Carbon-nanosheet-loaded noble metal nanoparticle catalyst and preparation method and application thereof

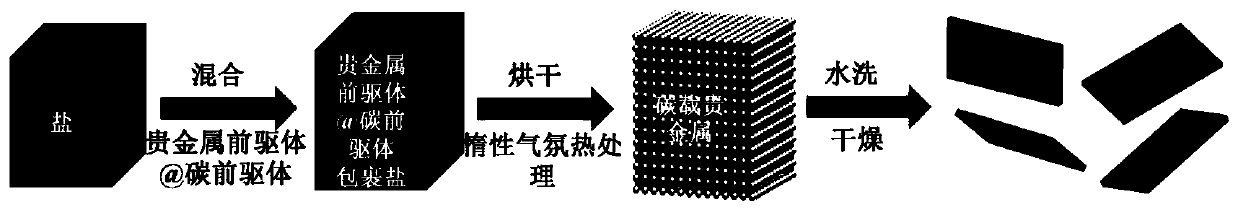

A technology of carbon nanosheets and nanoparticles, which is applied in the field of carbon-supported noble metal nanoparticle catalysts and their preparation, and in the field of catalysts. It can solve the problems of cycle stability restricting high performance, improve catalytic efficiency and cycle stability, and have a wide range of raw material sources. Benefits for large-scale implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1, 207.4mg RuCl 3 Dissolve in 2mL of deionized water, add 1.22g of sodium oleate under stirring. In order to make the mixture uniform, stir for two hours at 90℃ and add 10g of Na 2 SO 4 , Drying and placing it in a tubular furnace under an inert atmosphere and calcination at 500° C. for 3 hours, and washing and drying the resulting carbon nanosheet-supported Ru nanoparticle catalyst after calcination.

Embodiment 2

[0047] In Example 2, 263.3mg RhCl 3 Dissolve in 2mL of deionized water, add 1.22g of sodium oleate under stirring. In order to make the mixture uniform, stir for two hours at 90℃ and add 10g of Na 2 SO 4 , Dry and put it in a tube furnace under an inert atmosphere and calcine at 500° C. for 3 hours. After calcination, the Rh nanoparticle catalyst supported by the carbon nanosheets obtained is washed and dried. image 3 It is a TEM photo of carbon nanosheets loaded with Rh nanoparticles; a is a low-resolution TEM photo after magnification, b is a normal low-resolution TEM photo, and c is a high-resolution TEM photo.

Embodiment 3

[0048] Example 3, 293.2mgNa 4 Rh 2 (CO 3 ) 4 ·2.5H 2 O was dissolved in 2mL of deionized water, 1.22g of sodium oleate was added under stirring. In order to make the mixture uniform, 10g of Na was added after stirring for two hours at 90℃ 2 SO 4 , Dry and put it in a tube furnace under an inert atmosphere and calcine at 500° C. for 3 hours. After calcination, the Rh nanoparticle catalyst supported by the carbon nanosheets obtained is washed and dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com