Patents

Literature

35results about How to "With storage capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

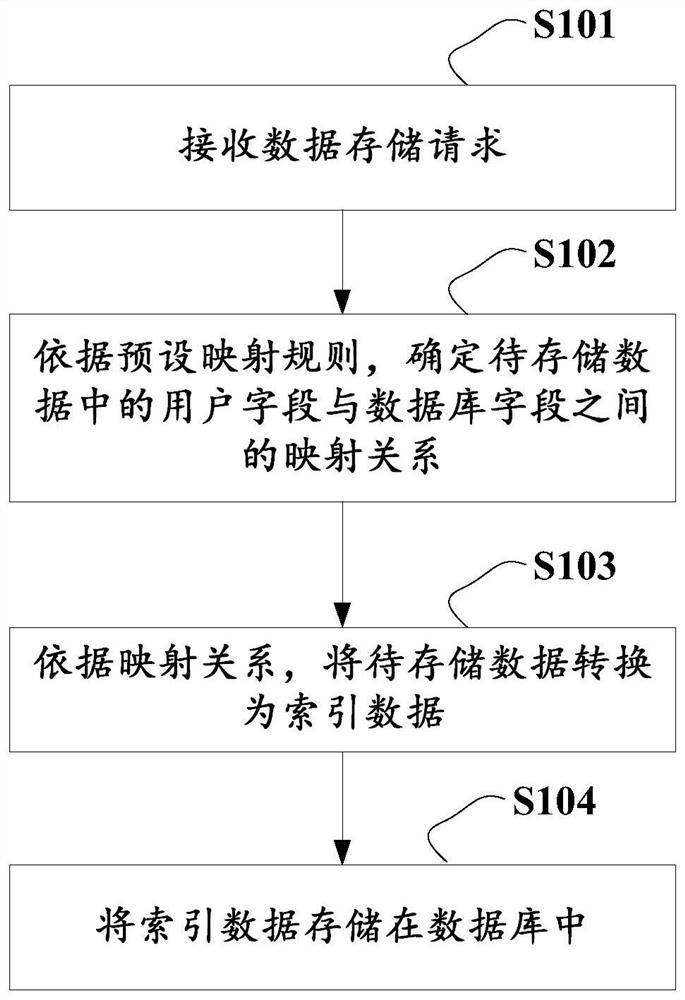

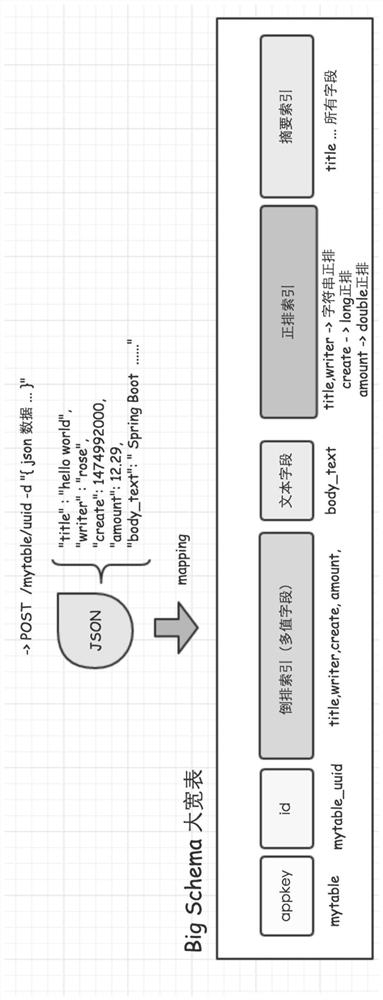

Data query method, data processing method and device

ActiveCN107038207AReduce use costImprove experienceSpecial data processing applicationsData processing systemUnstructured data

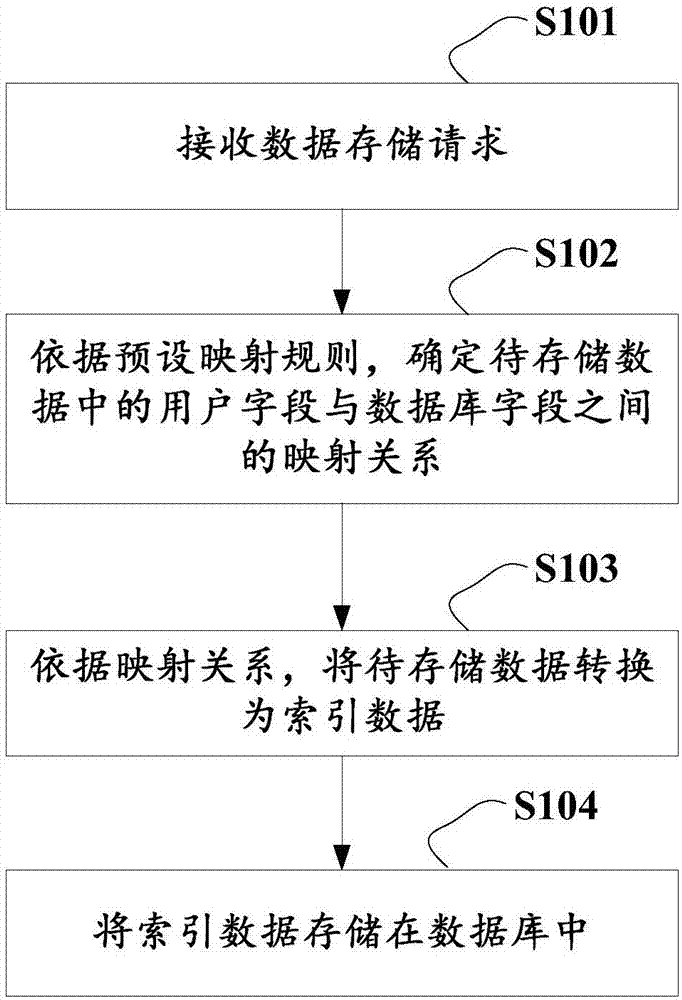

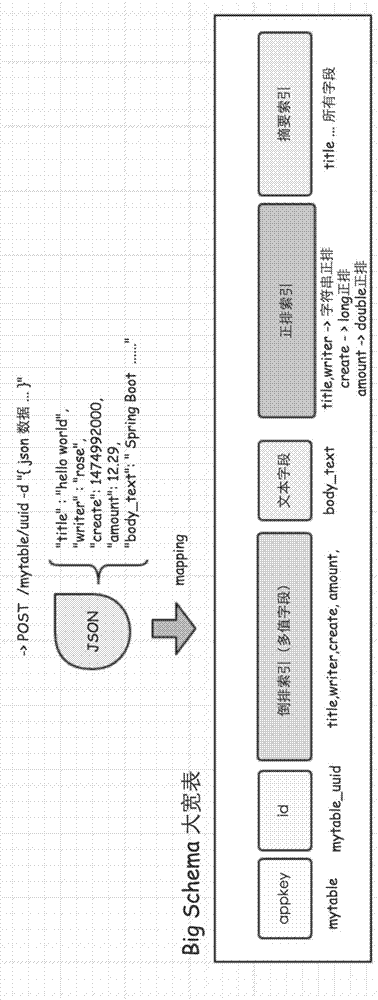

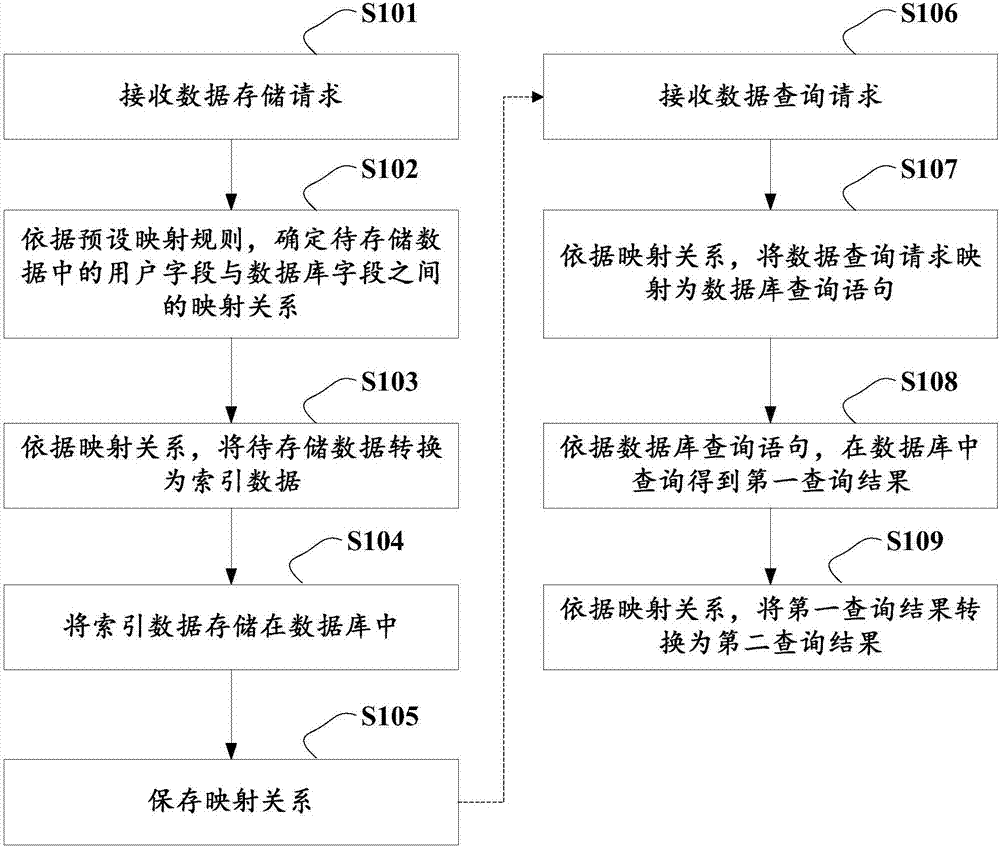

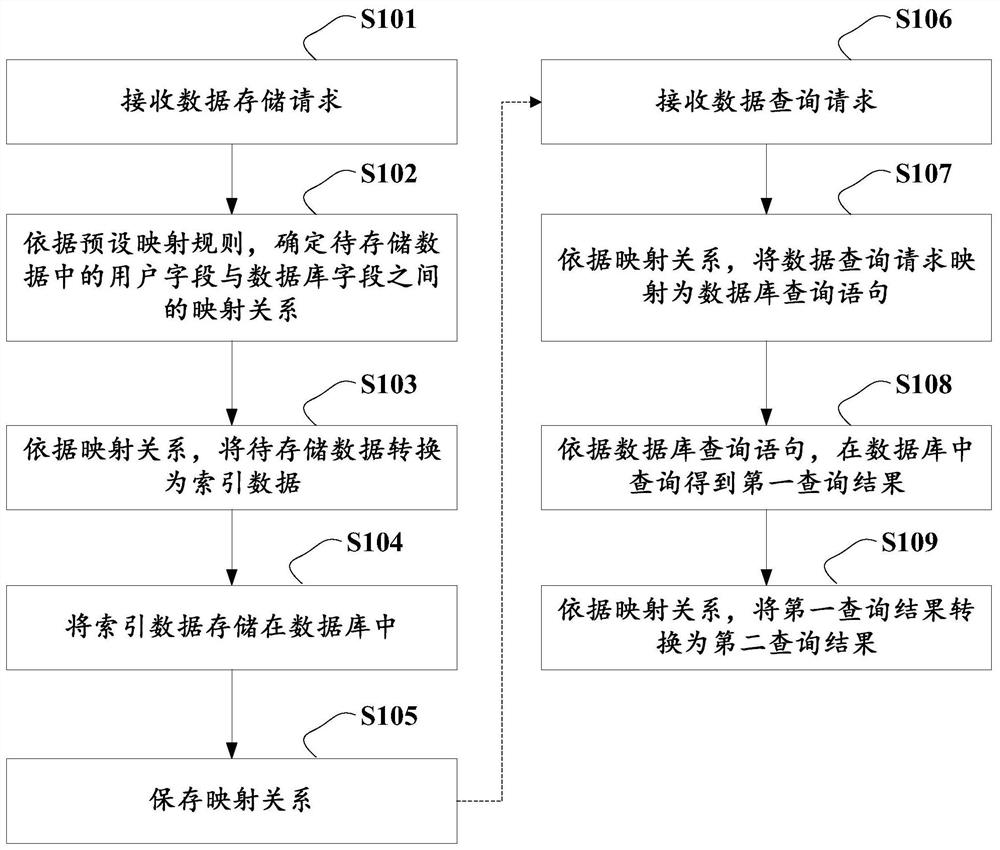

The invention discloses a data processing method. The method comprises the steps of determining a mapping relation between a user field and a database field in the to-be-stored data according to a preset mapping rule when a data storage request including to-be-stored data is received, wherein the to-be-stored data are unstructured data; converting the to-be-stored data into index data according to the mapping relation, wherein the index data are reflected in the form of database field; and storing the index data in a database. According to the method, the mapping relation can be stored, when the data query request is received, conversion between the user field and the database field is carried out and the data query is realized. The embodiment of the invention also provides a corresponding data query method and data processing system. Therefore, a data solution scheme which is easy to use, expand and maintain is provided, the method is suitable for processing of the unstructured data, and thus the usage cost of a user is reduced and the user experience is improved.

Owner:ADVANCED NEW TECH CO LTD

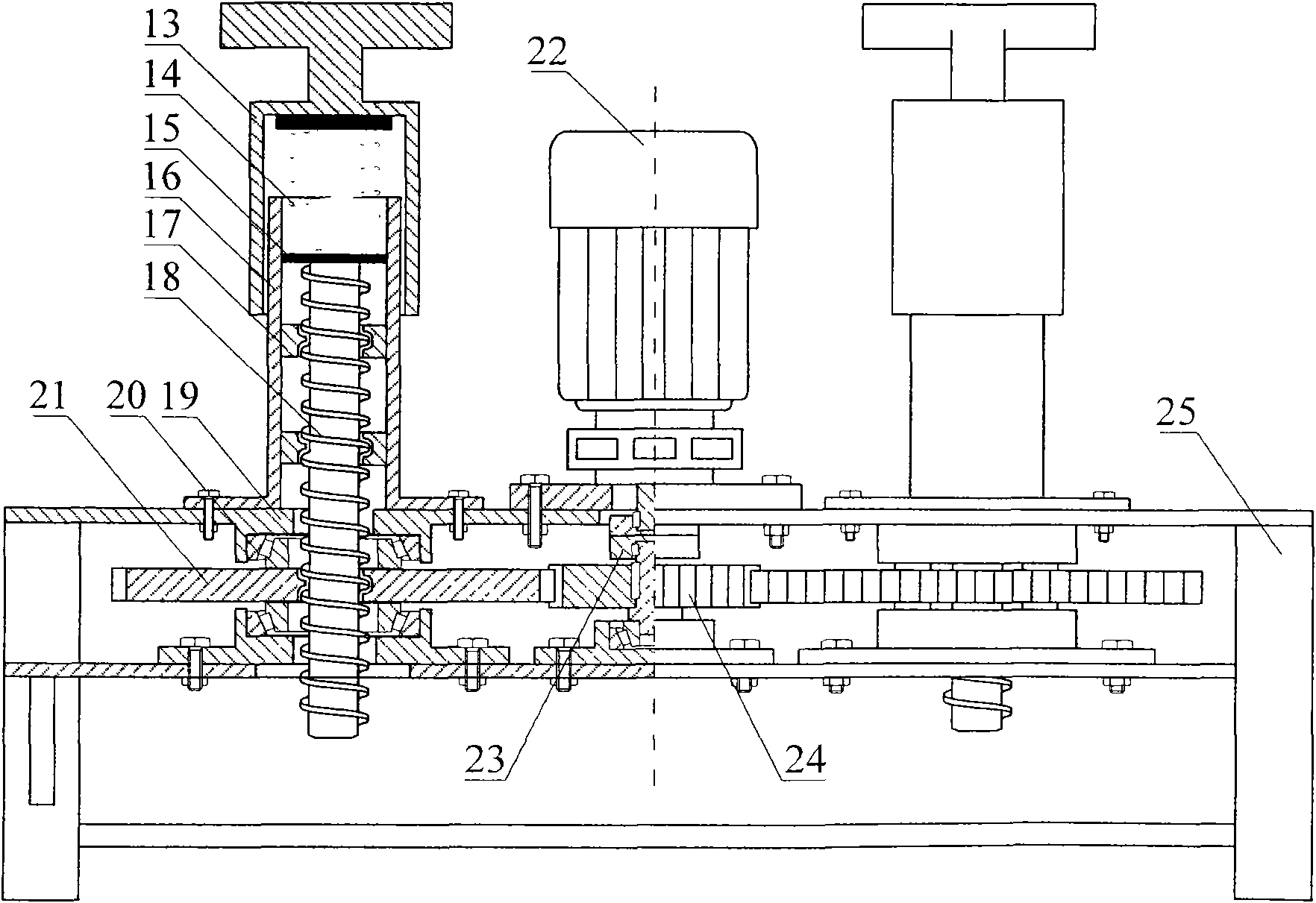

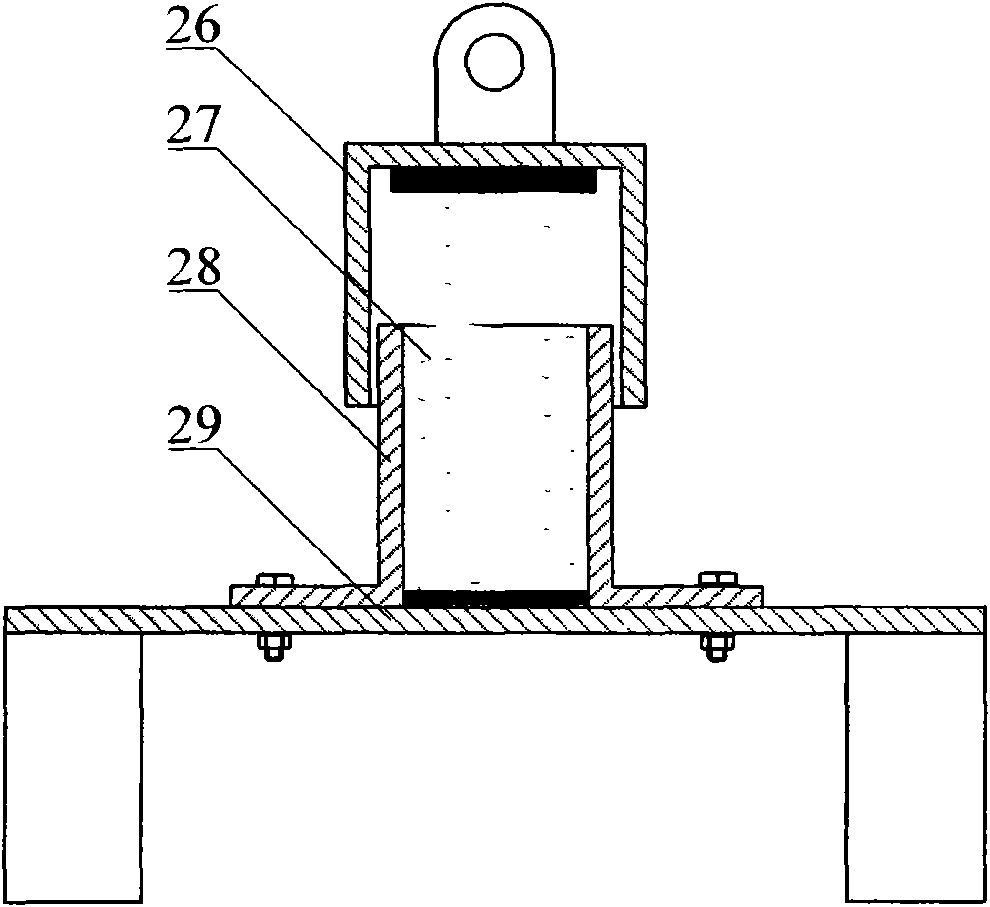

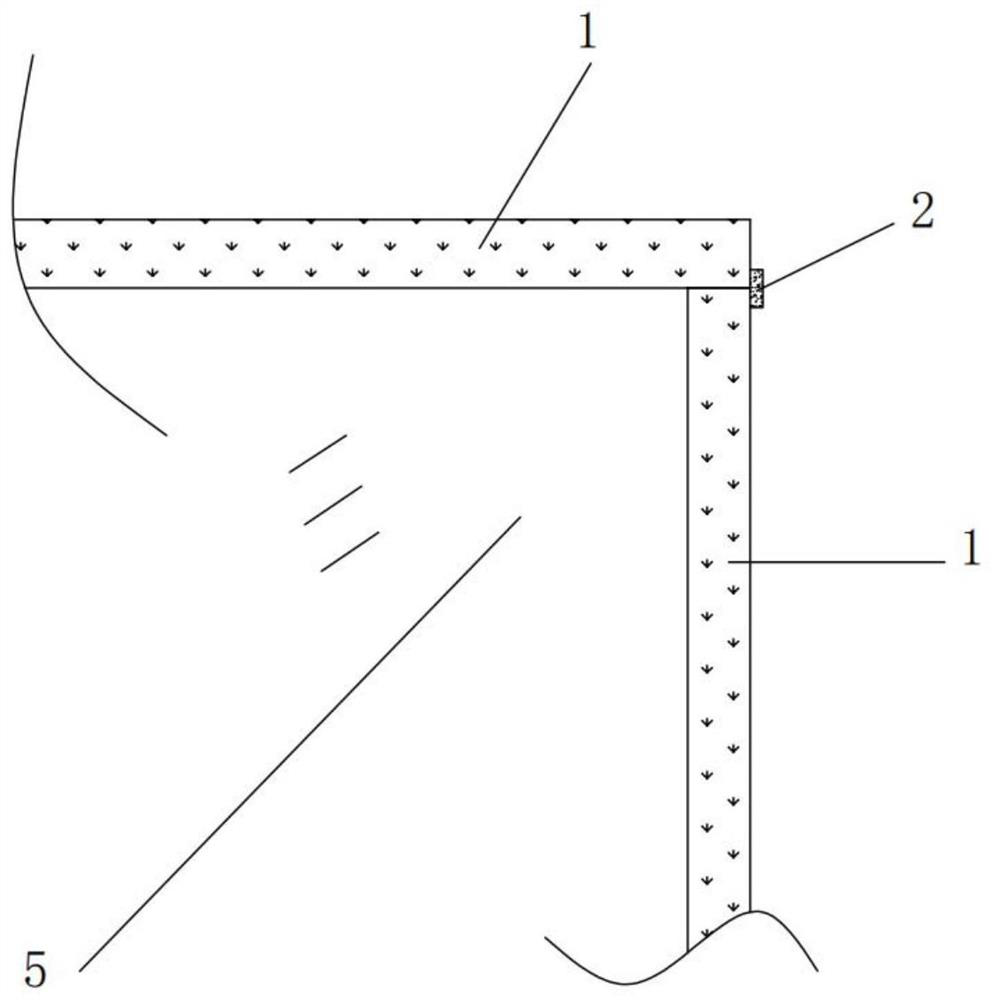

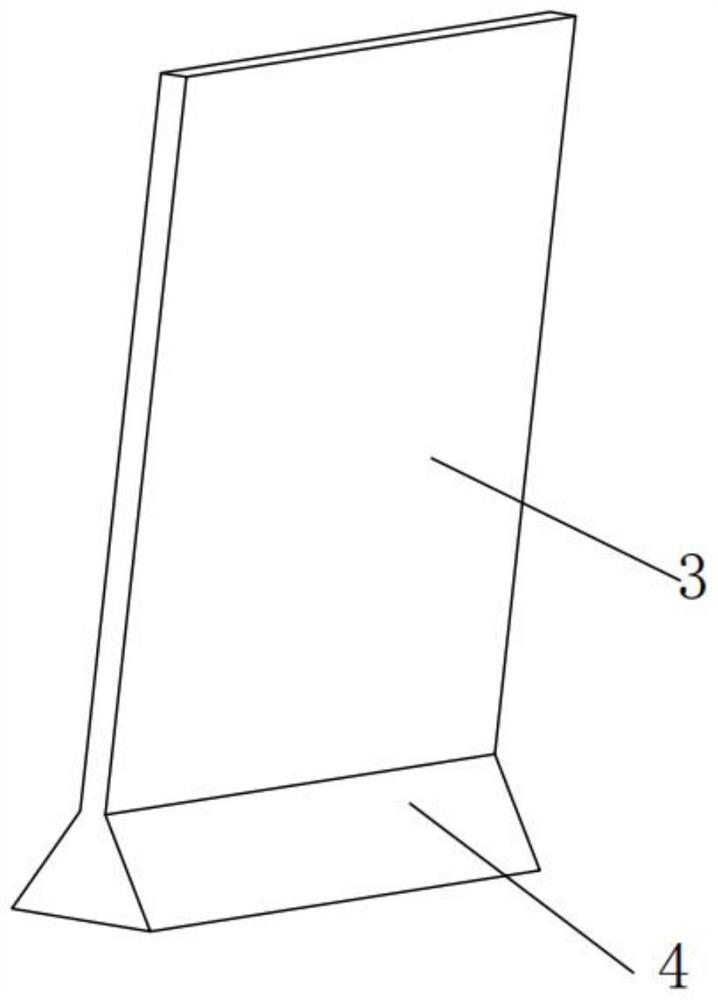

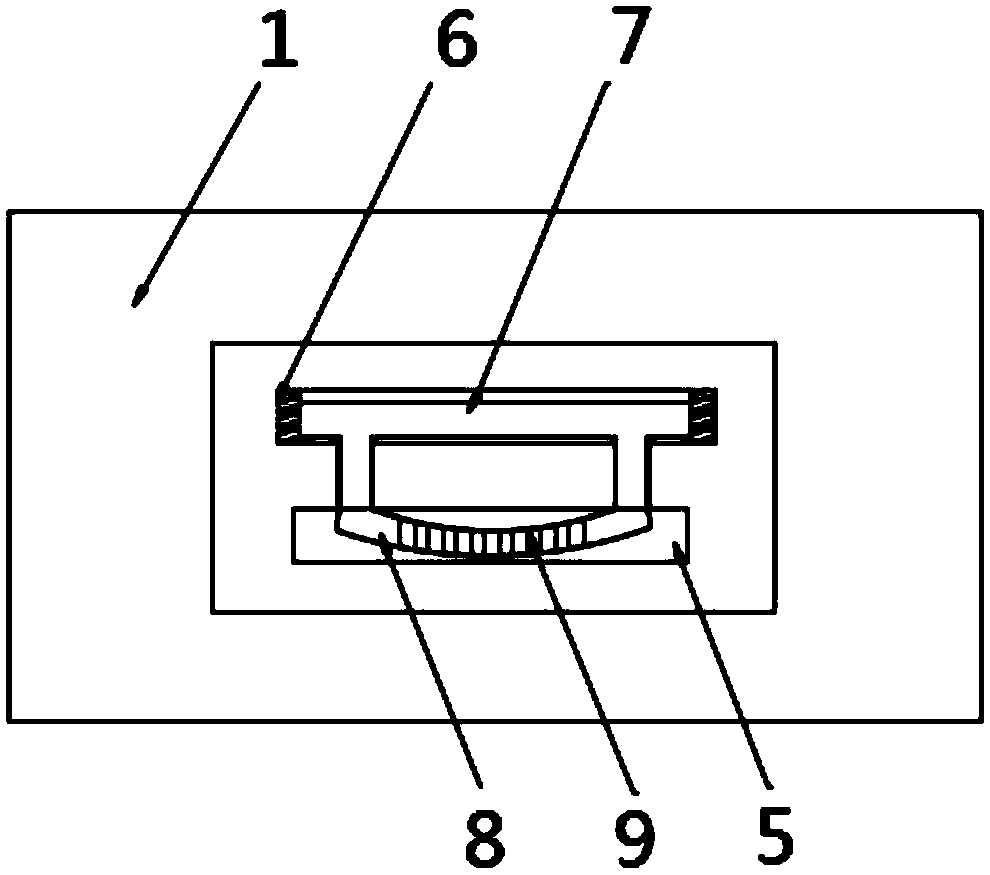

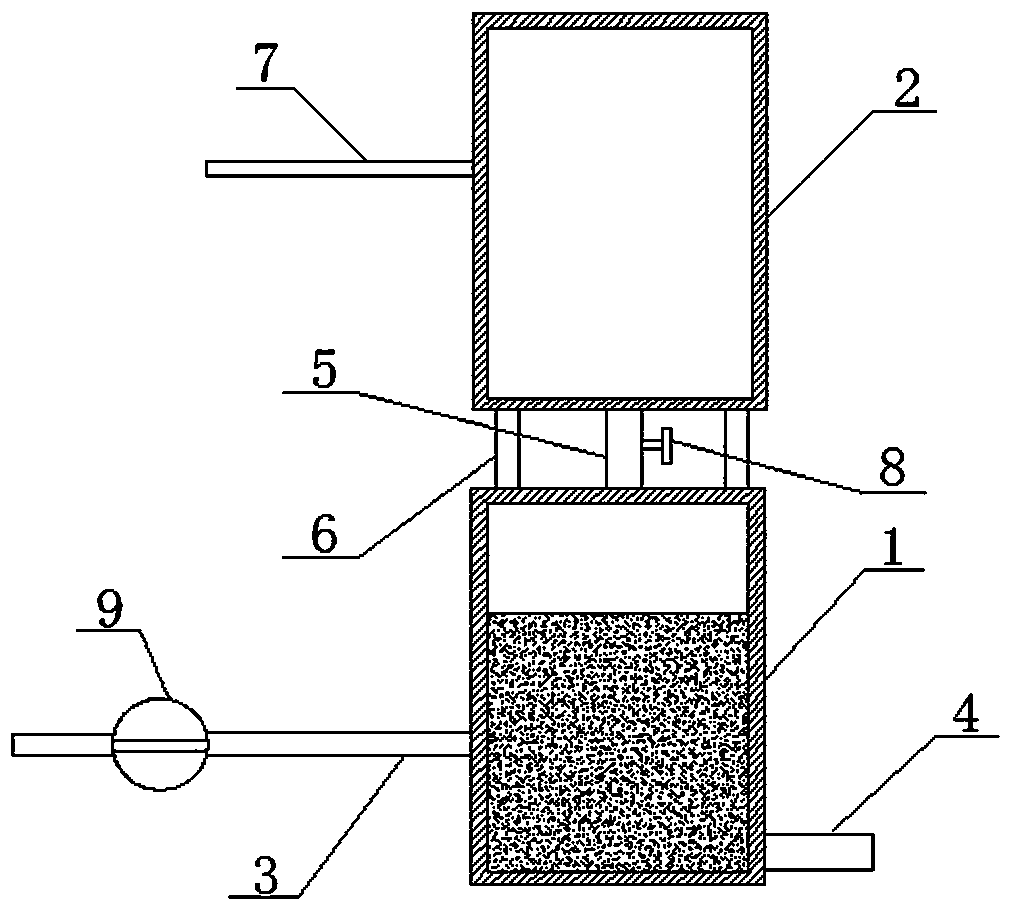

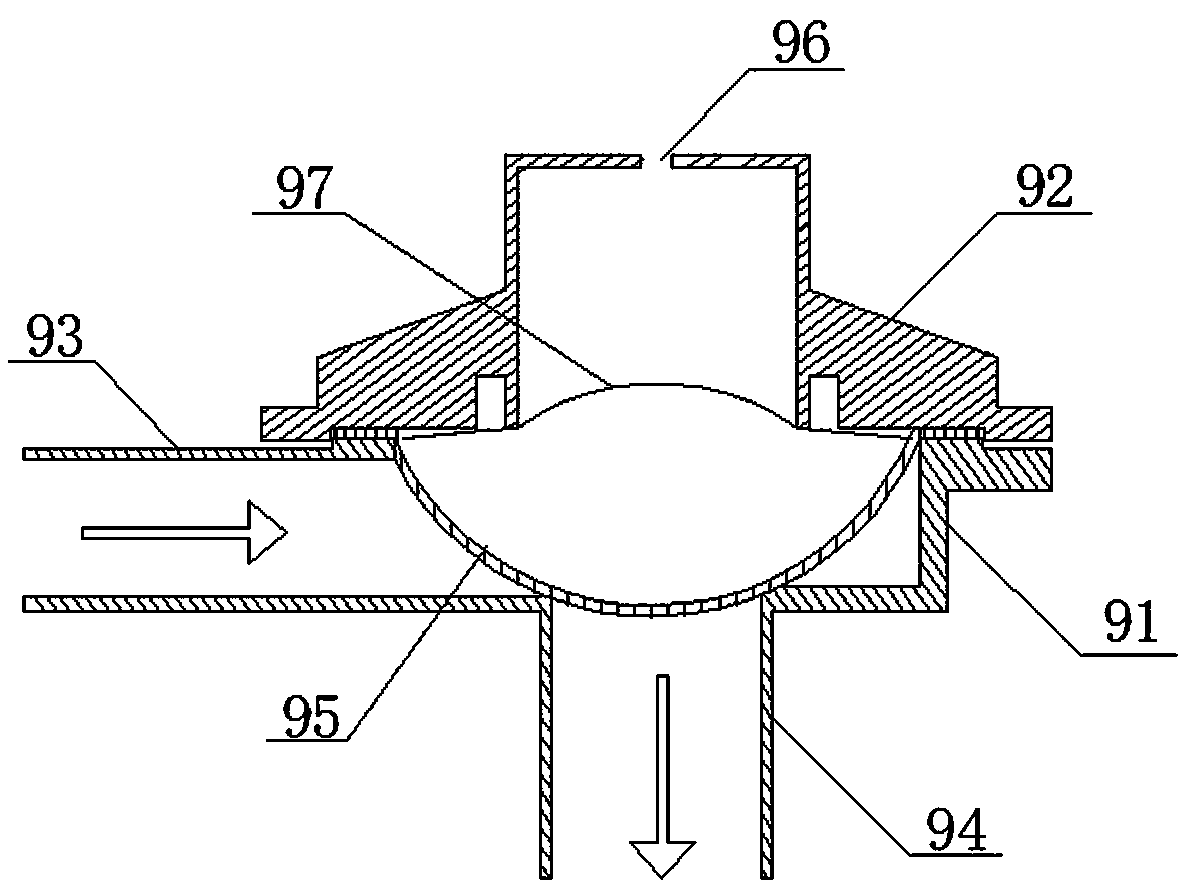

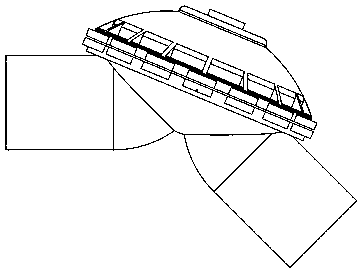

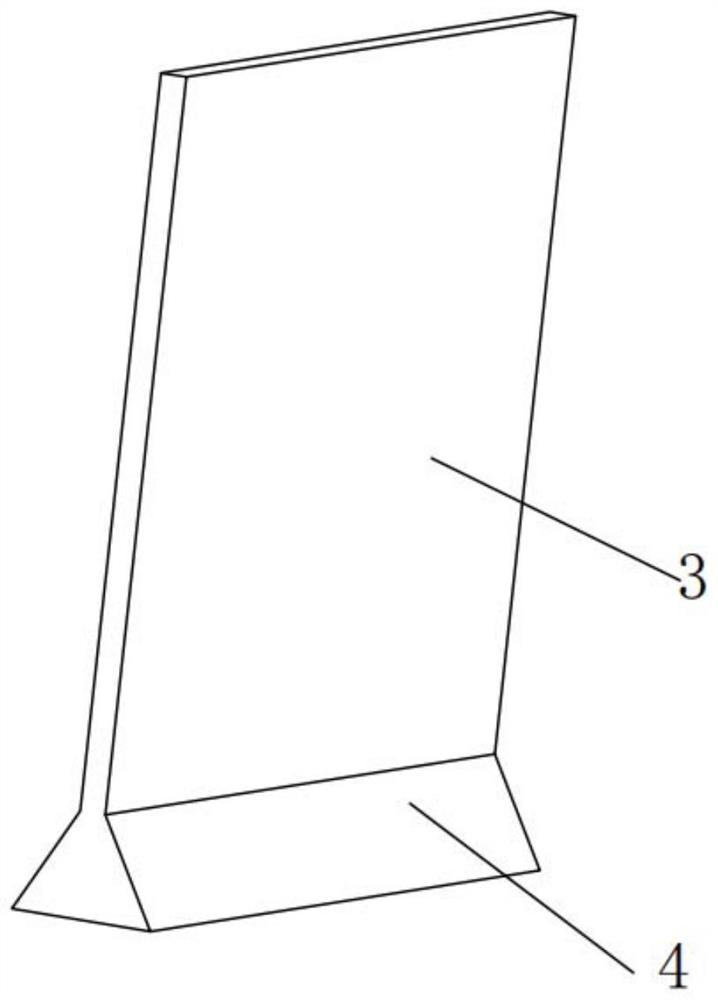

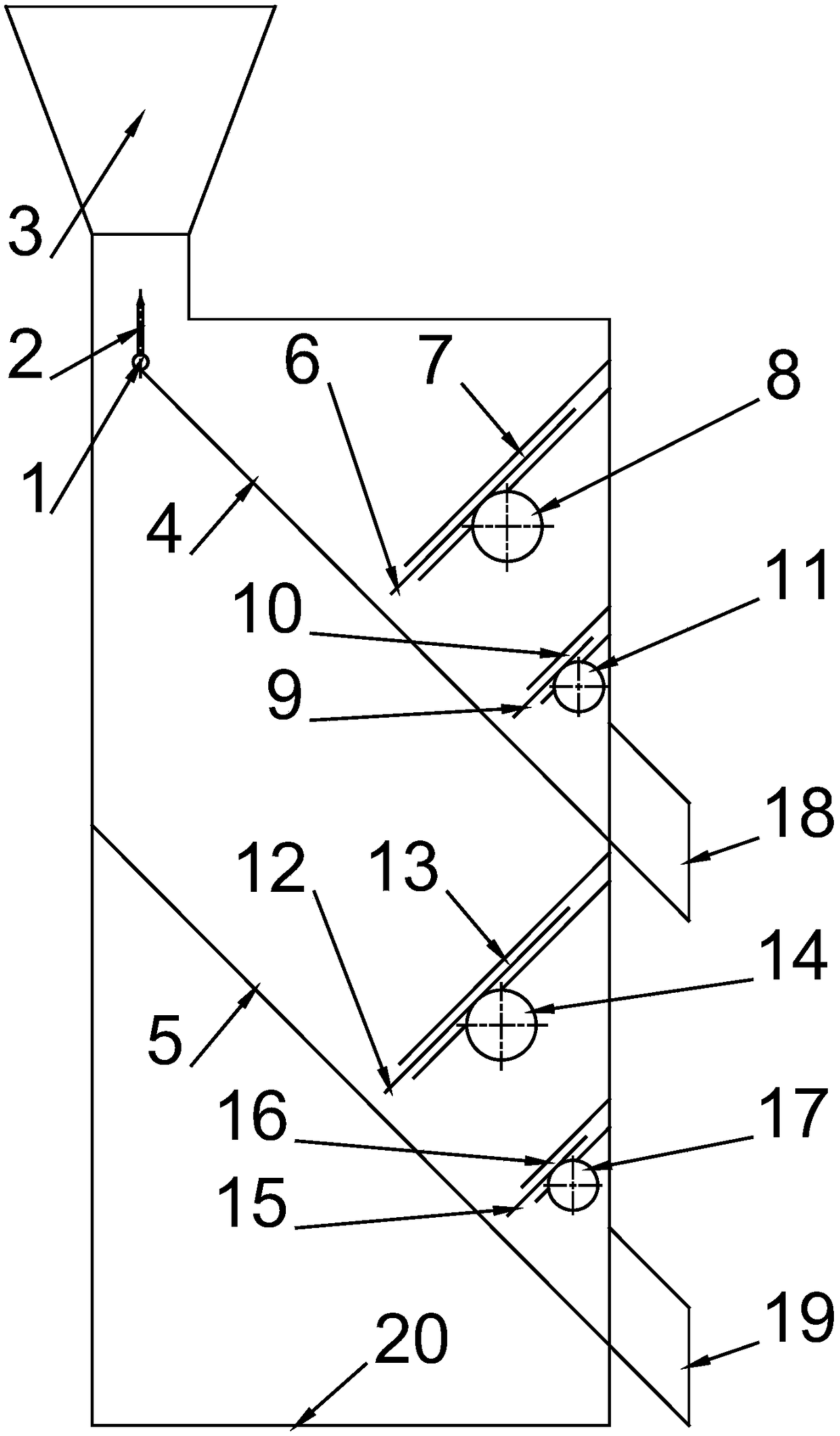

Biomass feed divider with changeable trough obliquity and vibration frequency and amplitude

ActiveCN101613039AContinuous, stable and even distribution of materialsAchieve free rotationLarge containersLoading/unloadingMultiple formsMaterial distribution

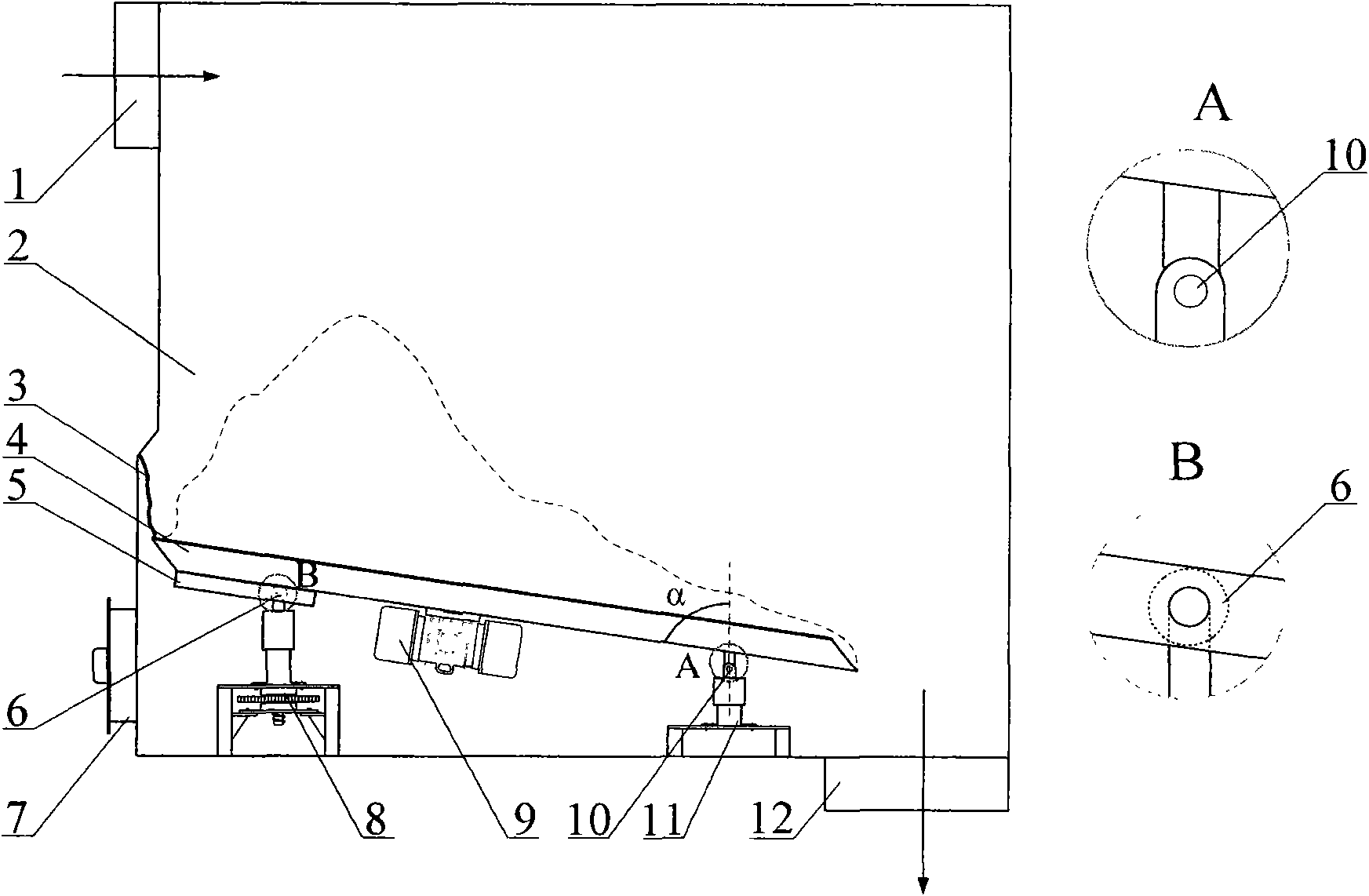

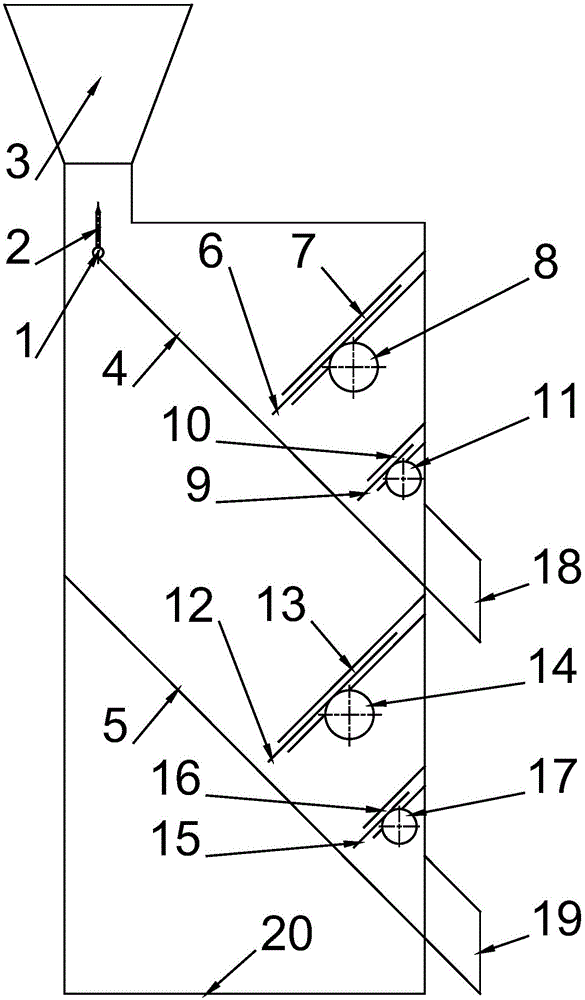

The invention relates to a biomass feed divider with changeable trough obliquity and vibration frequency and amplitude, which realizes continuous, stable and safe feed division by adopting two regulating measures of changing obliquity of a trough and changing vibration frequency and amplitude and by exciting force generated by a vibrating motor (9). The device is formed by arranging one or a plurality of independent distributors in parallel, wherein each distributor mainly comprises a trough body (4), a vibrating motor (9), an elevating (8), a spring supporting mechanism (11) and an auxiliary mechanism; the trough body (4) is supported by the spring supporting mechanism (11) at the front part and the elevating (8) at the rear part, the vibrating motor (9) is arranged in the middle of the bottom of the trough body (4), and the rear part of the trough body (4) is connected with bulkhead by canvas (3). The device integrates material storage and material distribution, is not only suitable for hard biomass but also is suitable for soft biomass, and has lateral expansibility, thereby being convenient to be used together with material equipment of various types.

Owner:SOUTHEAST UNIV

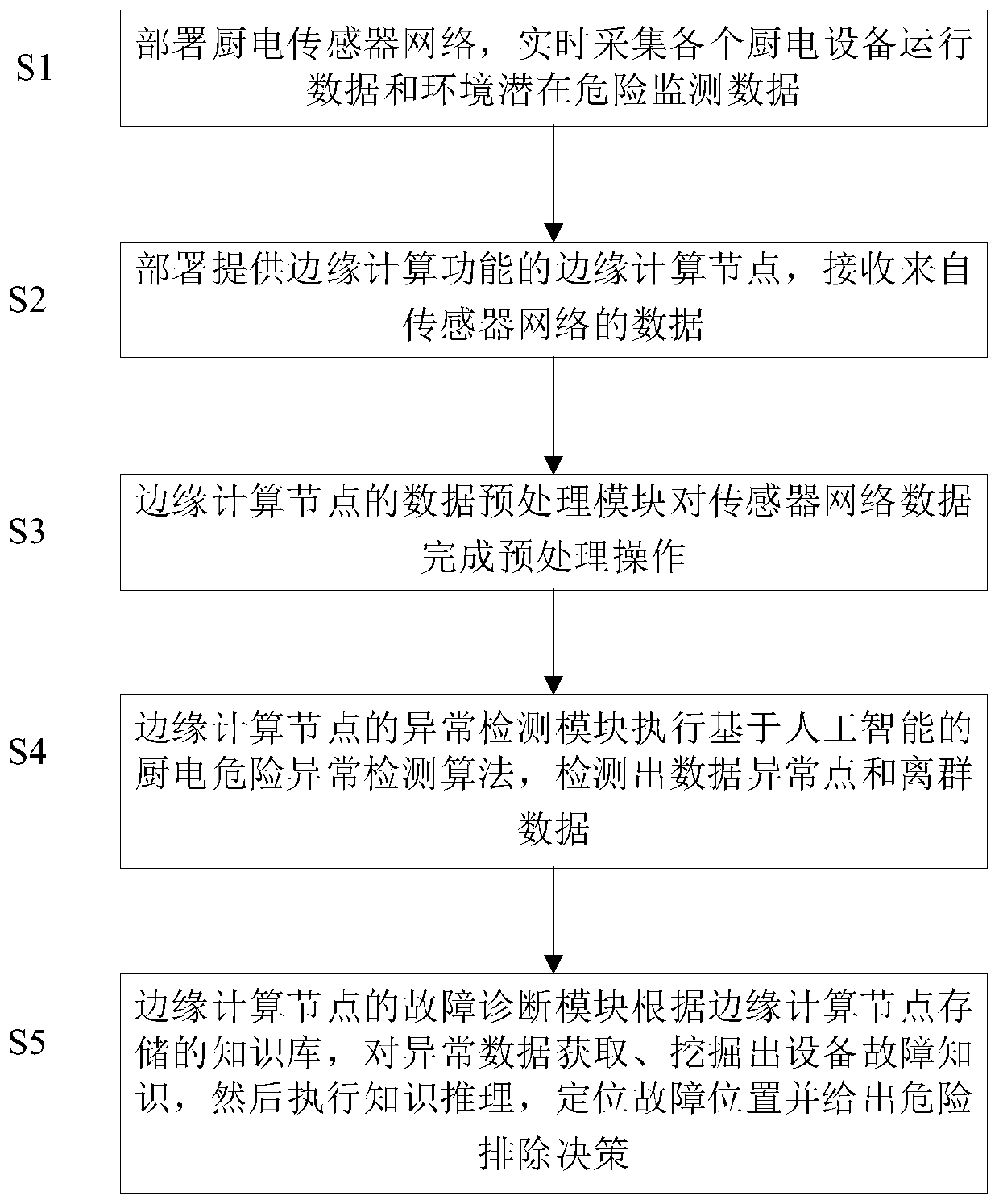

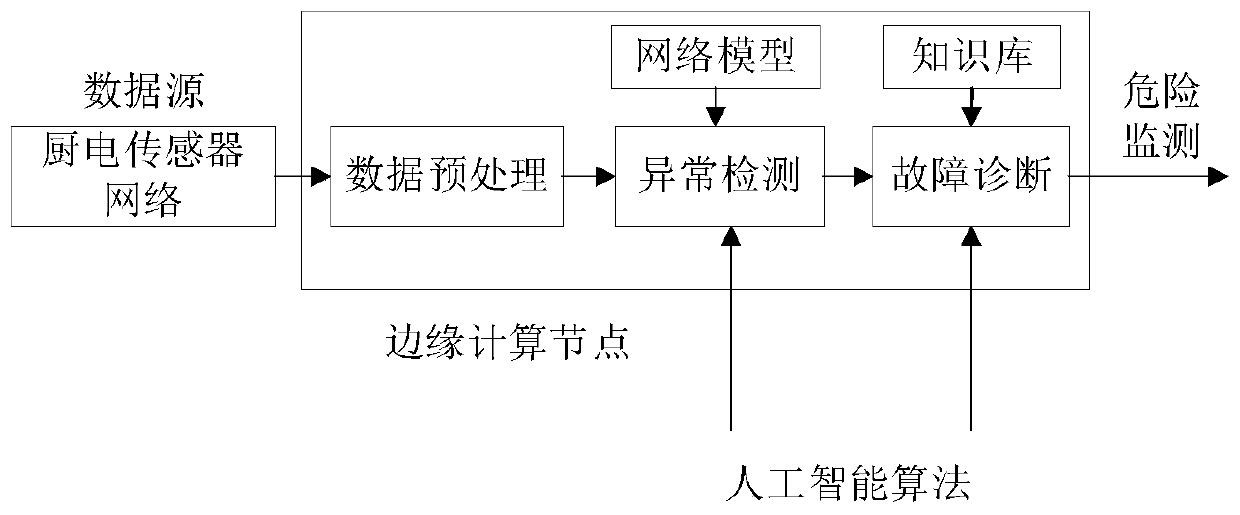

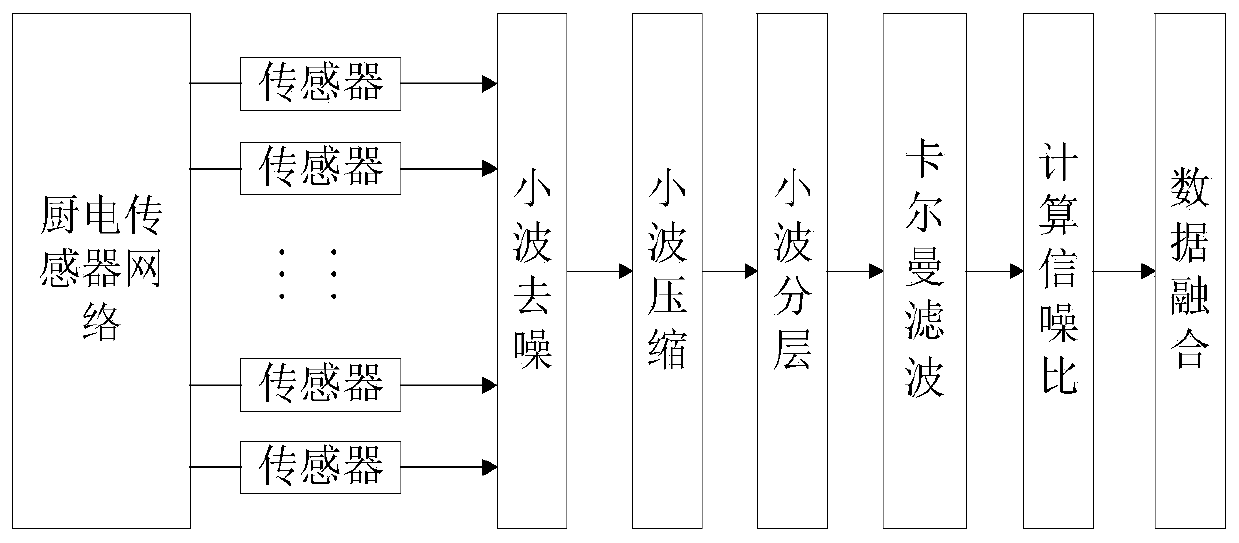

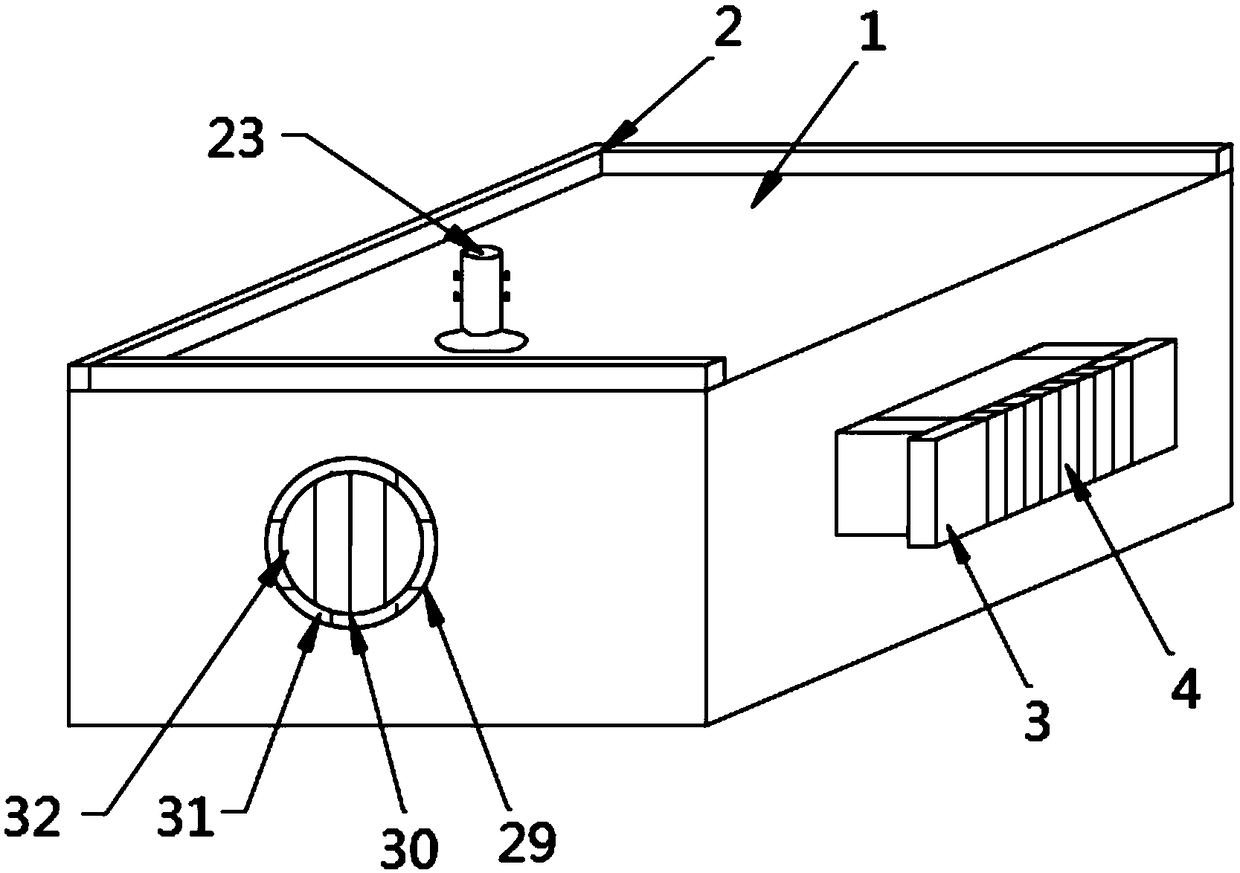

Kitchen electric appliance danger intelligent monitoring method combined with edge calculation

ActiveCN111024158AFully capture potential hazardsHave computing powerMeasurement devicesNeural architecturesNetwork modelLearning network

The invention discloses a kitchen electric hazard intelligent monitoring method combined with edge calculation, which comprises the following steps: different types of sensors are deployed at different equipment and different positions of a kitchen, a kitchen electric sensor network is formed by the sensors, and various related data are acquired in real time; the kitchen appliance sensor network transmits the acquired data to edge computing nodes which are arranged adjacently, and each edge computing node comprises a data preprocessing module, an anomaly detection module and a fault diagnosismodule; the edge computing node also stores a deep learning network model and a knowledge base required by knowledge-based fault reasoning; the kitchen electric sensor network adopted by the inventionis compatible with various sensors, various data can be collected in real time for various kitchen electric hidden dangers, and all-around potential hazard sources are fully obtained; and the edge computing nodes deployed close to a data source are adopted to process the kitchen appliance data, so that the system delay is reduced, and the reaction speed is increased.

Owner:GUANGDONG UNIV OF TECH

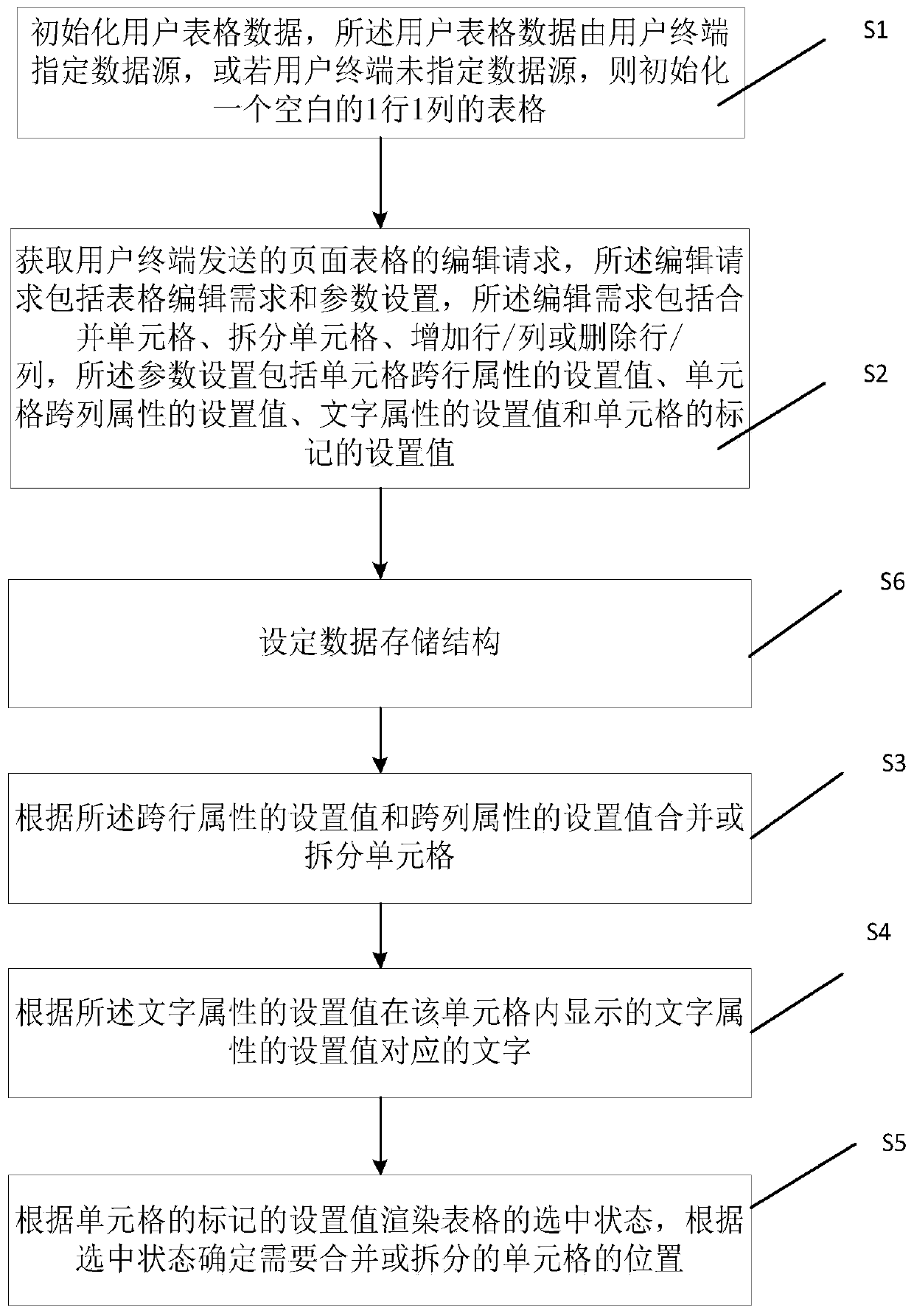

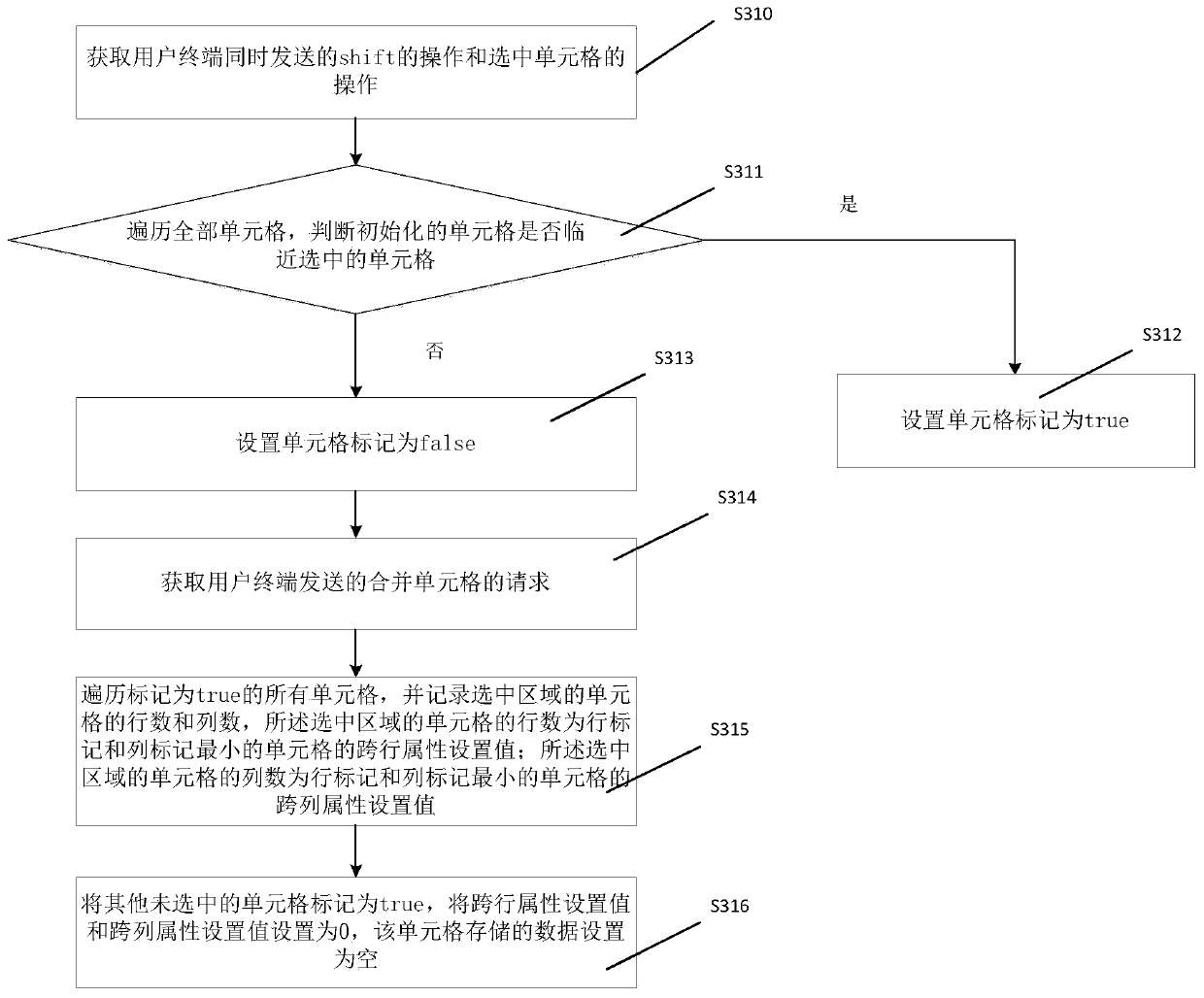

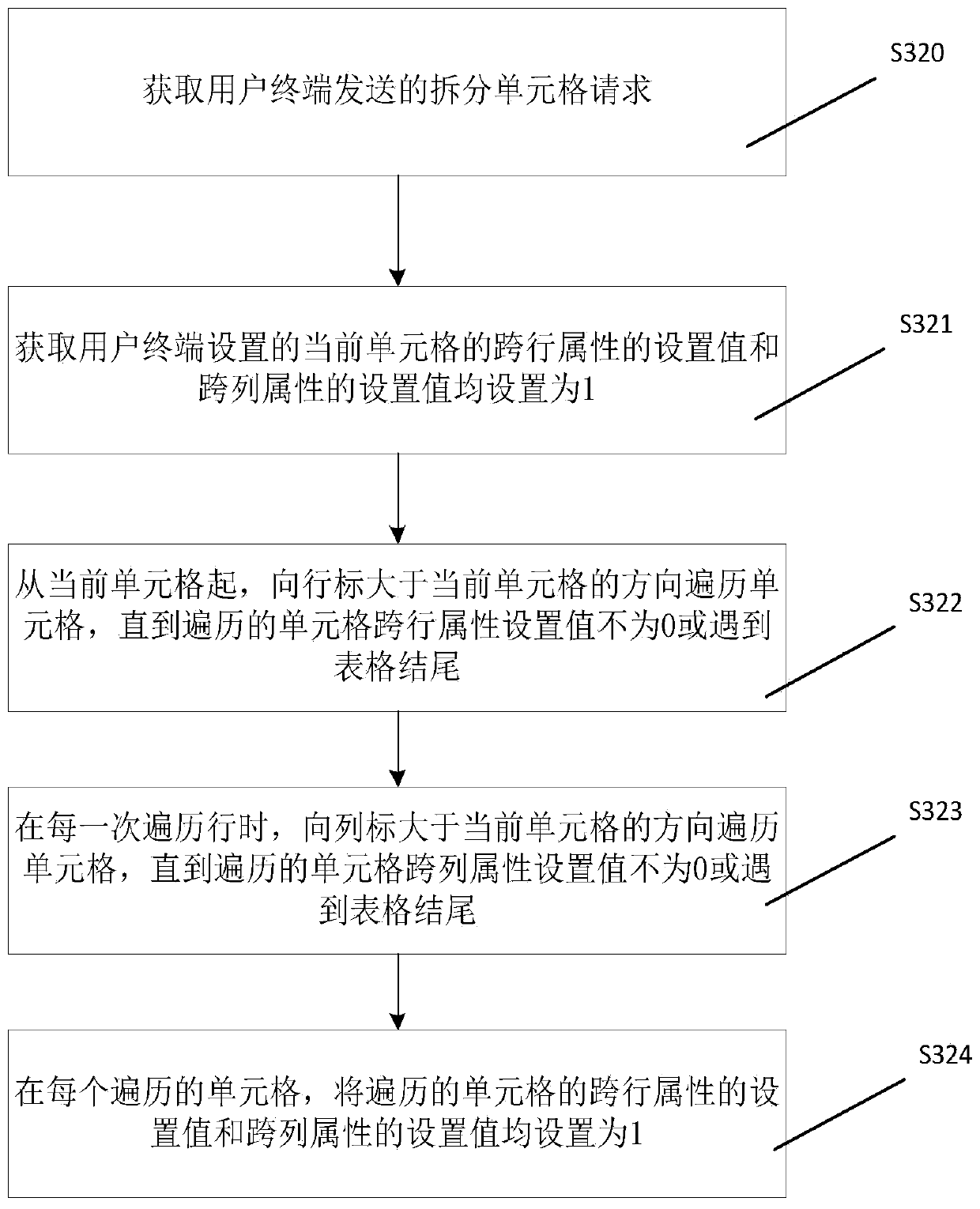

Page complex table rendering method and system, terminal and medium

InactiveCN110096507AWith storage capacityWith data difference comparison functionNatural language data processingSpecial data processing applicationsPage tableData mining

The invention discloses a page complex table rendering method, which comprises the following steps: initializing user table data, and obtaining a page table editing request sent by a user terminal, the editing request comprising a table editing demand and parameter setting; combining or splitting the cells according to the set value of the cross-row attribute and the set value of the cross-columnattribute; displaying the characters corresponding to the set values of the character attributes in the cell according to the set values of the character attributes; rendering the selected state of the table according to the set values of the marks of the cells, and determining the positions of the cells needing to be combined or split according to the selected state. According to the method, therow, the column and the cell merging state of the table are rendered according to the structured data, and the attributes of the structured data are modified by merging the cells and splitting the cells, so that the table can adapt to complex business logic, and the display of the page is kept consistent with the table required by the business.

Owner:北京博跃科技有限公司

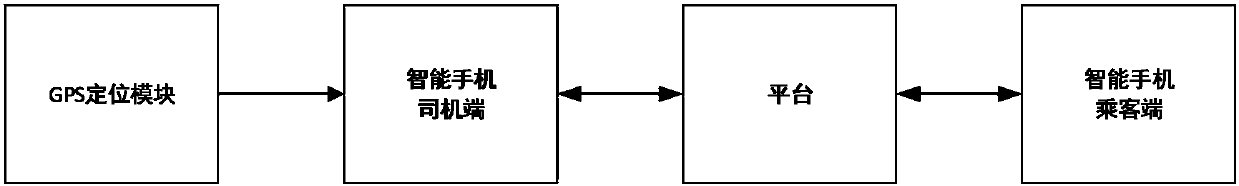

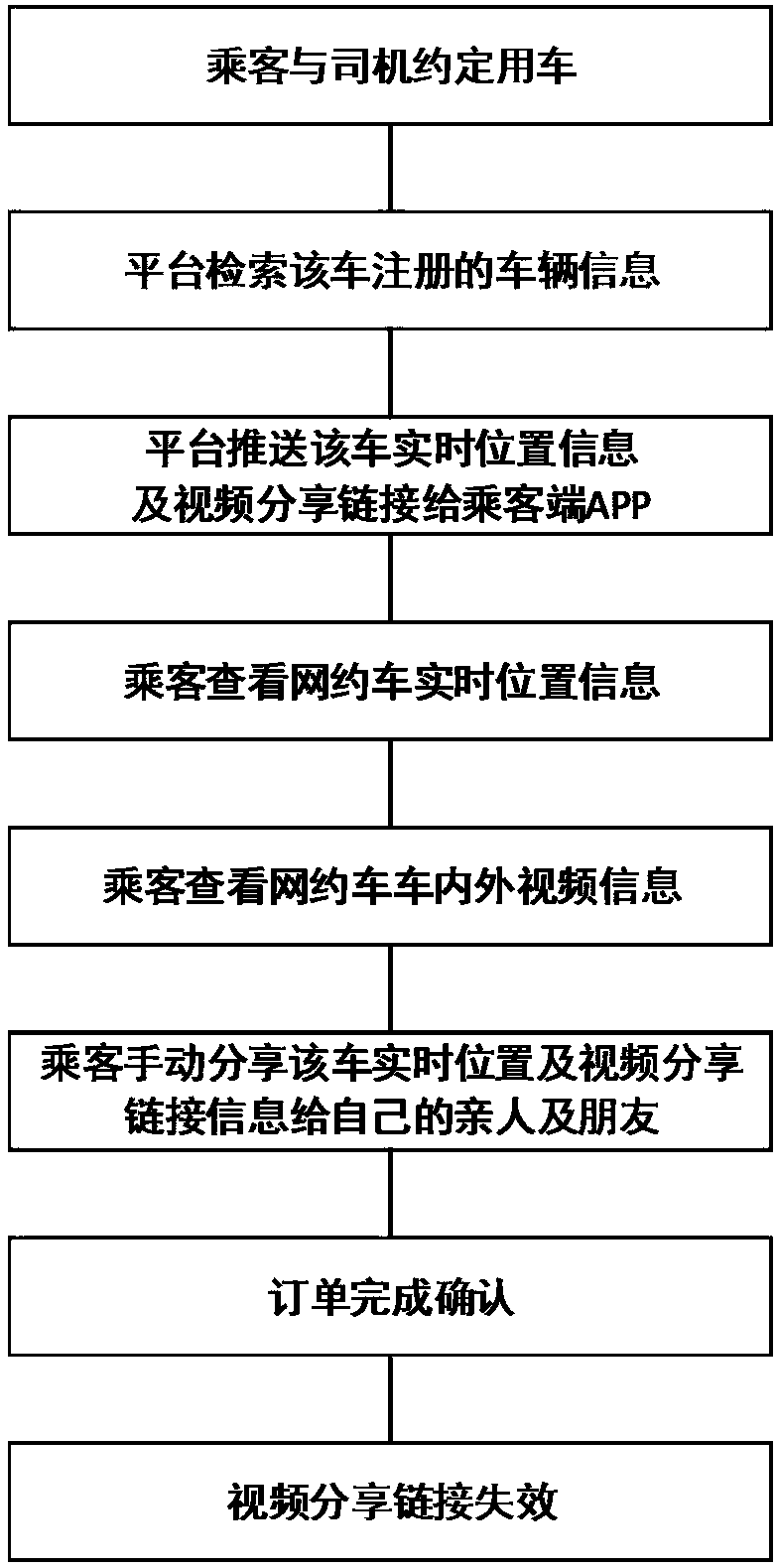

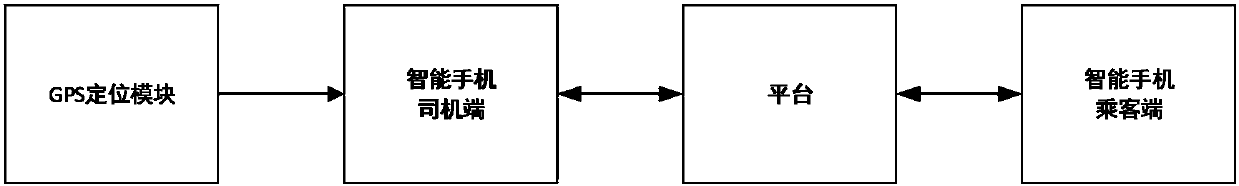

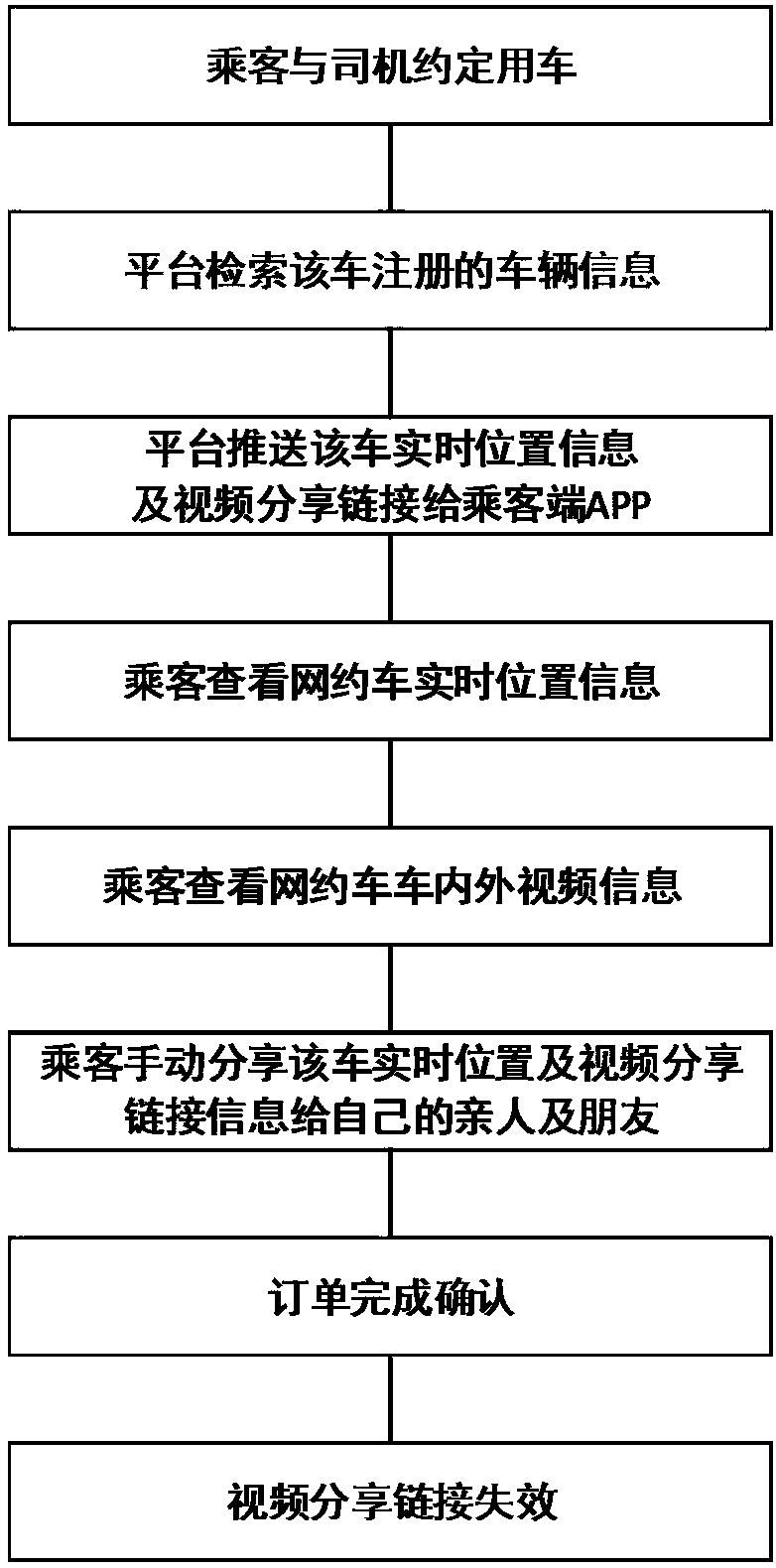

Network ride-hailing video sharing method and system

InactiveCN107784825AReduce the number of phone callsImprove driving safetyRoad vehicles traffic controlClosed circuit television systemsVideo sharingInternet video

The invention relates to a network ride-hailing video sharing method and system. The method comprises steps that a network ride-hailing instruction is sent by a passenger through a passenger end APP to a driver end APP; after the network ride-hailing instruction is received by the driver through the driver end APP, the registration information of a vehicle is retrieved by a network ride-hailing video sharing platform; the real-time vehicle position information and a video sharing link are pushed through the network ride-hailing video sharing platform to the passenger end APP; the real-time ride-hailing vehicle position information and the internal and external video information are checked by the passenger; the real-time ride-hailing vehicle position information and the video sharing linkinformation are shared manually by the passenger to friends and families. The method is advantaged in that the Internet video sharing platform is utilized, the real-time ride-hailing vehicle positioninformation and the internal and external video information are shared, a network ride-hailing driving safety problem is solved, and network ride-hailing service quality is further improved.

Owner:DALIAN ROILAND SCI & TECH CO LTD

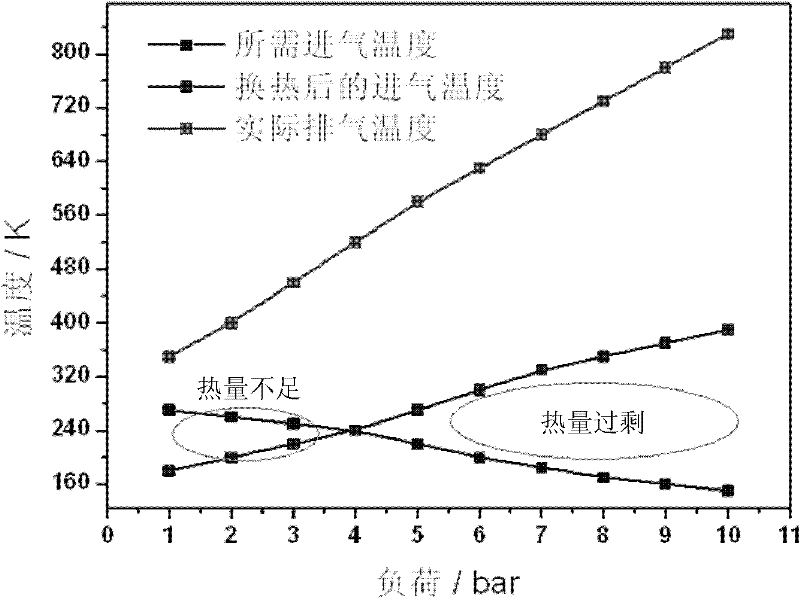

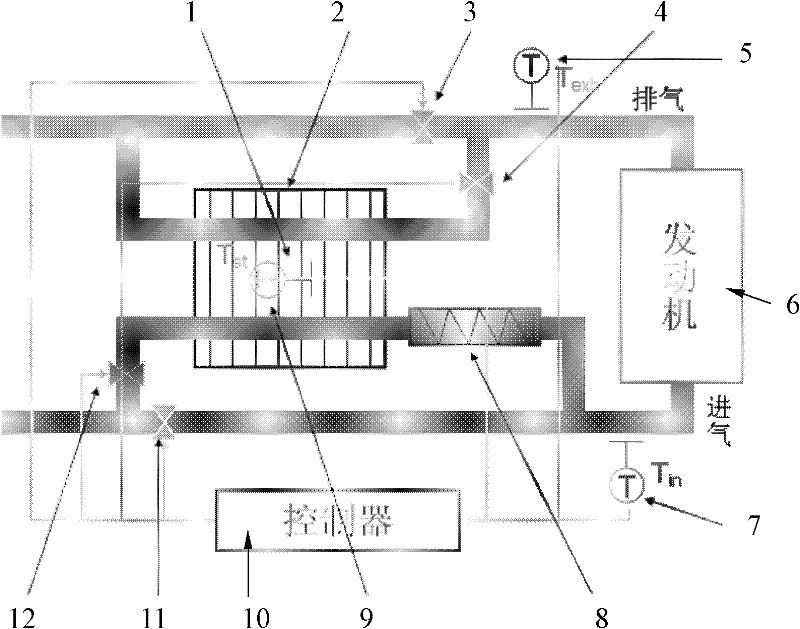

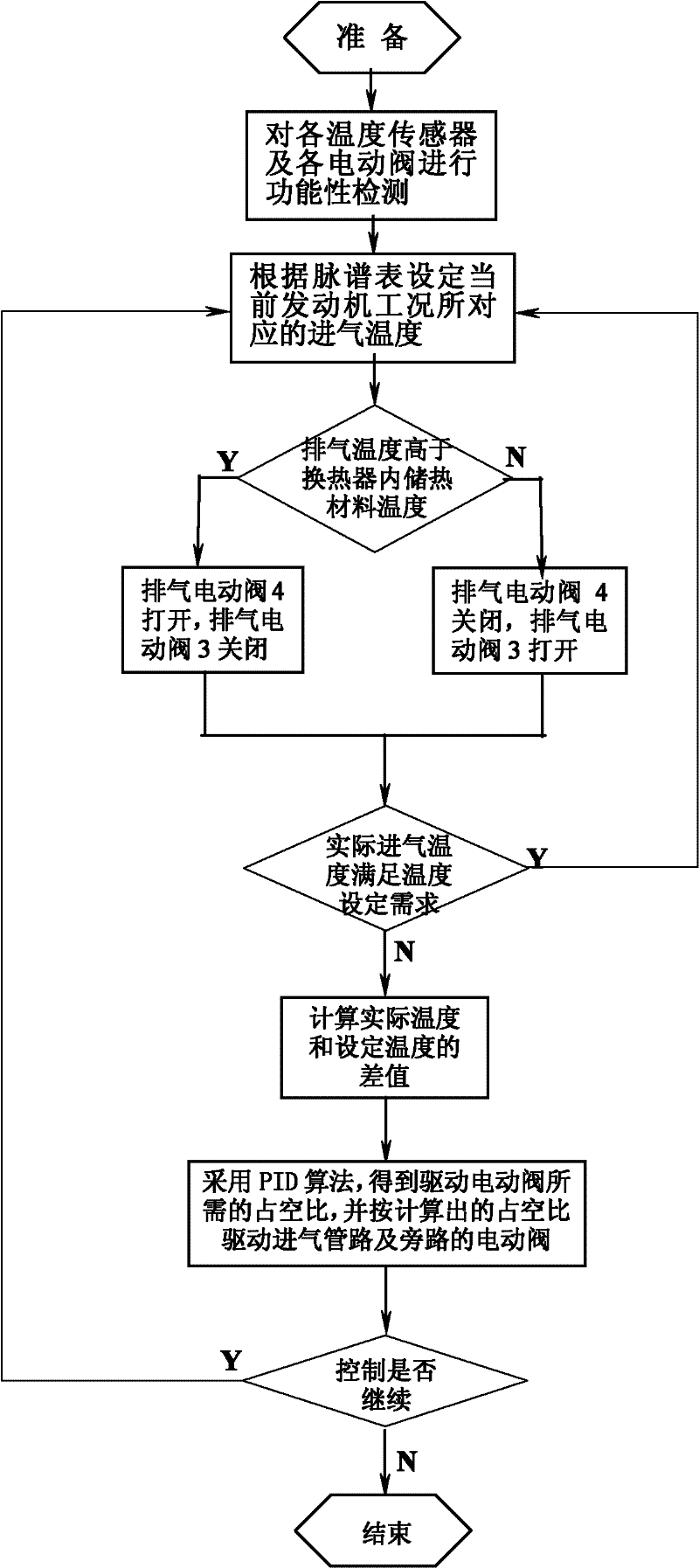

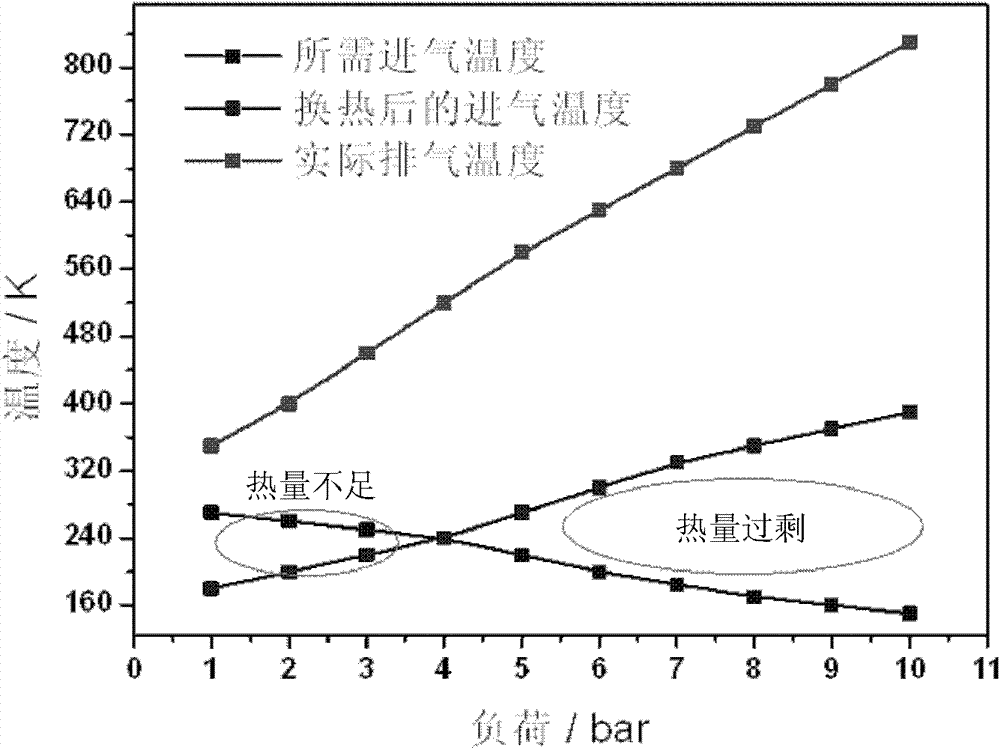

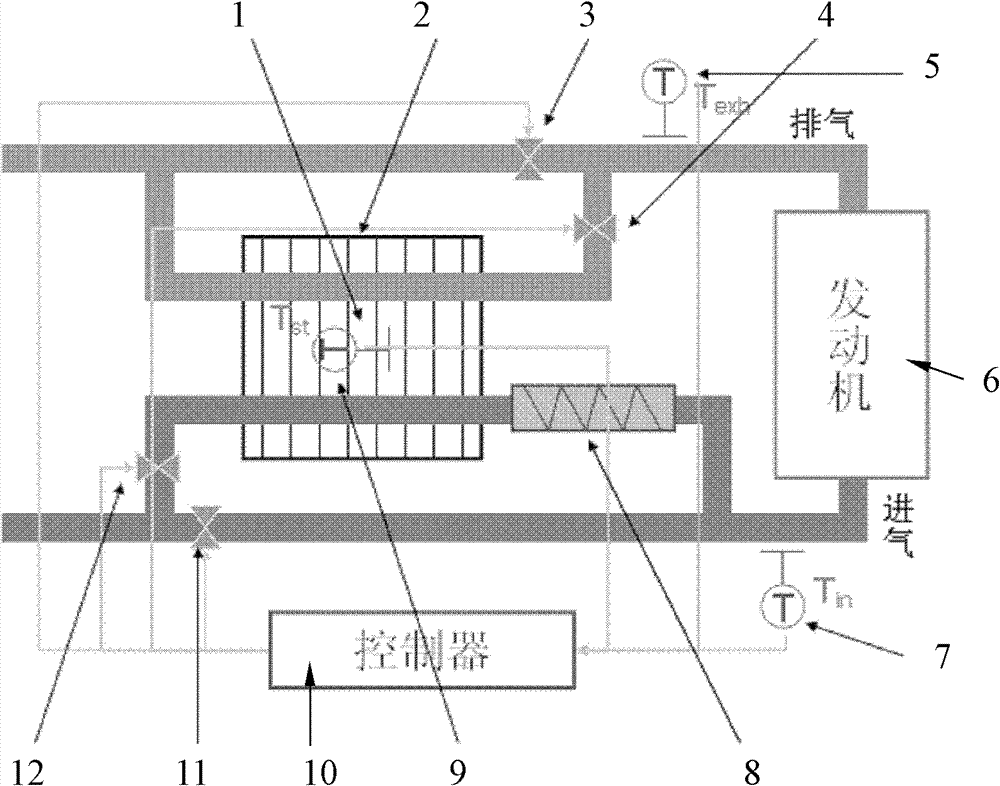

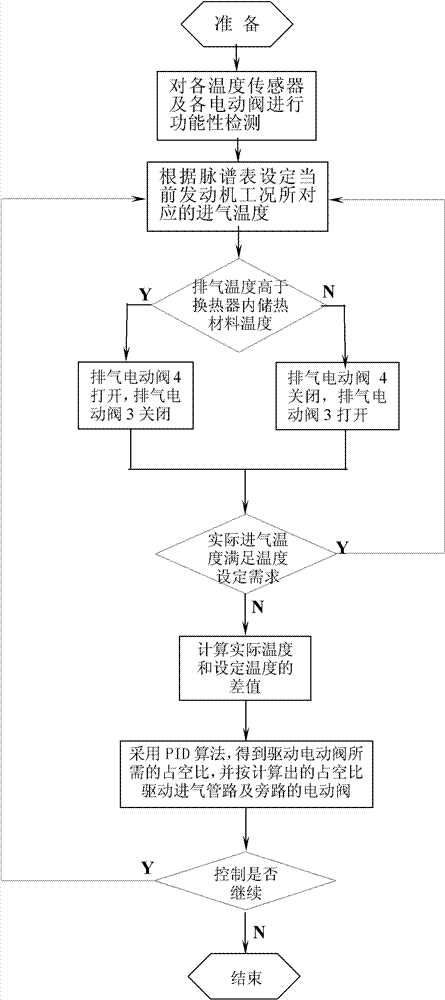

Air intake and exhaust thermal control device and method for implementing HCCI (homogeneous charge compression ignition) combustion of gasoline engine

ActiveCN102359411AAchieving Selective Appropriate UtilizationReasonable storage or releaseElectrical controlInternal combustion piston enginesHcci combustionEngineering

The invention discloses an air intake and exhaust thermal control system for implementing HCCI (homogeneous charge compression ignition) combustion of a gasoline engine. The system comprises an air intake pipeline, an air exhaust pipeline and an air exhaust-intake heat exchanger, wherein the heat exchanger is filled with heat storage materials; the air intake pipeline, the air exhaust pipeline and a bypass are respectively provided with an electrically operated valve; the pipelines are provided with a plurality of temperature sensors; the electrically operated valves and the temperature sensors are connected with a controller; and the controller comprises a signal conditioning circuit and a driving circuit which are connected with a singlechip and are used for implementing the thermal control of air intake and air exhaust. The device provided by the invention has the heat storage capability of the heat exchanger, reasonable storage and release of air exhaust heat can be realized. Whenthe gasoline engine operates at medium and large load, the storage and accumulation of surplus air exhaust heat in the heat exchanger can be realized, and the device is used for heating the intake air when the gasoline engine operates at low load, the problem that the air exhaust heat is insufficient to heat the intake air at low load is solved, the requirement of air exhaust-intake heat exchangeefficiency is lowered, and the device can be practically applied to the HCCI combustion of the gasoline engine.

Owner:TIANJIN UNIV

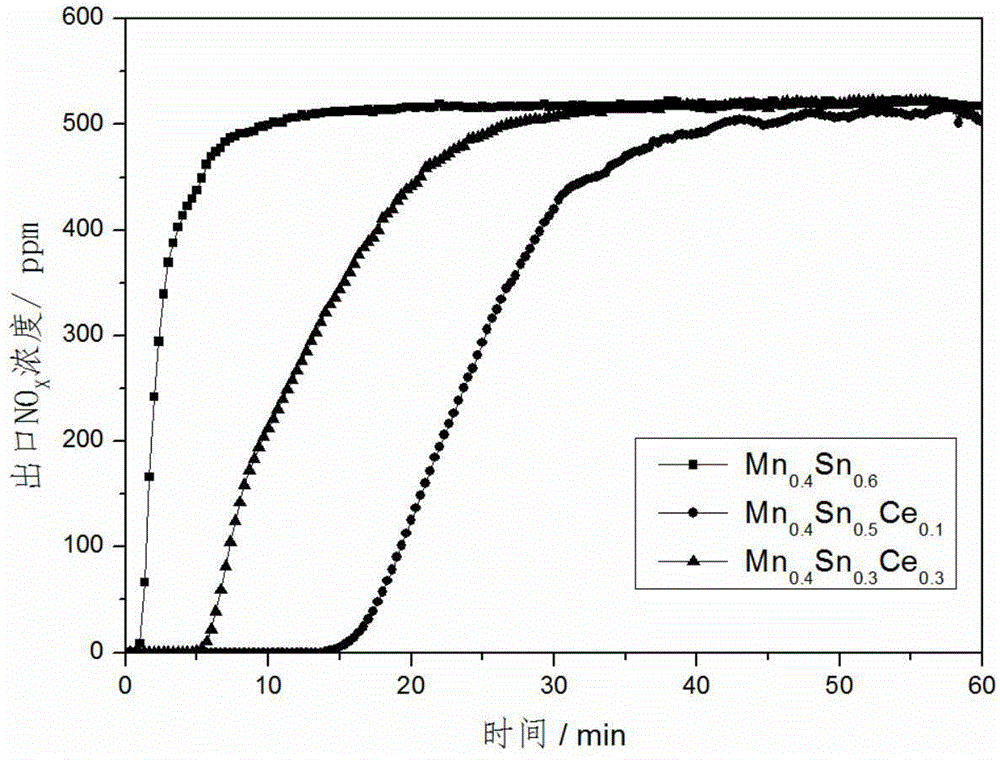

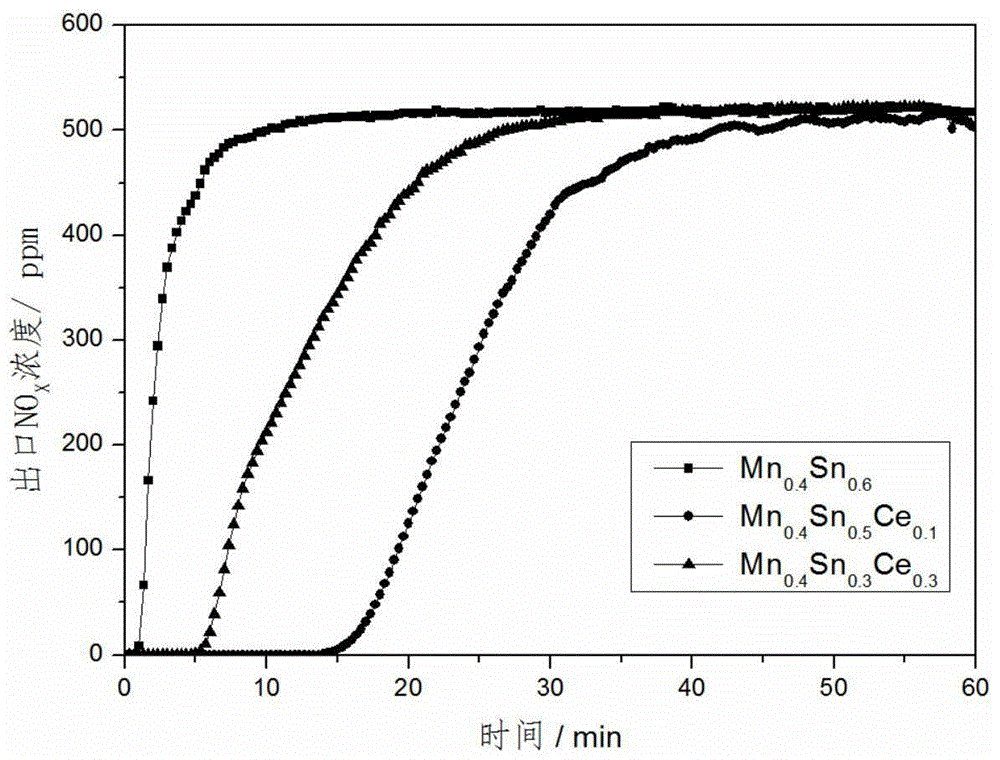

Absorbent for storing nitrogen oxides of diesel engine and lean-burn gasoline engine and preparation of absorbent

ActiveCN104475006ALow costImprove storage effectGas treatmentOther chemical processesFlue gasSorbent

The invention discloses an absorbent for storing nitrogen oxides of a diesel engine and a lean-burn gasoline engine. The absorbent comprises the following components in percentage by weight: 24-26wt% of MnOX, 35-75wt% of SnO2 and 0-41wt% of CeO2, wherein the MnOX represents an oxide of Mn. The invention also provides a preparation method of the absorbent. The absorbent disclosed by the invention has the advantages that due to no containing of noble metals such as Pt and Pd, the cost is greatly reduced; and under the conditions of simulated flue gas with the temperature of 100 DEG C, the air speed of 48,000mLh<-1>g<-1>, NO of 500ppm and O with the content of 25%, the storage capacity of the nitrogen oxides is 290.1-541.2 micromoles / g, so that the storage capability of the nitrogen oxides with the temperature of 100 DEG C is greatly improved.

Owner:TSINGHUA UNIV

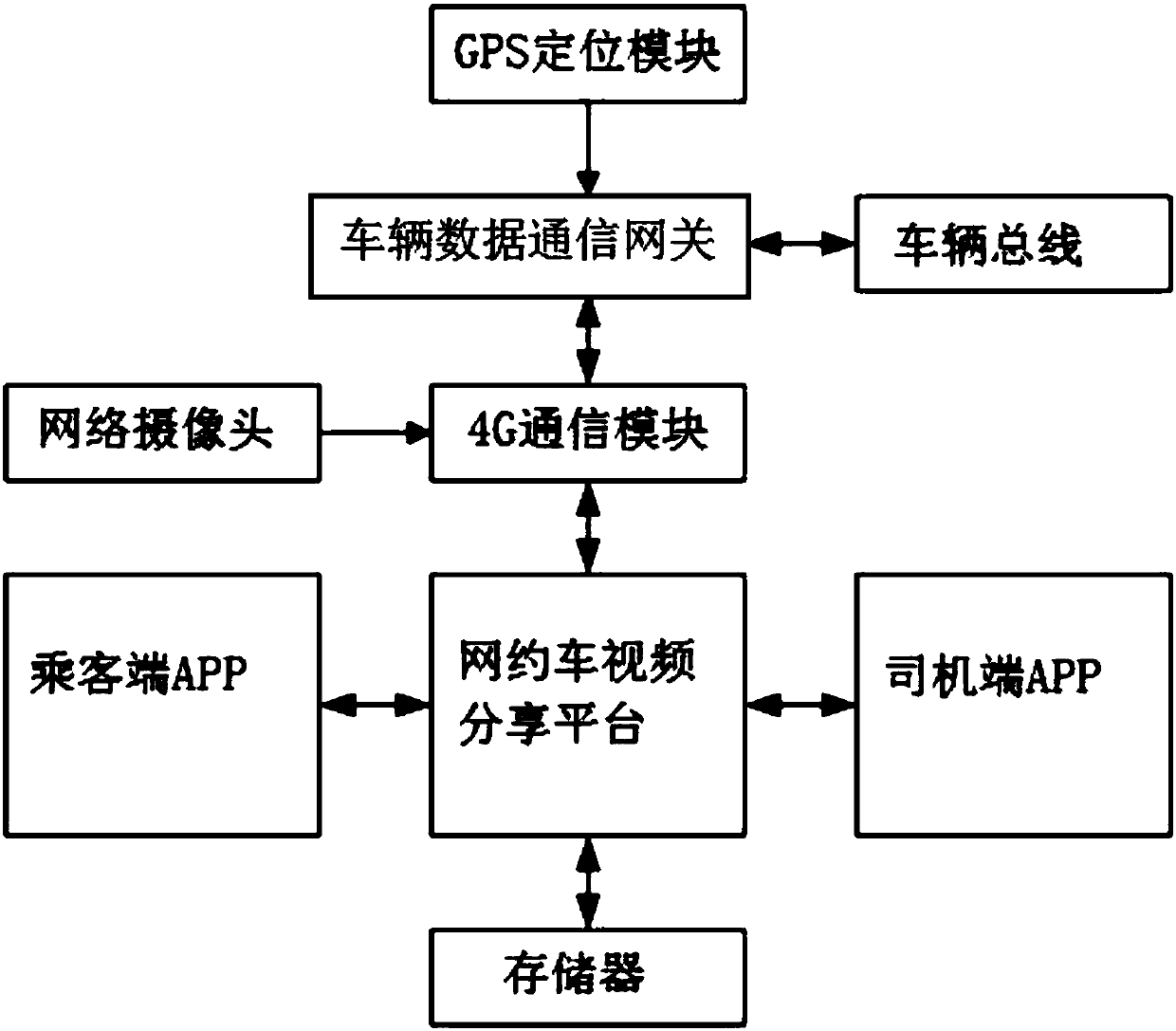

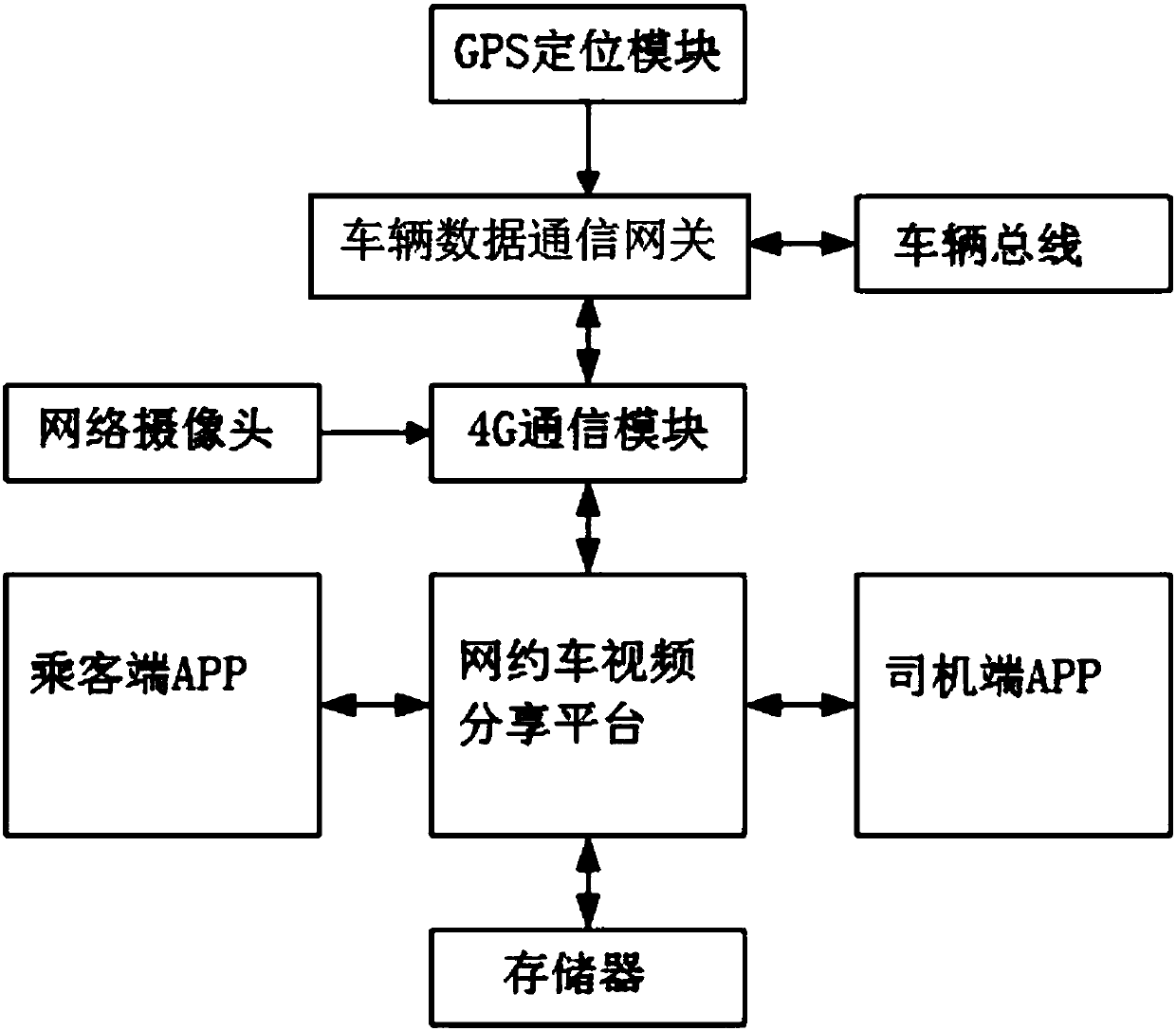

Online car-hailing platform based on video sharing

InactiveCN107784823APrevent arbitrary collageReduce the number of phone callsRoad vehicles traffic controlClosed circuit television systemsVideo sharingComputer terminal

The invention relates to an online car-hailing platform based on video sharing. The online car-hailing platform based on video sharing comprises a network camera used for uploading the acquired insideand outside vehicle video information to an online car-hailing video sharing platform, a vehicle data communication gateway used for acquiring the vehicle information, and the online car-hailing video sharing platform used for storing the video information uploaded by the network camera and pushing video sharing links to passenger terminals. The online car-hailing platform is advantaged in that the for-hire vehicle information, vehicle data communication gateway IDs and network camera IDs are registered on the online car-hailing video sharing platform; the online car-hailing video sharing platform is utilized, the real-time online car-hailing position and the inside and outside vehicle video information are shared, an online car-hailing driving safety problem is solved, and online car-hailing service quality is further improved.

Owner:DALIAN ROILAND SCI & TECH CO LTD

Adsorbent and its preparation for storage of nitrogen oxides in diesel engine and lean-burn gasoline engine

ActiveCN104475006BLow costImprove storage effectGas treatmentOther chemical processesSorbentFlue gas

The invention discloses an absorbent for storing nitrogen oxides of a diesel engine and a lean-burn gasoline engine. The absorbent comprises the following components in percentage by weight: 24-26wt% of MnOX, 35-75wt% of SnO2 and 0-41wt% of CeO2, wherein the MnOX represents an oxide of Mn. The invention also provides a preparation method of the absorbent. The absorbent disclosed by the invention has the advantages that due to no containing of noble metals such as Pt and Pd, the cost is greatly reduced; and under the conditions of simulated flue gas with the temperature of 100 DEG C, the air speed of 48,000mLh<-1>g<-1>, NO of 500ppm and O with the content of 25%, the storage capacity of the nitrogen oxides is 290.1-541.2 micromoles / g, so that the storage capability of the nitrogen oxides with the temperature of 100 DEG C is greatly improved.

Owner:TSINGHUA UNIV

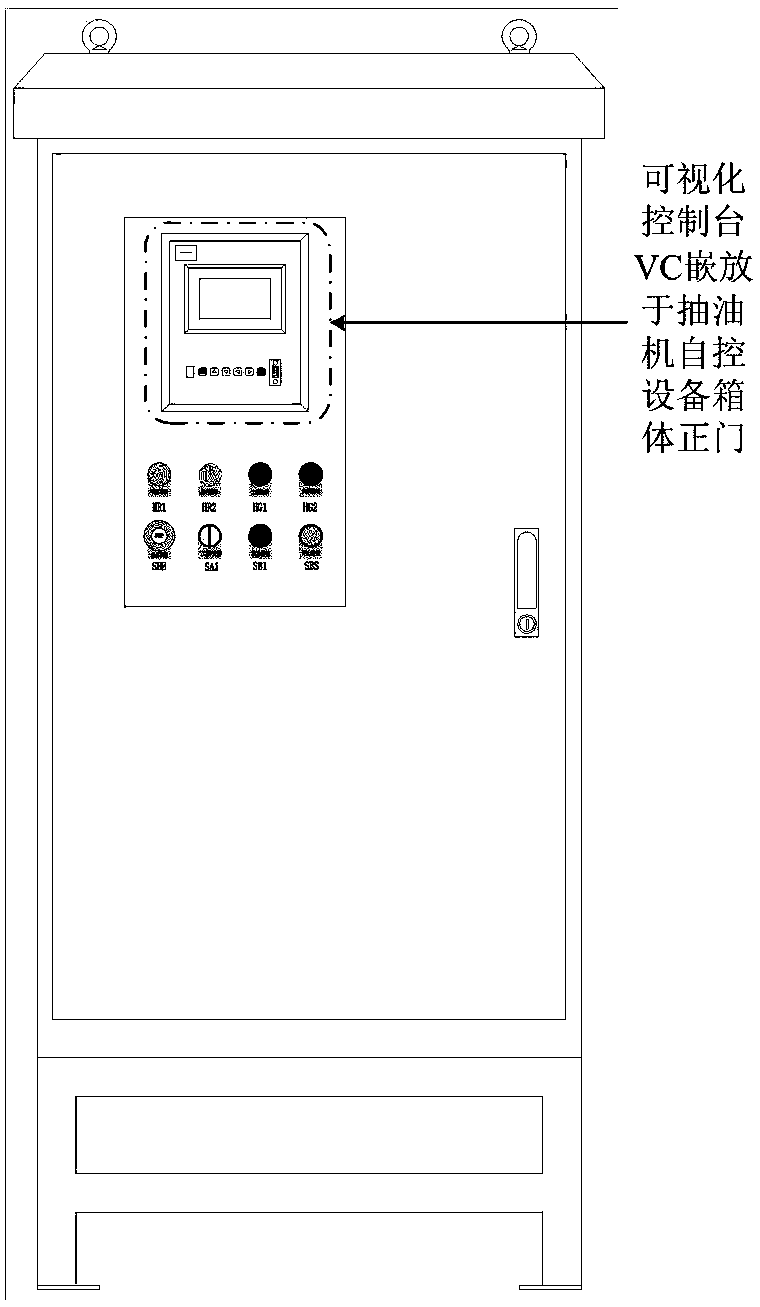

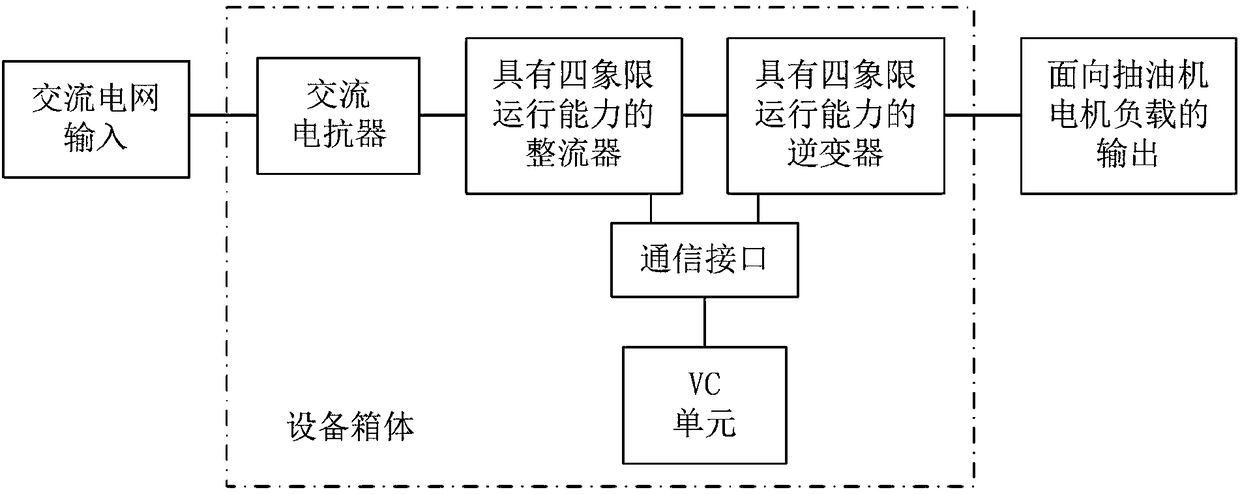

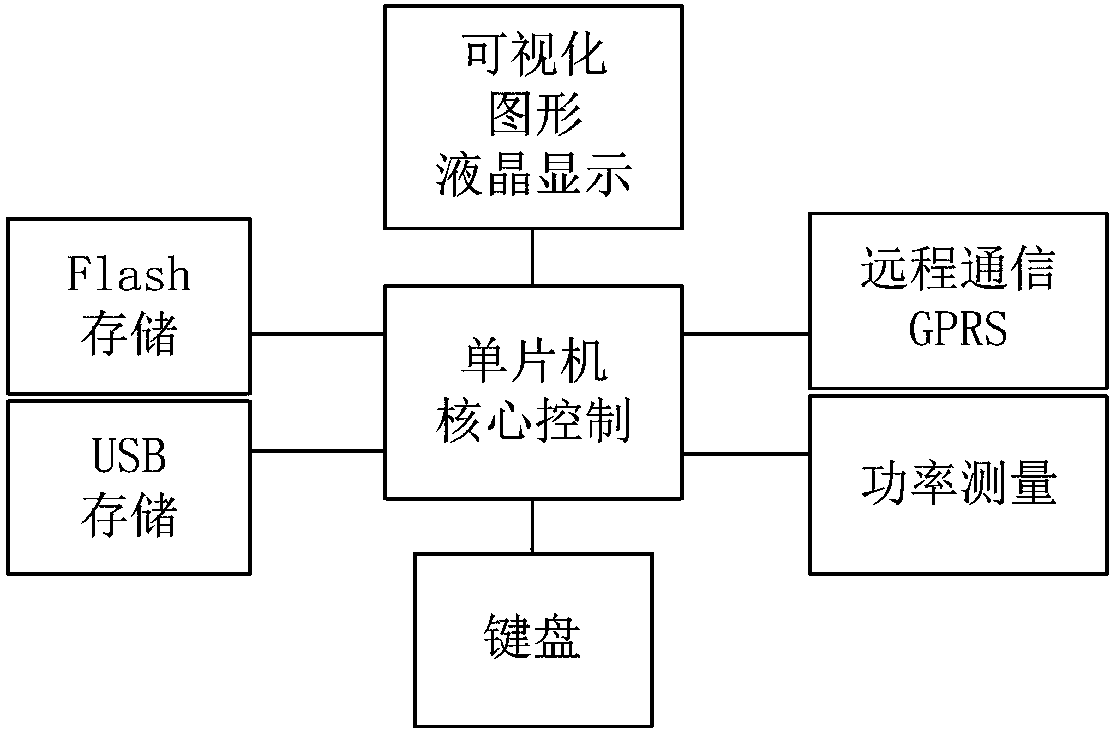

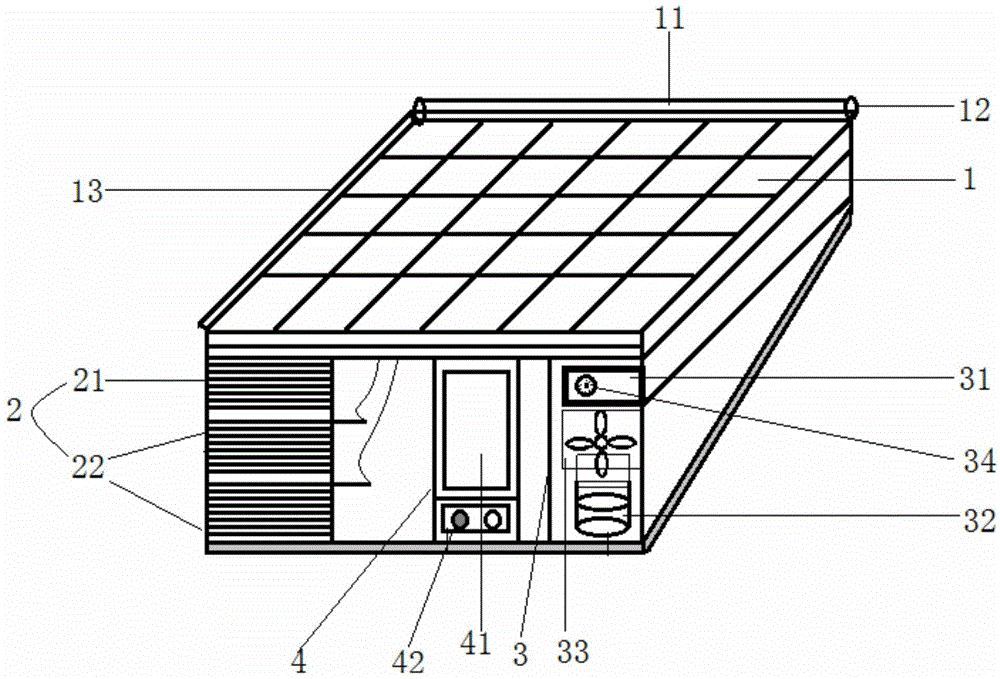

Local and remote dual-purpose oil pumping unit automatic control equipment based on visual control console

PendingCN108825171AVisible and easy to operateEasy to digitizeProgramme controlComputer controlAutomatic controlCommunication unit

The invention discloses local and remote dual-purpose oil pumping unit automatic control equipment based on a visual control console. The local and remote dual-purpose oil pumping unit automatic control equipment is composed of an automatic control equipment box body, a visual control console VC unit, a power driving unit and a communication interface of the VC unit and the power driving unit. Theequipment can achieve local use and remote use and has the advantages of visualization, digitalization and intelligence. The VC unit adopts a single chip microcomputer as a core digital unit. The equipment further comprises a visual liquid crystal display unit, a power state measuring unit, a keyboard, a local serial communication unit facing the power unit, a flash storage unit, a USB interfaceunit and a remote GPRS communication unit facing a control center. The local and remote dual-purpose oil pumping unit automatic control equipment has the advantages of visualization, digitalization, intelligence and the like.

Owner:秦皇岛美城润麒自控设备有限公司

Vehicle solar energy automatic memory

InactiveCN105634403AWith power supplyWith storage capacityPhotovoltaicsEnergy storageSolar energy storageControl circuit

The present invention discloses a vehicle solar energy automatic memory. The vehicle solar energy automatic memory comprises a solar energy receiving board, a solar energy storage battery, a control circuit and a control device. The solar energy receiving board includes groups of solar energy receiving machines, a protection curtain is arranged at the outer side of the solar energy receiving board, and rolling blind machines are arranged at two sides of the protection curtain; the solar energy storage battery includes three groups of storage batteries, the first group of storage batteries is a backup storage battery, and two groups of power supply batteries are arranged at the lower side of the backup storage battery; and the control circuit includes a control circuit board made by semiconductor silicon, a cooling electric fan is arranged at the lower side of the control circuit board, and a silencing device is installed at the upper portion of the cooling electric fan. The vehicle solar energy automatic memory has advantages of power supply and electric quantity storage, can be used in overcast and rainy weather, has automatic opening and closing functions, may be controlled through controlling a device, and is more humanized.

Owner:HARBIN JUJIXUAN SCI & TECH DEV CO LTD

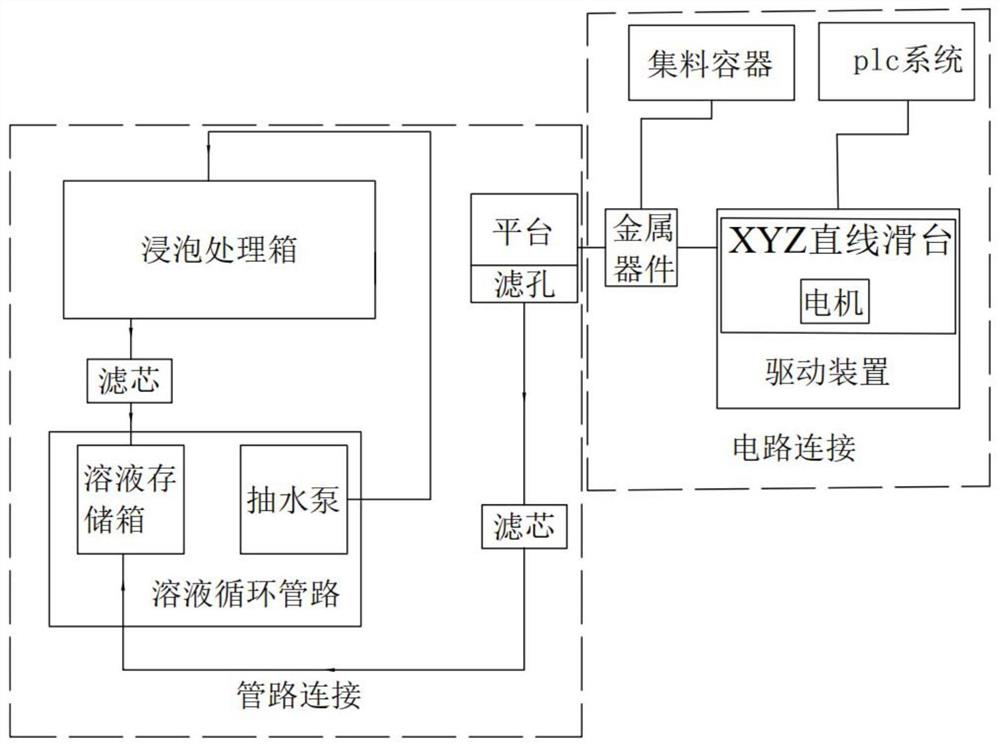

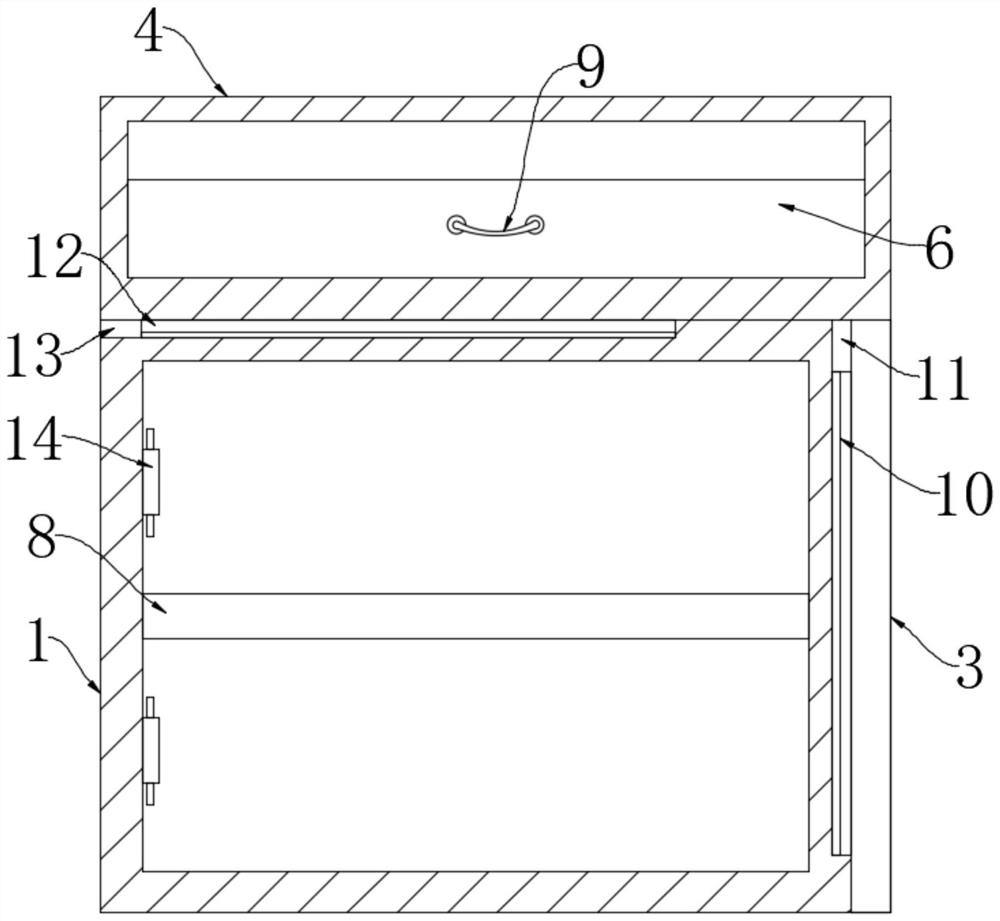

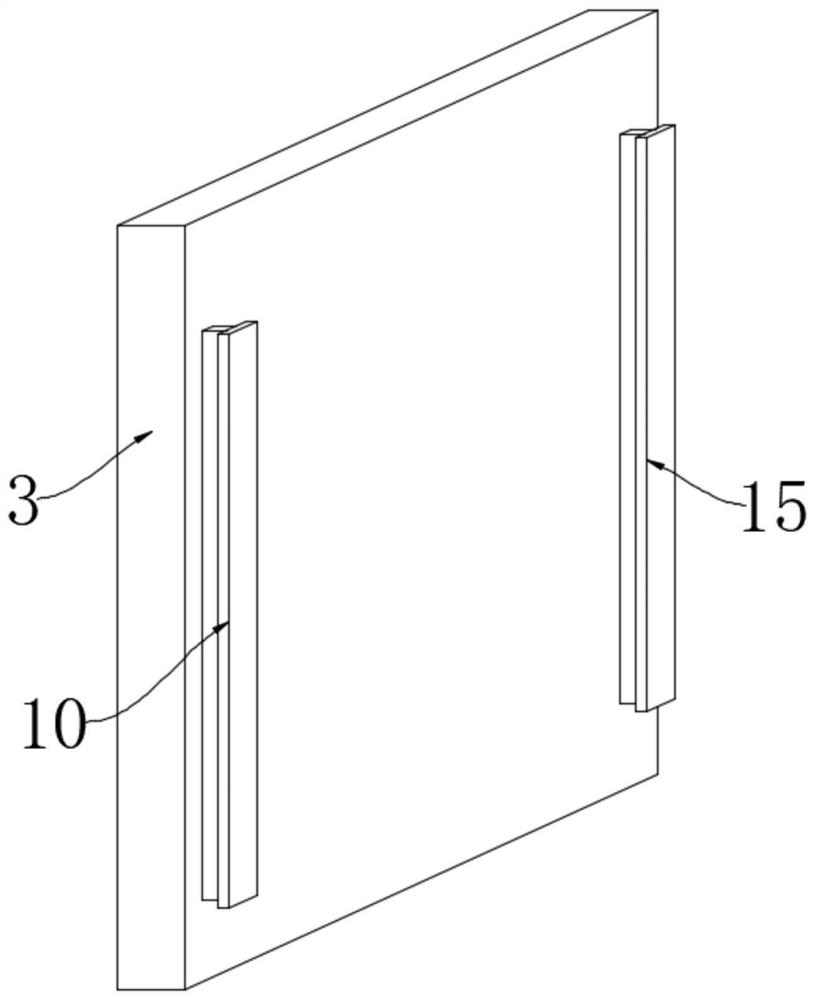

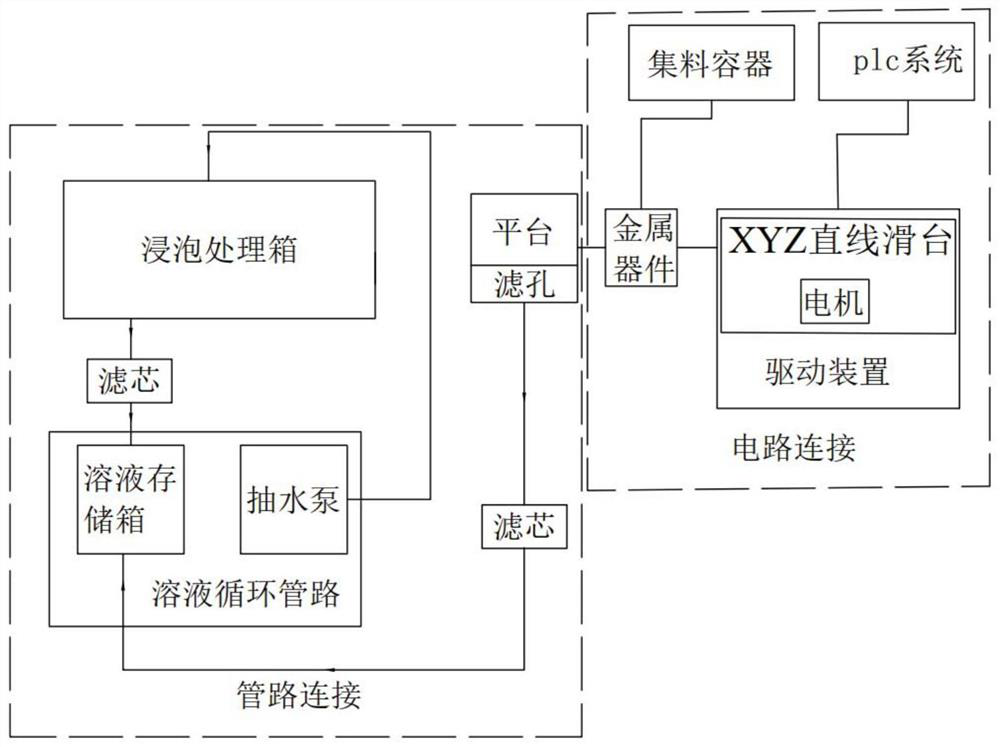

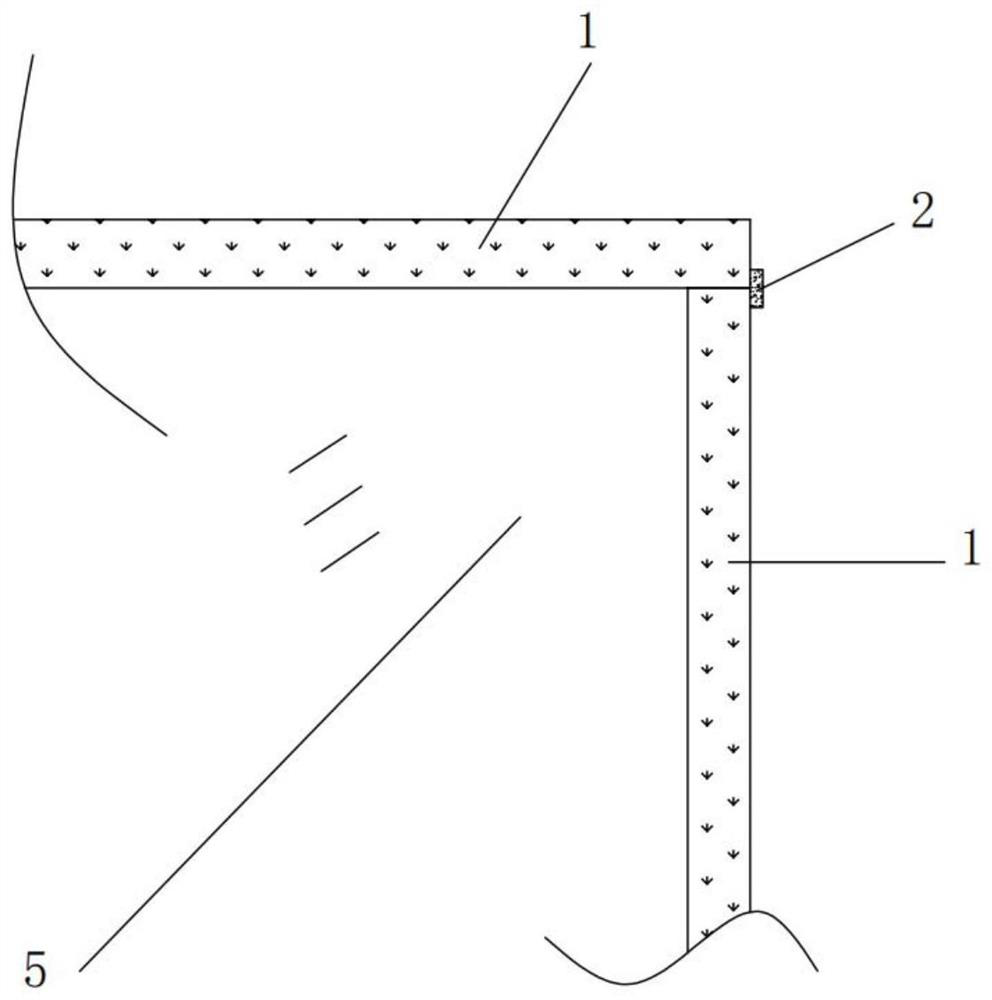

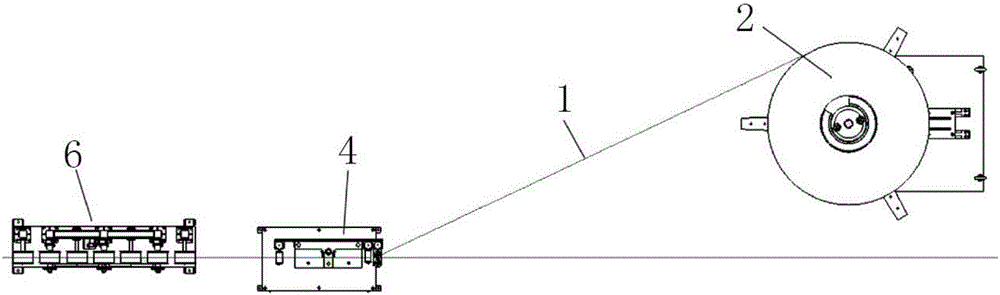

Batch recovery process and equipment for preparing membrane electrode catalyst by spraying method

ActiveCN112542594AAvoid damageAvoid accumulationFuel cells disposal/recyclingFinal product manufacturePtru catalystFuel cells

The invention discloses a batch recovery process and equipment for preparing a membrane electrode catalyst by a spraying method. According to the invention, a catalyst exceeding a spraying area in a spraying process is recovered; before the catalyst layer is prepared, the auxiliary equipment is completely coated with a carrier sheet, it is guaranteed that catalyst slurry completely falls on the carrier sheet outside an effective area, and then efficient recovery of the catalyst adhering to hardware auxiliary equipment such as a clamp is achieved through the procedures of soaking, scraping, collecting, washing and vacuum drying. The cost is reduced, and meanwhile, the air environment pollution is reduced. Meanwhile, the invention further discloses batch recovery equipment for the fuel cellcatalyst, which can achieve batch work of the catalyst recovery method, improve the working efficiency, increase the utilization rate of raw materials in production, and reduce the manufacturing cost.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

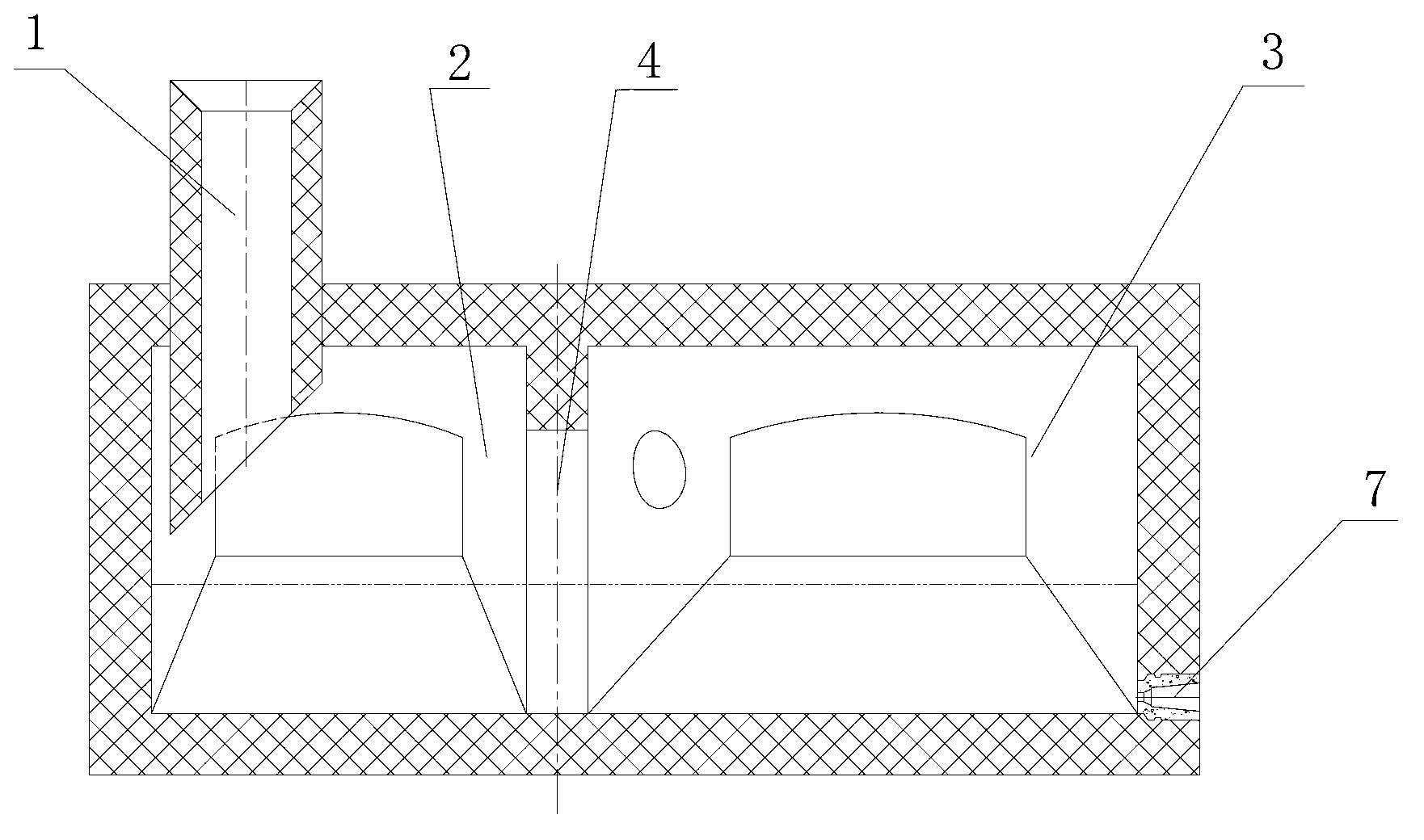

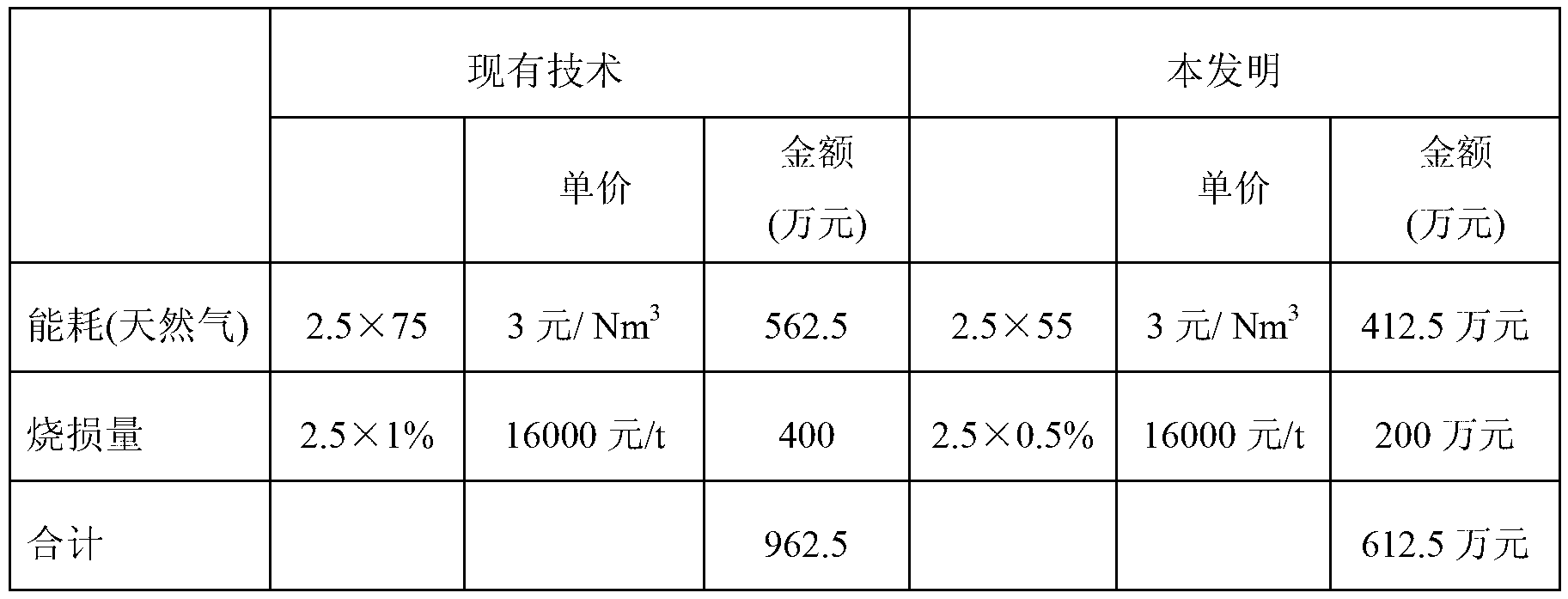

Method of transferring and pouring aluminum liquid in process of preparation of electrician round aluminum rod

ActiveCN103162539AReduce lossesImprove thermal efficiencyCharge manipulationHeat lossesMelting furnace

The invention provides a method of transferring and pouring aluminum liquid in the process of preparation of an electrician round aluminum rod. The method of transferring and pouring the aluminum liquid in the process of the preparation of the electrician round aluminum rod includes the following steps: A, monitoring the amount of the aluminum liquid in a melting furnace, wherein the temperature of the aluminum liquid is 720-760DEG C; B, opening a dewatering outlet of the melting furnace in order to enable the aluminum liquid to be transferred and poured into a maintaining furnace through a flow groove and a water inlet of the maintaining furnace from the dewatering outlet of the melting furnace when the quantity of aluminum liquid reaches a rated quantity, and keeping the dewatering outlet of the melting furnace closed when the aluminum liquid does not need to be transferred and poured; and C, closing the dewatering outlet when the quantity of the aluminum liquid in the maintaining chamber reaches a rated quantity. According to the method of the transferring and pouring the aluminum liquid in the process of preparation of the electrician round aluminum rod, the melting furnace is capable of storing the liquid and heating up, the dewatering outlet in the bottom of the melting furnace keeps closed, only when the aluminum liquid needs to be transferred and poured, the dewatering outlet is opened, once transferring and pouring of the aluminum liquid is achieved, and heat loss is reduced.

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

Method of melting aluminum ingot in process of preparation of electrician round aluminum rod

The invention provides a method of melting an aluminum ingot in the process of preparation of an electrician round aluminum rod. The method of melting the aluminum ingot in the process of the preparation of the electrician round aluminum rod includes the following steps: A, filling the aluminum ingot in a shaft furnace, wherein the shaft furnace is communicated with a melting chamber, the aluminum ingot is heated in a smoke waste heat environment in the shaft furnace, and the temperature of smoke of an inlet of the shaft furnace is 800-1000DEG C; B, enabling aluminum liquid melted in the melting chamber to be stored at the bottom of the melting chamber and the bottom of a heating chamber through a channel between the melting chamber and the heating chamber, and soaking the aluminum ingot moving downward from the shaft furnace into the aluminum liquid at the bottom of the melting chamber; C, starting a main burner of the heating chamber, wherein the main burner heats the aluminum liquid in the heating chamber; and D, enabling high-temperature smoke of the heating chamber to enter the melting chamber through the channel between the melting chamber and the heating chamber, heating the aluminum liquid in the melting chamber and melting the ingot through the high-temperature smoke, and preheating the aluminum ingot filled in the shaft furnace after the high-temperature smoke enters the shaft furnace. The method of melting the aluminum ingot in the process of the preparation of the electrician round aluminum rod not only utilizes the smoke waste heat to melt and preheat the aluminum ingot and improves the heat efficiency but also achieves soaking type melting and reduces burnt loss.

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

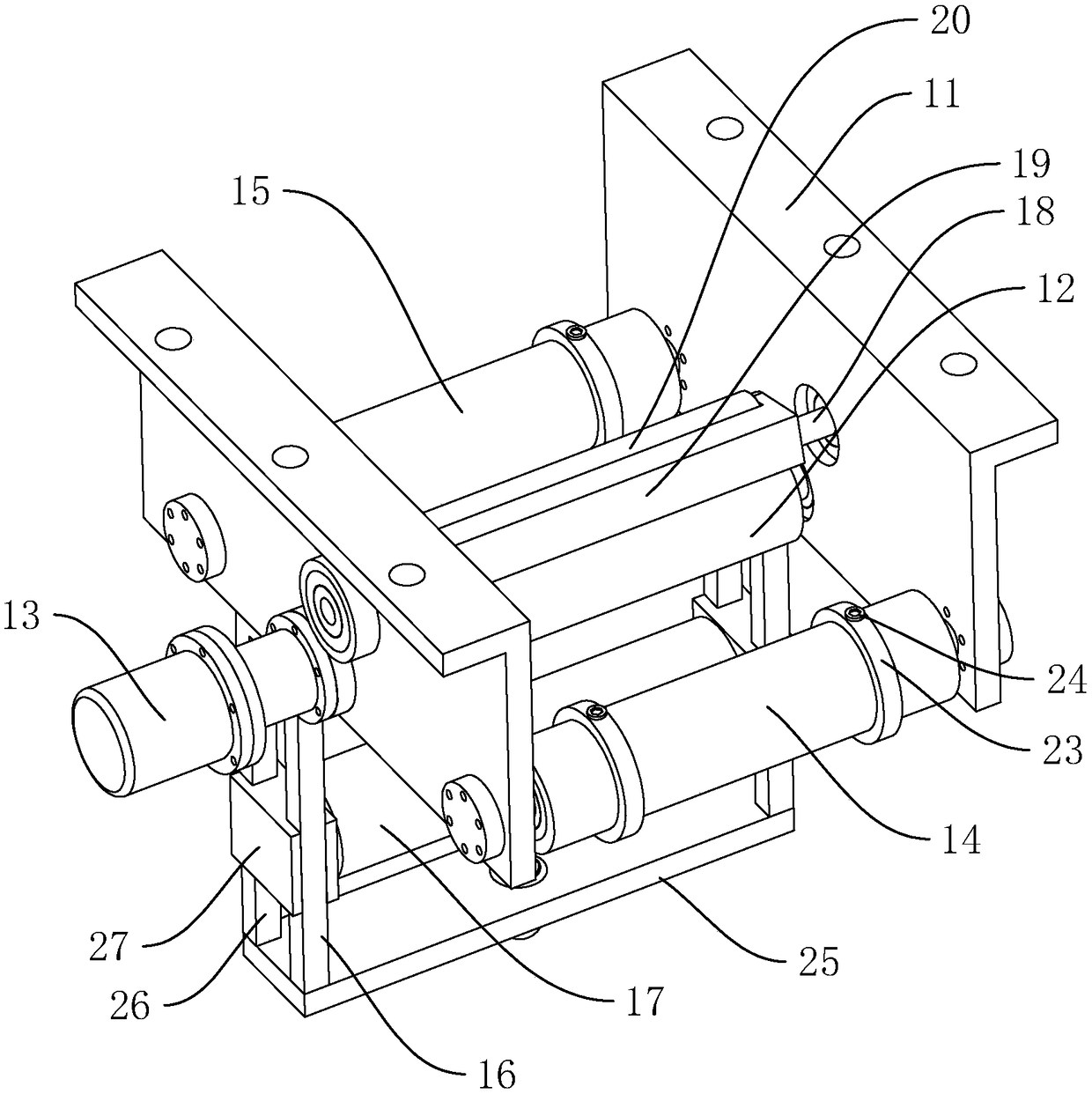

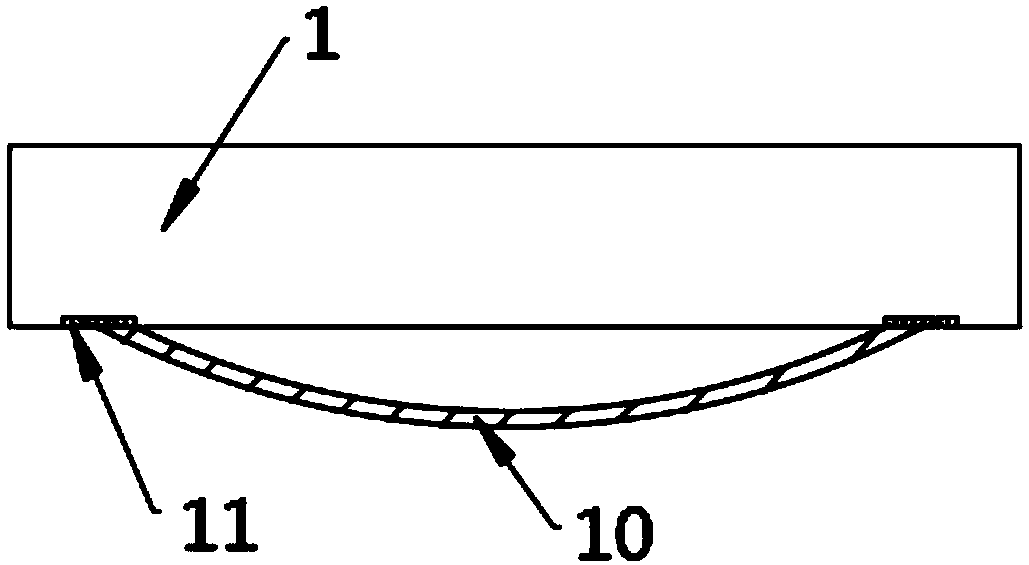

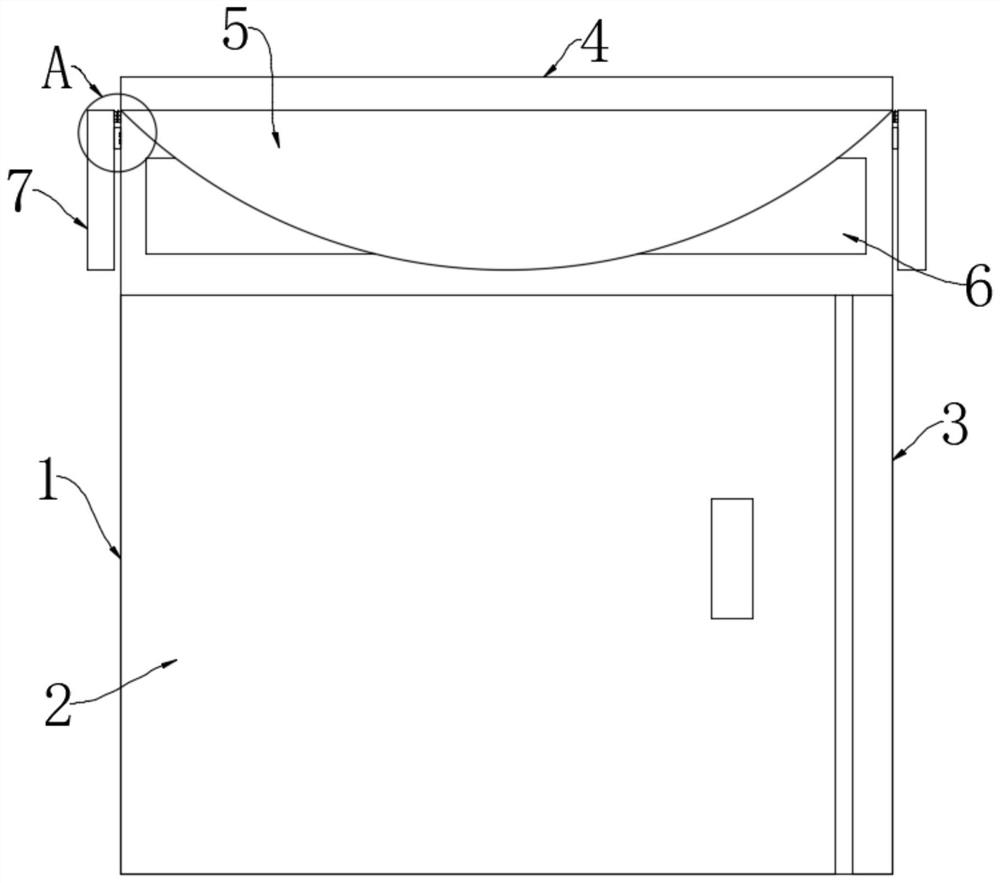

Packaging paper traction mechanism used for packaging paper feeding device

PendingCN109455326APrevent sidewaysReduce the risk of slippingWrapping material feeding apparatusLiquid materialPulp and paper industry

The invention discloses a packaging paper traction mechanism used for a packaging paper feeding device, relates to a filling machine and aims at solving the problem of not controlling the traction mechanism easily due to high coordination requirement with other devices of the filling machine. The technical scheme is as follows: a packaging paper traction mechanism used for a packaging paper feeding device comprises two relative plates, a friction roller rotationally connected with the two relative plates and a servo motor used for driving the friction roller; a paper inlet guide roller and a paper outlet guide roller are also arranged between the two relative plates; the friction roller is located between the paper inlet guide roller and the paper outlet guide roller; the two relative plates are respectively, vertically and fixed provided with travel guide plates between the friction roller and the paper outlet guide roller; and a gravity pressure roller slips between the two travel guide plates and is rotationally connected with the two travel guide plates. With the storage capacity of the packaging paper, the packaging paper traction mechanism used for the packaging paper feedingdevice provided by the invention can adapt to the intermittent filling machine without starting the servo motor, so the technical effect of convenient control can be achieved.

Owner:浙江旭翔机械科技有限公司

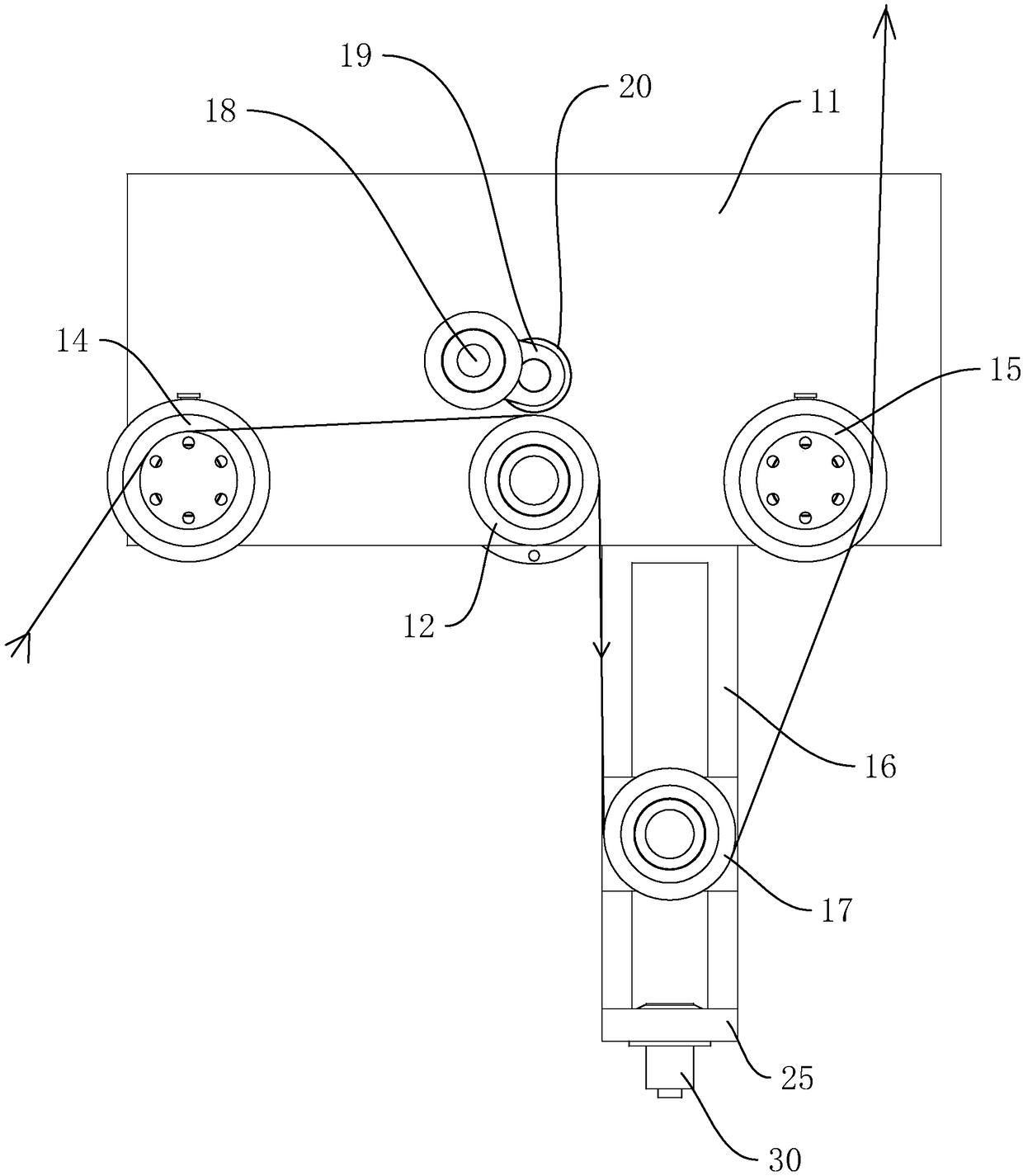

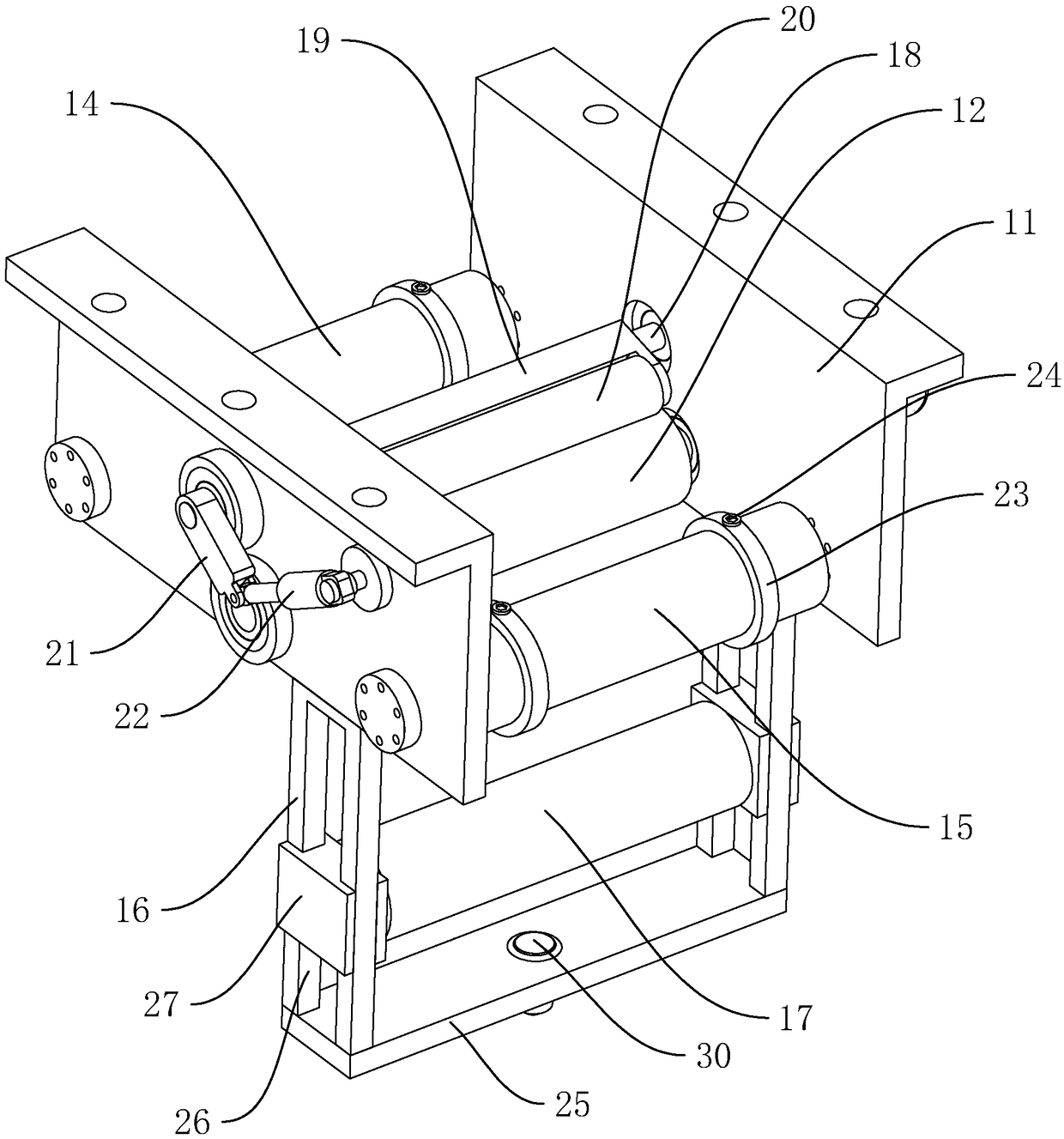

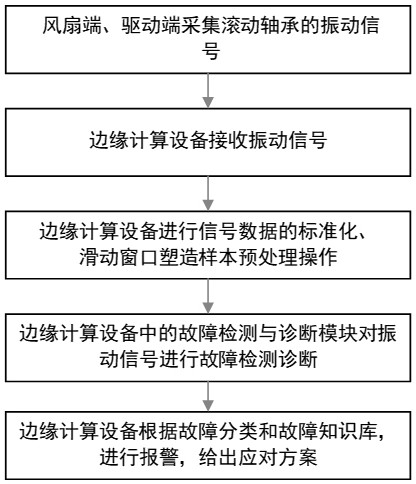

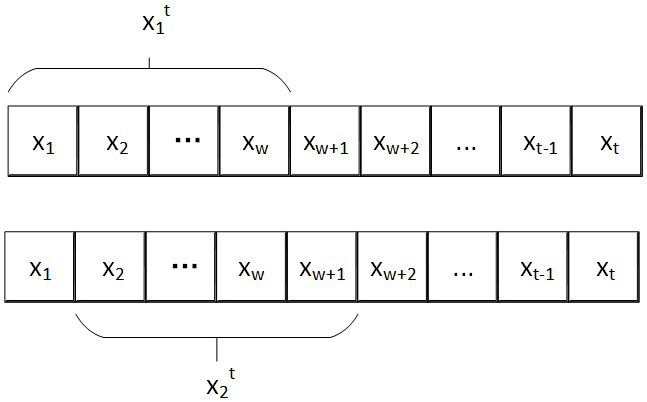

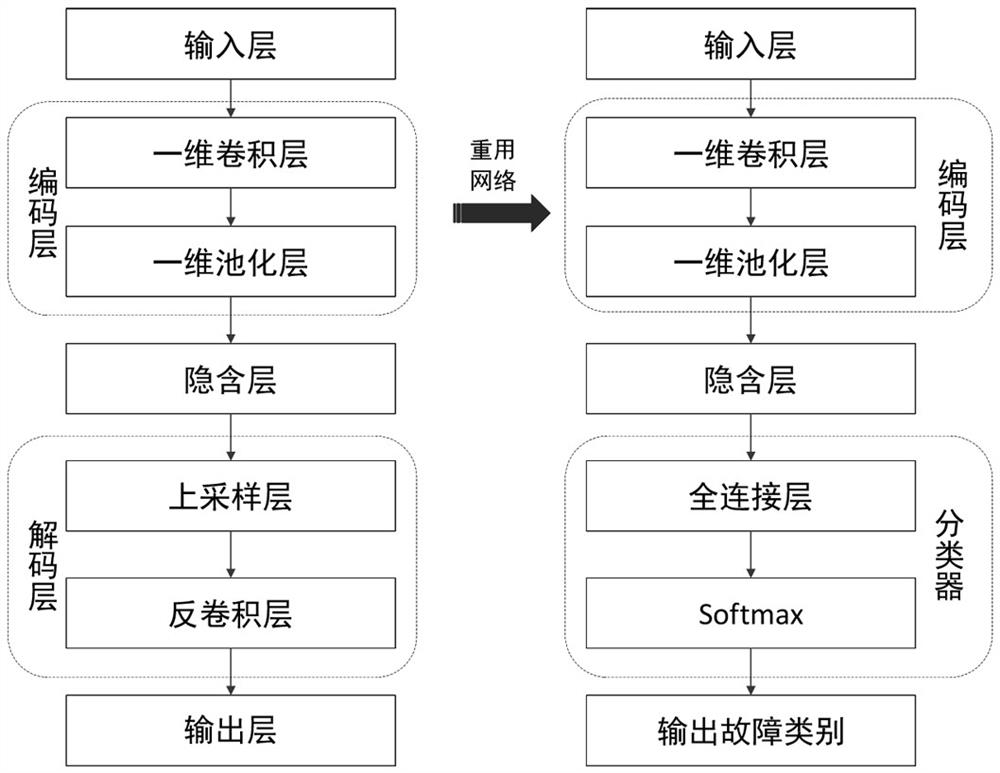

Rolling bearing fault diagnosis method and system combining edge calculation and deep learning

PendingCN113758709AEasy accessEfficient use ofMachine part testingCharacter and pattern recognitionEdge computingData source

The invention discloses a rolling bearing fault diagnosis method and system combining edge calculation and deep learning, and the method comprises the steps: enabling a data preprocessing module in edge calculation equipment to carry out the preprocessing of a collected vibration signal of a rolling bearing, and obtaining sample data; performing fault diagnosis and classification on the sample data obtained through preprocessing in the previous step by using a fault detection and diagnosis module based on deep learning in the edge computing equipment; storing a fault processing knowledge base in the edge computing device, and giving an alarm signal and a coping scheme according to the fault category. The system comprises a signal acquisition module, a signal transmission module, and an edge computing device carrying a data preprocessing module, a fault detection and diagnosis module and a fault processing knowledge base, wherein the edge computing device is arranged at a data source. According to the method, edge calculation and deep learning are combined, the response speed and accuracy of rolling bearing fault diagnosis are improved, and real-time performance and intelligence are met.

Owner:HENAN UNIV OF SCI & TECH

An anchor fixing device

The invention discloses a ground anchor fixing device. One side of a fixing device body is provided with a first handle. The outer side of the middle of the first handle is sleeved with a first rubber cover. Another side of the fixing device body is provided with a handle groove which is internally provided with a first rotary shaft cover. A first rotary shaft is sleeved with the first rotary shaft cover. One end of the first rotary shaft is connected with a second handle. The outer side of the middle of the second handle is sleeved with a second rubber cover. A storage net is arranged in the middle of the bottom end of the fixing device body. In the operating process, the fixing device is convenient to hold and carry and has the storage capacity to a certain extent, and damage to the fixing device caused by fuel starvation can be conveniently prevented; by adoption of a half-and-half combined mode, an expanded head is inlaid in the fixing device and externally fixed with a nut, operation is easy and convenient, the fixing device is kept on the same straight line all the time in the whole force-transfer process, time and labor are saved, machining is convenient, and cost is not high.

Owner:FUJIAN YONGZHENG CONSTR QUALITY INSPECTION CO LTD

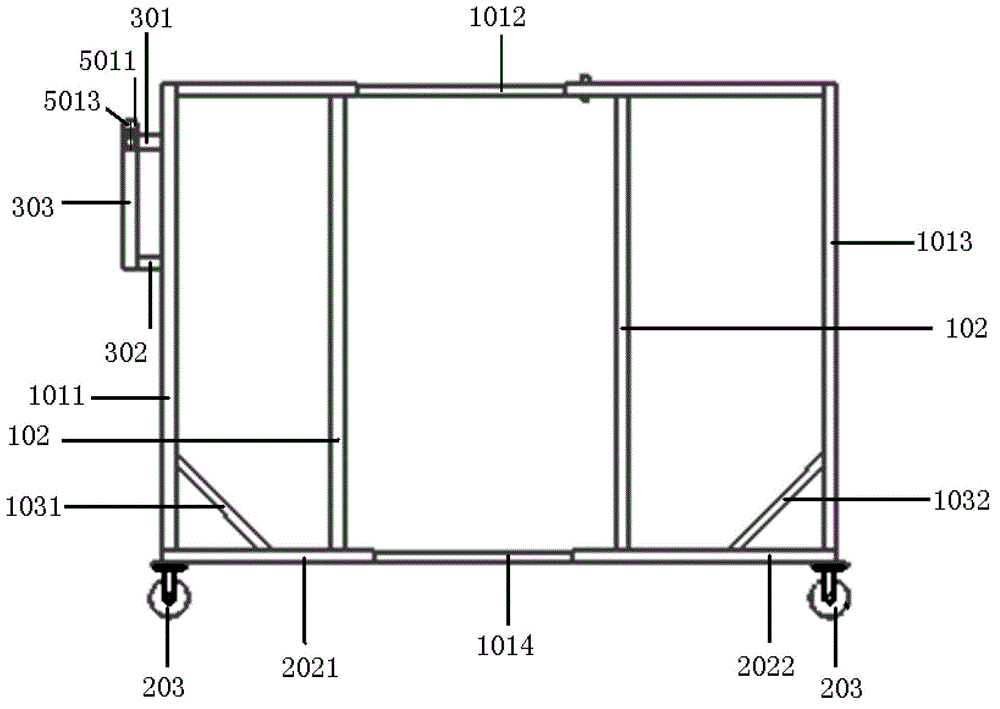

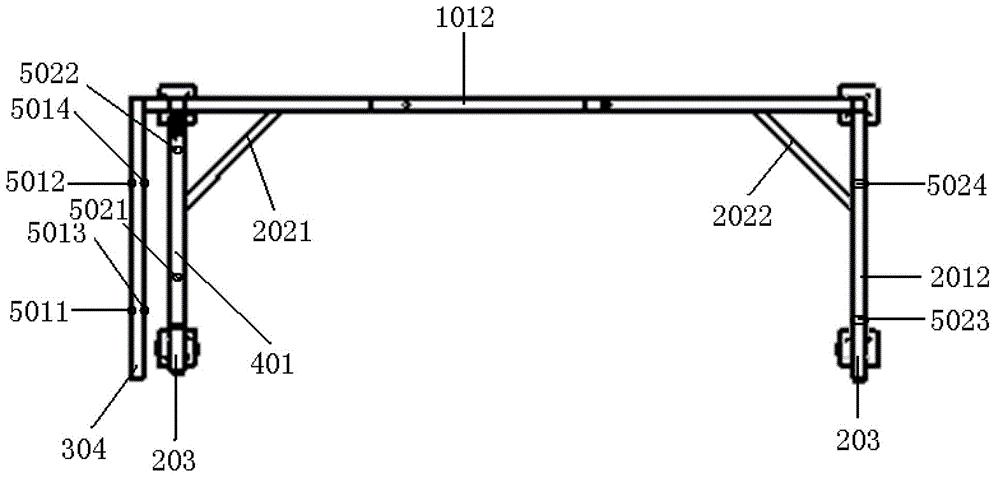

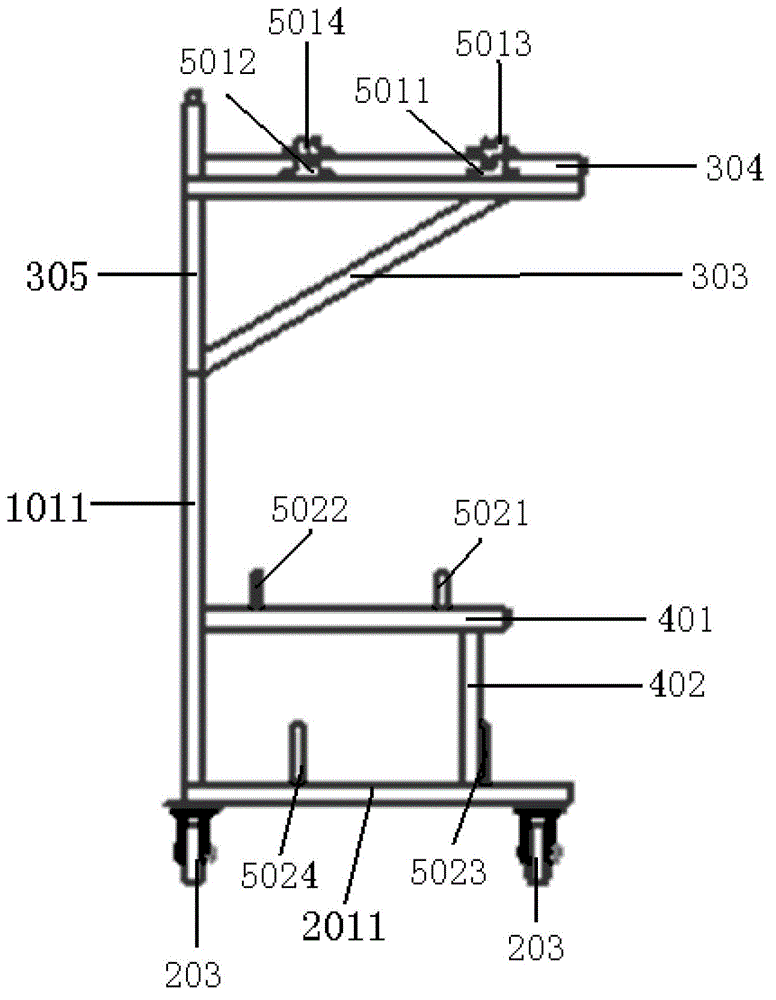

Automobile side wall flowing instrument

ActiveCN103331743BMove doesn't happenSimple structureWork tools storageOther workshop equipmentProduction lineWork cycle

The invention discloses an automobile side wall flowing instrument. The automobile side wall flowing instrument comprises a movable frame, an upper supporting structure which is used for fixing upper ends of at least two automobile side walls, and a lower supporting structure which is used for fixing lower ends of the at least two automobile side walls. The automobile side wall flowing instrument can transport multiple automobile side walls once, has a certain storage capability, and can satisfy the working cycle of the production line; as each automobile side wall is fixed on the flowing instrument, each automobile side wall can be prevented from being bumped and damaged during transporting process; and the flowing instrument is simple in structure, low in cost, economic and practical, and can satisfy requirements and save investment.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

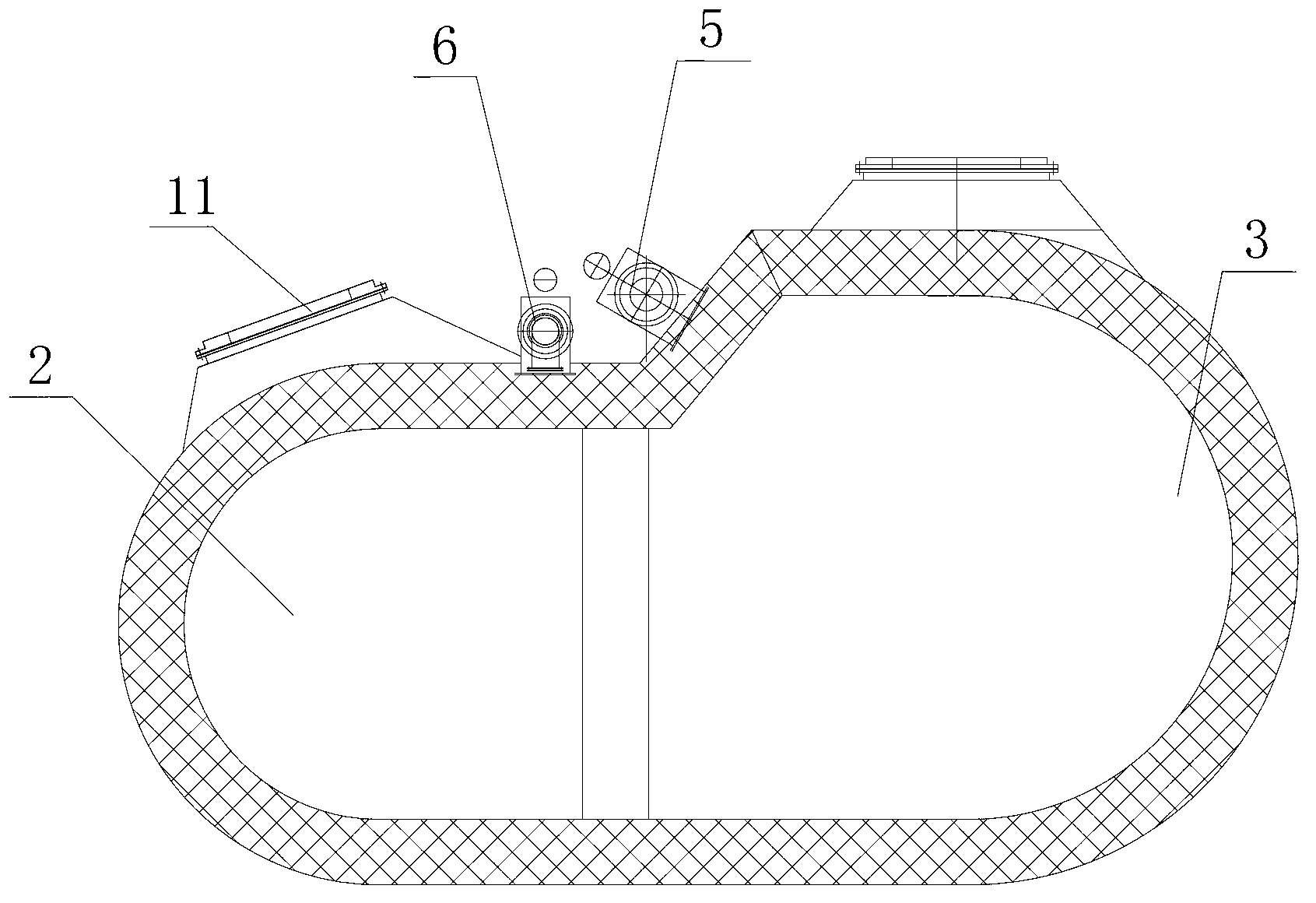

Pollutant suction system applied to vacuum toilet

The invention discloses a pollutant suction system applied to a vacuum toilet. The system comprises two vacuum negative pressure tanks which are in air pressure communication through a connecting pipe, one vacuum negative pressure tank is an adsorption tank used for sucking pollutants and temporarily storing the pollutants, the other vacuum negative pressure tank is a pressure supply tank for supplying vacuum negative pressure to the adsorption tank, a constant pressure device is arranged on the connecting pipe, a pollutant inlet pipe used for sucking the pollutants and a pollutant dischargingpipe used for discharging pollutants are arranged on the adsorption tank, a vacuum stop valve is arranged on a pollutant inlet pipe, and an exhausting pipe used for extracting air is arranged on thepressure supply tank. With the adoption of the structure, the adsorption tank can always keep higher pollutant adsorption capability, requirements for the power supply environment are reduced, and thevacuum toilet can be really promoted and popularized.

Owner:CHENGDU QIANJI ENTERPRISE MANAGEMENT CONSULTING CO LTD

Foldable multifunctional small storage cabinet

PendingCN111955928ASave spaceEasy to classifyExtensible tablesFolding cabinetsStructural engineeringMechanical engineering

Owner:宁波米高家具有限公司

A batch recovery process and equipment for membrane electrode catalyst slurry

ActiveCN112542594BAvoid damageAvoid accumulationFuel cells disposal/recyclingFinal product manufacturePtru catalystFuel cells

The invention discloses a batch recovery process and equipment for membrane electrode catalyst prepared by spraying method, and recovers the catalyst beyond the spraying area during the spraying process; before preparing the catalytic layer, the auxiliary equipment is completely covered with a carrier sheet to ensure that all the catalyst slurry is outside the effective area. It falls on the carrier sheet, and then through processes such as soaking, scraping, collecting, washing, and vacuum drying, the efficient recovery of the catalyst adhered to the hardware auxiliary equipment such as fixtures is realized, which reduces the cost and reduces the pollution of the air environment; at the same time, the present invention Also disclosed is a fuel cell catalyst batch recovery device, which can realize the batch work of the catalyst recovery method, improve work efficiency, improve the utilization rate of raw materials in production, and reduce production costs.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

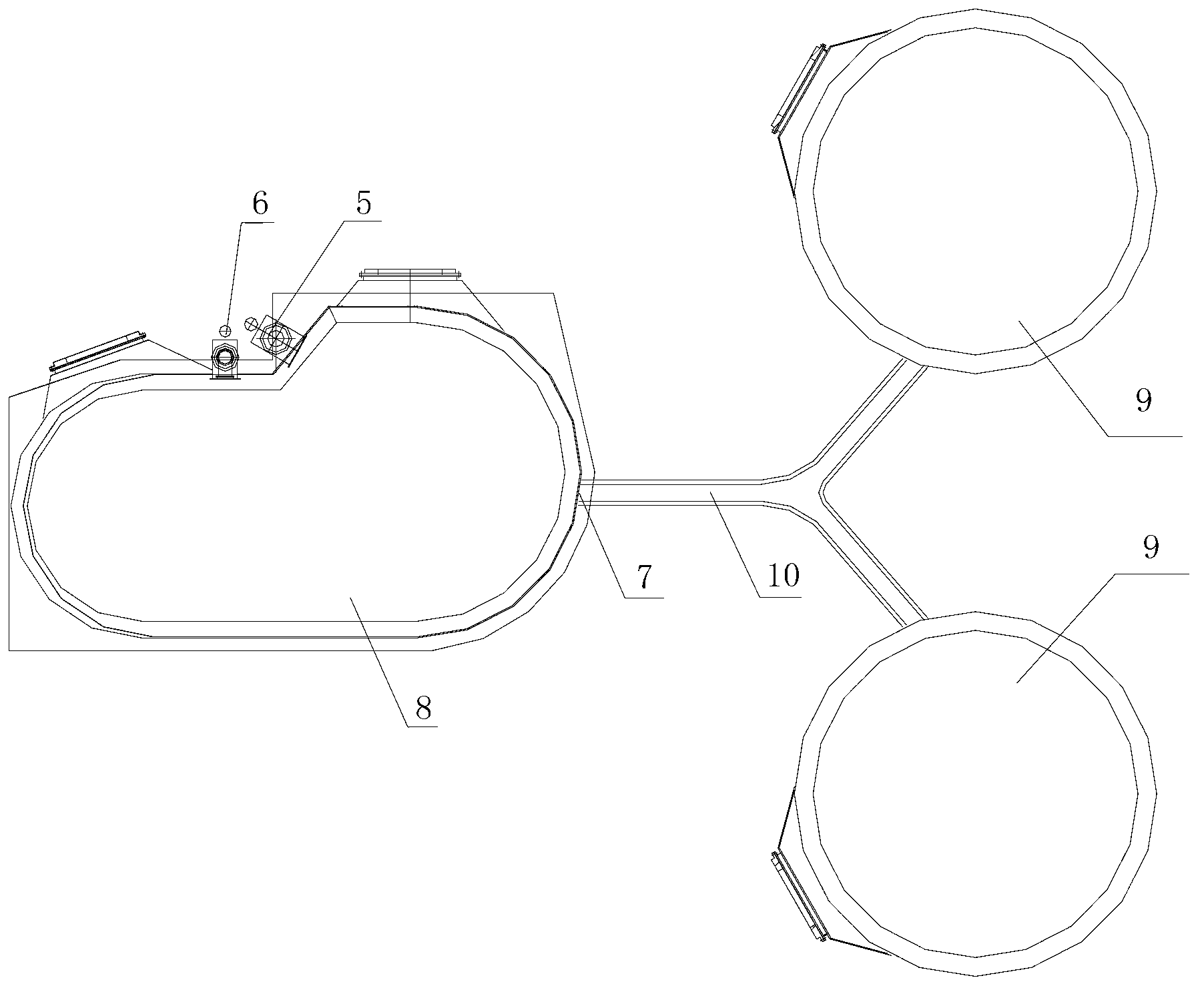

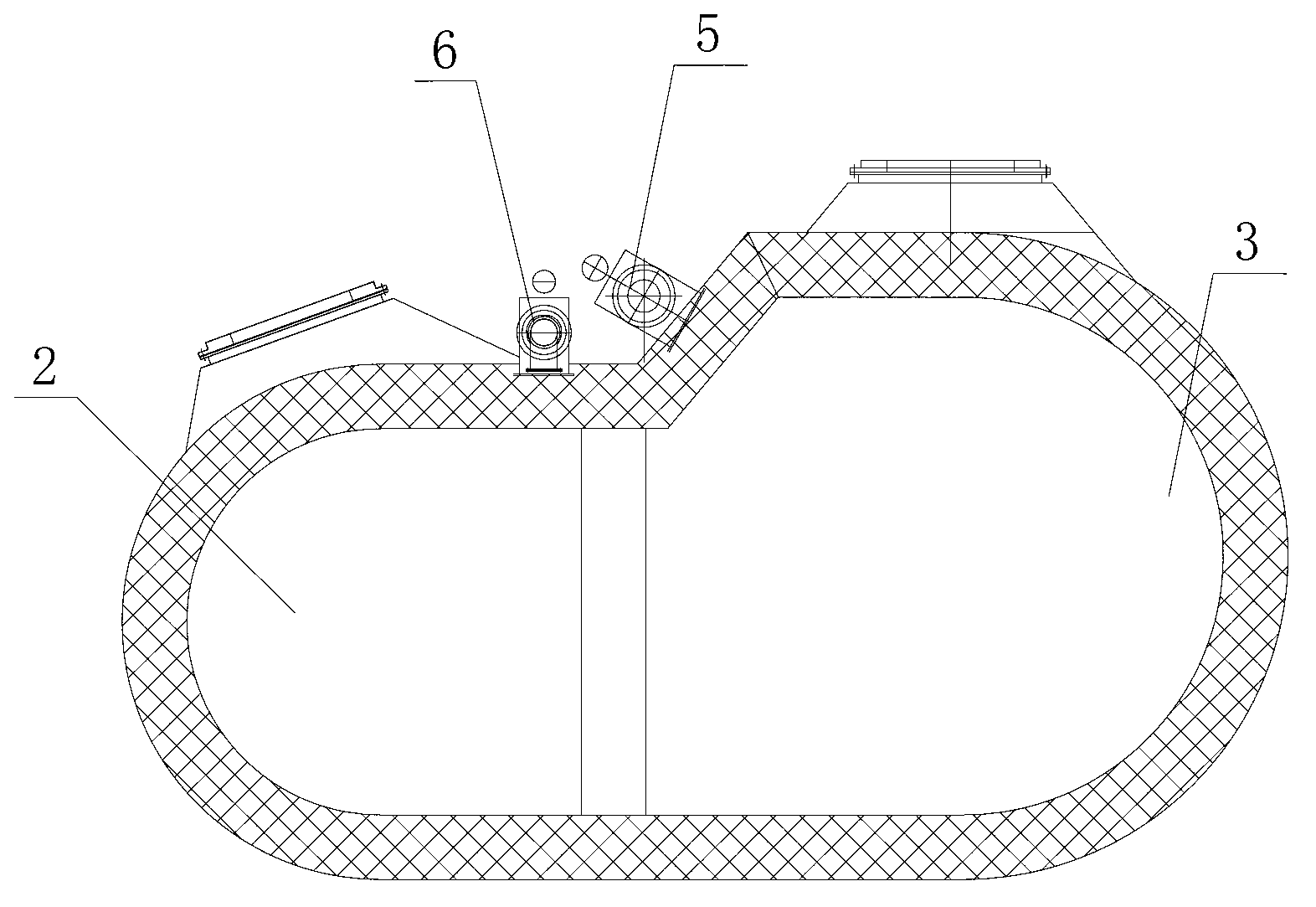

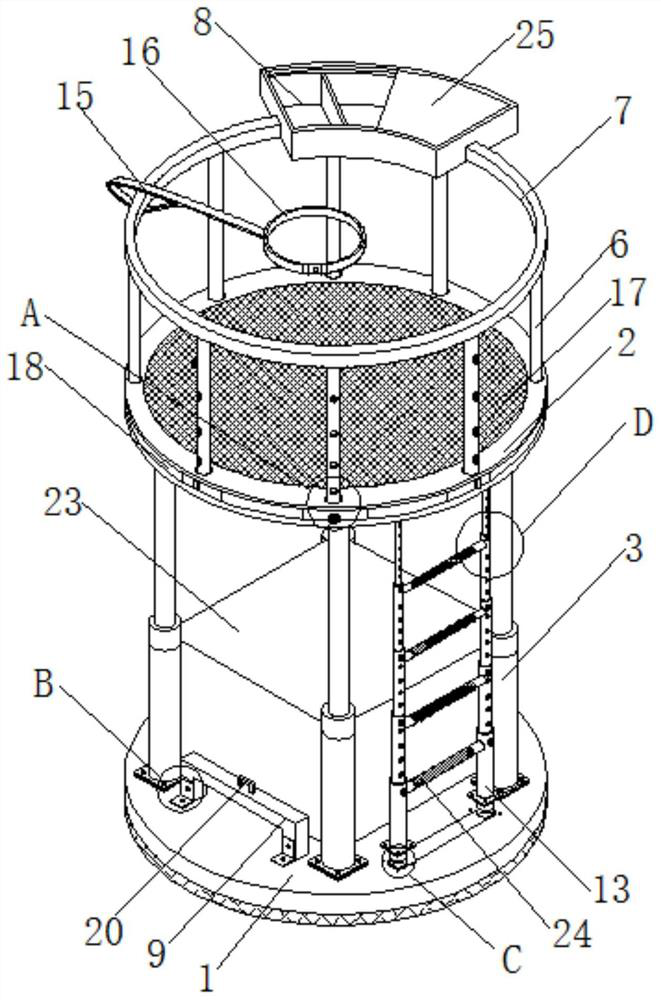

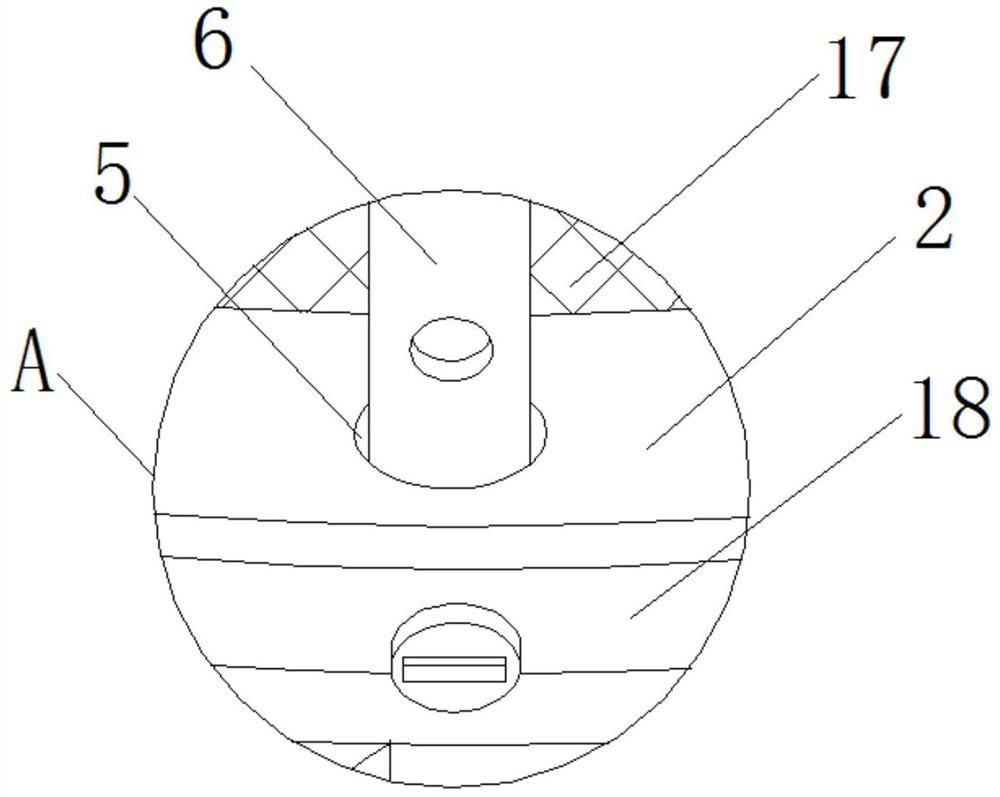

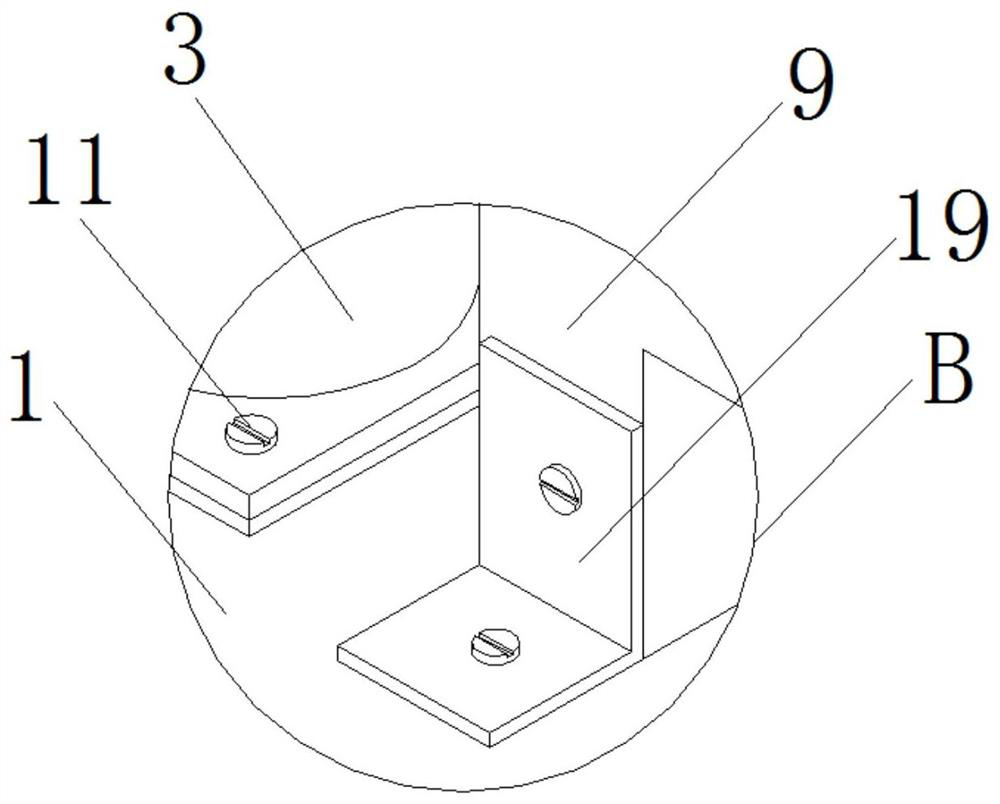

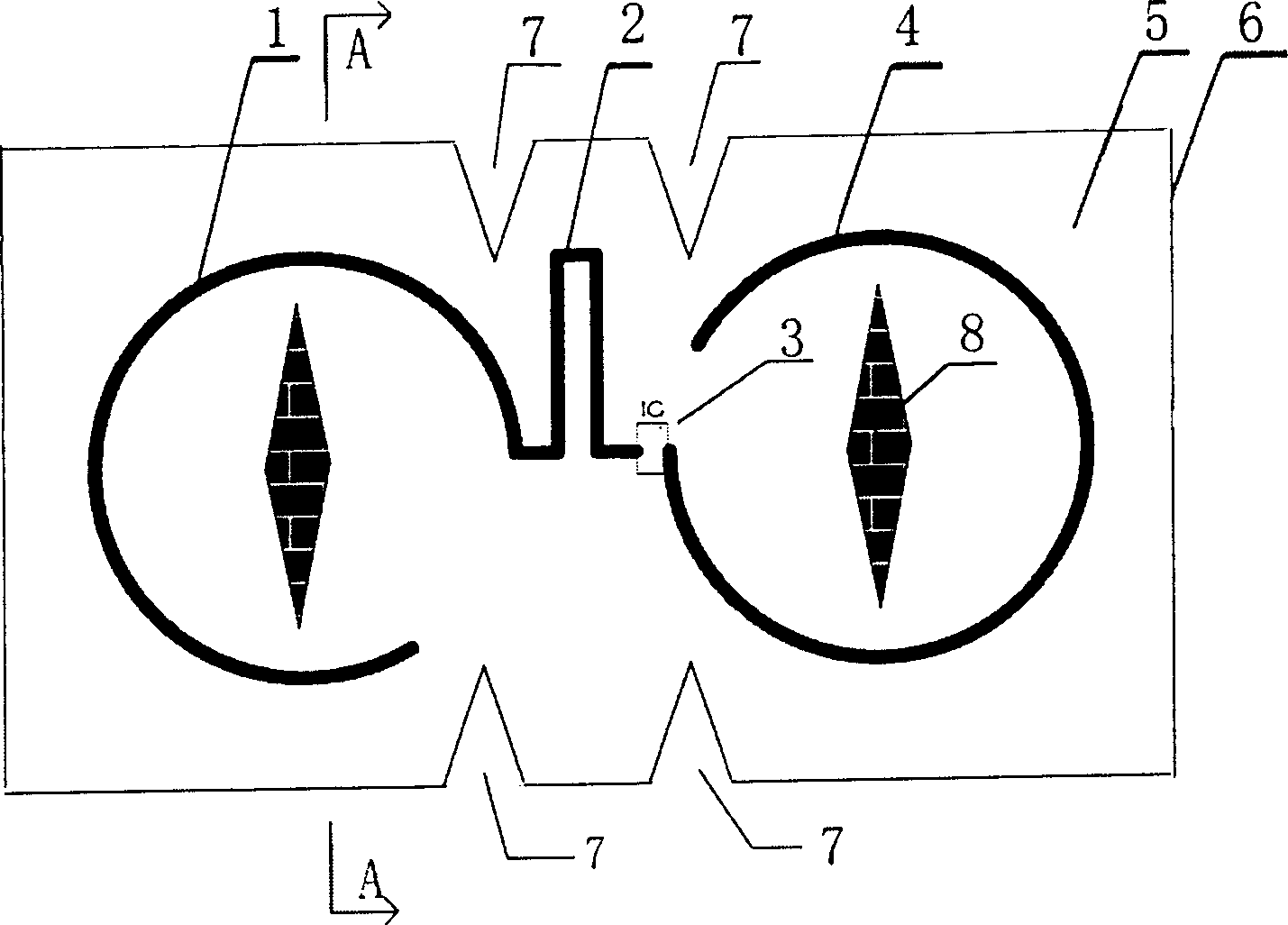

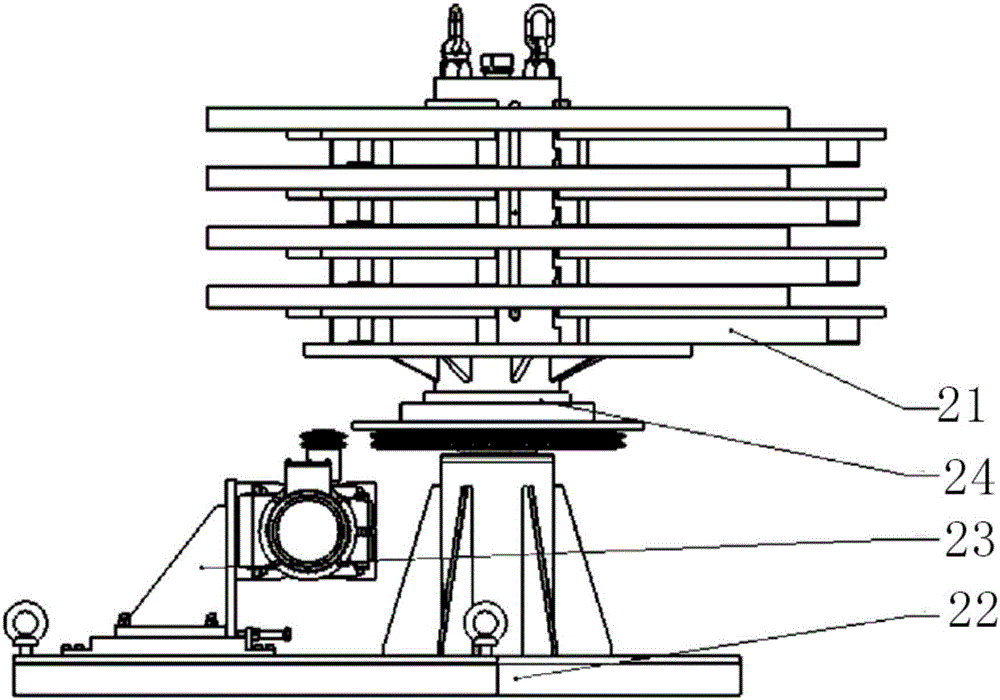

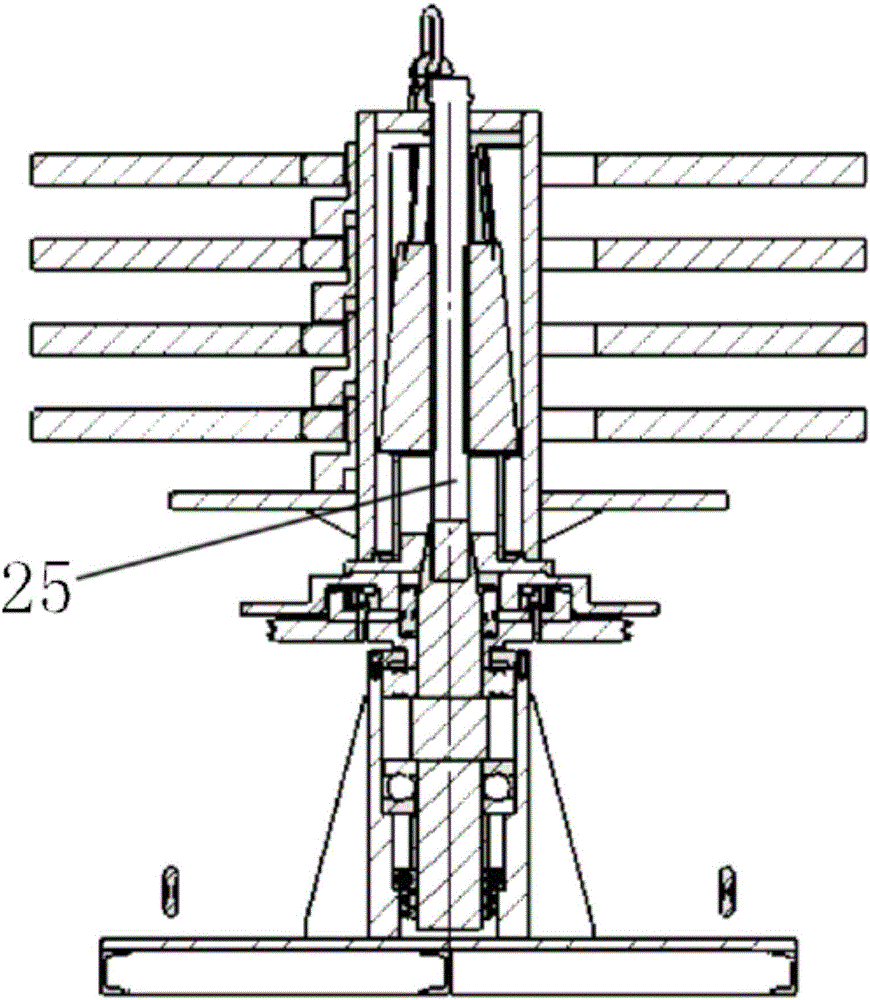

An energy-saving particle distribution device

ActiveCN106381352BReduce energy consumptionWith storage capacityRecycling and recovery technologiesEngineeringMechanical engineering

Owner:XI AN JIAOTONG UNIV

Lifting workbench for garden construction

InactiveCN112125250AImprove protectionEffective protectionSafety devices for lifting equipmentsStructural engineeringWorkbench

The invention relates to the technical field of garden construction auxiliary equipment, and discloses a lifting workbench for garden construction. The lifting workbench comprises a base and a workbench body, the top of the base is movably connected with a hydraulic rod through a bolt, the top of the hydraulic rod is fixedly connected with a reinforcing plate, the top of the reinforcing plate is fixedly connected with the workbench body, a round hole is formed in the surface of the workbench body, and a movable column is connected into the round hole in a sleeved mode. According to the liftingworkbench for garden construction, through the arrangement of a containing box and a sliding cover, when an operator operates, tools can be conveniently placed, the operator does not need to repeatedly bend down to taken the tools, through the arrangement of a movable frame and movable wheels, the movable wheels can be collected when a device stops, so that the situation that the device automatically moves due to the movable wheels, and the operator can be hurt is avoided, through the arrangement of a safety rope and a protection waistband, when the operator works, the operator can be effectively protected, and the safety of the device is greatly improved.

Owner:怀化都市麦田园林景观工程有限公司

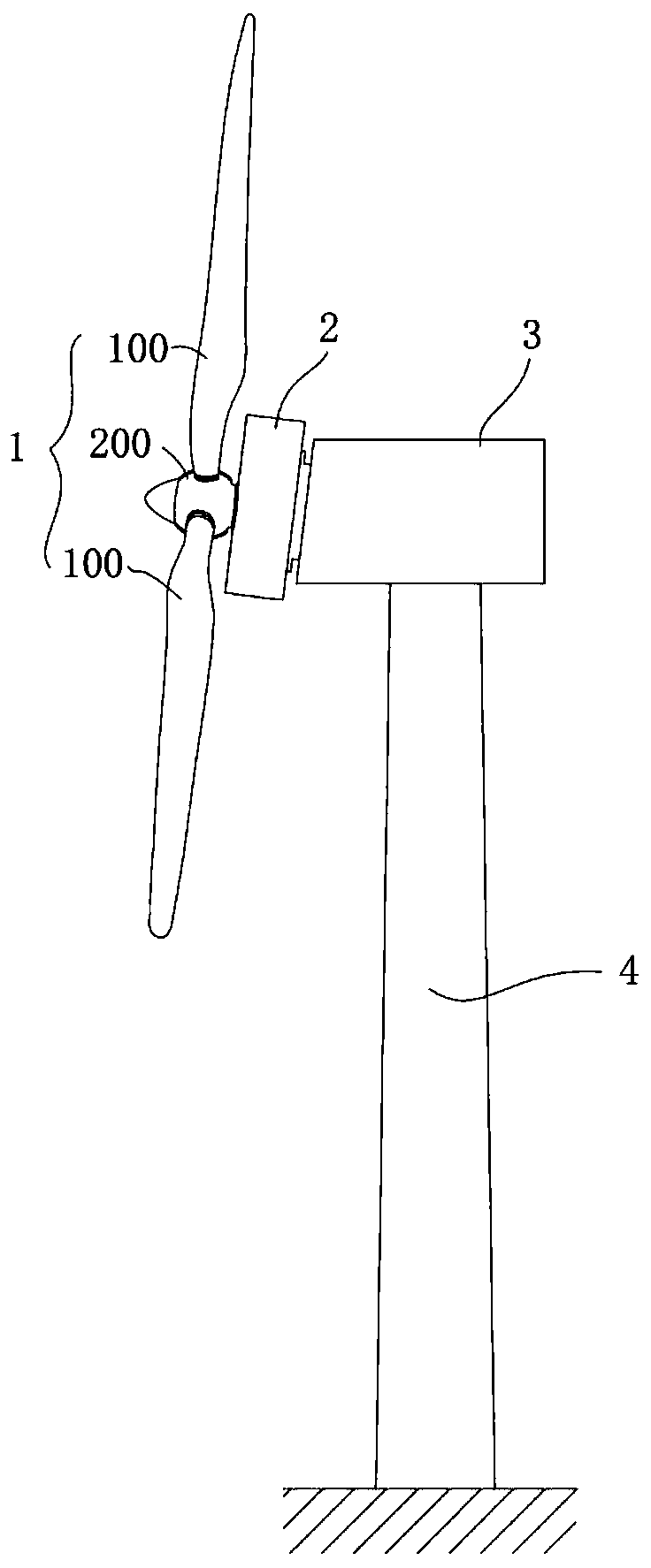

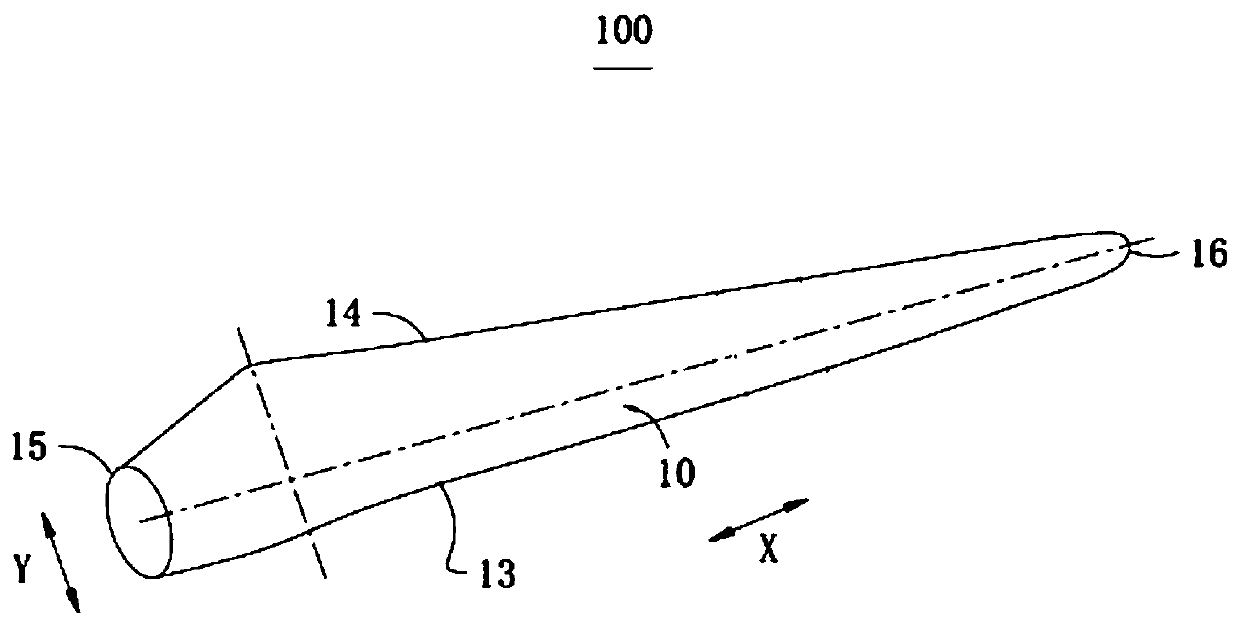

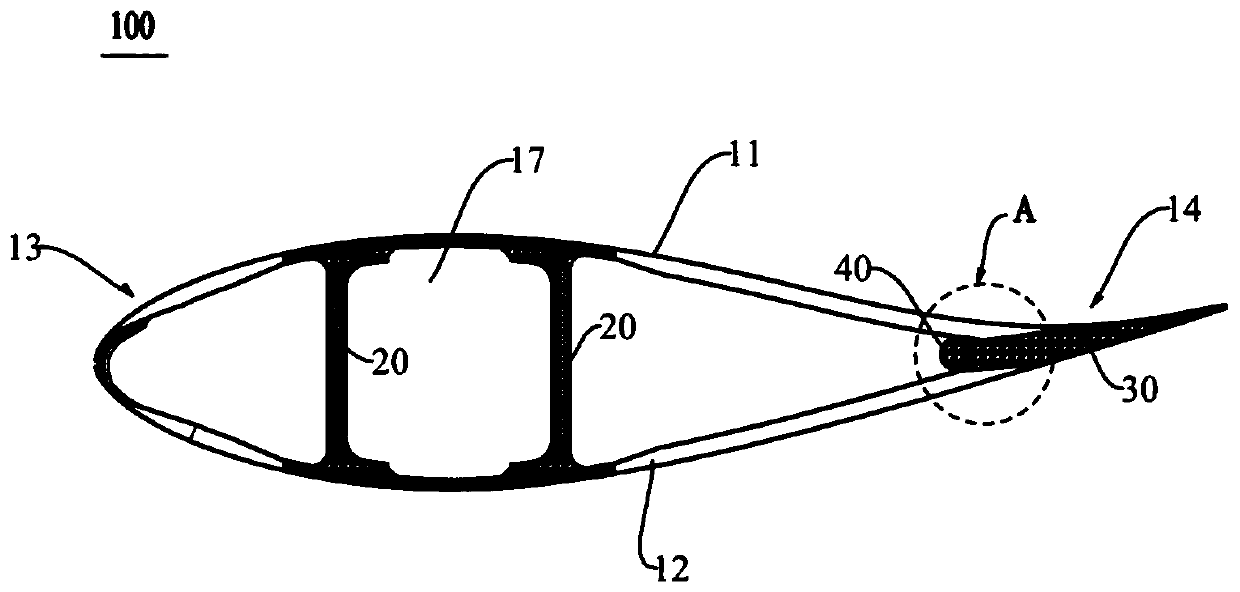

Glue blocking device, blade and blade forming method

PendingCN110388300AGuarantee production quality and service lifeWith storage capacityEngine manufactureMachines/enginesLong axisBiomedical engineering

The invention discloses a glue blocking device, a blade and a blade forming method. The glue blocking device is used for the blade, the blade comprises a windward side shell and a leeward face shell which are oppositely arranged, an adhesive bonding layer is arranged between the rear edge area of the windward side shell and the rear edge area of the leeward face shell, the glue blocking device comprises a body, wherein the body is provided with a containing space and a first port communicating with the containing space, the containing space extends in the long axis direction of the body, the outer surface of the body comprises a protruding portion, the protruding portion protrudes to the part, away from the containing space, from the containing space, and the first port penetrates throughthe protruding portion; and the glue blocking device can be arranged in the hollow space and is connected with the windward side shell and the leeward surface shell through the body, the first port and the protruding portion are arranged towards the adhesive bonding layer, and at least a part of the adhesive bonding layer can be arranged in the containing space through the first port. According tothe glue blocking device, the blade and the blade forming method, the quality of blade and the operation stability of the blade can be improved.

Owner:SINOMATECH WIND POWER BLADE

A data query method, data processing method and device

ActiveCN107038207BReduce use costImprove experienceText database indexingSpecial data processing applicationsData processing systemData transformation

The invention discloses a data processing method. The method comprises the steps of determining a mapping relation between a user field and a database field in the to-be-stored data according to a preset mapping rule when a data storage request including to-be-stored data is received, wherein the to-be-stored data are unstructured data; converting the to-be-stored data into index data according to the mapping relation, wherein the index data are reflected in the form of database field; and storing the index data in a database. According to the method, the mapping relation can be stored, when the data query request is received, conversion between the user field and the database field is carried out and the data query is realized. The embodiment of the invention also provides a corresponding data query method and data processing system. Therefore, a data solution scheme which is easy to use, expand and maintain is provided, the method is suitable for processing of the unstructured data, and thus the usage cost of a user is reduced and the user experience is improved.

Owner:ADVANCED NEW TECH CO LTD

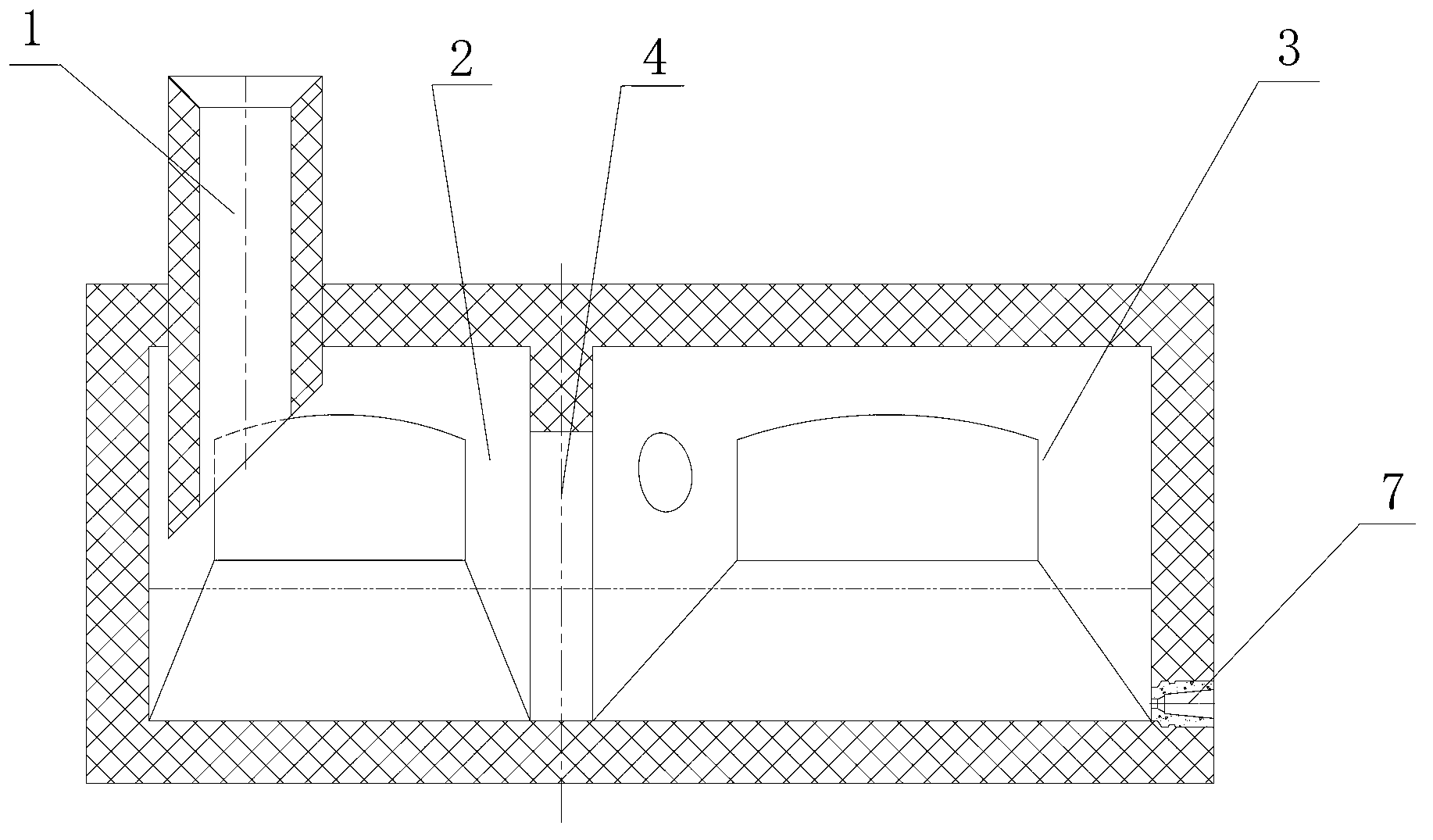

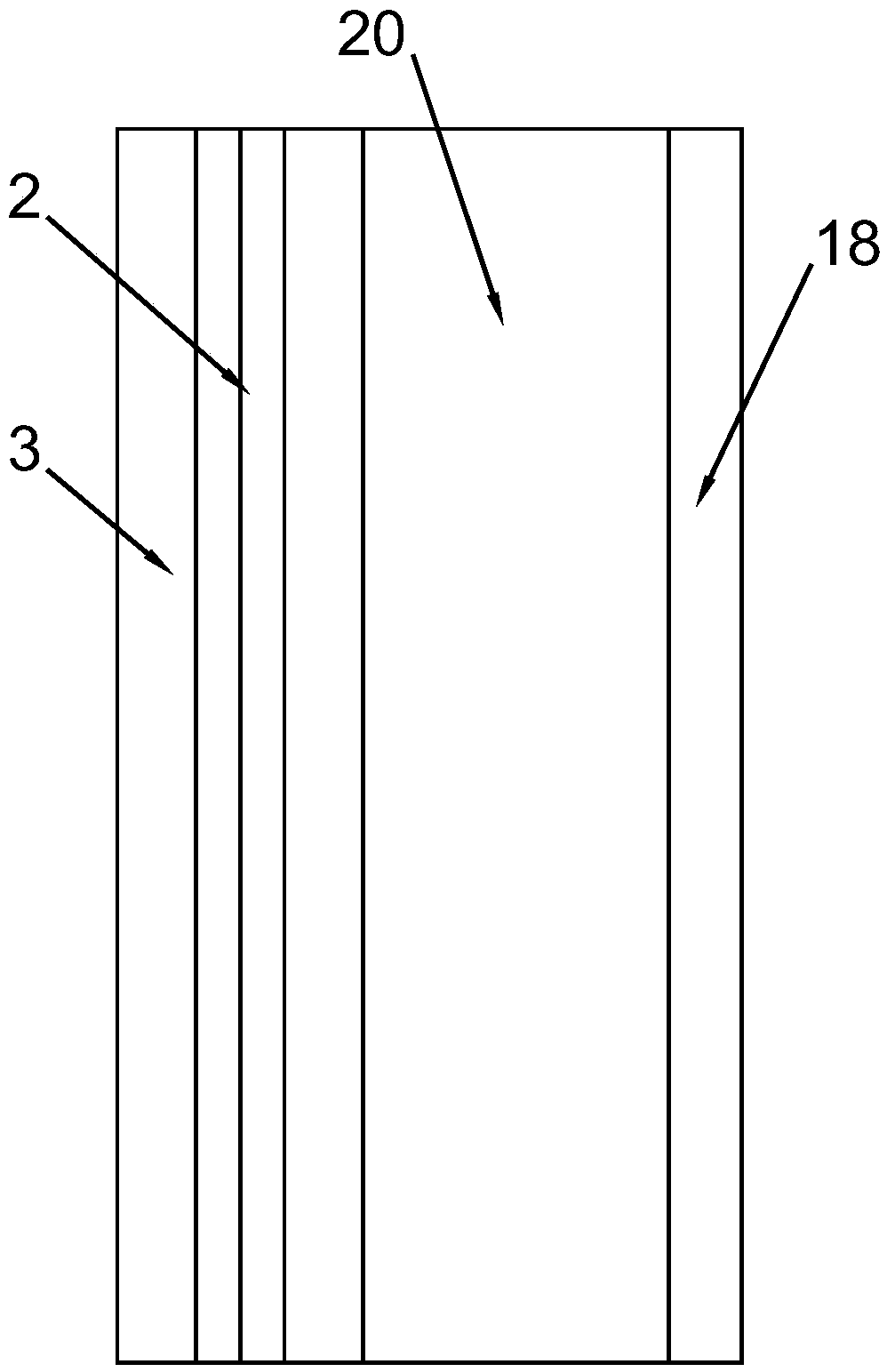

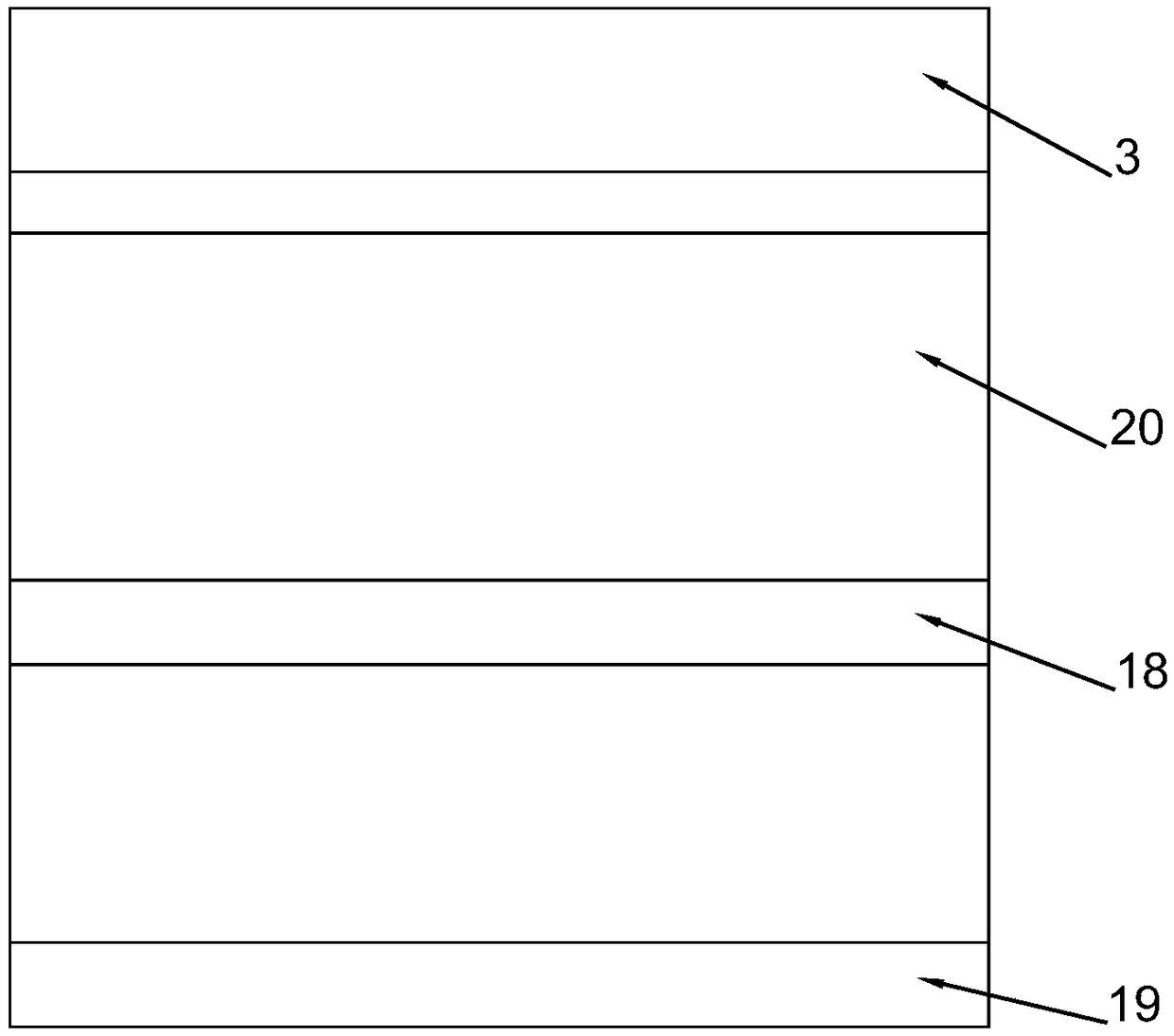

Energy-saving particle distributing device

ActiveCN106381352AReduce energy consumptionWith storage capacityRecycling and recovery technologiesEngineeringMechanical engineering

An energy-saving particle distributing device comprises a rotating shaft, a rotating plate, a funnel, an upper partition plate, a lower partition plate, movable baffles, fixed baffles, gears, an upper outlet, a lower outlet and a shell. The energy-saving particle distributing device is characterized in that the funnel is of a symmetrical structure, the rotating shaft is located on the symmetrical sections of the funnel, the rotating plate can adjust the rotation angle under the drive of the rotating shaft, and after entering the shell from the funnel, particles fall to the inclined upper partition plate and the inclined lower partition plate correspondingly from the two sides of the rotating plate due to partition of the rotating plate; and the movable baffles are provided with racks, and the movable baffles can be driven by the gears to move up and down along hollow structures of the fixed baffles so that the sizes of the gaps between the movable baffles and the partition plates can be changed. According to the energy-saving particle distributing device, the fallen particles are distributed to the two partition plates through the rotating plate arranged below the funnel, distribution of the particles to the two partition plates can be adjusted through the control over the angle of the rotating plate and the sizes of the gaps between the movable baffles and the partition plates, reciprocating swinging is not needed, the energy consumption is small, and the structure is simple.

Owner:XI AN JIAOTONG UNIV

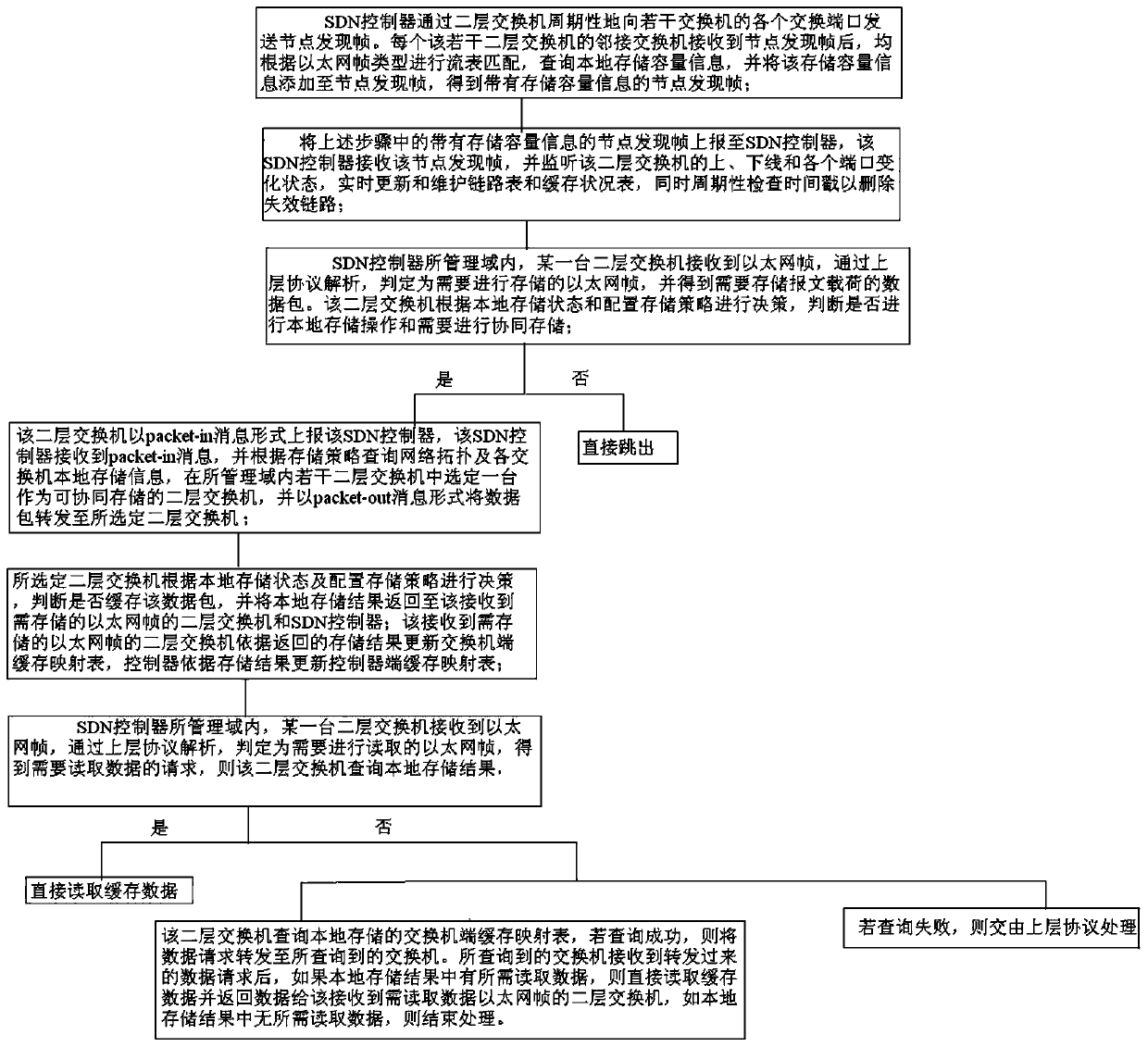

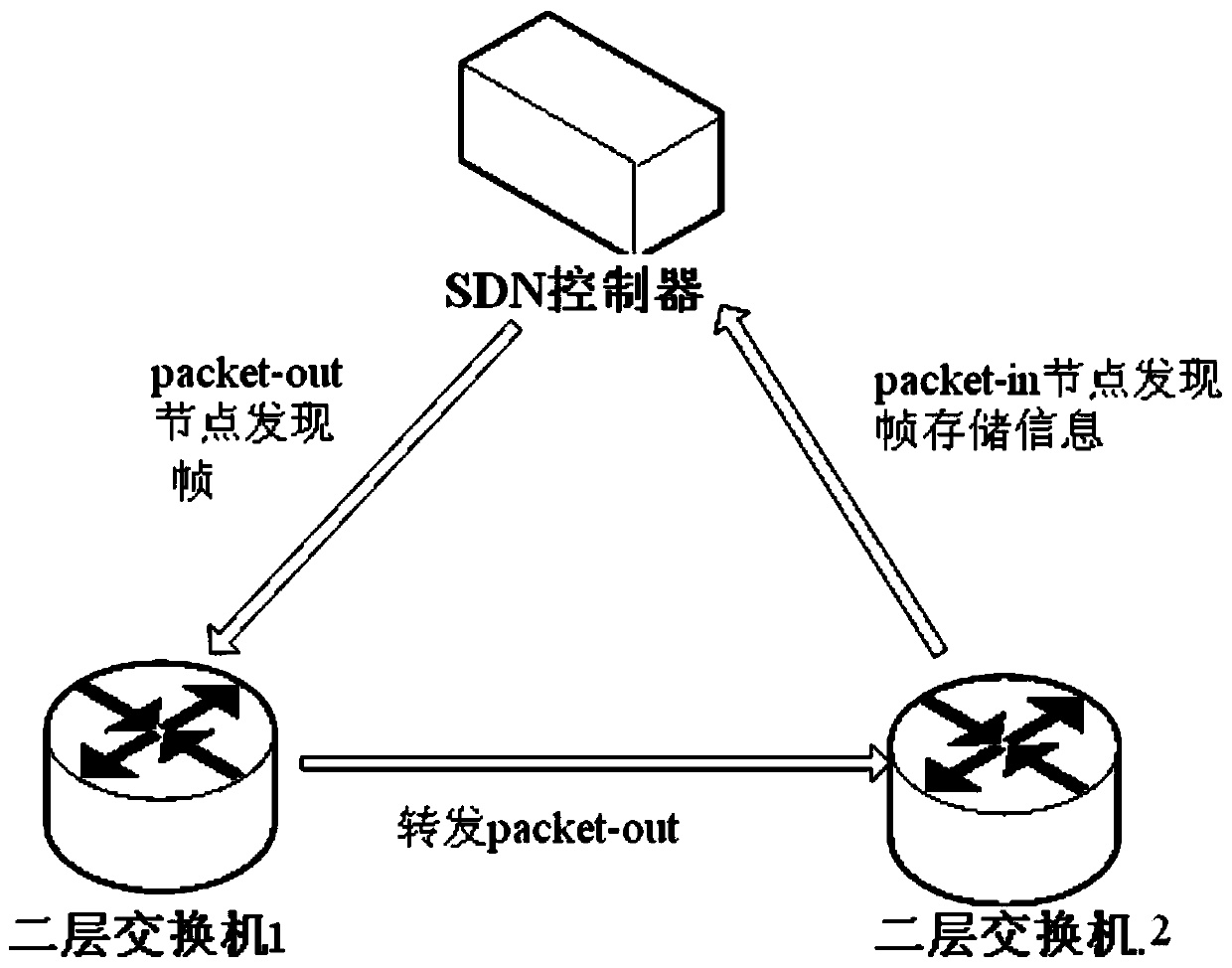

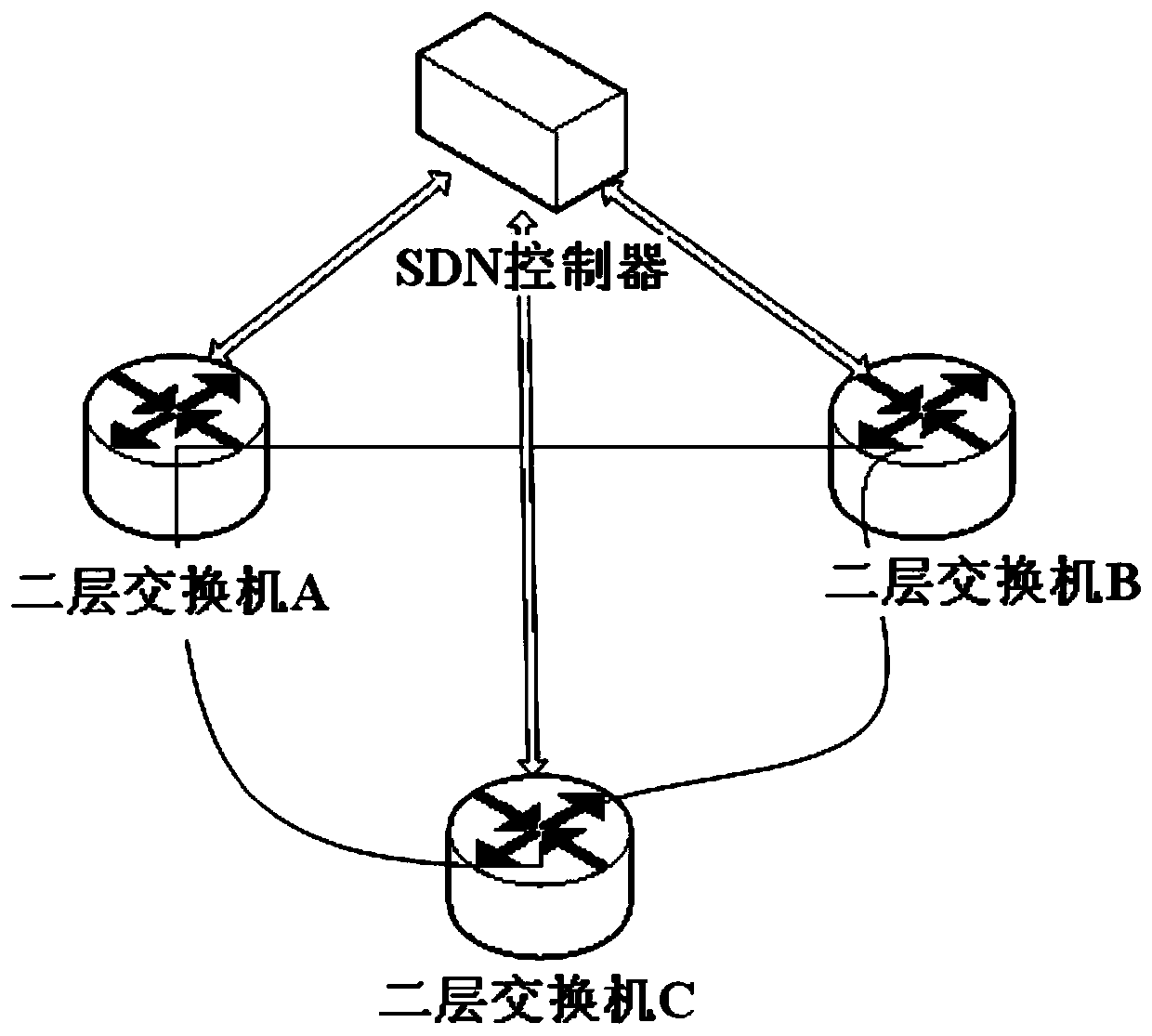

A Method for Layer 2 Switch Content Collaboration Based on Software Defined Networking

ActiveCN108390899BWith storage capacitySolve the technical problem of lack of effective content collaboration mechanismTransmissionData packData needs

The present invention provides a method for coordinating the contents of two-layer switches based on software-defined networks. The method specifically includes: Step 1. The SDN controller periodically sends node discovery frames to each switch port of several switches, and performs flow according to the Ethernet frame type. Table matching, query local storage capacity information, obtain node discovery frame with storage capacity information; Step 2, report the node discovery frame in step 1 to the SDN controller, update and maintain the link table and cache status table in real time, delete Invalid link; step 3, through the analysis of the upper layer protocol, obtain the data packet that needs to store the message load; make a decision according to the local storage status and configuration storage strategy, and judge whether to perform local storage operation; the selected layer 2 switch makes a decision, judges Whether to cache the data packet; step 4, through the analysis of the upper layer protocol, it is determined that it is an Ethernet frame that needs to be read, and the layer 2 switch queries the local storage result to determine whether the cached data needs to be read.

Owner:北京中科海网科技有限公司

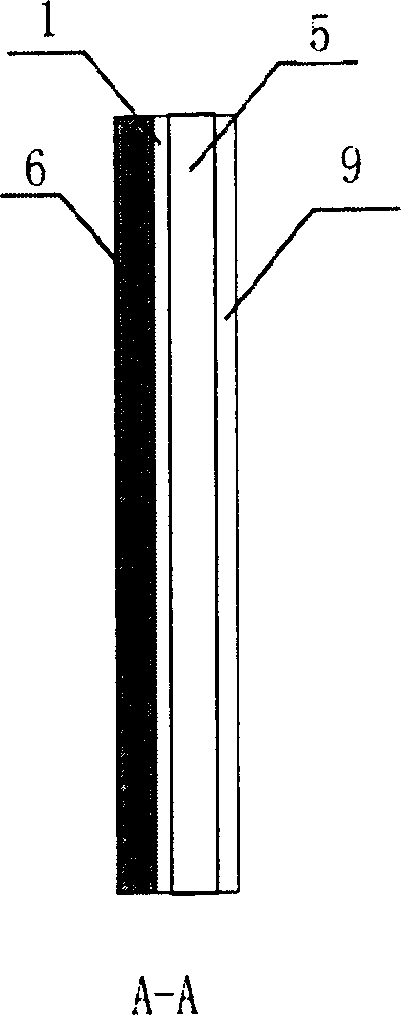

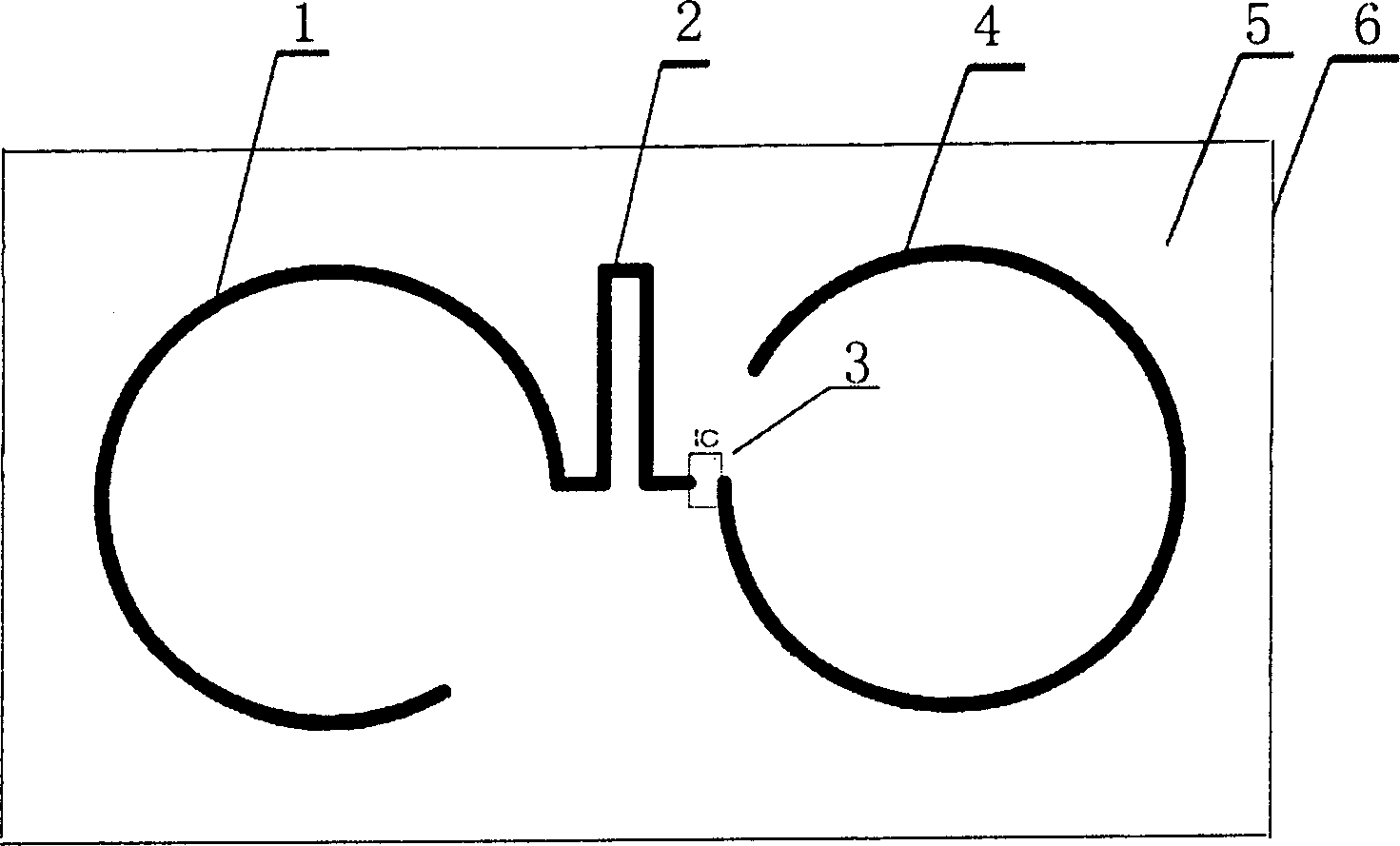

Passive double-ring identifying card for circularly polarized linear antenna

InactiveCN1157689CImprove matchWith storage capacityRecord carriers used with machinesAviationTraffic system

The present invention relates to electronic recognizer, and is especially passive double-ring circularly polarized linear antenna identifying card. It consists of double ring, phase shift matching microstrip line, passive microwave reflecting modulator, substrate with cuts and grain carving reginos. The identifying card has simple structure, easy manufacture, convenient use, great memory capacity, frequency band width up to 13% and identifying distance up to 10 m, and can be used widely in railway and highway vehicle management, aviation cargo transport, intelligent traffic system, logistics management, and other fields.

Owner:赖声礼

Air intake and exhaust thermal control device and method for implementing HCCI (homogeneous charge compression ignition) combustion of gasoline engine

ActiveCN102359411BRealize comprehensive utilizationRealize accumulationElectrical controlInternal combustion piston enginesHcci combustionSignal conditioning circuits

The invention discloses an air intake and exhaust thermal control system for implementing HCCI (homogeneous charge compression ignition) combustion of a gasoline engine. The system comprises an air intake pipeline, an air exhaust pipeline and an air exhaust-intake heat exchanger, wherein the heat exchanger is filled with heat storage materials; the air intake pipeline, the air exhaust pipeline and a bypass are respectively provided with an electrically operated valve; the pipelines are provided with a plurality of temperature sensors; the electrically operated valves and the temperature sensors are connected with a controller; and the controller comprises a signal conditioning circuit and a driving circuit which are connected with a singlechip and are used for implementing the thermal control of air intake and air exhaust. The device provided by the invention has the heat storage capability of the heat exchanger, reasonable storage and release of air exhaust heat can be realized. When the gasoline engine operates at medium and large load, the storage and accumulation of surplus air exhaust heat in the heat exchanger can be realized, and the device is used for heating the intake air when the gasoline engine operates at low load, the problem that the air exhaust heat is insufficient to heat the intake air at low load is solved, the requirement of air exhaust-intake heat exchange efficiency is lowered, and the device can be practically applied to the HCCI combustion of the gasoline engine.

Owner:TIANJIN UNIV

Superposed copper strip unreeling device

The invention provides a superposed copper strip unreeling device comprising an unreeling device, a copper strip lifting device and an unreeling dancer which are arranged sequentially in the copper strip unreeling direction, wherein a plurality of copper strip reels are arranged on the unreeling device and superposed from top to bottom, and copper strips on the adjacent copper strip reels are connected end to end; the copper strip lifting device is used for adjusting the unreeling height of the copper strips, so that when different copper strip reels are varied for unreeling, the copper strip on the current copper strip reel can be horizontally unreeled; the unreeling dancer comprises a plurality of moving dance wheels and fixed dance wheels which are arranged alternatively, and the copper strips are released from the copper strip lifting device and then sequentially pass through the alternated moving dance wheels and fixed dance wheels to unreel. By configuring the plurality of superposed copper strip reels, long-time continuous unreeling can be realized, and stop receiving is not needed, so that the unreeling speed and the unreeling efficiency are improved; meanwhile, by configuring the copper strip lifting device and the unreeling dancer matched with the copper strip reels, the unreeling quality and the stability and controllability of the unreeling tension can be improved.

Owner:JIANGSU HENGTONG MARINE CABLE SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com