Pollutant suction system applied to vacuum toilet

A vacuum and toilet technology, applied in applications, waterway systems, sewage discharge, etc., can solve problems such as inability to replenish vacuum in time, incomplete suction of sewage, and inability to suck away.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

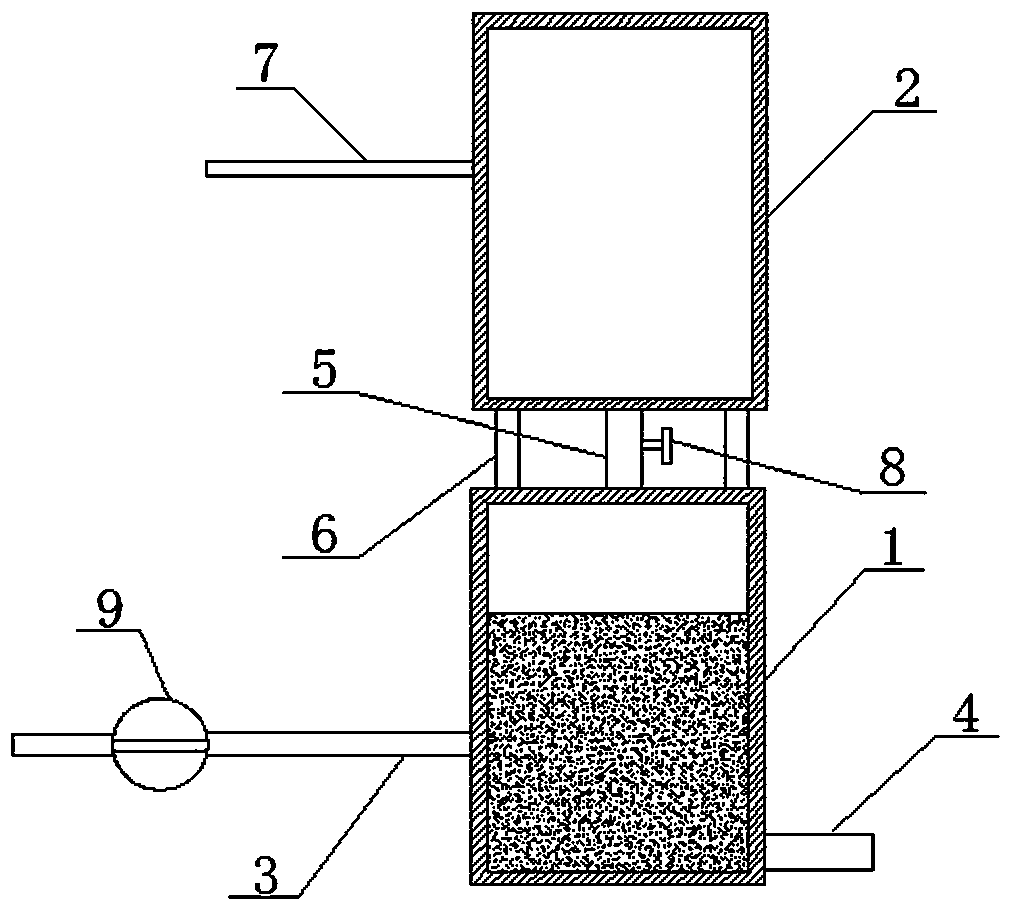

[0038] Such as figure 1 As shown, a sewage suction system applied to a vacuum toilet shown in a preferred embodiment of the present invention includes two vacuum negative pressure tanks that realize air pressure communication through the pressure guiding pipe 5, and one of the vacuum negative pressure tanks is used for suction The adsorption tank 1 for dirt and temporary storage of dirt, and another vacuum negative pressure tank is used as a pressure supply tank 2 for providing vacuum negative pressure to the adsorption tank 1, and the pressure guiding pipe 5 is provided with a constant pressure device 8, and the The adsorption tank 1 is provided with a sewage inlet pipe 3 for inhaling dirt and a sewage discharge pipe 4 for discharging dirt. The sewage inlet pipe 3 is provided with a vacuum shut-off valve 9. The pressure supply tank 2 is provided with a Air extraction pipe 7 for extracting air.

[0039] In the present embodiment, taking the vacuum toilet as an example, the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com