Energy-saving particle distributing device

A technology of distributing device and particles, applied in the field of mechanical equipment, can solve the problems of waste of heat and water resources, and achieve the effect of less energy consumption and better heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

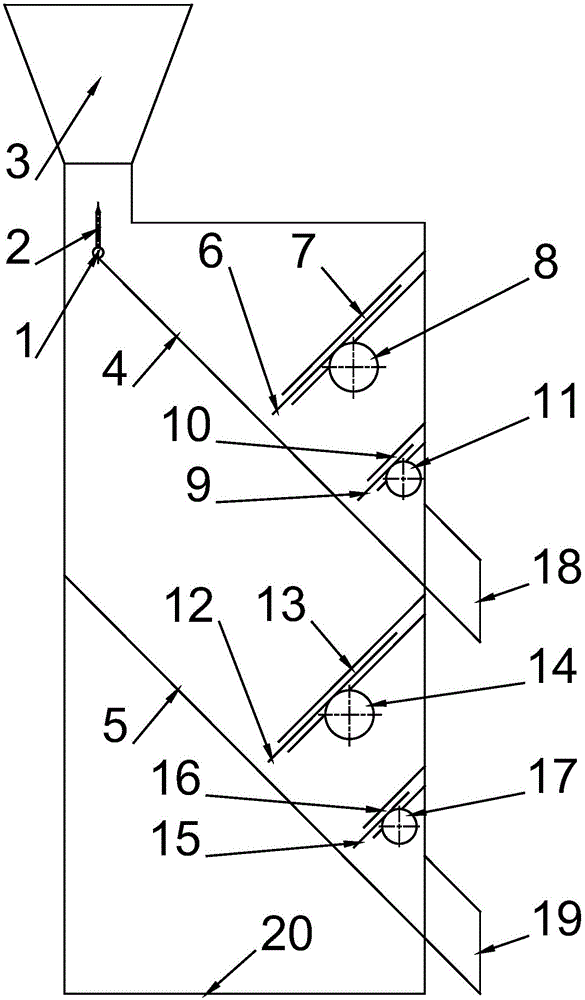

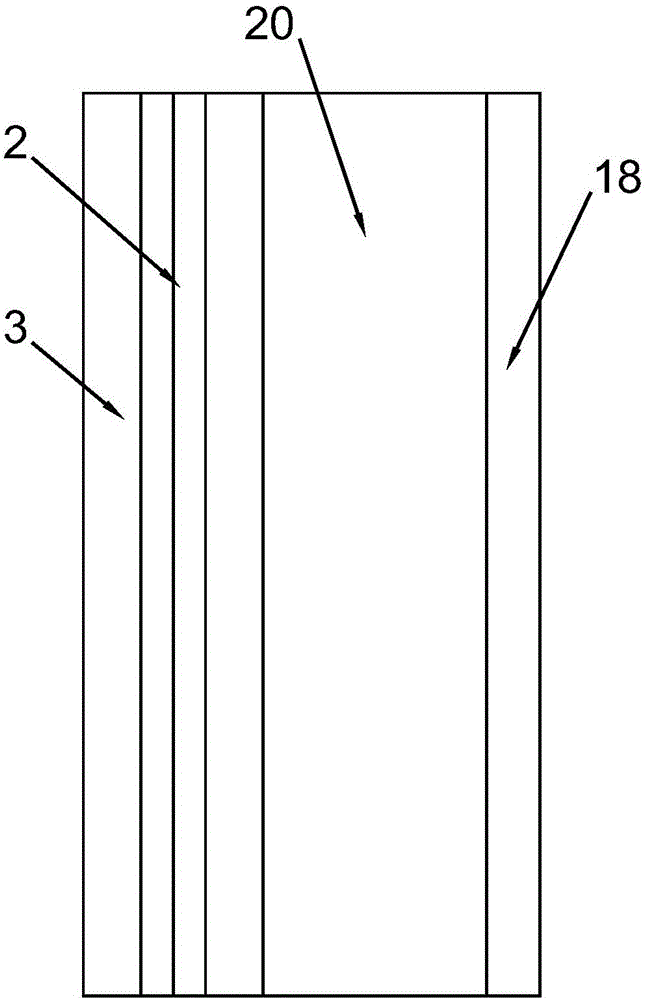

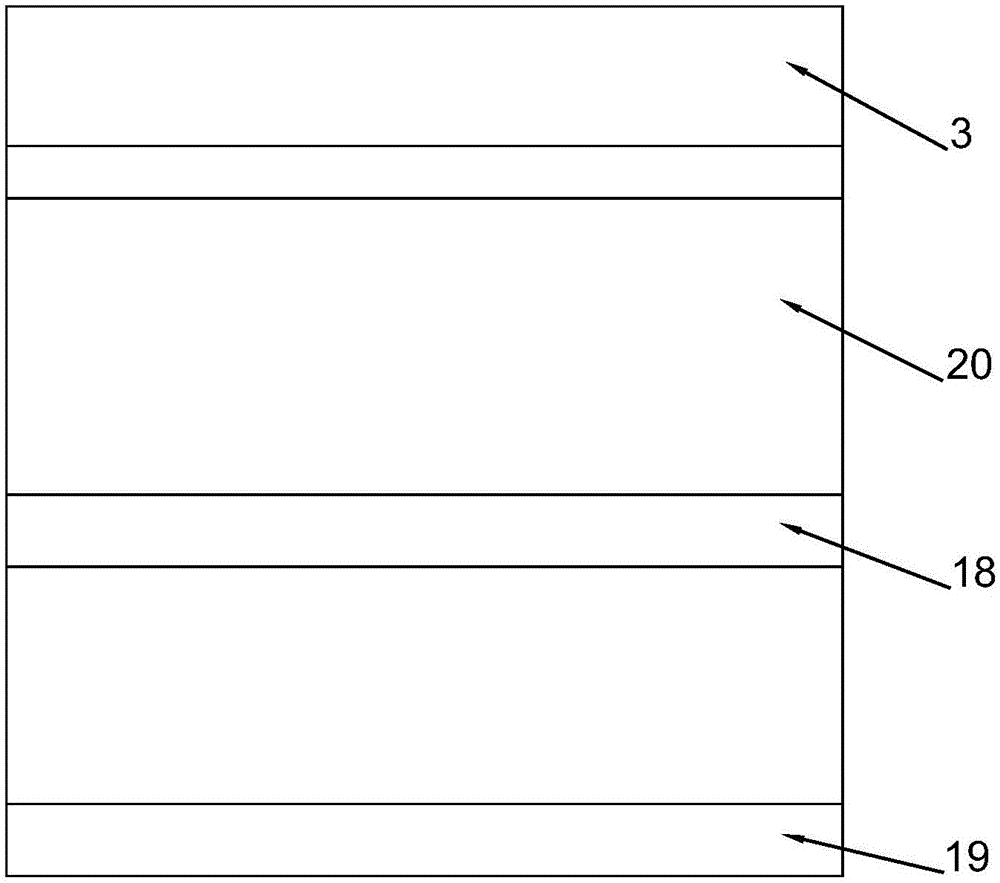

[0015] Such as figure 1 , figure 2 with image 3 As shown, an energy-saving particle distribution device includes a rotating shaft 1, a rotating plate 2, a funnel 3, an upper partition 4, a lower partition 5, a movable baffle a6, a fixed baffle a7, a gear a8, a movable baffle b9, Fixed baffle b10, gear b11, movable baffle c12, fixed baffle c13, gear c14, movable baffle d15, fixed baffle d16, gear d17, upper outlet 18, lower outlet 19, and housing 20.

[0016] Such as figure 1 As shown, the funnel 3 is a symmetrical structure, the rotating shaft 1 is located on the symmetrical plane of the funnel 3, and the rotating plate 2 can adjust the rotation angle under the drive of the rotating shaft 1. , will drop to the upper partition 4 and the lower partition 5 arranged obliquely on both sides of the rotating plate 2 respectively. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com