A connection method between prefabricated concrete wall panel and main structure

A prefabricated concrete and connection technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of increasing structural rigidity, collapse, damage, etc., and achieve the effect of preventing the whole from falling off, connecting tightly, and enhancing energy dissipation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

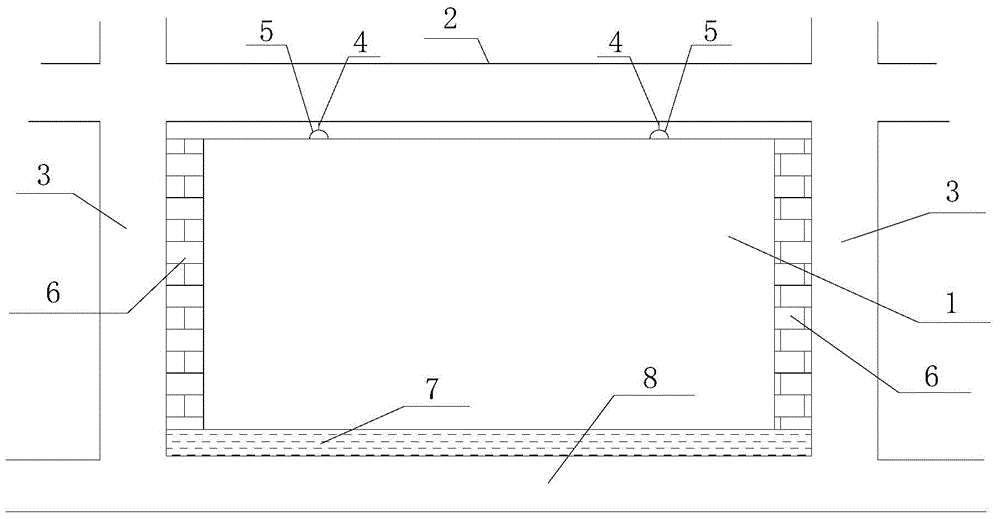

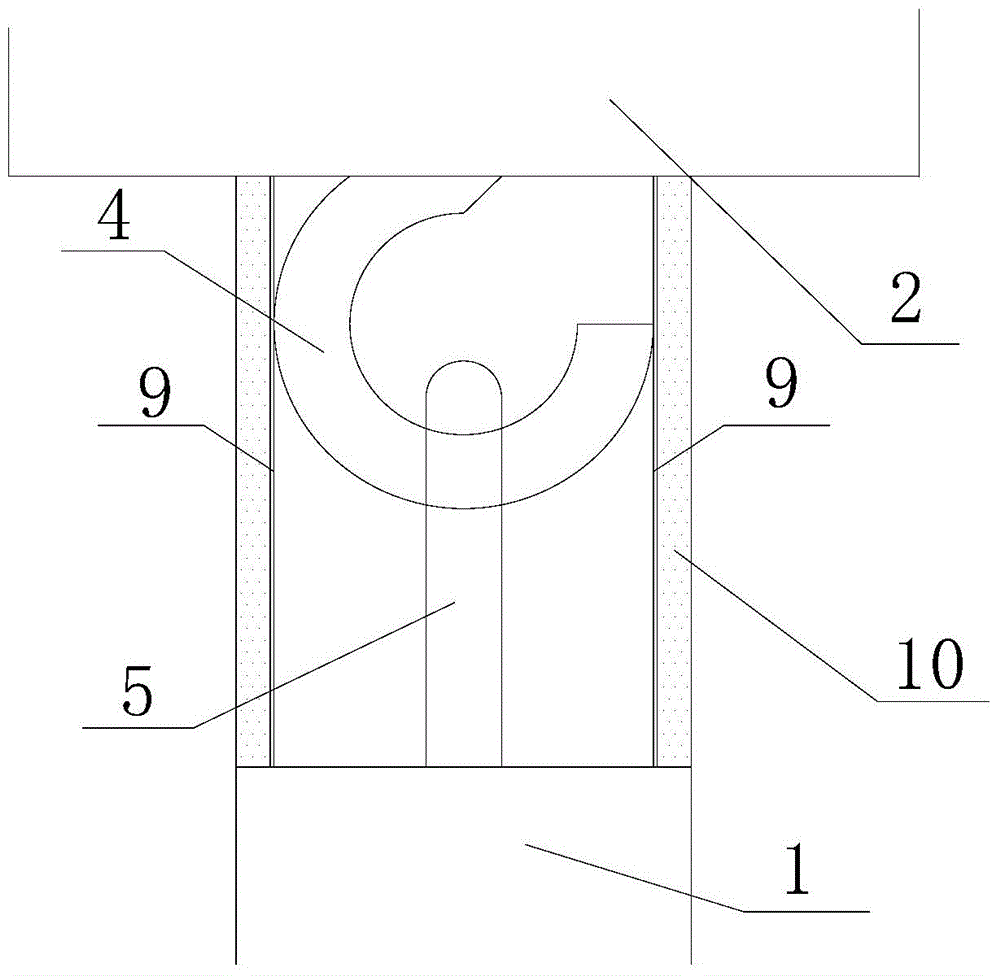

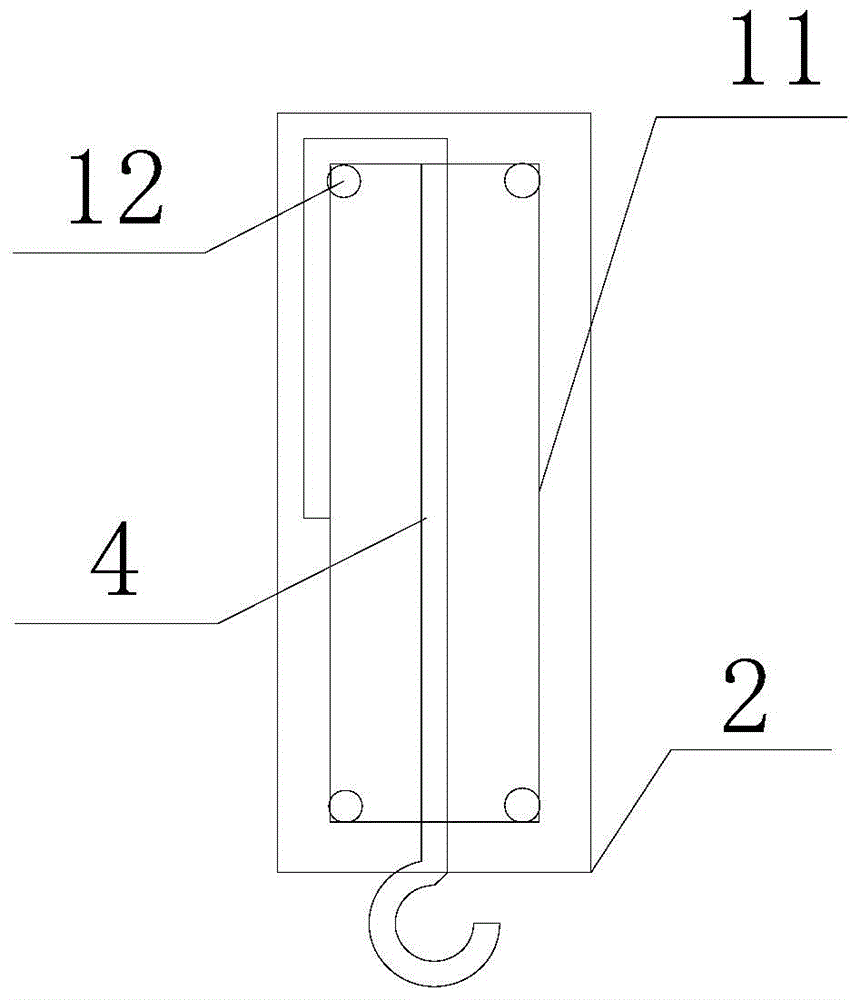

[0024] Such as figure 1 As shown, the upper part of the precast concrete wall panel 1 is hinged with the concrete beam 2 through the beam hook 4 and the wall hook 5 to realize flexible connection. The rubber brick 6 is a seismic isolation device, and the gap between the side of the precast concrete wall panel 1 and the column 3 is filled with mortar 10, so that the side of the precast concrete wall panel 1 has sufficient energy dissipation performance through the rubber superelastic material , reduce the force of the pillar 3 on the precast concrete wall panel 1 during an earthquake, and prevent the cracking and damage of the precast concrete wall panel 1 . The bottom baffle 7 is connected to the concrete bottom beam 8, and the bottom of the precast concrete wall panel 1 is limited by the bottom baffle 7 to prevent the lateral swing of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com