Dynamic sealing device for rotary blowout preventer

A rotary blowout preventer and dynamic sealing technology, applied in sealing/packaging, wellbore/well components, earth-moving drilling, etc., can solve the problems of fast heating, easy sintering, short life, etc., achieve a single cooling system, increase The effect of longevity and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

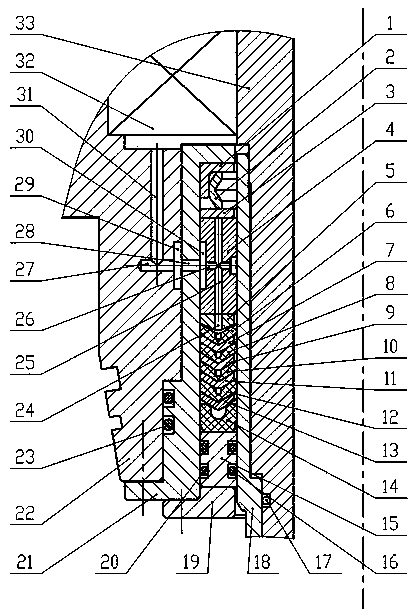

[0010] As shown in the drawings, a dynamic sealing device of a rotary blowout preventer, a support ring 4 is installed in the packing box 21, and an oil hole b25 and an oil hole c26 are arranged on the support ring 4, and the oil hole b25 and the oil hole c26 is evenly distributed in the circumferential direction, the number is 4 oil holes each, and the outer surface of the support ring 4 is provided with an annular groove b30; The inner surface of the disc spring adopts a clearance fit, the disc spring 2 is installed in the support sleeve 1, and is in a compressed state during installation. The spacer ring 3 is installed on the lower part of the disc spring 2, and the support ring 4 is installed between the spacer ring 3 and the pressure ring 5. The support ring 4 The outer surface of the support ring 4 and the inner surface of the packing box 21 adopt an interference fit, and the inner surface of the support ring 4 and the outer surface of the center pipe bushing 18 adopt a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com