Compound needle for flat knitting machine

A flat knitting machine and composite needle technology, applied in the field of composite needles, can solve problems such as increased driving load, increased sliding resistance, and insufficient rigidity, and achieve the effects of reducing sliding resistance, improving opening and closing precision, and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

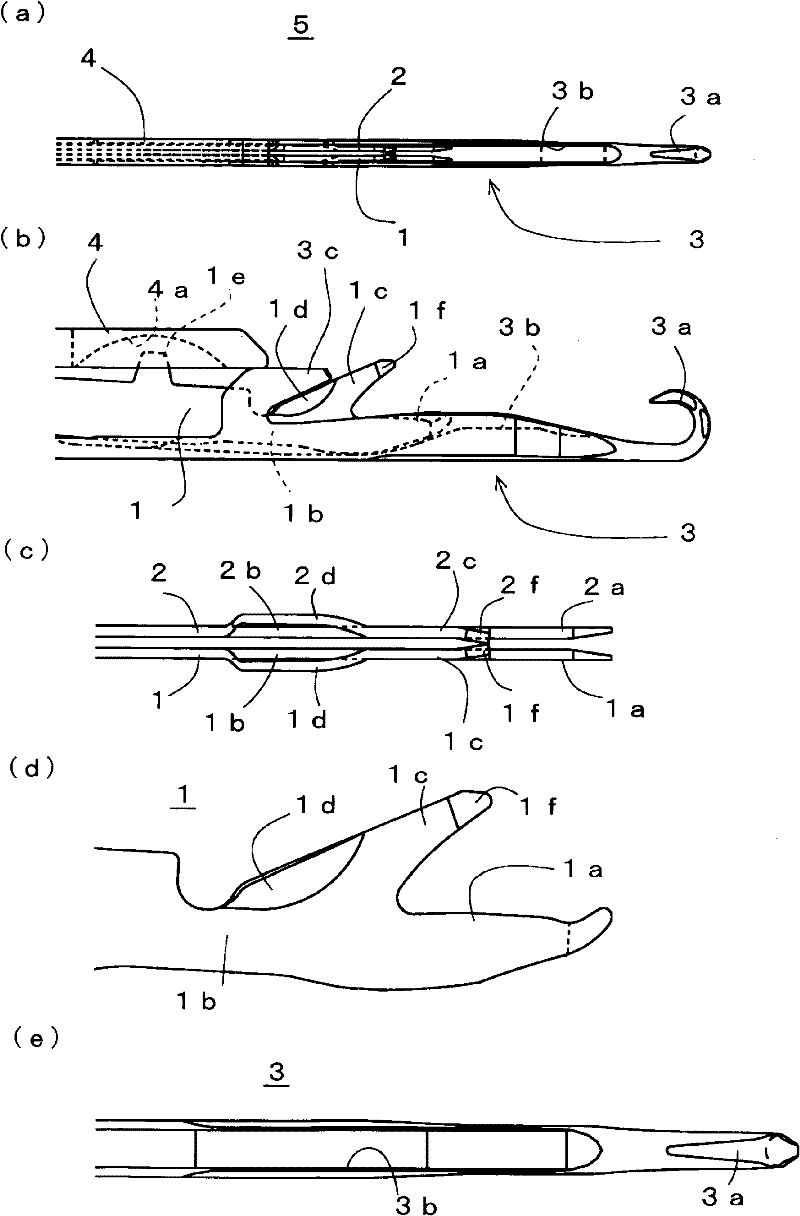

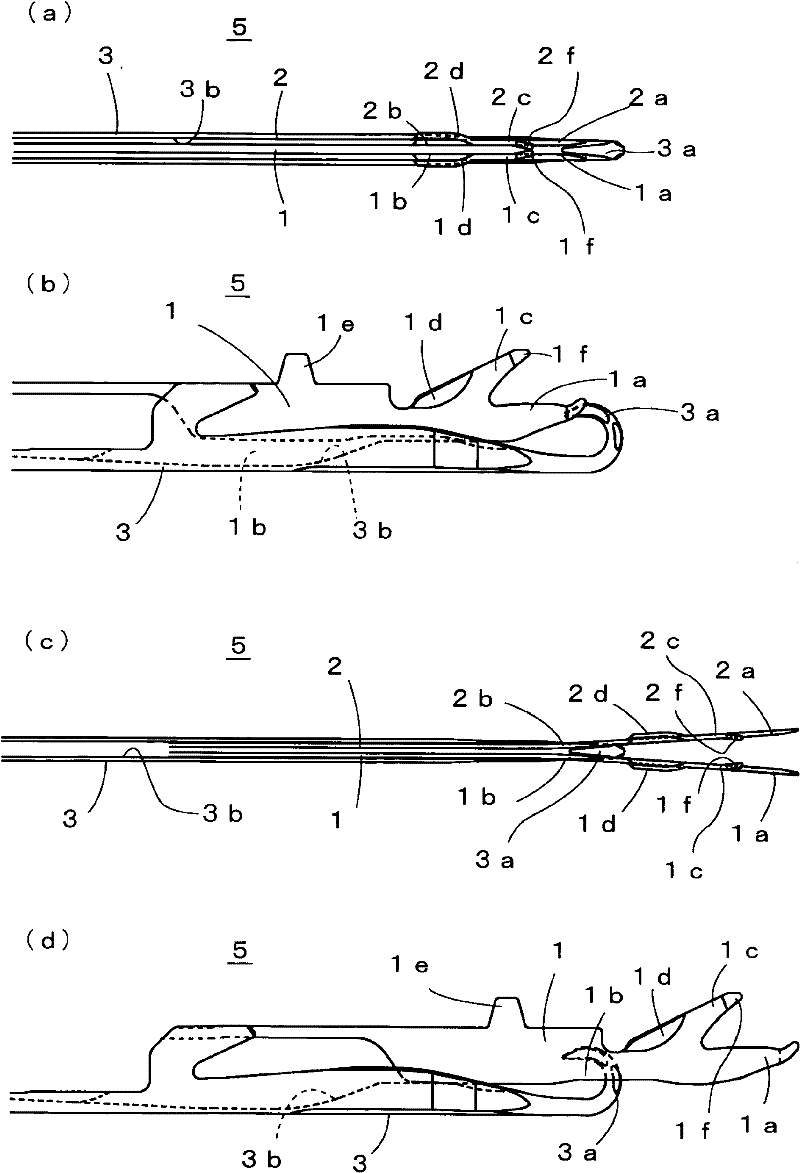

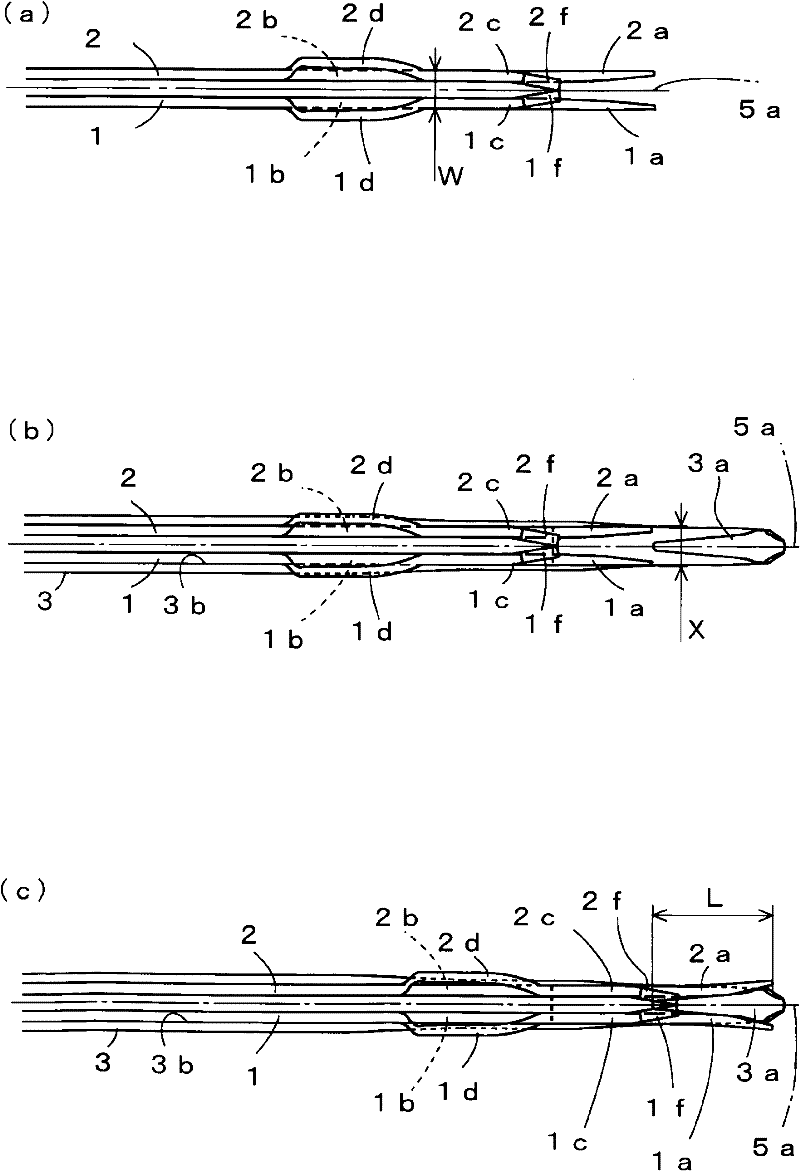

[0031] under, figure 1 The structures of the composite needle 5 and the two blades 1 and 2 are shown as one embodiment of the present invention. figure 2 express figure 1 The action state of compound needle 5. image 3 express figure 1 The action of the blade 1, 2. The blade 1 and the blade 2 are symmetrical about parallel planes provided at the center, and even if the blade 2 is omitted from illustration, a portion corresponding to the blade 1 exists in the blade 2 .

[0032] In addition, in the description of each figure, reference signs not attached to the figure to be described may be referred to by reference signs attached to the previously described figures. In addition, the compound needle 5 is shown in a state of being housed in a needle groove formed on a needle bed of a flat knitting machine, and illustration of the needle groove itself is omitted. However, although the needle bed of the flat knitting machine is inclined so as to become higher toward the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com