Electrolyte sealing device for tubular electrode electrolytic machining

A technology of tubular electrodes and sealing devices, which is applied in the field of electrolyte sealing devices, can solve problems such as difficult sealing of electrolytes, achieve the effects of improving processing accuracy and processing efficiency, and preventing lateral swinging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

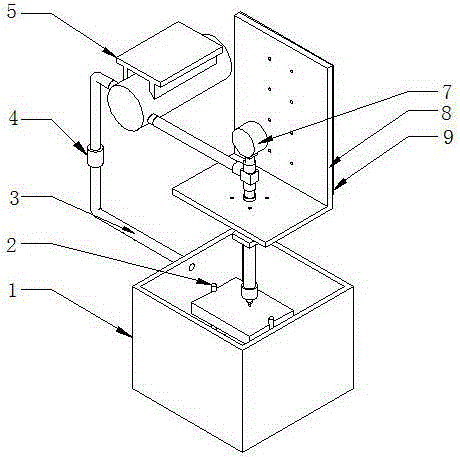

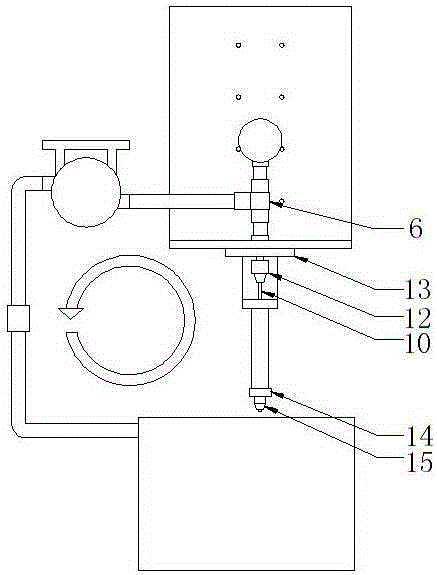

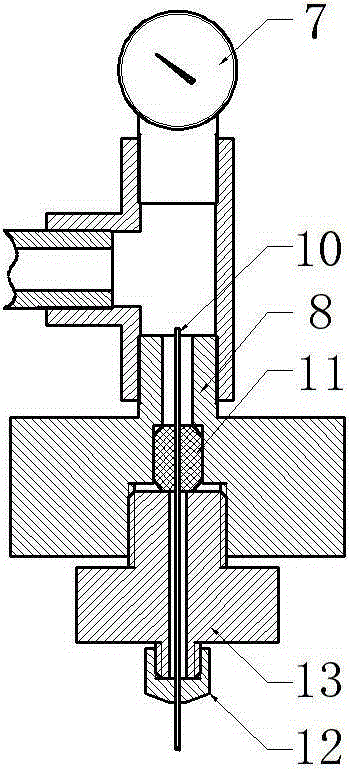

[0015] like figure 1 , 2 An electrolyte sealing device for tubular electrode electrolytic processing shown in and 3, which includes: electrolyte tank 1, workpiece fixture 2, pipeline 3, filter 4, high-pressure isolation pump 5, tee joint 6, pressure gauge 7 , Main body fixture one 8, insulating gasket 9, tubular electrode 10, water stopper 11, tubular electrode fixture 12, main body fixture two 13, guide fixture 14, guide 15.

[0016] like figure 1 , figure 2 , image 3 As shown, the pipeline 3 is connected to the liquid outlet of the electrolyte tank 1, and connected to the filter 4 and the high-pressure diaphragm pump 5 in sequence. The upward interface is connected to the pressure gauge 7. The pressure gauge 7 detects the working pressure of the electrolyte water outlet section in real time during the electrolytic processing, and the vertical downward interface is connected to the main body fixture 18. The main body fixture 18 has a groove for placing the water stopper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com