Adsorbent and its preparation for storage of nitrogen oxides in diesel engine and lean-burn gasoline engine

A nitrogen oxide and adsorbent technology, which is applied in the field of nitrogen oxide storage adsorbent for diesel engine and lean-burn gasoline engine and its preparation field, can solve the problem of ineffective storage, poor nitrogen oxide storage capacity, and lack of adsorption storage capacity. and other problems to achieve the effect of reducing costs and improving storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of Mn-Sn-O X Adsorbent. Prepare 0.12mol L -1 of (NH 4 ) 2 S 2 o 4 Solution 500mL, add 2.02824g MnSO 4 ·H 2 O, 6.3104g SnCl 4 ·5H 2 0; after stirring evenly, add an appropriate amount of ammonia water drop by drop, and adjust the pH value at about 10.0; stir and age for 3h at 50°C on a magnetic stirrer; wash with deionized water and suction filter 4 times to remove impurity ions in the solution; The samples were dried in an oven at 110°C for 24h, the dried block was crushed, and roasted in a muffle furnace at 500°C for 4h to obtain a Mn, Sn molar ratio of 4:6 (expressed as Mn 0.4 sn 0.6 ) Mn-Sn-O X .

[0026] MnO X with SnO 2 The mass fractions are 25.9% and 74.1%, respectively.

[0027] Adsorption performance test reaction conditions:

[0028] 0.2g catalyst, 500ppm NO, 5% O 2 , the balance gas is nitrogen, and the space velocity is 48,000mLh -1 g -1 .

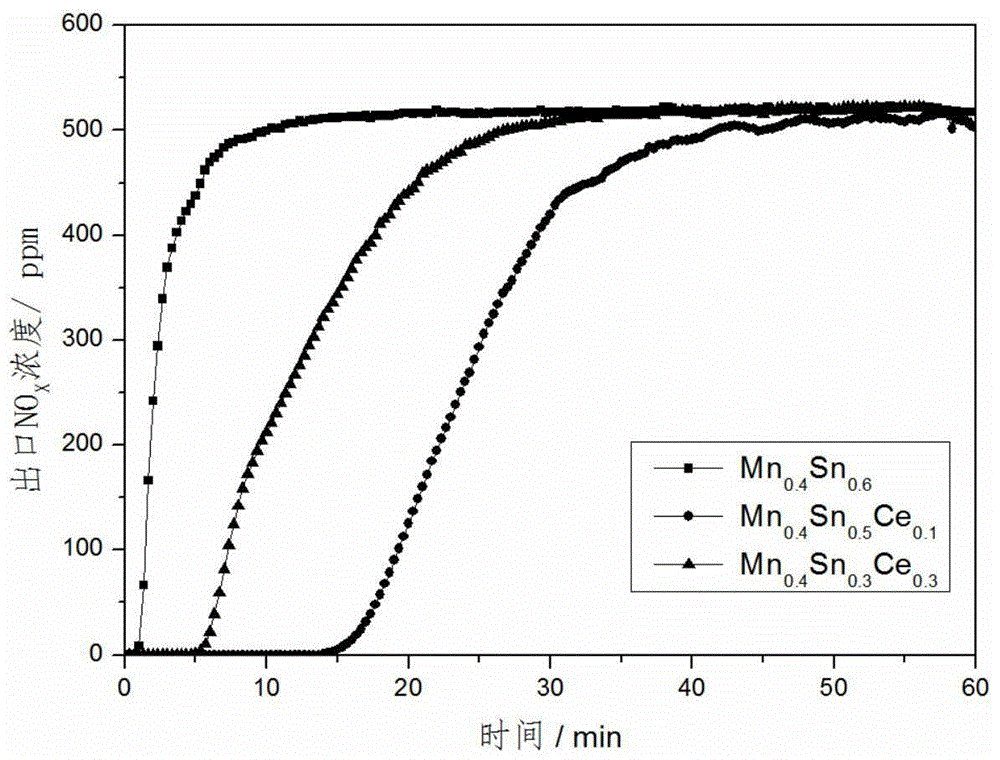

[0029] Mn at 100°C 0.4 sn 0.6 Adsorption performance results such as figure 1 As sh...

Embodiment 2

[0031] Preparation of Mn-Sn-Ce-O X Adsorbent. Prepare two 0.12mol L -1 of (NH 4 ) 2 S 2 o 4 Each solution is 500mL. 2.02824g MnSO was added successively to the first solution 4 ·H 2 O, 5.2587g SnCl 4 ·5H 2 O and 1.3027g Ce(NO 3 ) 3 ·6H 2 O; 2.02824 g MnSO was sequentially added to the second solution 4 ·H 2 O, 3.1552g SnCl 4 ·5H 2 O and 3.9080g Ce(NO3 ) 3 ·6H 2 O; After stirring evenly, add an appropriate amount of ammonia water drop by drop to adjust the pH value to about 10.0; stir and age on a magnetic stirrer at 50°C for 3 hours; then wash with deionized water and suction filter 4 times to remove impurity ions in the solution; The obtained sample was dried in an oven at 110°C for 24h, the dried block was crushed, and roasted in a muffle furnace at 500°C for 4h to obtain a molar ratio of Mn, Sn, and Ce of 4:5:1 (expressed as Mn 0.4 sn 0.5 Ce 0.1 ) and 4:3:3 (expressed as Mn 0.4 sn 0.3 Ce 0.3 ) of Mn-Sn-Ce-O X .

[0032] In both cases, MnO X , CeO ...

Embodiment 3

[0035] Preparation of Mn-Sn-Ce-O X Adsorbent. Prepare two 0.12mol L -1 of (NH 4 ) 2 S 2 o 4 Each solution is 500mL. Add 2.02824g MnSO successively to the first solution 4 ·H 2 O, 5.2587gSnCl 4 ·5H 2 O and 1.3027g Ce(NO 3 ) 3 ·6H 2 O; 2.02824 g MnSO was sequentially added to the second solution 4 ·H 2 O, 3.1552g SnCl 4 ··5H 2 O and 3.9080g Ce(NO 3 ) 3 ·6H 2 O; After stirring evenly, add an appropriate amount of ammonia water drop by drop to adjust the pH value to about 10.0; stir and age on a magnetic stirrer at 50°C for 2 hours; then wash with deionized water and suction filter 3 times to remove impurity ions in the solution; The obtained sample was dried in an oven at 110°C for 24h, the dried block was crushed, and roasted in a muffle furnace at 500°C for 6h to obtain a molar ratio of Mn, Sn, and Ce of 4:5:1 (expressed as Mn 0.4 sn 0.5 Ce 0.1 ) and 4:3:3 (expressed as Mn 0.4 sn 0.3 Ce 0.3 ) of Mn-Sn-Ce-O X .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com