Tension leg net cage model test device

A model test device and technology of tension legs, which are applied in the field of tension leg cage model test devices, can solve the problems of not being able to know the anchoring of gravity anchors, and not being able to simply measure the ability to resist ocean current impact, so as to reduce errors, improve accuracy, Eliminate sideways swing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

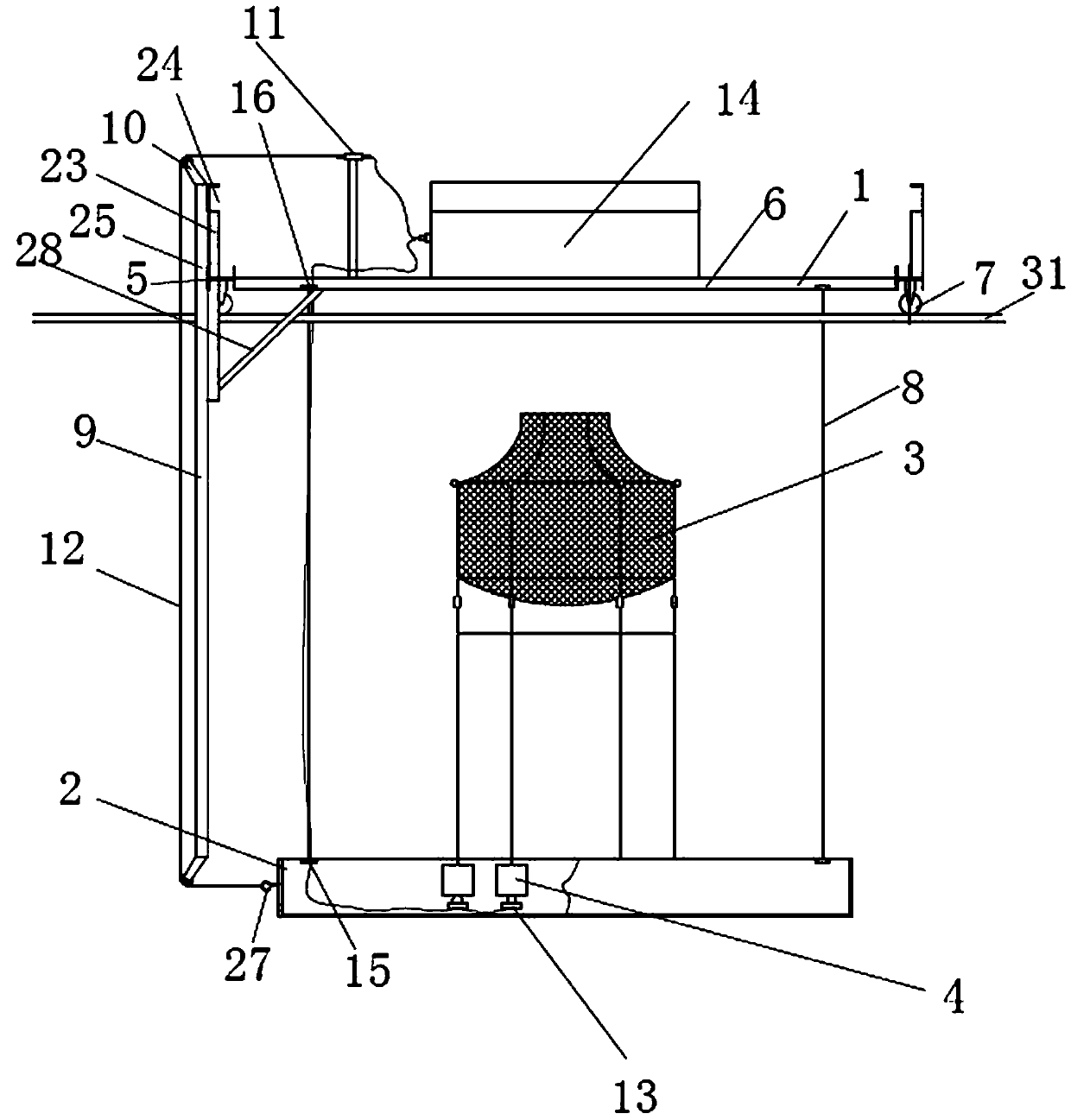

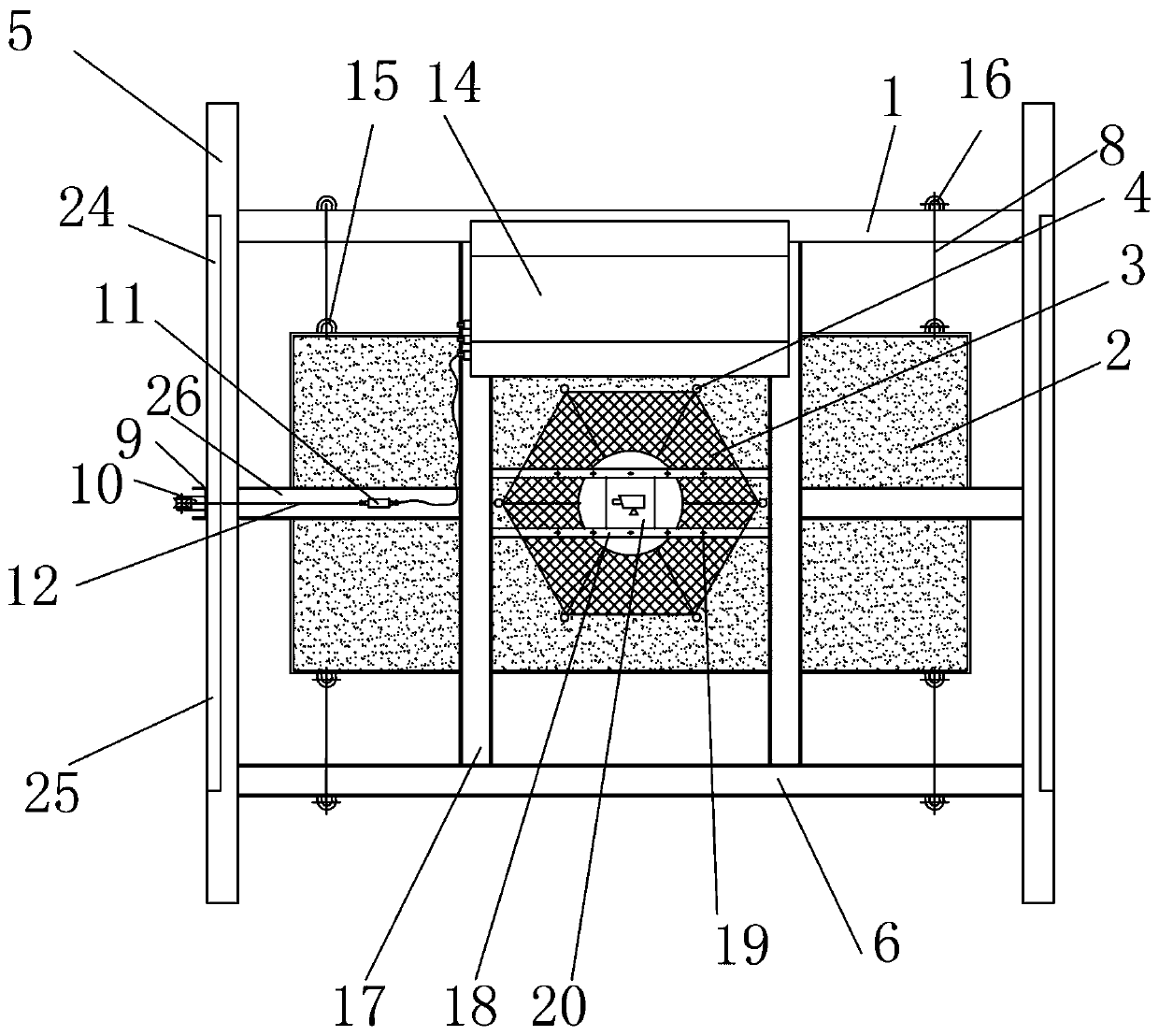

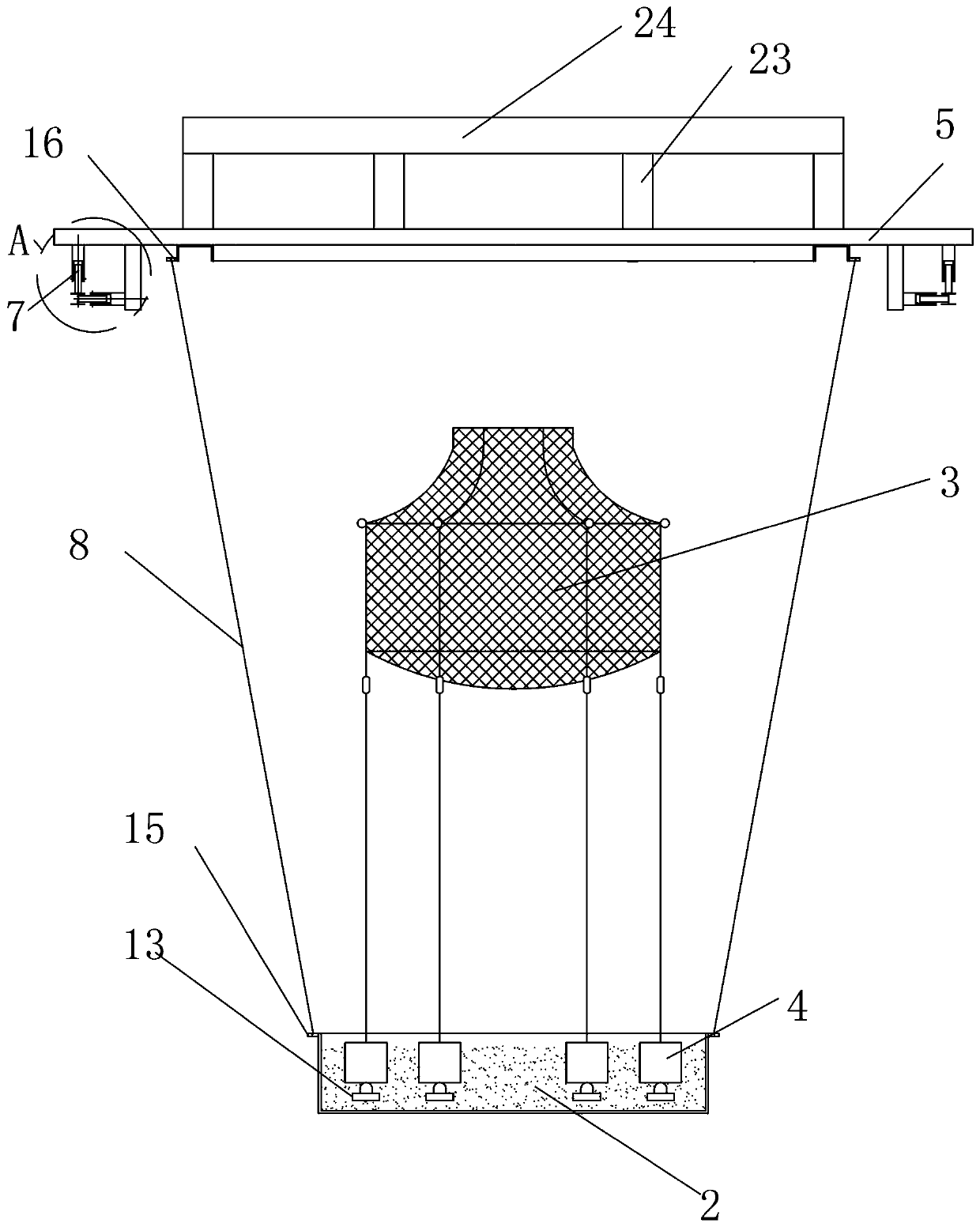

[0023] Such as Figure 1-Figure 6 As shown, a kind of tension leg net cage model test device provided by the present embodiment includes a device frame 1, and an underwater sand tank 2 is provided below the device frame 1, and the underwater sand tank 2 is used to fix the bottom of the net cage model 3 A certain number of gravity anchors 4 around, the device frame 1 includes two transverse main beams 5 across the guide rails 31 on both sides of the water tank and two longitudinal main beams 6 fixed between the two transverse main beams 5, in Both sides of each transverse main beam 5 are provided with a group of guide rail wheels 7 standing on the upper surface and side surfaces of the guide rail 31, and the underwater sand tank 2 is connected with the longitudinal main beam 6 by an iron chain 8. The side of the horizontal main beam 5 is provided with a vertically arranged drawbar 9, and traction pulleys 10 are arranged above and below the drawbar 9, and the device frame 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com