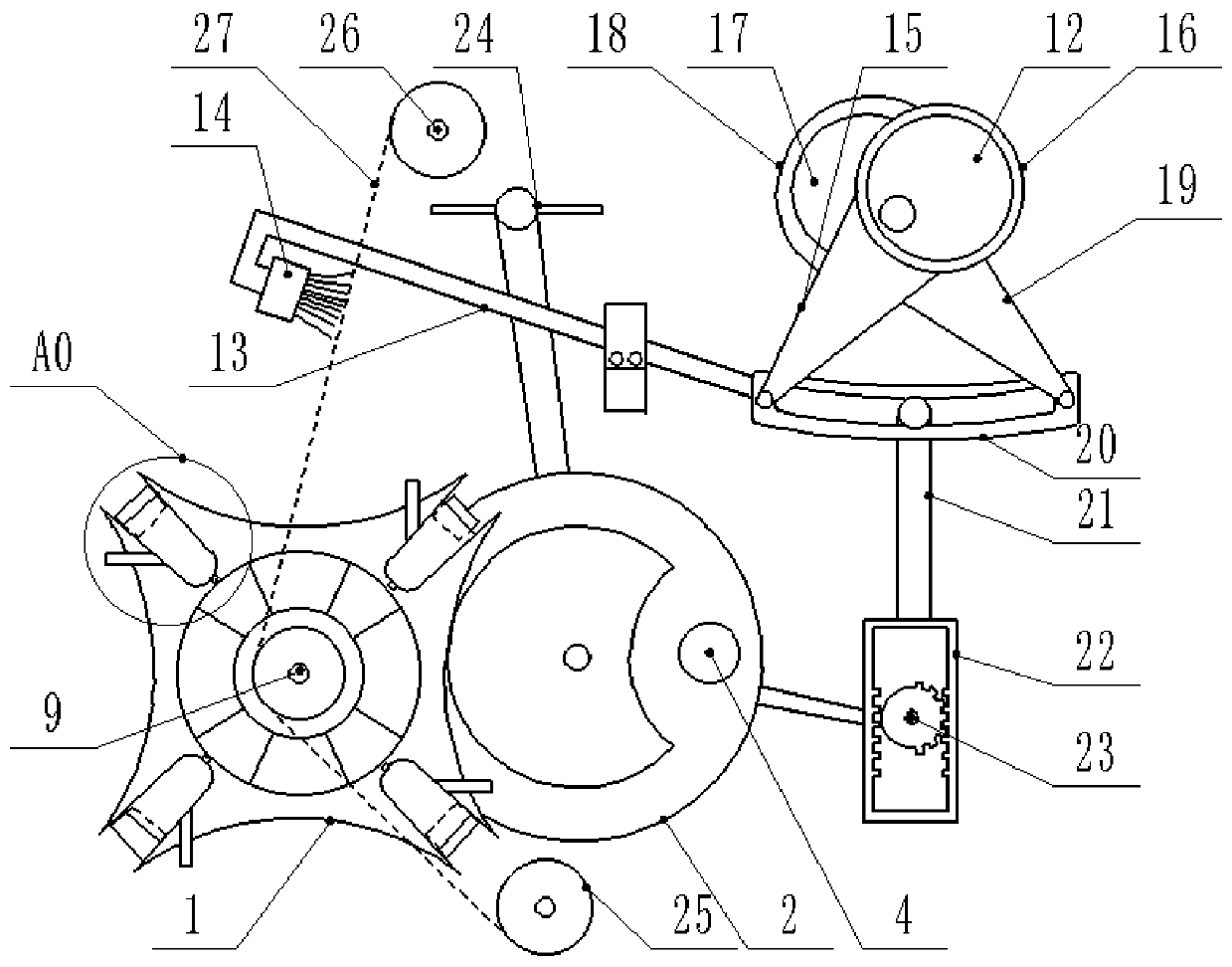

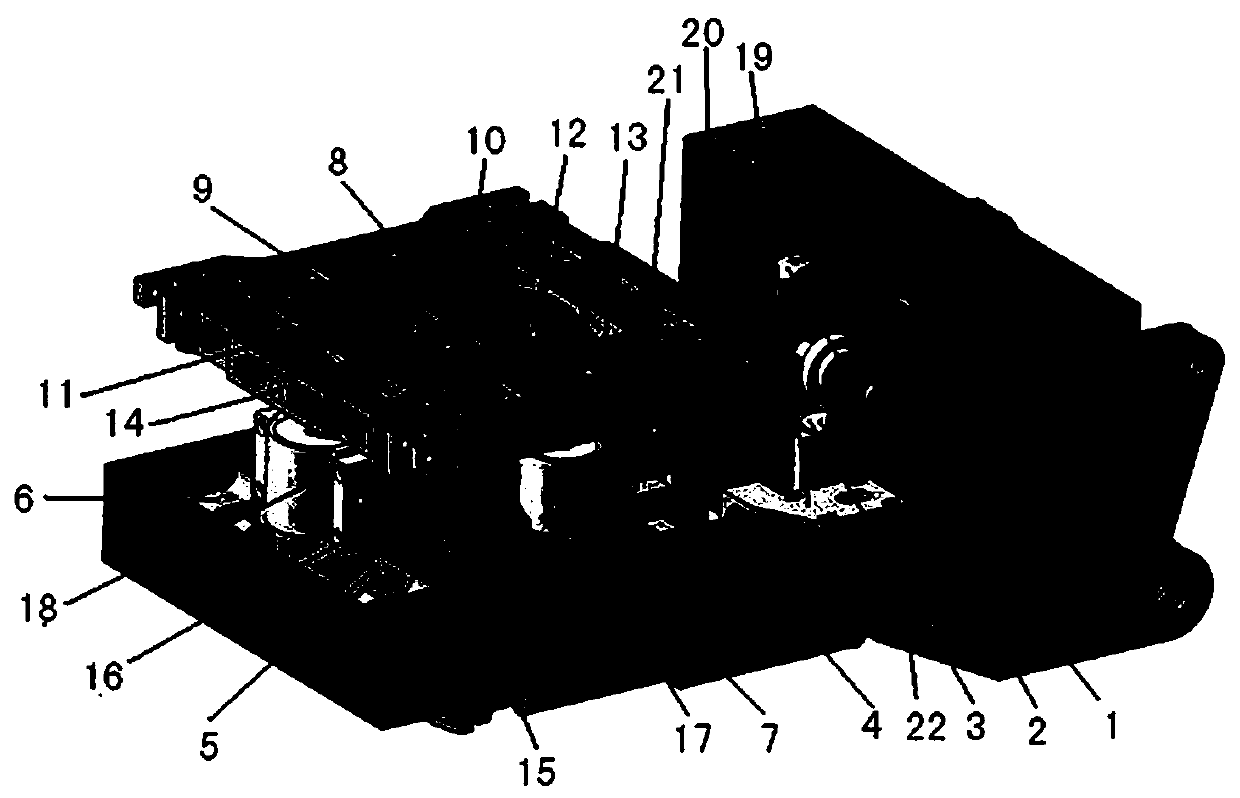

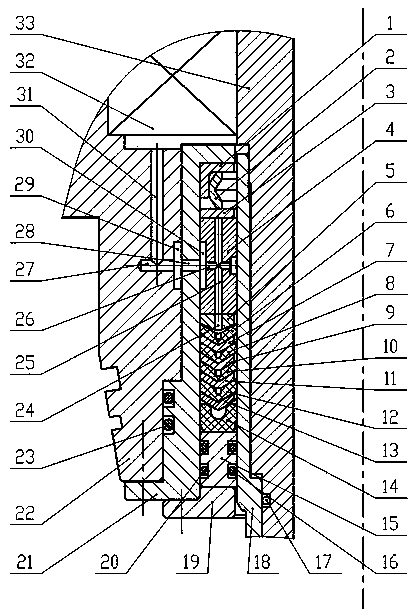

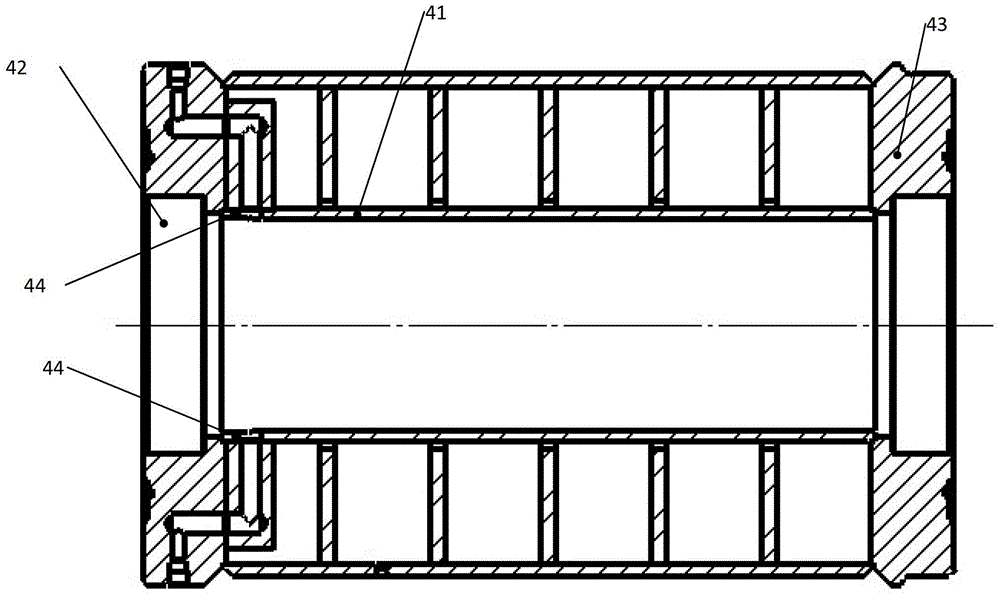

Electrolyte sealing device for tubular electrode electrolytic machining

InactiveCN105195842APrevent lateral swingImprove machining accuracyMachining working media supply/regenerationElectric machineryEngineering

The invention provides an electrolyte sealing device for tubular electrode electrolytic machining. The electrolyte sealing device is characterized by comprising an electrolyte tank (1), a workpiece clamp (2), a pipeline (3), a filter (4), a high-pressure isolation pump (5), a three-way joint (6), a pressure gauge (7), a main body clamp I (8), an insulating pad (9), a tubular electrode (10), a water stop plug (11), a tubular electrode clamp (12), a main body clamp II (13), a guider clamp (14) and a guider (15). The water stop plug is used for sealing the device; the guider is used for preventing transverse swinging of a workpiece during machining; the insulating pad is used for insulating a motor; the tubular electrode clamp, the guider clamp, the workpiece clamp, the main body clamp I and the main body clamp II are respectively used for clamping and sealing fit of the tubular electrode, the guider and the workpiece; therefore, the clamping on the electrode, motor insulation and electrolyte sealing and circulation during tubular electrode electrolytic machining can be well realized.

Owner:SHANDONG UNIV OF TECH

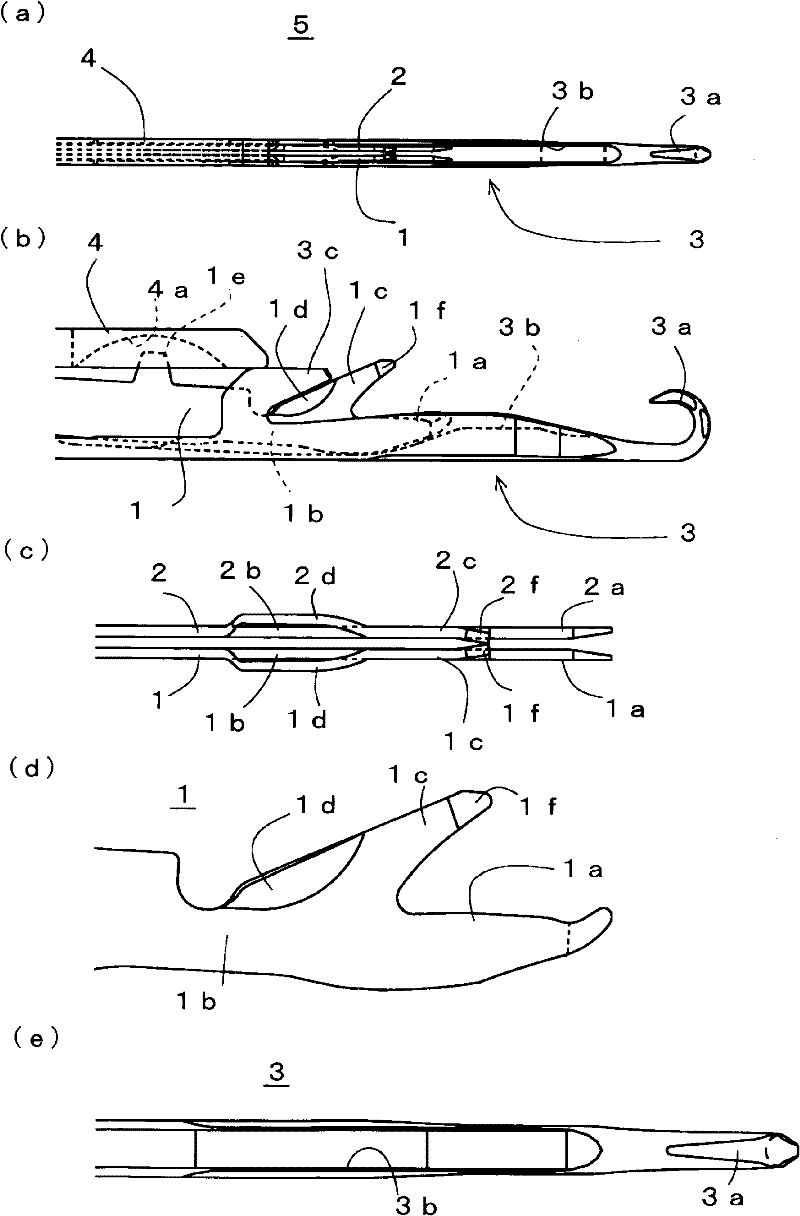

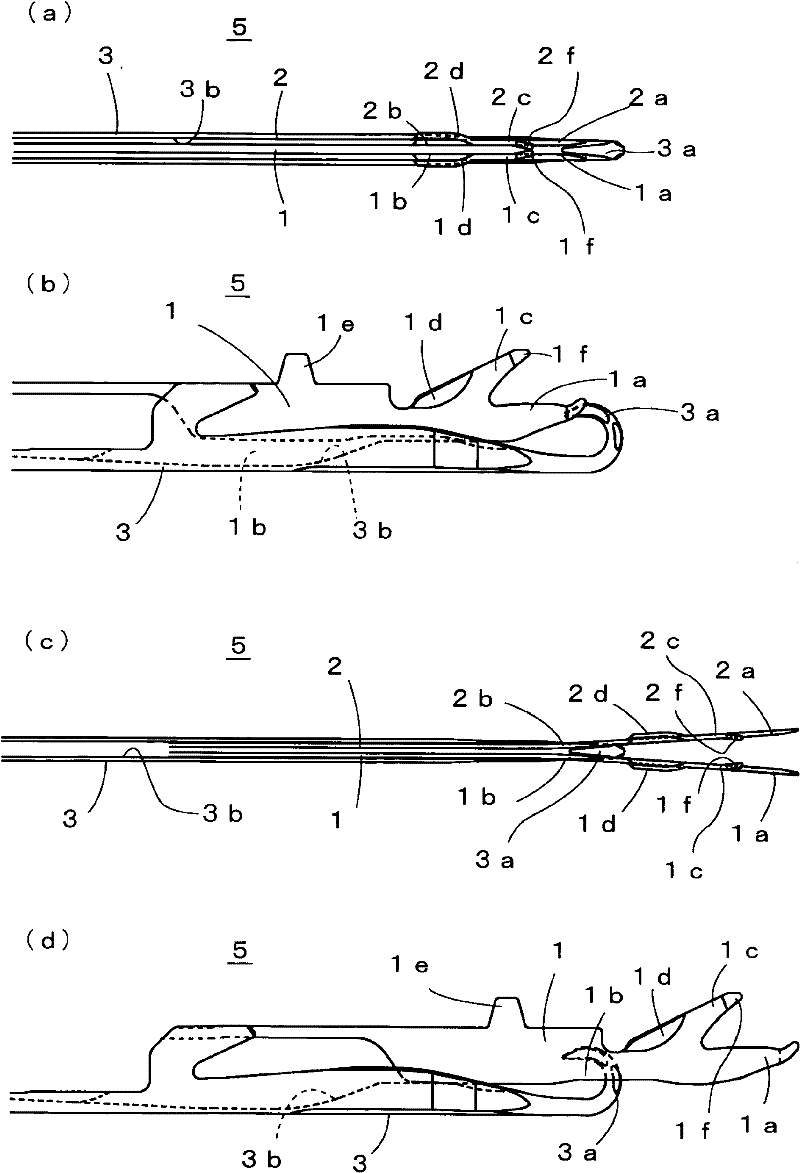

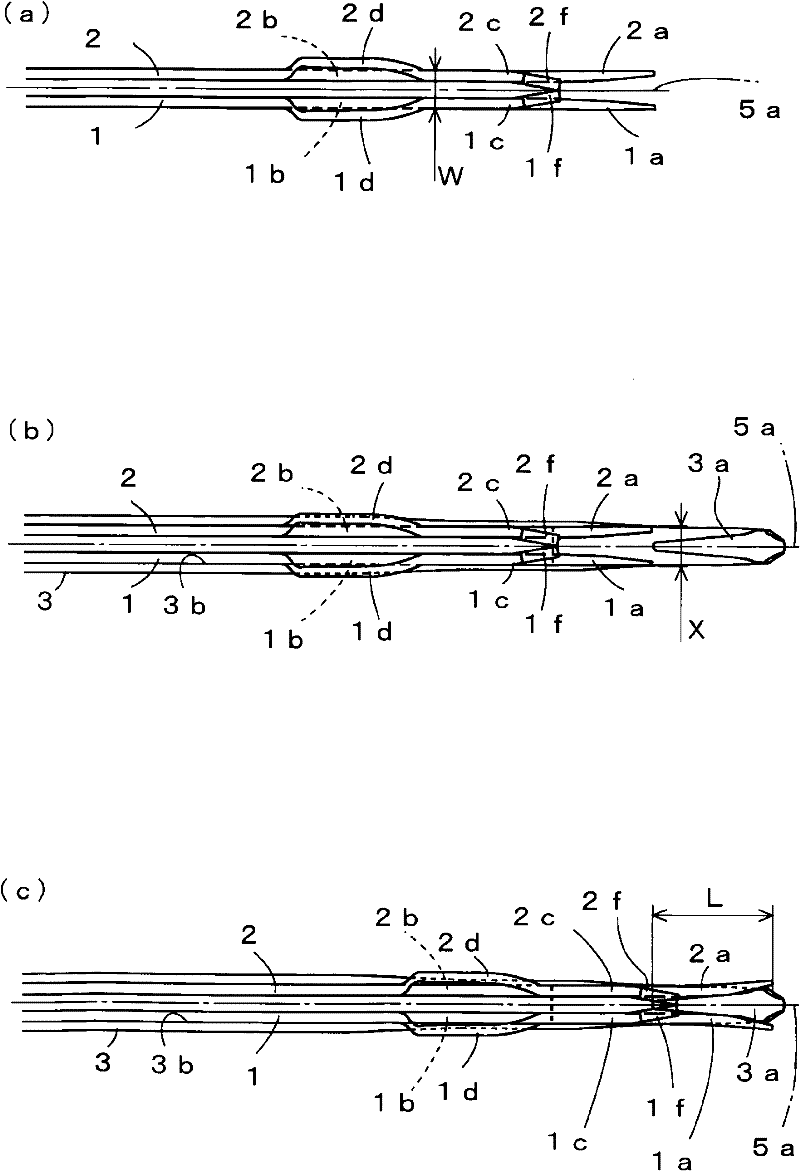

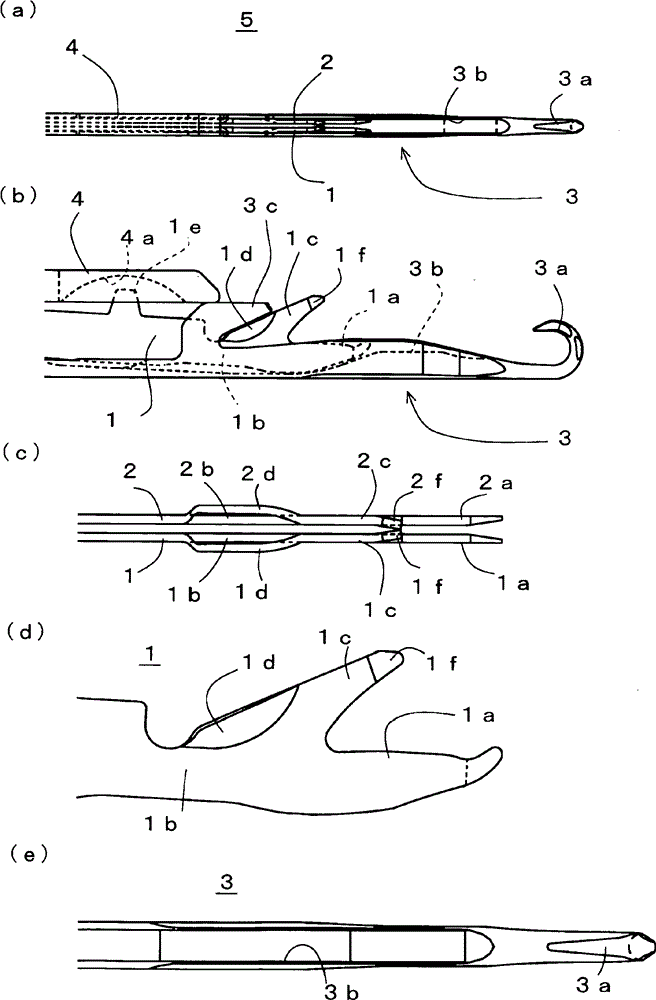

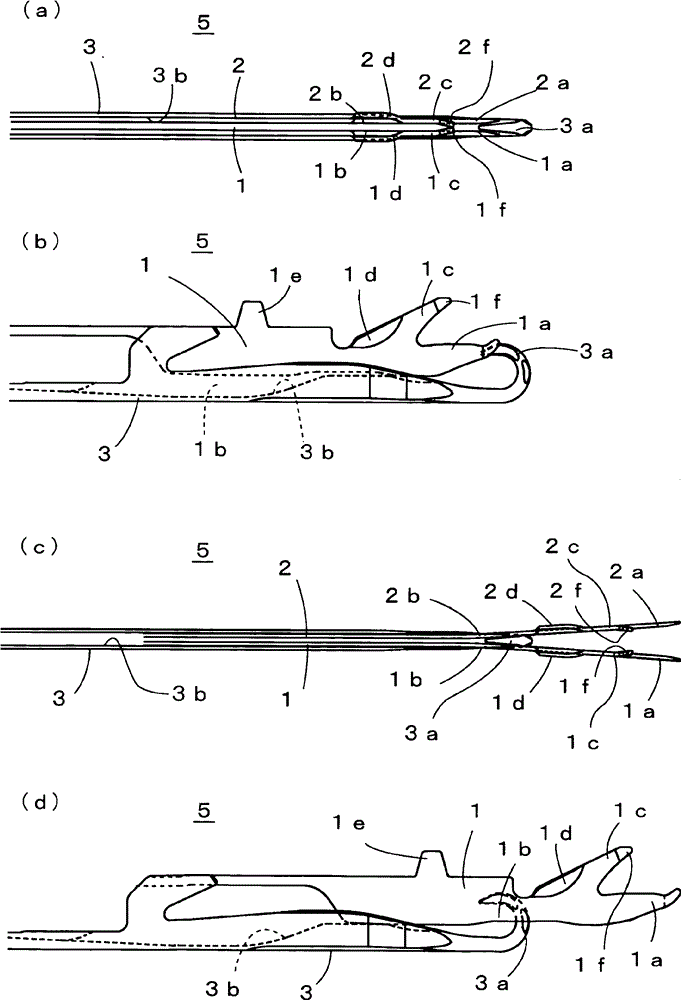

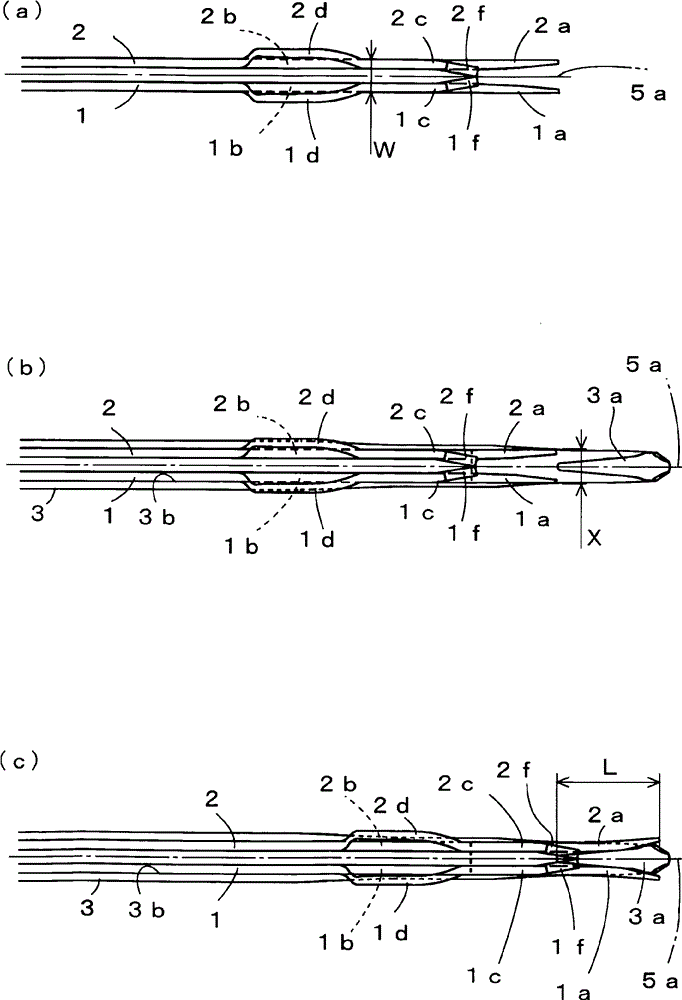

Compound needle for flat knitting machine

The present invention provides a compound needle for a flatbed knitting machine in which sliding resistance can be made small and opening / closing accuracy to an aperture of a hook by a tongue can be enhanced with a simple structure. Tongues (1a, 2a) have no bent and have linear shaped portions (1b, 2b) provided at the rear side of the tongues (1a, 2a), so that blades (1, 2) have stable finishing shapes and manufacturing thereof can be easily performed. Since lower portions of the blades (1, 2) are not bent in a blade groove, sliding resistance can be made small. Shoulder portions (1c, 2c) which come out of the blade groove from rear portions of the tongues (1a, 2a) are bent inward between the shoulder portions (1c, 2c) opposed to each other such that front ends of the shoulder portions (1c, 2c) make closer to and contact with each other so as to form contacting portions (1f, 2f), therefore, a centering effect can be obtained. A space generated between the tongues (1a, 2a) is kept so that resistance when a hook (3a) opens between the tongues (1a, 2a) can be made small and opening / closing accuracy of the hook 3a can be enhanced.

Owner:SHIMA SEIKI MFG LTD

Assembly type bridge

InactiveCN112681108AChange widthNo need to increase build widthBridge structural detailsProtective buildings/sheltersSteel platesSlide plate

The invention discloses an assembly type bridge which comprises a horizontal sliding plate and an elastic arc plate, the horizontal sliding plate and the elastic arc plate are rotationally connected, side edge supporting columns are installed at the bottom of the elastic arc plate, supporting bottom plates are fixedly connected to the bottoms of the side edge supporting columns, and elastic steel plates are evenly installed at the tops of the supporting bottom plates. And the tops of the elastic steel plates are fixedly connected with lifting supporting columns, and T-shaped sliding grooves are formed in the tops of the side supporting columns and the tops of the lifting supporting columns. The invention relates to the technical field of bridge construction. According to the assembly type bridge, the purpose of the flexibility degree of the assembly type bridge is achieved, the width of the bridge and the height of the guardrails can be flexibly adjusted according to the width of passing vehicles, the width of the bridge does not need to be increased when the vehicles with the larger width pass, the bridge construction cost is reduced, and the bridge safety is improved; when a large vehicle passes, friction and collision between the large vehicle and the side wall of a bridge can be avoided, and the technical requirements for vehicle drivers are lowered.

Owner:徐智勇

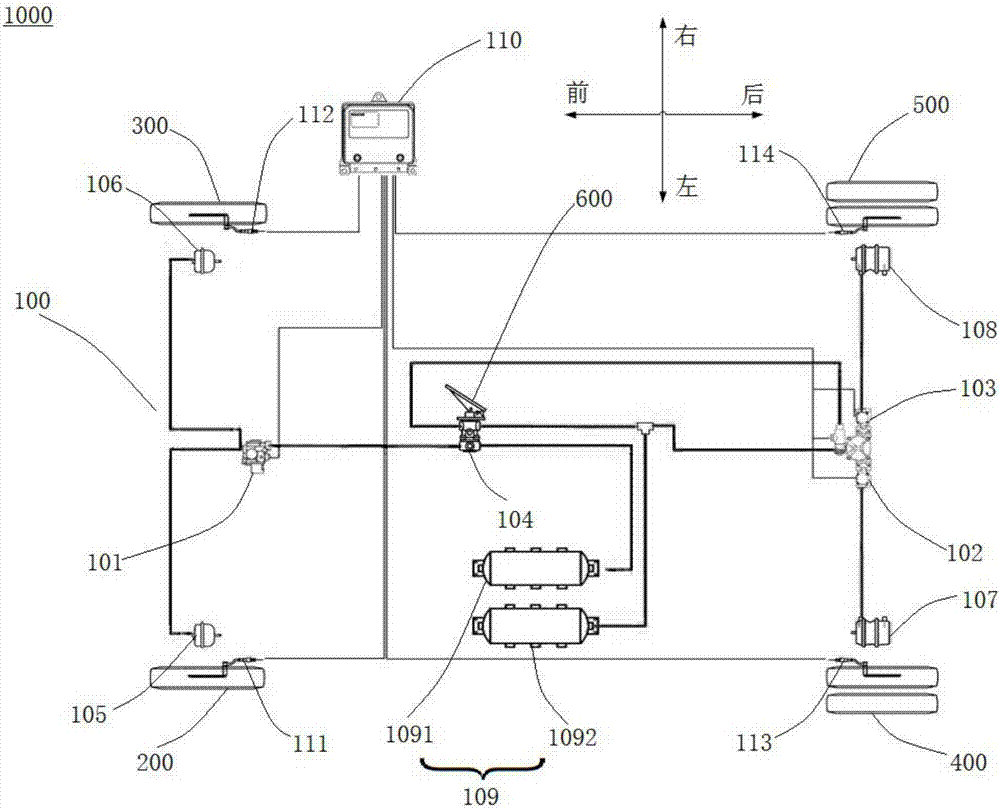

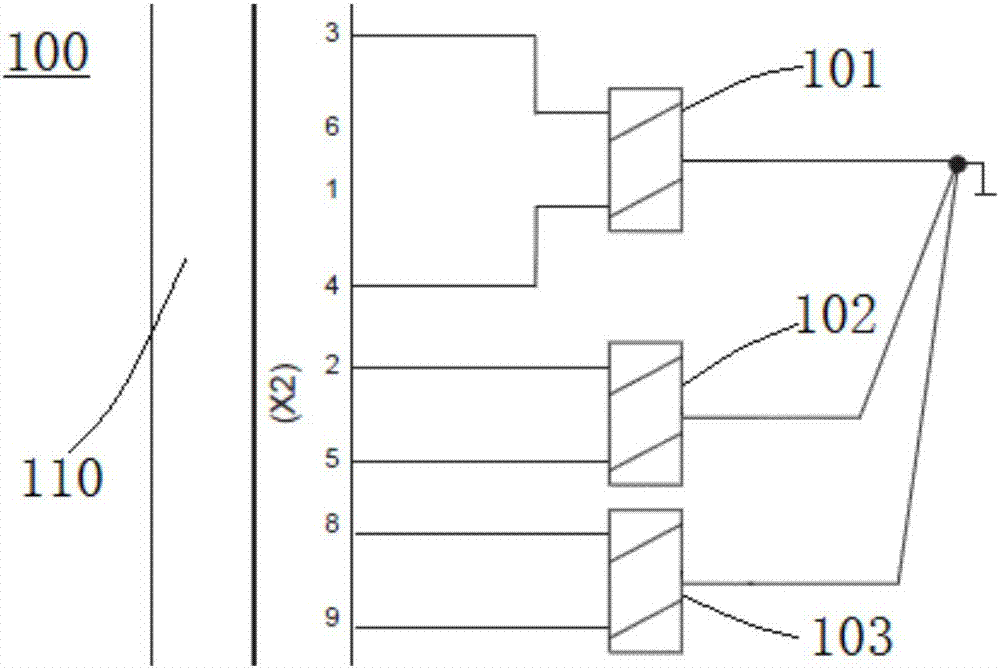

ABS for vehicle, and vehicle with ABS

InactiveCN107953873ASmooth brakingPrevent lateral swingBraking action transmissionControl valvesAutomotive engineering

The invention discloses an ABS for a vehicle, and the vehicle with the ABS. The ABS for the vehicle comprises a first control valve, a second control valve, a third control valve, a braking valve, anair storing cylinder, a first front braking air chamber, a second front braking air chamber, a first rear braking air chamber and a second rear braking air chamber. The braking valve is connected witha braking control mechanism of the vehicle, and the air storing cylinder is connected with the braking valve. The first front braking air chamber and the second front braking air chamber selectivelycommunicate with the braking valve or the air storing cylinder through the first control valve correspondingly. The first rear braking air chamber selectively communicates with the braking valve or the air storing cylinder through the second control valve. The second rear braking air chamber selectively communicates with the braking valve or the air storing cylinder through the third control valve. The four braking air chambers are used for braking four wheels of the vehicle correspondingly. According to the ABS for the vehicle, the more stable effect is achieved during braking of the vehicle,meanwhile, the production cost is saved, and maintenance is convenient.

Owner:BEIQI FOTON MOTOR CO LTD

A connection method between prefabricated concrete wall panel and main structure

The invention discloses a novel connection mode between a prefabricated concrete wall and a main structure and belongs to the technical field of prefabricated concrete component in housing industrialization. The novel connection mode comprises: connecting the upper part of the prefabricated concrete wall with a concrete beam, a beam hook and a wall hook in a flexible connection; filling in gaps on the side edges of the prefabricated concrete wall with rubber bricks to reduce the acting force exerted by a pillar on the prefabricated concrete wall at an earthquake; limiting the bottom part of the prefabricated concrete wall by a bottom-part blocking plate to prevent the prefabricated concrete wall from wobbling transversely. Suspension connecting mode is primary in the novel connection mode, gaps between the side edges of the prefabricated concrete wall and pillars are filled with the rubber bricks as a base-isolated device and the limit connection is arranged on the bottom part of the prefabricated concreted wall. According to this arrangement, the energy-dissipating capacity of the structure is improved, transverse wobbling of the prefabricated concrete wall is prevented, and the rigidity is reduced compared with that of a wet connection so that the prefabricated concrete wall of a building designed by standards of frame structure is effectively protected at an earthquake.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

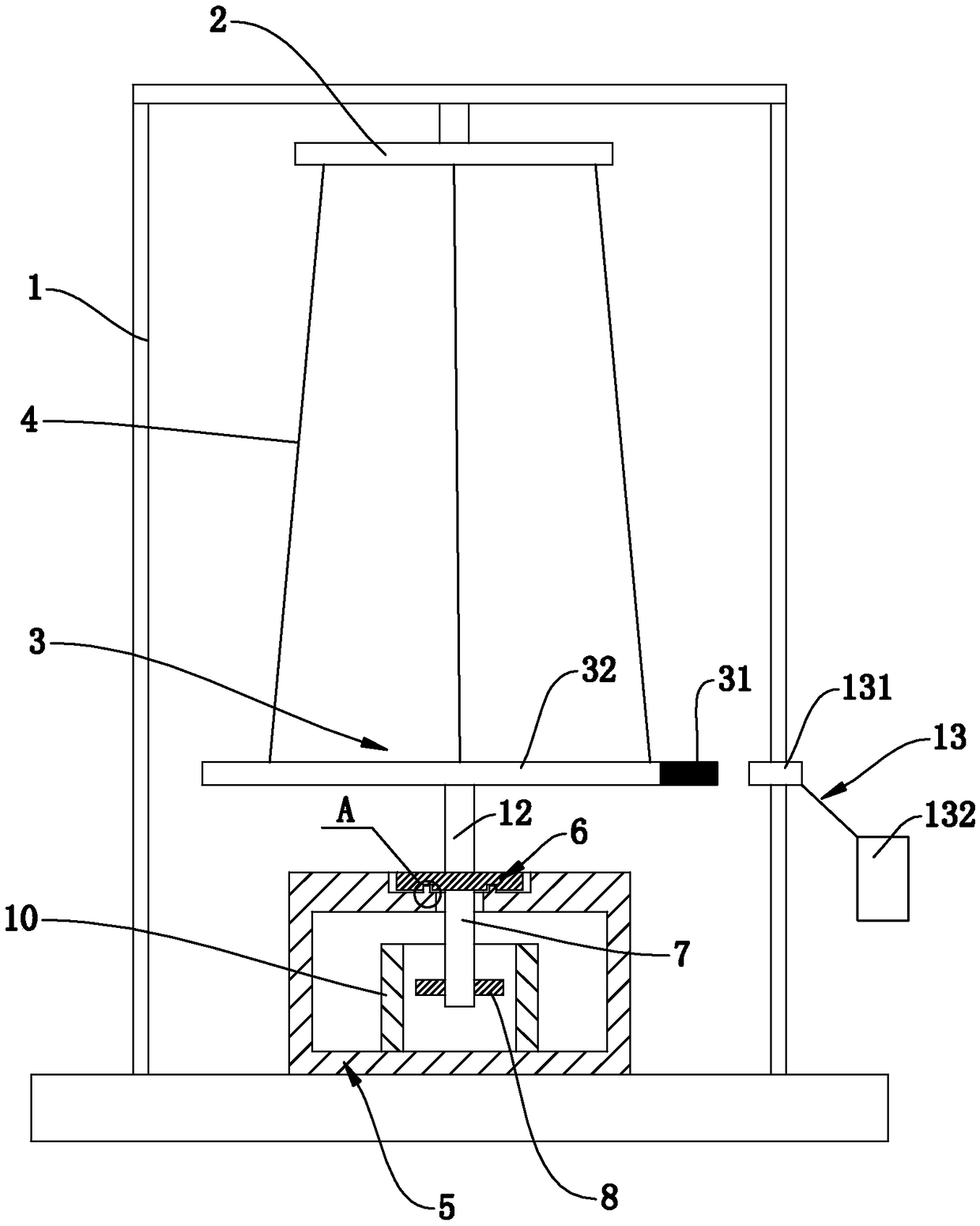

Three-line pendulum capable of measuring rotational inertia of object not rotating around center of mass

ActiveCN107246934APrevent lateral swingImprove measurement efficiencyStatic/dynamic balance measurementGas compressorMoment of inertia

The invention discloses a three-line pendulum capable of measuring the rotational inertia of an object not rotating around the center of mass, and belongs to the technical field of the mechanical experiment instrument. The three-line pendulum comprises a support, an upper disc, a lower disc and three suspension lines. The bottom part of the support is fixedly provided with an internal cylinder. The lower end of the internal cylinder is open, and the upper end is provided with a cylinder cover. The side wall of the internal cylinder is provided with multiple ventilation holes. A gas compressor is connected on the opening of the lower end of the internal cylinder. An external cylinder sleeves outside the internal cylinder. The two ends of the external cylinder are open. The gas compressor pressurizes the gas in the internal cylinder. The gas in the internal cylinder can enter the gap between the internal cylinder and the external cylinder through the ventilation holes and then can be discharged out of the upper open end and the lower open end of the external cylinder. The three-line pendulum is simple in structure and can measure the rotational inertia of the object not rotating around the center of mass and can also measure the rotational inertia of the object rotating around the center of mass, and the three-line pendulum is high in measurement efficiency and great in measurement accuracy.

Owner:WEIFANG UNIVERSITY

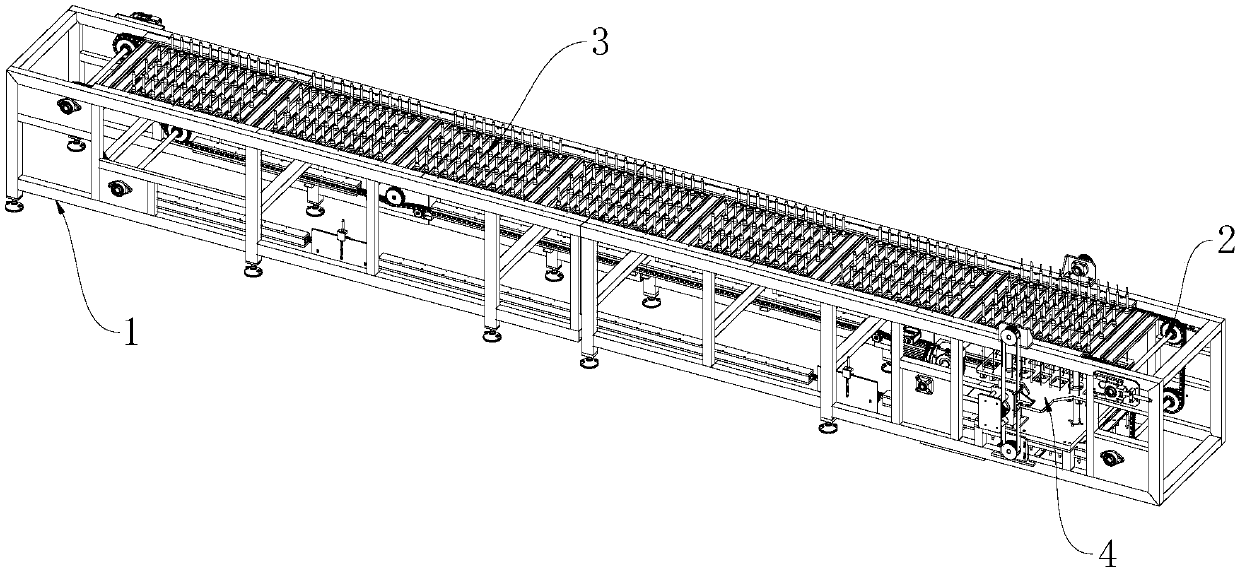

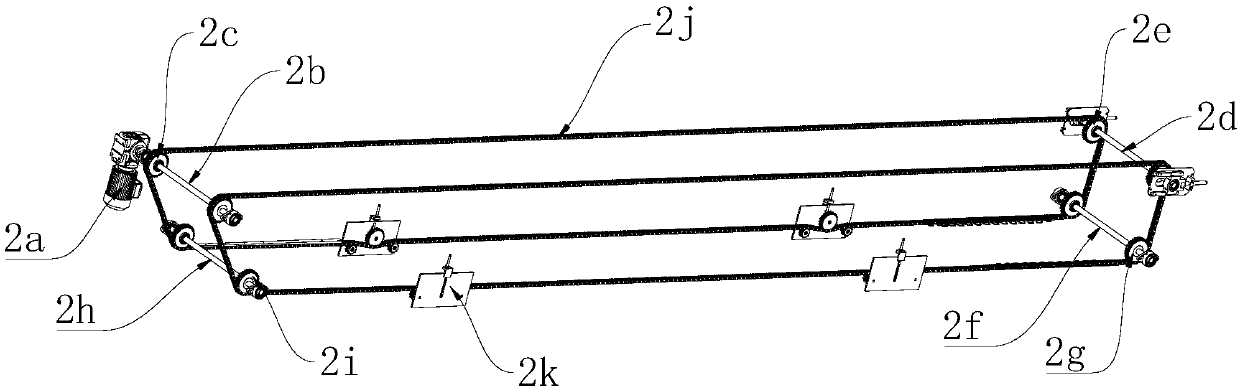

Damage-free preform conveyor

The invention relates to the technical field of bottle preform production, in particular to a damage-free preform conveyor. The damage-free preform conveyor comprises a support, a chain transmission assembly, a preform carrying assembly and a preform receiving assembly. The chain transmission assembly is mounted on the support, the preform carrying assembly is mounted on the chain transmission assembly, and the preform receiving assembly is mounted on the front side of the support. During preform receiving, bottle preforms are transferred to the preform carrying assembly located under a preform outlet mechanism from the preform outlet mechanism through the preform receiving assembly, and the preform carrying assembly loaded with the bottle preforms moves to the rear side of the support through the chain transmission assembly. The damage-free preform conveyor has the beneficial effects that after the bottle preforms are turned over through the preform outlet mechanism, openings of the bottle preforms are downward, inserting rods of the preform receiving assembly stretch out of preform bearing parts until the inserting rods stretch into the bottle preforms and abut against the innerbottoms of the bottle preforms, meanwhile, the bottle preforms are loosened by the preform outlet mechanism, the bottle preforms fall on the inserting rods, the inserting rods retract, and the preformbearing parts are stably sleeved with the bottle preforms. The whole process is stable in operation, the bottle preforms and the preform bearing parts are not in hard contact collisions, and it can be guaranteed that the inner and outer walls of the bottle preforms are not scratched to a large degree.

Owner:广州铂特机电设备有限公司

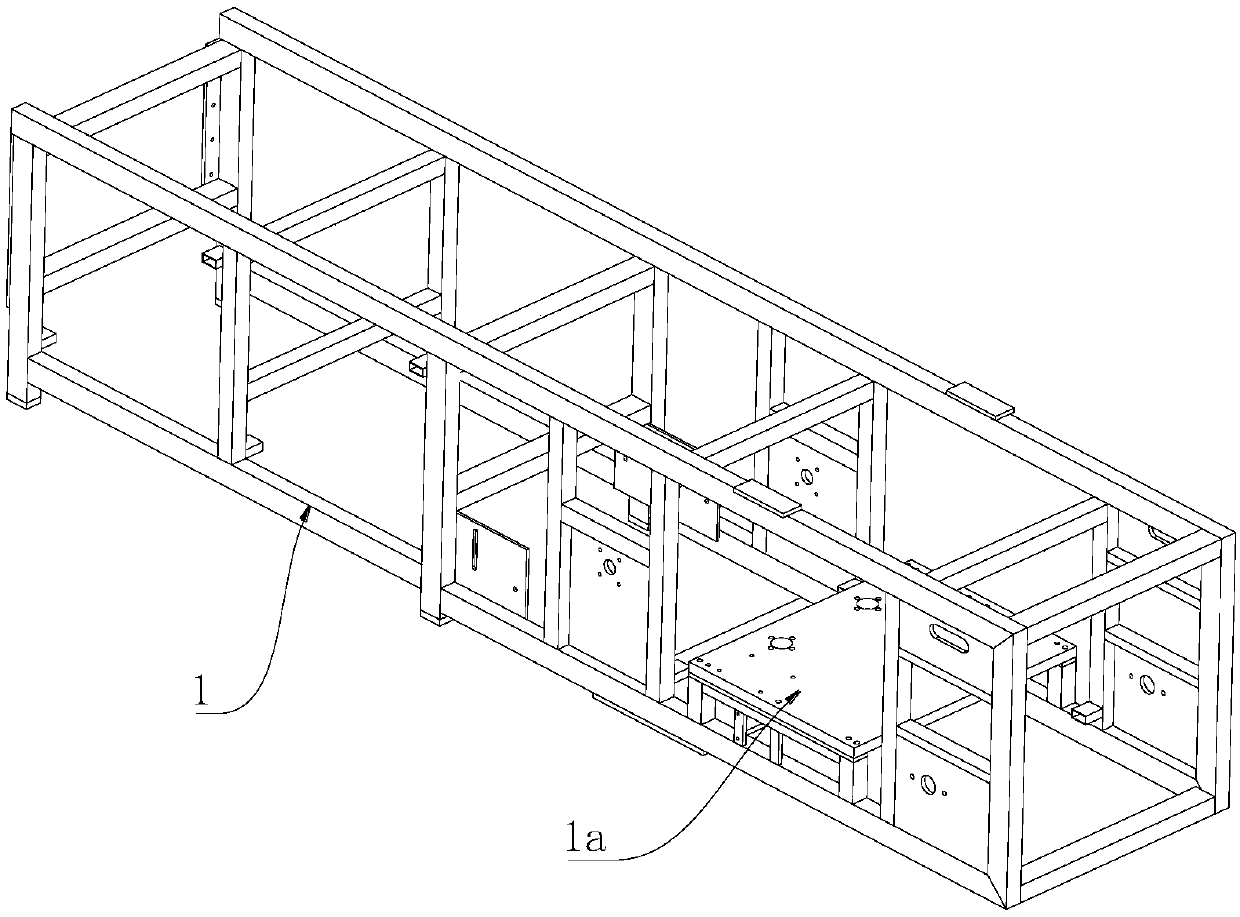

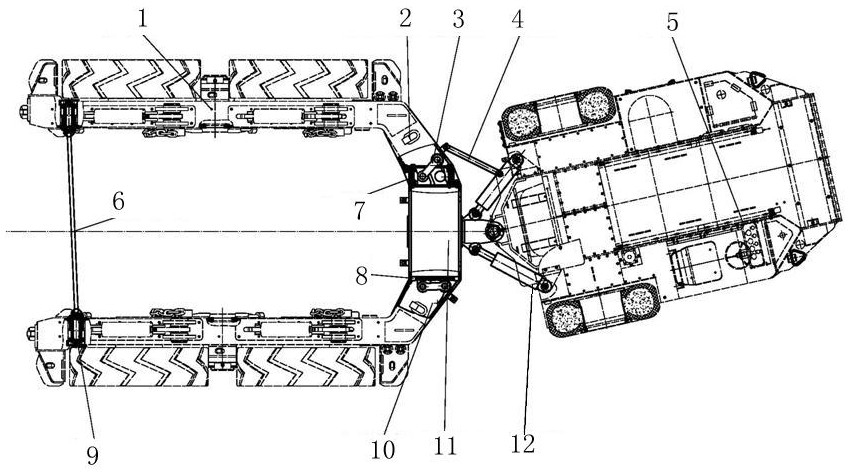

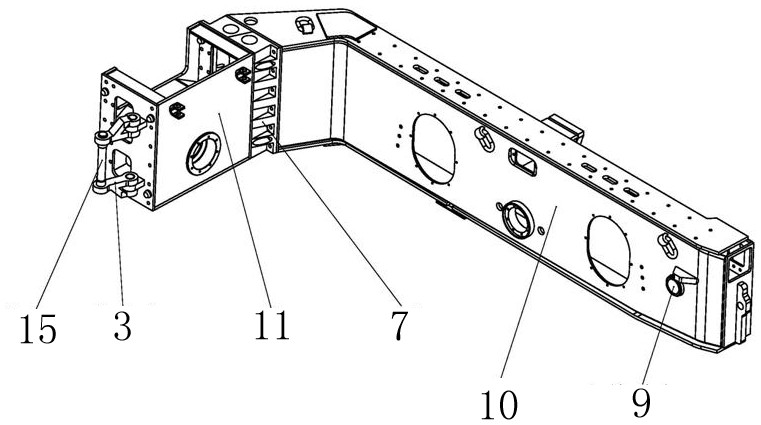

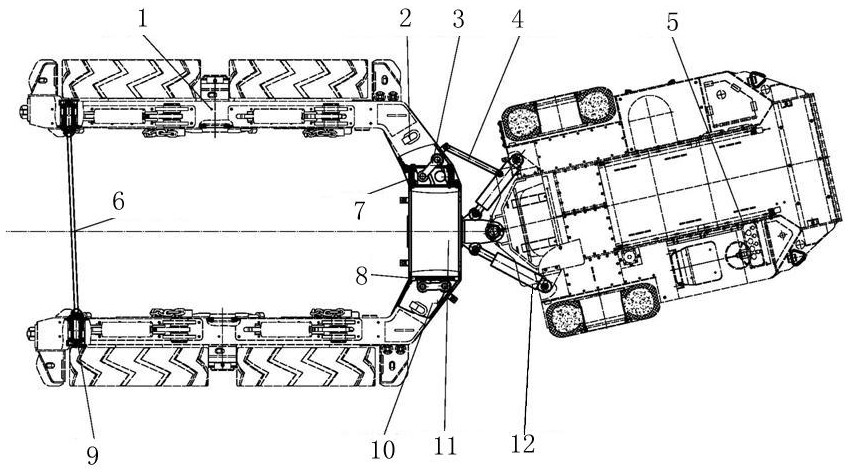

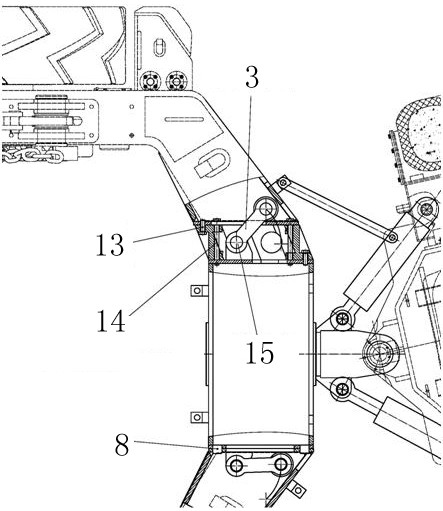

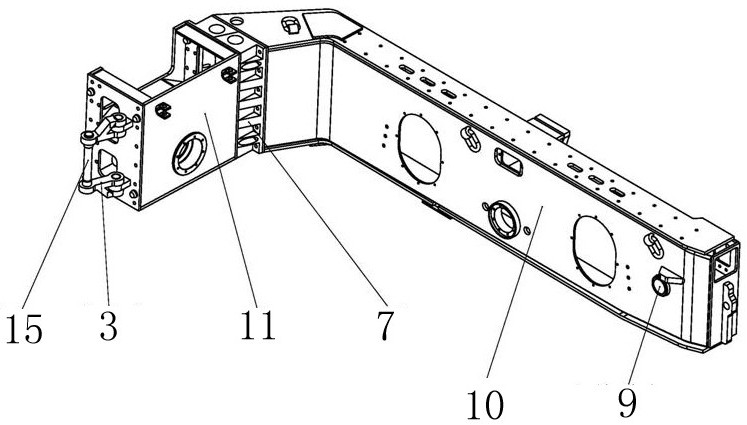

Bracket carrier rear frame capable of quickly changing loading width and using method

ActiveCN112141219APrevent lateral swingAlleviate the problem of ultra-wideUnderstructuresVehicle frameControl theory

The invention belongs to the technical field of underground coal mine transport vehicles, and particularly relates to a bracket carrier rear frame capable of quickly changing the loading width and a using method. The bracket carrier rear frame comprises a front frame and a rear frame; the rear frame comprises a middle box body, rotating frames, a left bearing frame and a right bearing frame; the middle box body is in hinged connection with the front frame, the two sides of the middle box body are connected with the left bearing frame and the right bearing frame respectively, the joint face between the middle box body and the left bearing frame or the right bearing frame is fixed through positioning pins and short bolts, and a group of concave cushion blocks can be added in the middle of the joint face; the left bearing frame or the right bearing frame is fixed with the concave cushion blocks through long bolts; one rotating frame is further connected between the middle box body and theleft bearing frame, the other rotating frame is connected between the middle box body and the right bearing frame, one sides of the rotating frames are connected with the middle box body, and the other sides of the rotating frames are connected with the left bearing frame or the right bearing frame; and the inner sides of the tails of the left bearing frame and the right bearing frame are each provided with a clamping oil cylinder, and a double-ball-head pull rod is connected between the clamping oil cylinders on the two sides.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

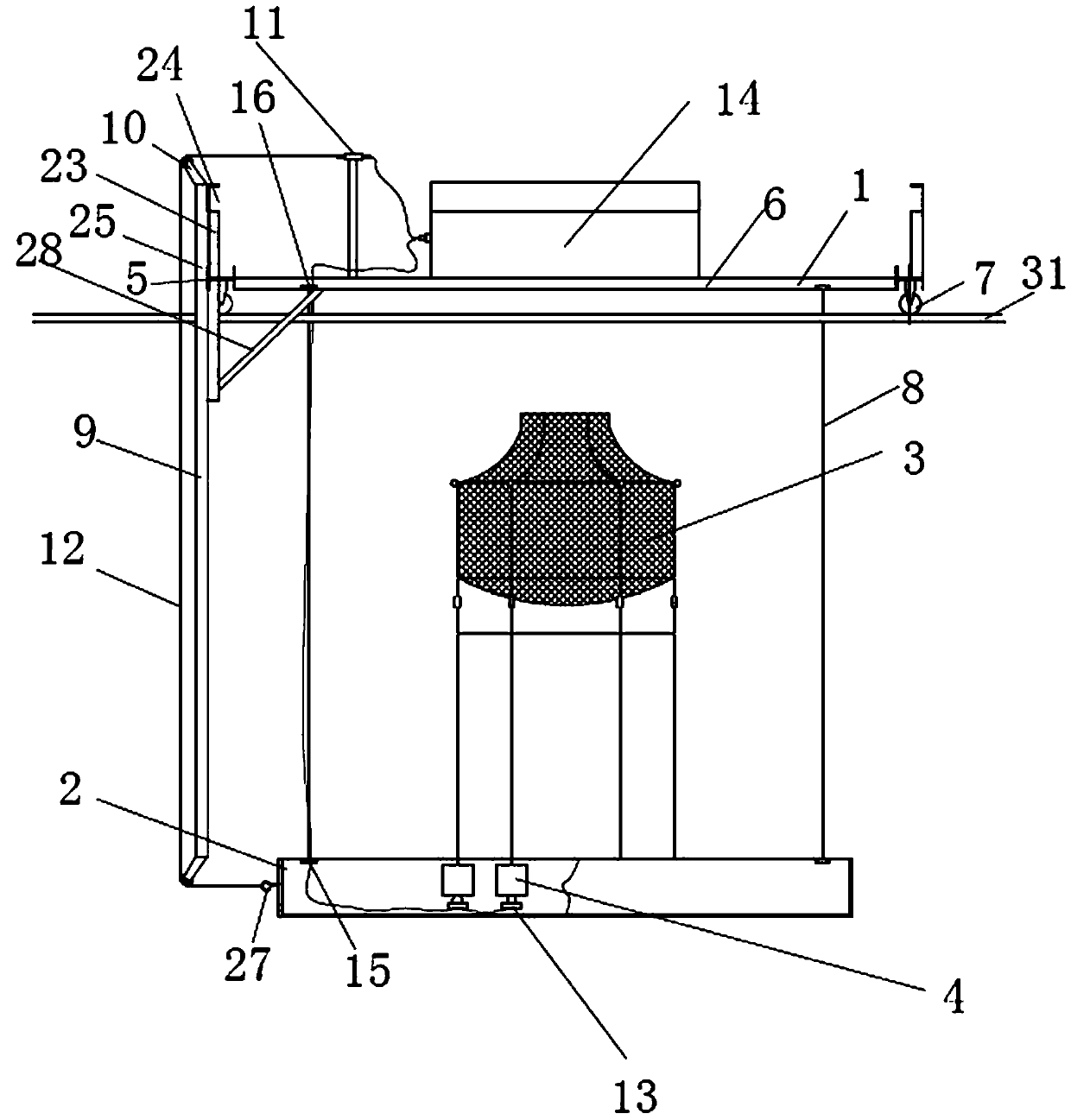

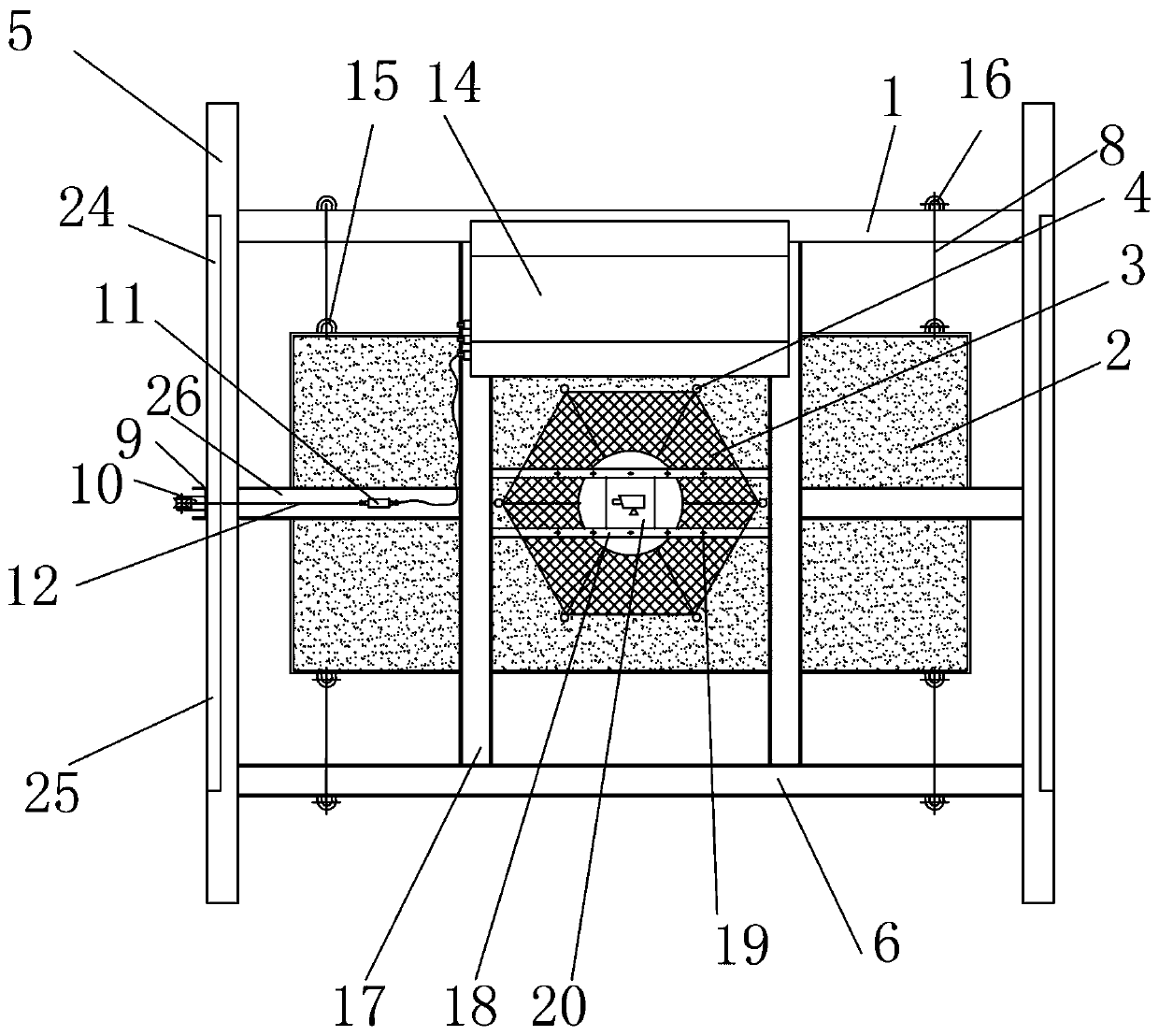

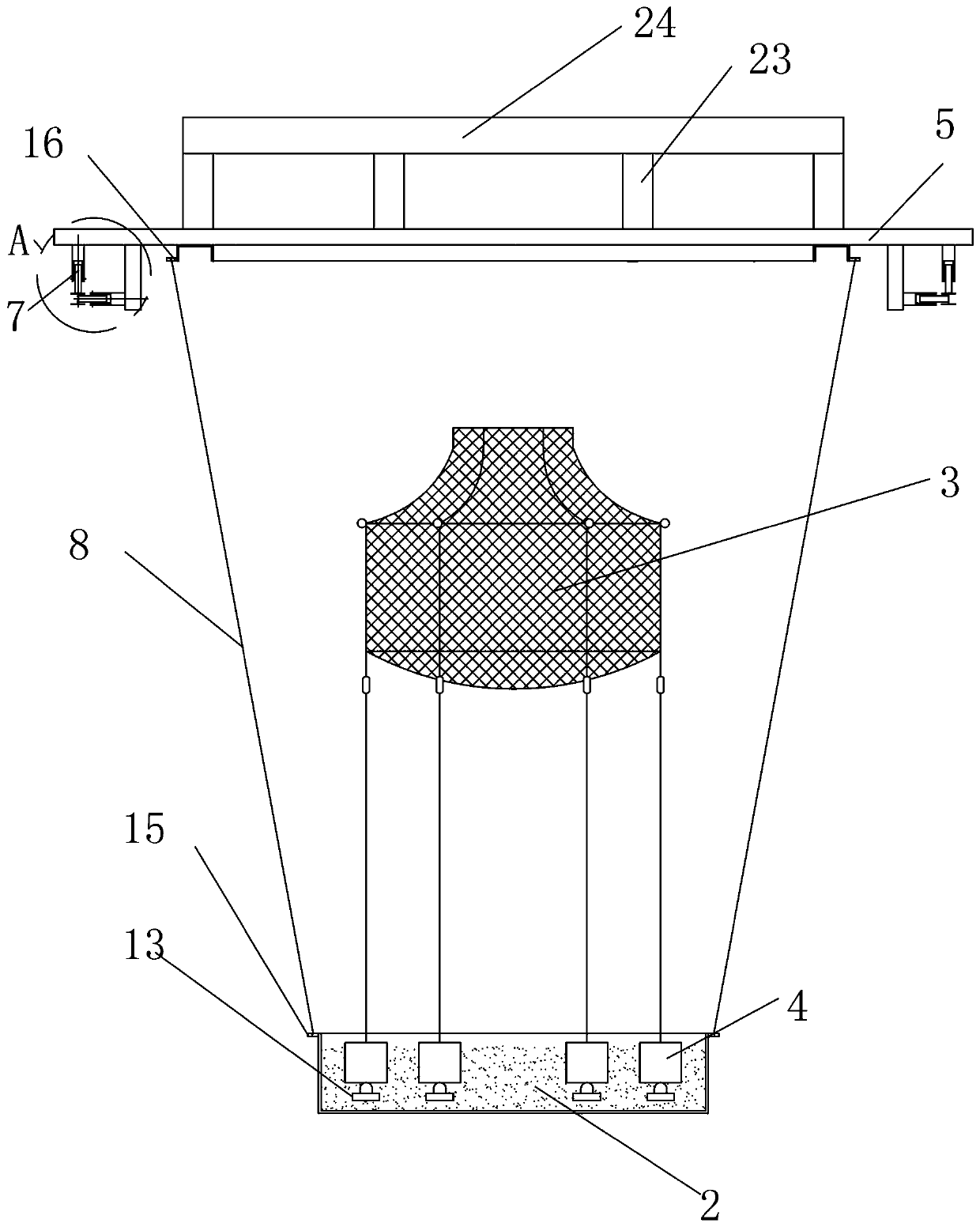

Tension leg net cage model test device

The invention discloses a tension leg net cage model test device. The device comprises a device framework and an underwater sand tank, wherein the device framework comprises two transverse girders stretching across guide rails at the two sides of a water tank and two longitudinal girders fixed between the two transverse girders, the underwater sand tank is connected with each longitudinal girder through an iron chain, a traction rod is arranged at the side edge of the transverse girder at the left side, traction pulleys are arranged above and below the traction rod respectively, a tension sensor, which is used for detecting deformation generated when the underwater sand tank is pulled, is arranged on the device framework, the tension sensor is connected with the underwater sand tank through a tension steel cable located on the two traction pulleys to form a tension conduction detection device, a tension steel cable of the underwater sand tank needs to be pre-tightened in advance, waterproof travel switches in one-to-one correspondence with gravity anchors of a tested tension leg net cage model are arranged in the underwater sand tank, and a controller electrically connected with the waterproof travel switches and the tension sensor is arranged above the device framework. Through the device, the maximum water flow impact force capable of being borne by an anchoring system of thetension leg net cage model can be tested.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

An aircraft engine installation device

ActiveCN103639973BPrevent slippingEasily brokenLifting framesMetal-working hand toolsManufacturing technologyLocking mechanism

The invention relates to an aircraft manufacturing technology, belongs to mechanical products and particularly provides an aircraft engine installing device. The aircraft engine installing device comprises a base, a moving bracket, an L-shaped bracket, a guide rail placing assembly, a lifting mechanism, a locking mechanism and adjustable screw rods, wherein the guide rail placing assembly is installed between the L-shaped bracket and the moving bracket. Moving trundles are installed at four ends of the base. The adjustable screw rods are arranged on four sides of the moving bracket. The locking mechanism is used for limiting and fixing the L-shaped bracket and the lifting mechanism. A lifter is installed on the moving bracket. A jack is installed on the base. The aircraft engine installing device jacks up an engine and performs ascending motion by utilizing the ascending hydraulic jack, the jack can be locked by using a check nut and prevented from sliding downward in the event of oil leakage when ascending any height, the problem that a steel wire rope in the prior art is easily broken and corroded during traction motion is solved, and the using safety is improved.

Owner:JIANGXI HONGDU AVIATION IND GRP

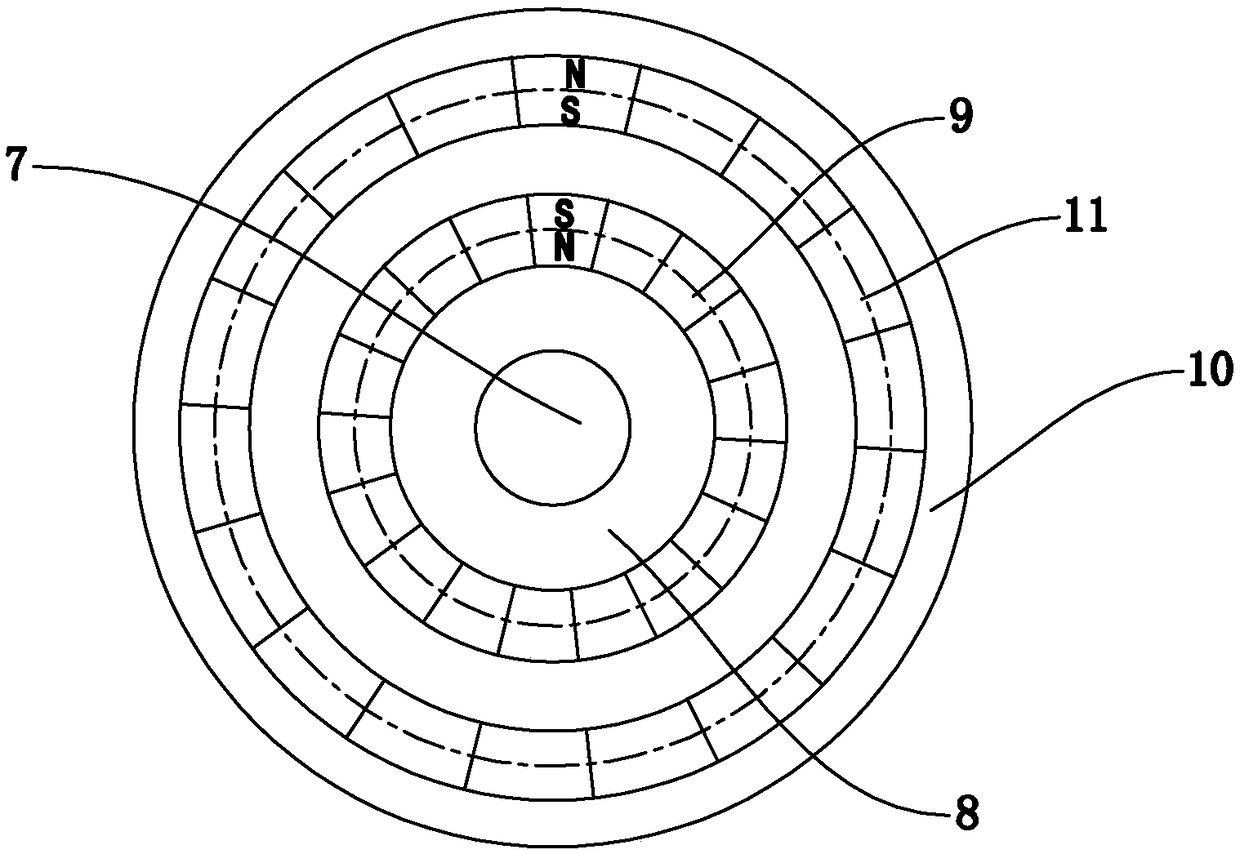

a three-wire pendulum

ActiveCN107389265BPrevent lateral swingInsulate the influenceStatic/dynamic balance measurementEducational modelsCircular discElectrical polarity

The invention discloses a three-line pendulum and belongs to the technical field of mechanical experiment instruments. The three-line pendulum comprises a support, an upper plate, a lower plate, two suspended lines and an anti-leakage magnetic shell and an anti-leakage magnetic cover plate which can relatively rotate, the anti-leakage magnetic shell and the anti-leakage magnetic cover plate are made of permeability magnetic materials, the anti-leakage magnetic cover plate is fixedly mounted on the bottom of the lower plate, and a first connection column is fixedly mounted on the lower surface of the anti-leakage magnetic cover plate; a circle disk is fixedly mounted at the bottom of the first connection column, and multiple internal magnets which are distributed in the peripheral direction are arranged on the outer surface of the circle disk; a cylinder is fixedly mounted on the portion, outside the circle disk, in the anti-leakage magnetic shell, multiple external magnets which are distributed in the peripheral direction are arranged on the inner surface of the cylinder, the external magnets and the internal magnets are correspondingly arranged, and the polarities of the opposite surfaces of the external magnets and the internal magnets are same. The three-line pendulum is simple in structure, can measure the rotational inertia of an object which does not rotate around the mass center, can also measure the rotational inertia of an object which rotates around the mass center, and is high in measurement efficiency and in measurement accuracy.

Owner:WEIFANG UNIVERSITY

A three-wire pendulum capable of measuring the moment of inertia of objects not rotating around the center of mass

ActiveCN107246934BPrevent lateral swingImprove measurement efficiencyStatic/dynamic balance measurementGas compressorEngineering

The invention discloses a three-line pendulum capable of measuring the rotational inertia of an object not rotating around the center of mass, and belongs to the technical field of the mechanical experiment instrument. The three-line pendulum comprises a support, an upper disc, a lower disc and three suspension lines. The bottom part of the support is fixedly provided with an internal cylinder. The lower end of the internal cylinder is open, and the upper end is provided with a cylinder cover. The side wall of the internal cylinder is provided with multiple ventilation holes. A gas compressor is connected on the opening of the lower end of the internal cylinder. An external cylinder sleeves outside the internal cylinder. The two ends of the external cylinder are open. The gas compressor pressurizes the gas in the internal cylinder. The gas in the internal cylinder can enter the gap between the internal cylinder and the external cylinder through the ventilation holes and then can be discharged out of the upper open end and the lower open end of the external cylinder. The three-line pendulum is simple in structure and can measure the rotational inertia of the object not rotating around the center of mass and can also measure the rotational inertia of the object rotating around the center of mass, and the three-line pendulum is high in measurement efficiency and great in measurement accuracy.

Owner:WEIFANG UNIVERSITY

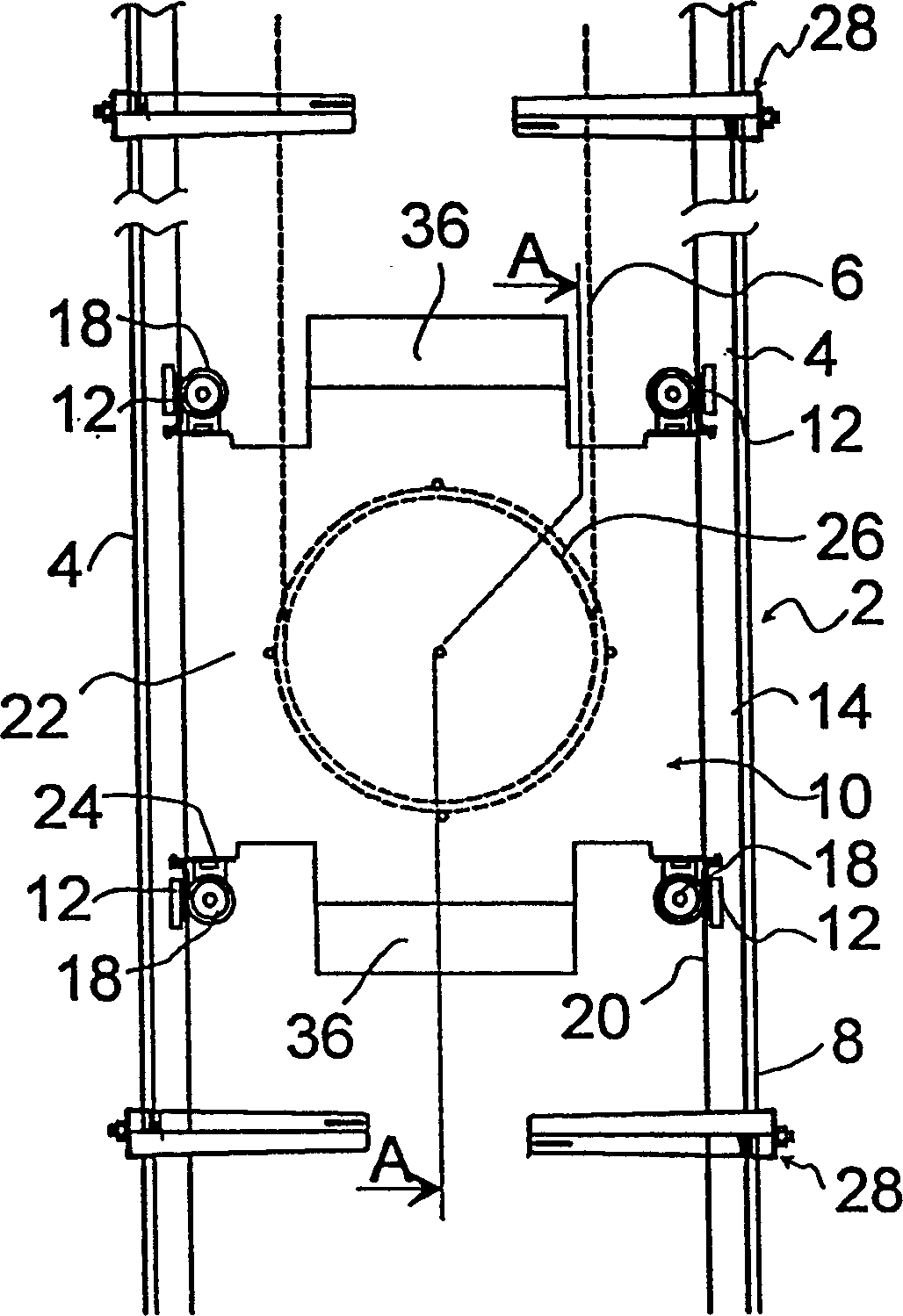

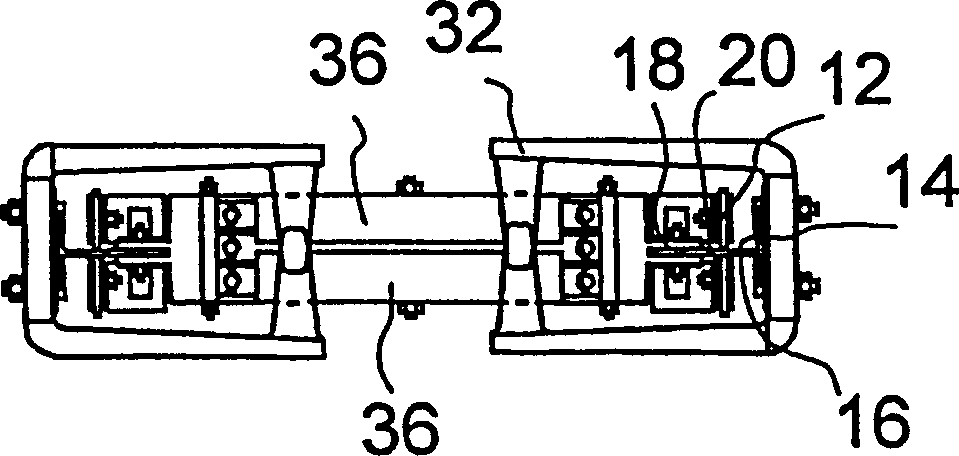

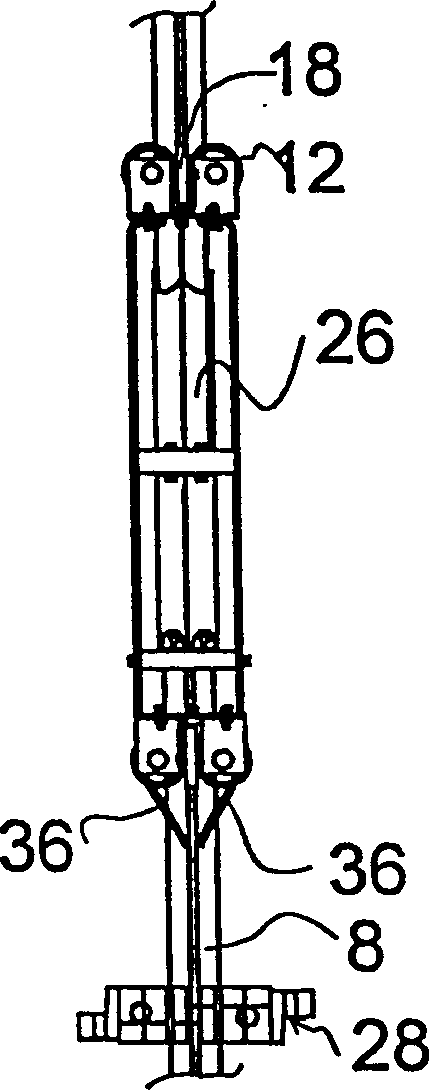

Arrangement for guiding car cable

Arrangement for guiding a car cable (6), one end of said car cable (6) being attached to the elevator car while the other end is attached to a connection point in the elevator shaft. The car cable (6) forms a loop hanging below its points of attachement. The arrangement comprises at least one cable holder (28). The cable portion between the attachment point and the lowest point of the cable loop can be held by the cable holder (28) so as to limit the lateral motion of the cable (6).

Owner:KONE CORP

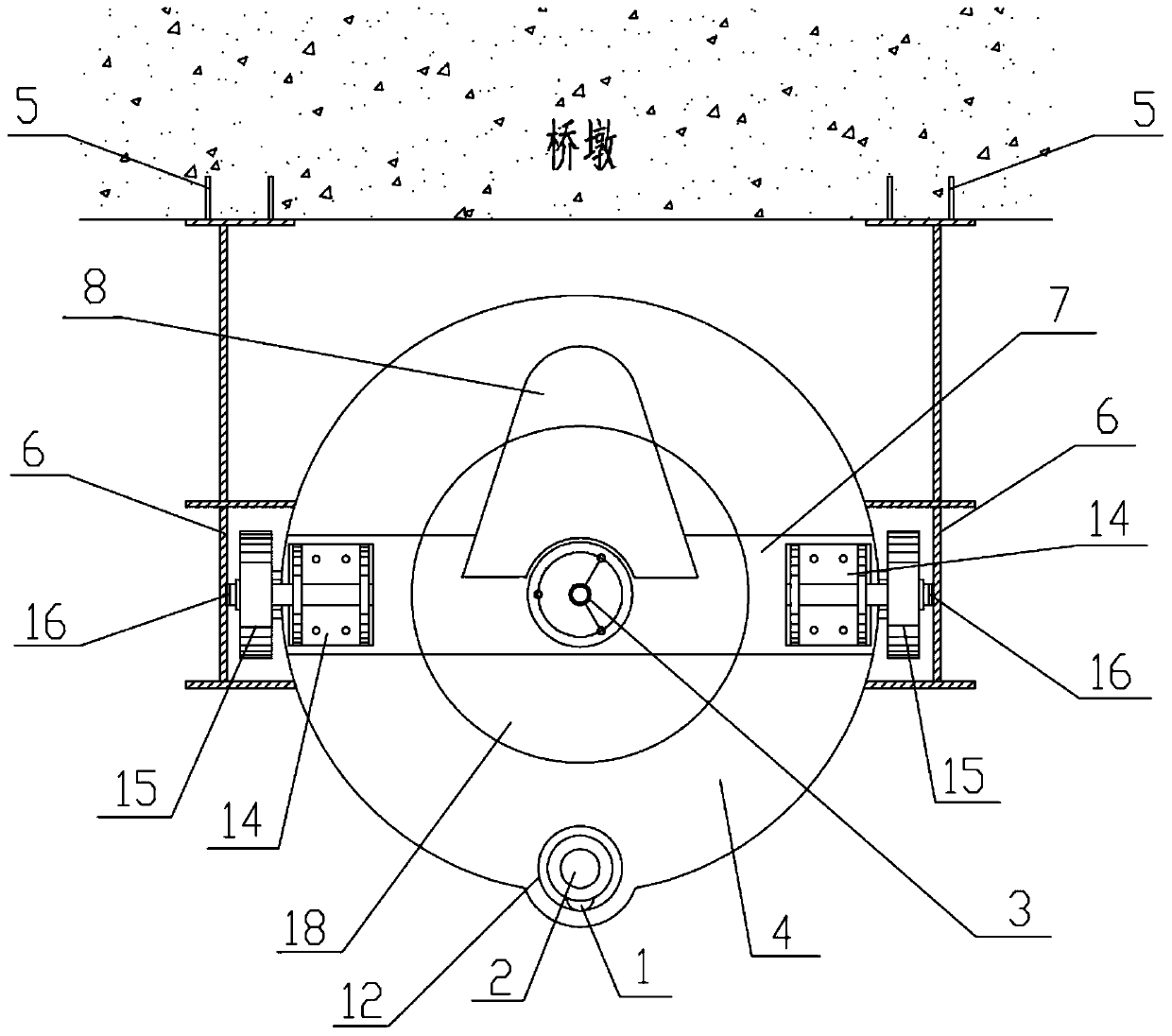

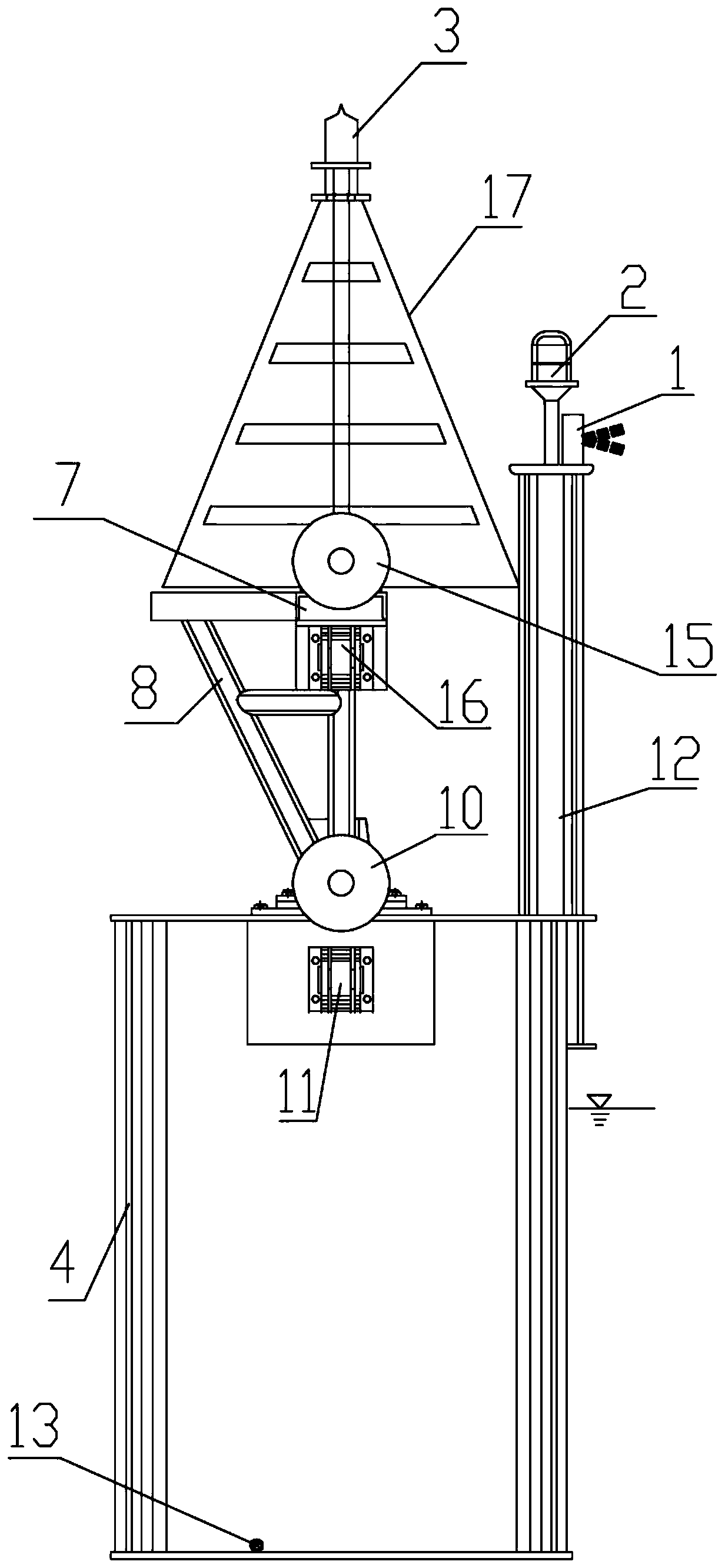

A bridge collision avoidance warning system and method

ActiveCN107358818BPrevent lateral swingRealize automatic vertical liftNavigational route markingMarine craft traffic controlEarly warning systemRadar

The invention discloses a bridge anti-collision early warning system and method. The system comprises a control center and a plurality of early warning apparatuses, each early warning apparatus comprises a radar detector, an audible-visual alarm, a navigation mark, a navigation mark lamp, a closed buoy, buoy elevation guiding limiting assemblies, anchor bars, and guide rails, the radar detector comprises a radar, a control module and a wireless communication module, the radar and the audible-visual alarm are electrically connected with the control module, the control module is electrically connected with the wireless communication module, the wireless communication module communicates with the control center in a wireless manner, the radar detector, the audible-visual alarm, and the navigation mark are arranged on the buoy, the buoy can move up and down relative to the guide rails under the buoyancy effect of water through the buoy elevation guiding limiting assemblies, and whether an alarm is given and / or whether intrusion ships are notified are / is determined according to the time and area of the ships intruding into a radar monitoring defense area. According to the system and method, the ships can be accurately guided, the alarm is given when the navigation of the ship deviates, and the ships can be prevented from colliding with the bridge.

Owner:祖小鸿

A rear frame of a support truck capable of quickly changing the loading width and its use method

ActiveCN112141219BPrevent lateral swingAlleviate the problem of ultra-wideUnderstructuresVehicle frameTruck

The invention belongs to the technical field of coal mine underground transport vehicles, in particular to a rear frame of a support transport vehicle capable of quickly changing the loading width and a use method thereof. It includes a front frame and a rear frame. The rear frame includes a middle box, a rotating frame, a left load frame and a right load frame. The middle box is hingedly connected with the front frame. The bearing frame is connected. The joint surface between the middle box and the left or right bearing frame is fixed by positioning pins and short bolts. A set of concave pads can be added in the middle of the joint surface. The pads are fixed by long bolts, and a rotating frame is connected between the middle box and the left and right bearing frames. One side of the rotating frame is connected with the middle box, and the other side of the rotating frame is connected with the left or right carrier. ; The inside of the tail of the left bearing frame and the right bearing frame are respectively provided with a clamping oil cylinder, and double ball head pull rods are connected between the clamping oil cylinders on both sides.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

a printing device

Owner:重庆博创知识产权运营有限公司

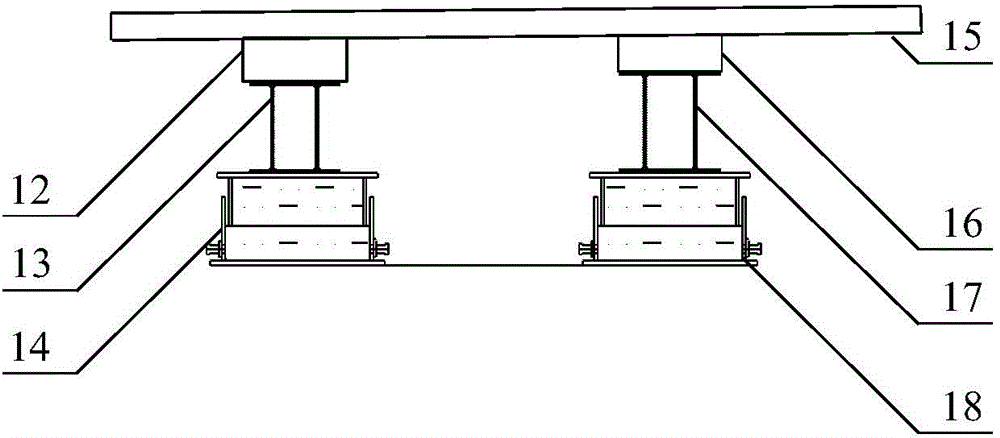

a sports tray

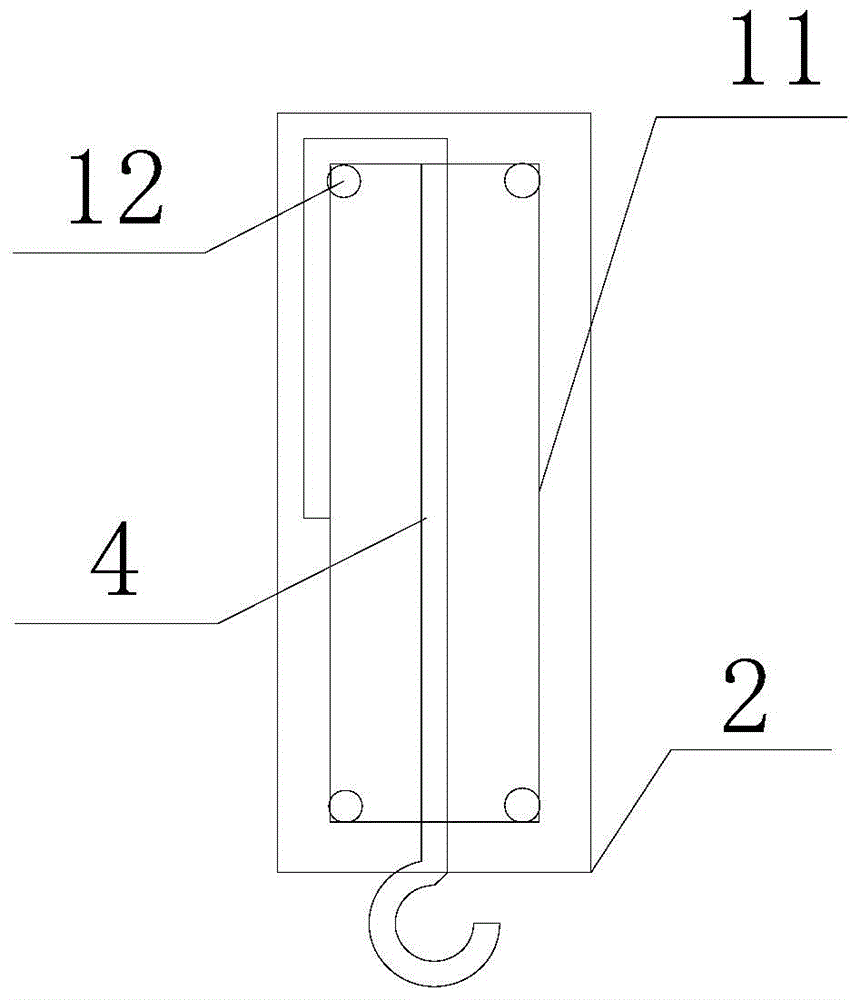

ActiveCN104591042BClose contactPrevent lateral swingLifting framesMiniaturizationMechanical engineering

The invention discloses a movement tray. The movement tray comprises a lifting disc sliding groove (1). A lifting disc (4) is arranged in the lifting disc sliding groove (1). The root of the lifting disc (4) is provided with eight sets of lifting rolling wheels (2), each lifting rolling wheel (2) is a bearing set composed of two cylindrical roller bearings. The four sets of lifting rolling wheels (2) are arranged in a vertical groove of the lifting sliding groove, a lifting cylinder (3) is arranged below the four sets of lifting rolling wheels (2), and the lifting disc (4) achieves upward movement in the lifting disc sliding groove (1) by jacking the four sets of lifting rolling wheels (2) through the lifting cylinder (3). The movement tray is used for achieving the concept that airplane ground support equipment is assembled and disassembled precisely and quickly, and simplification and miniaturization of the movement tray are guaranteed through the structure.

Owner:西安飞豹科技有限公司

Compound needle for flatbed knitting machine

Owner:SHIMA SEIKI MFG LTD

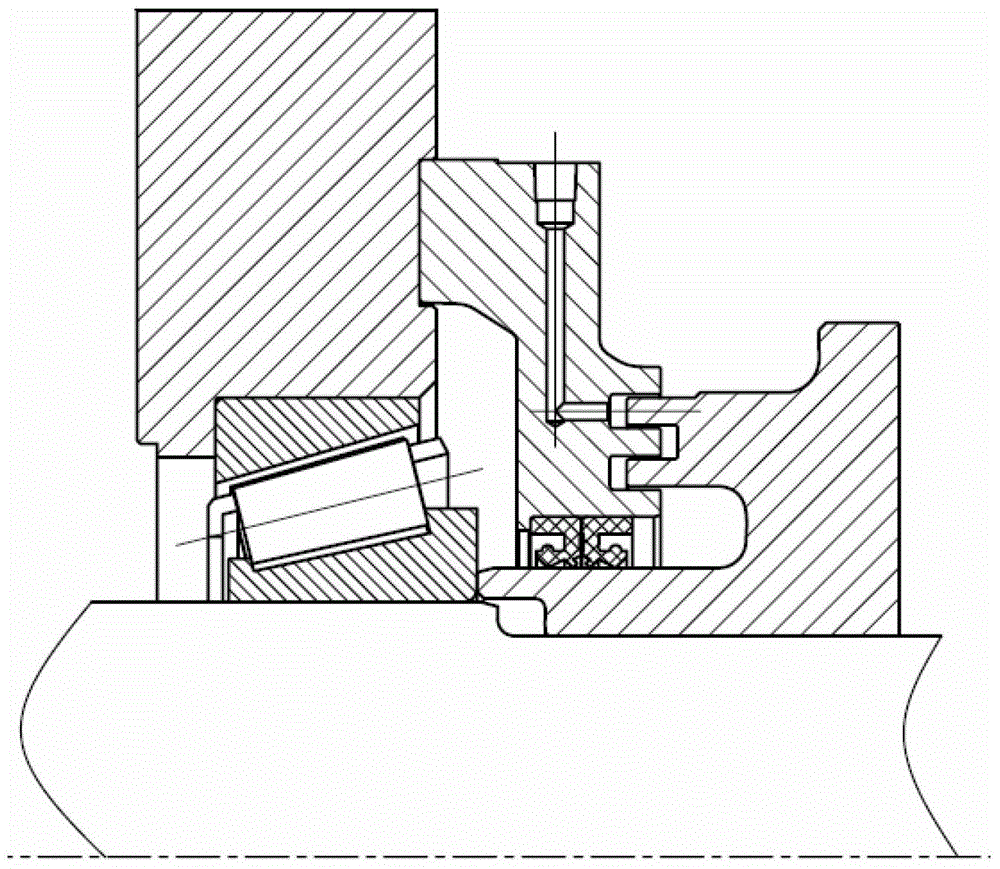

Dynamic sealing device for rotary blowout preventer

InactiveCN102364039BHigh direct contact cooling efficiencyReduce sinteringSealing/packingInterference fitEngineering

The invention relates to a dynamic sealing device for blocking a rotary blowout preventer between a drill column and a borehole in drilling of oil-gas fields. The dynamic sealing device overcomes the defects that the conventional dynamic sealing device has short service life, is quick in heat emission and is easily sintered. The invention adopts the technical scheme that: a supporting ring is arranged in a packing box, the supporting ring is provided with an oil hole b and an oil hole c, and the outer surface of the supporting ring is provided with an annular groove b; a disc spring is arranged in the supporting ring, a caulking ring is arranged at the lower part of the disc spring, and the supporting ring is arranged between the caulking ring and a pressure ring; the pressure ring is provided with an oil hole a, and a V-shaped sealing ring and a spacing ring are sequentially arranged at the lower part of the pressure ring at intervals; a packing pressure ring is arranged at the lower end of a floating ring, the packing pressure ring is fixed at the end of the packing box, and the packing pressure ring is in clearance fit with a central pipe bush; and the central pipe bush is in interference fit with a central pipe, the packing box is in interference fit with an upper shell of the blowout preventer, and lubricating oil enters an oil hole in the upper shell of the blowout preventer through a bearing. The dynamic sealing device is suitable for relatively high dynamic sealing pressure, reduces sintering of the sealing ring, has low heat emitting abrasion and long service life, and reduces the abrasion rate.

Owner:SOUTHWEST PETROLEUM UNIV

Movement tray

The invention discloses a movement tray. The movement tray comprises a lifting disc sliding groove (1). A lifting disc (4) is arranged in the lifting disc sliding groove (1). The root of the lifting disc (4) is provided with eight sets of lifting rolling wheels (2), each lifting rolling wheel (2) is a bearing set composed of two cylindrical roller bearings. The four sets of lifting rolling wheels (2) are arranged in a vertical groove of the lifting sliding groove, a lifting cylinder (3) is arranged below the four sets of lifting rolling wheels (2), and the lifting disc (4) achieves upward movement in the lifting disc sliding groove (1) by jacking the four sets of lifting rolling wheels (2) through the lifting cylinder (3). The movement tray is used for achieving the concept that airplane ground support equipment is assembled and disassembled precisely and quickly, and simplification and miniaturization of the movement tray are guaranteed through the structure.

Owner:西安飞豹科技有限公司

A kind of single and parallel bars for remote teaching

InactiveCN104147748BImprove balanceImprove stabilityParallel barsHorizontal barsElectricityRemote control

Owner:天津秀乐文化传播有限公司

Horizontal vibrating centrifuge

ActiveCN103567079BExtended service lifeSimple structureEngine sealsRotary centrifugesFrequency changerAutomatic control

The invention relates to a horizontal type vibration centrifugal machine, comprising a spindle, a sleeve, a vibration box, a vibration motor, belt wheels and a screen basket, wherein the sleeve is sleeved outside the spindle; the vibration box is sleeved outside the sleeve and is fixedly connected with the sleeve; the vibration motor is arranged outside the vibration box; the belt wheels are respectively arranged at the two ends of the spindle; fixed labyrinths are respectively arranged at the two ends of the vibration box; the end, close to the screen basket, of the spindle is sleeved with a rotatable labyrinth adaptive to the fixed labyrinths; the horizontal type vibration centrifugal machine also comprises an automatic control system used for controlling the vibration motor, wherein the automatic control system comprises a vibration centrifugal machine working parameter obtaining device, a controller and a frequency converter; the vibration centrifugal machine working parameter obtaining device is connected with the frequency converter by the controller; the frequency converter is connected with the vibration motor; the vibration centrifugal machine working parameter obtaining device obtains the processing amount of the vibration centrifugal machine, the water content of materials, the working amplitude of the vibration centrifugal machine and the working frequency of the vibration centrifugal machine.

Owner:西安海泰科技有限公司

A forming and sealing device for food packaging machine

ActiveCN104494942BEliminate tedious adjustmentsStrong coherenceWrapper twisting/gatheringPackaging machine

The invention discloses a forming and sealing device used for a hollow packaging machine of food. The forming and sealing device comprises a rack, a cutter sealing angle component and a bag forming component, wherein the cutter sealing angle component comprises a bracket, a first expansion link, a second expansion link, an upper fixing plate, a lower fixing plate, an upper heat sealing seat, a lower heat sealing seat, a first angle plate and a second angle plate, wherein the upper fixing plate and the lower fixing plate penetrate through the first expansion link and the second expansion link; the upper heat sealing seat is fixedly arranged on the upper fixing plate; the lower heat sealing seat is fixedly arranged on the lower fixing plate; the first angle plate and the second angle plate are positioned between the upper heat sealing seat and the lower heat sealing seat; the upper heat sealing seat and the lower heat sealing seat are driven by an air cylinder assembly installed on the bottom of the bracket; the first angle plate is driven by a first angle air cylinder sheathing the first expansion link; the second angle plate is driven by a second angle air cylinder sheathing the second expansion link; the first angle plate and the second angle plate are symmetrically arranged. According to the forming and sealing device used for the hollow packaging machine, the cutter sealing angle component can be used for carrying out continuous end surface angle and sealing on a vertical sealing square bag, so that the forming and sealing efficiency of whole package is improved so as to improve the packaging efficiency of a finished product.

Owner:FOSHAN SOONTRUE MACHINERY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com