Horizontal vibrating centrifuge

A vibrating centrifuge and vibrating motor technology, which is applied in the field of vibrating centrifuges and horizontal vibrating centrifuges, can solve the problems of high manufacturing cost, long downtime, and easy deformation of support frames, so as to improve reliability, service life, and ditch The effect of simple groove structure and convenient processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

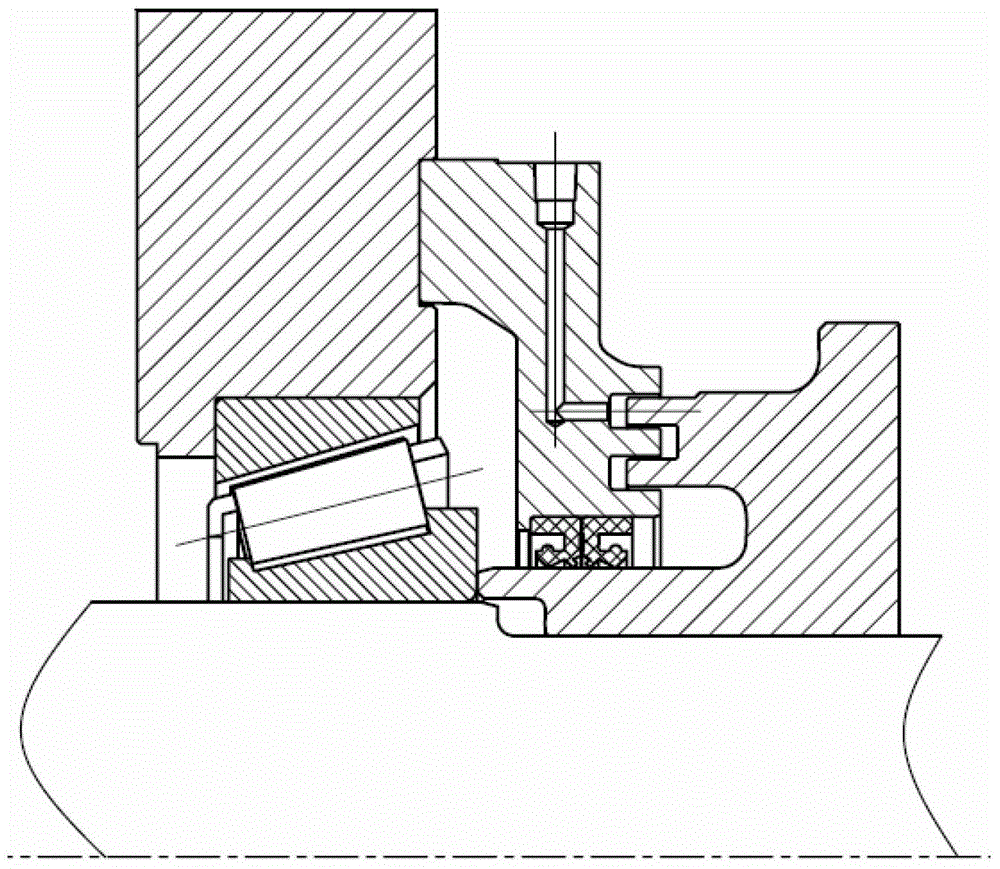

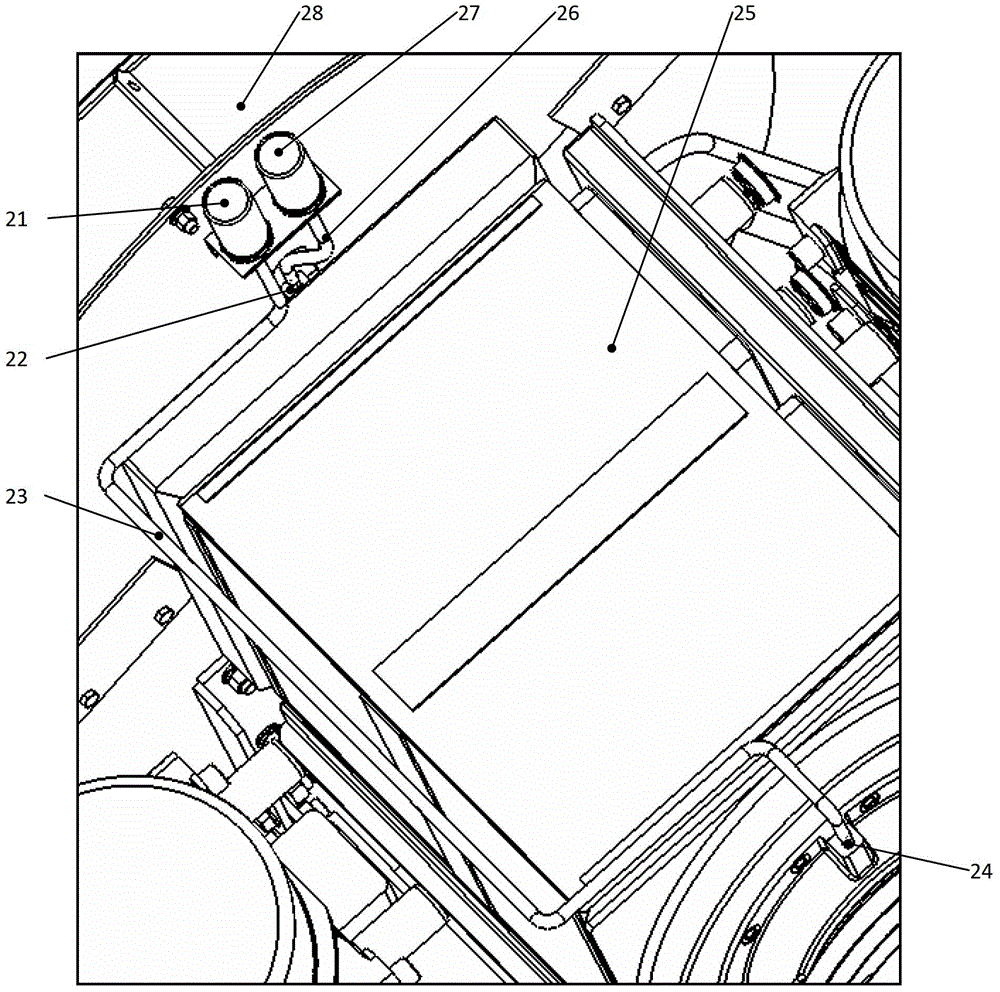

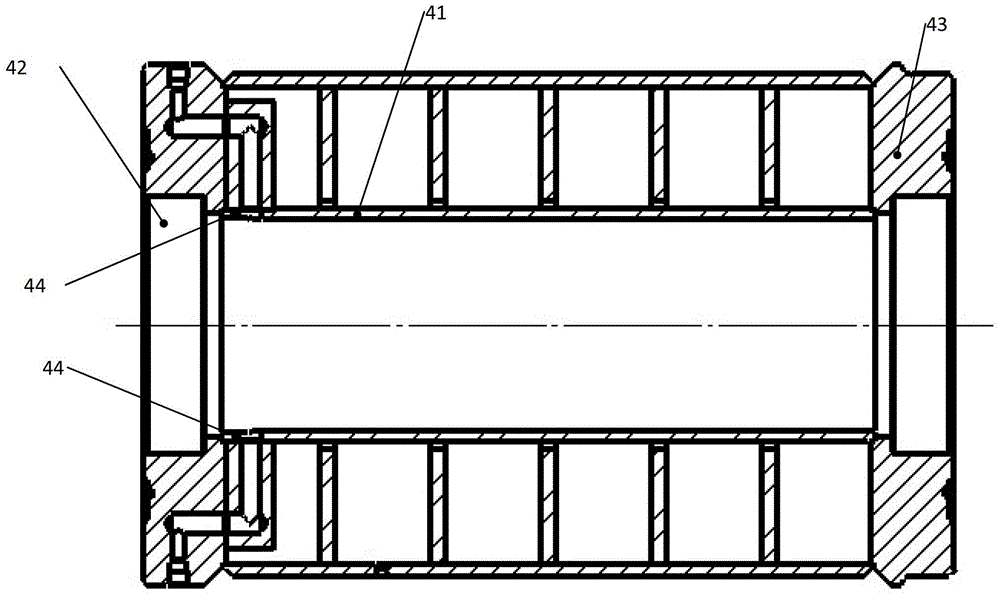

[0039] The present invention provides a horizontal vibrating centrifuge, including a frame 8, a lubrication system 10, a water tank 9, a main shaft, a sleeve set outside the main shaft, and a vibration box set outside the sleeve and fixedly connected with the sleeve 1. A vibrating motor, pulleys and screen baskets are arranged on the outside of the vibrating box; fixed mazes are respectively arranged at both ends of the vibrating box; a rotating maze matching the fixed labyrinth is set on the main shaft near the end of the sieve basket; The main motor 7 sequentially drives the screen basket to rotate through the belt 11, the pulley and the main shaft; the vibrating motor drives the vibrating box to vibrate axially along the axial direction of the main shaft; the horizontal vibrating centrifuge also includes an automatic control system for controlling the vibrating motor. The control system includes a vibrating centrifuge working parameter acquisition device, a controller and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com