Patents

Literature

48 results about "Vacuum shut-off valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

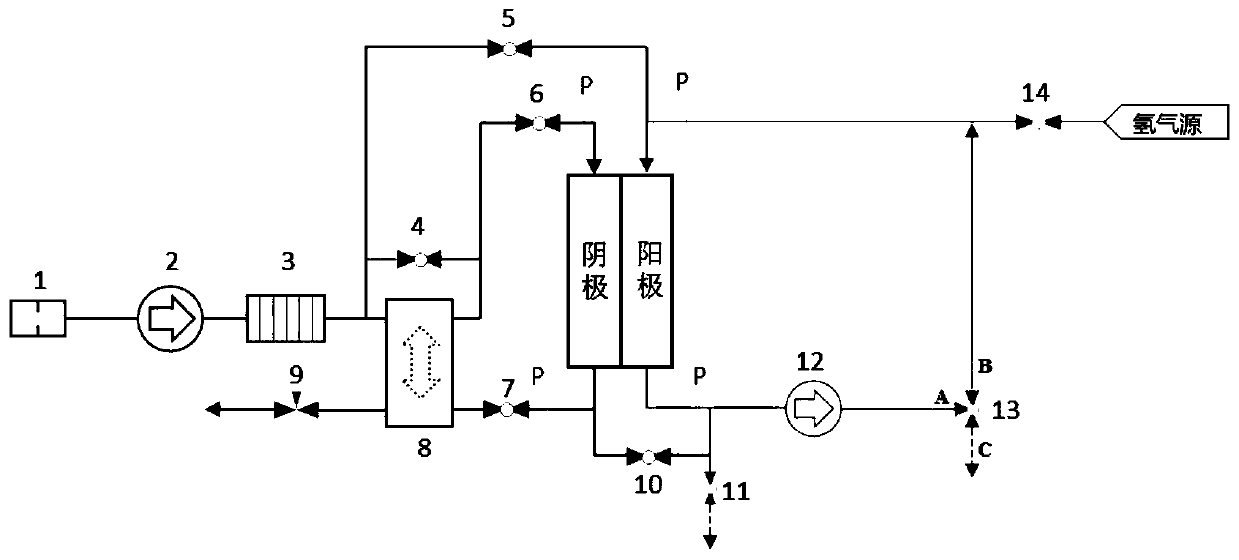

Fuel cell engine purging system and control method thereof

The invention discloses a fuel cell engine purging system and a control method thereof. The fuel cell engine purging system is mainly composed of an air filter, an air compressor, an intercooler, a humidifier bypass valve, an anode purging shut-off valve, an electric pile air inlet shut-off valve, an electric pile air outlet shut-off valve, an air humidifier, a back pressure valve, a vacuum shut-off valve, a hydrogen tail exhaust valve, a hydrogen cycle pump, a three-way steering valve and a hydrogen inlet shut-off valve. The residual water can be fully removed in a short time with low energyconsumption.

Owner:佛山市清极能源科技有限公司

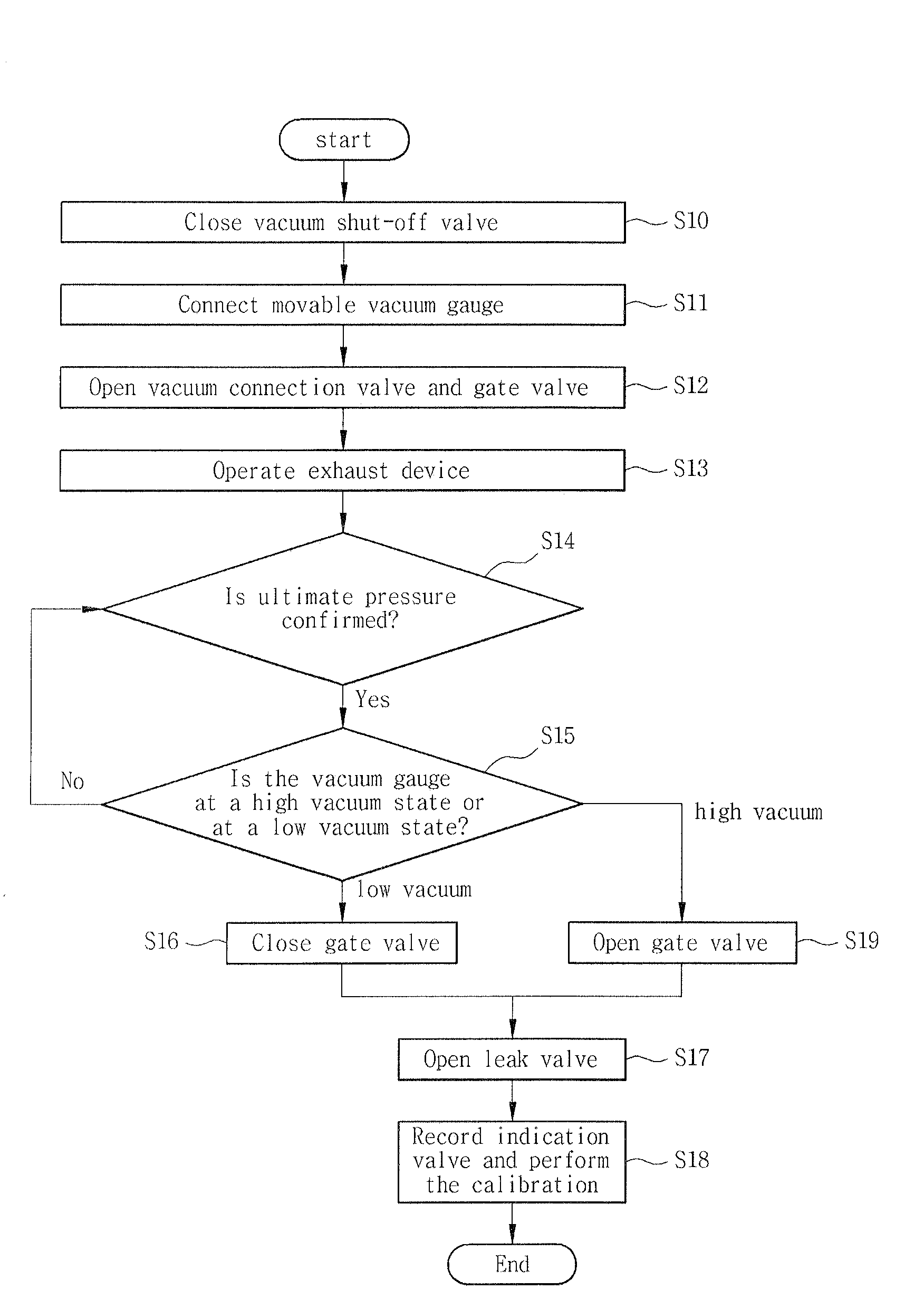

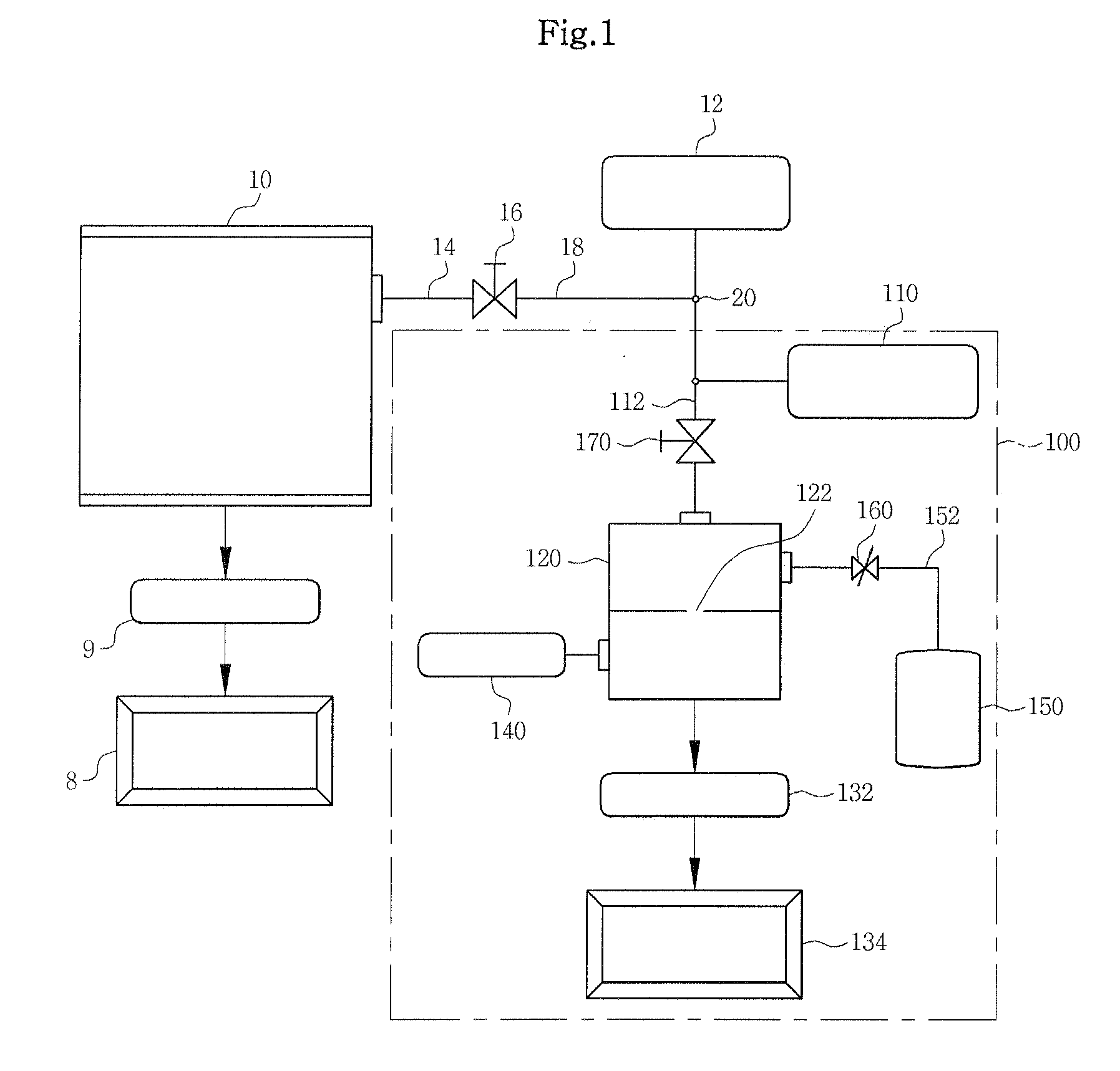

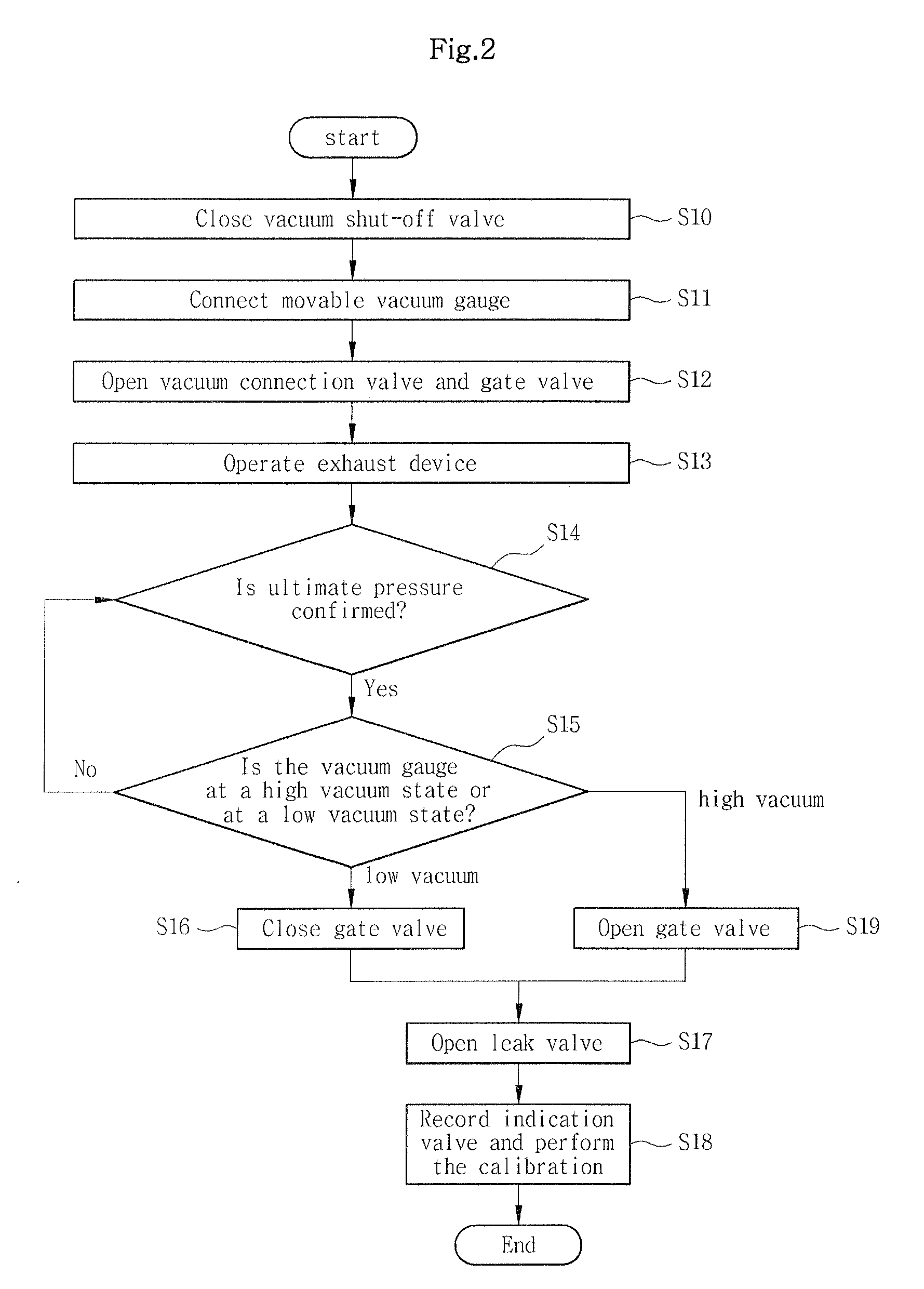

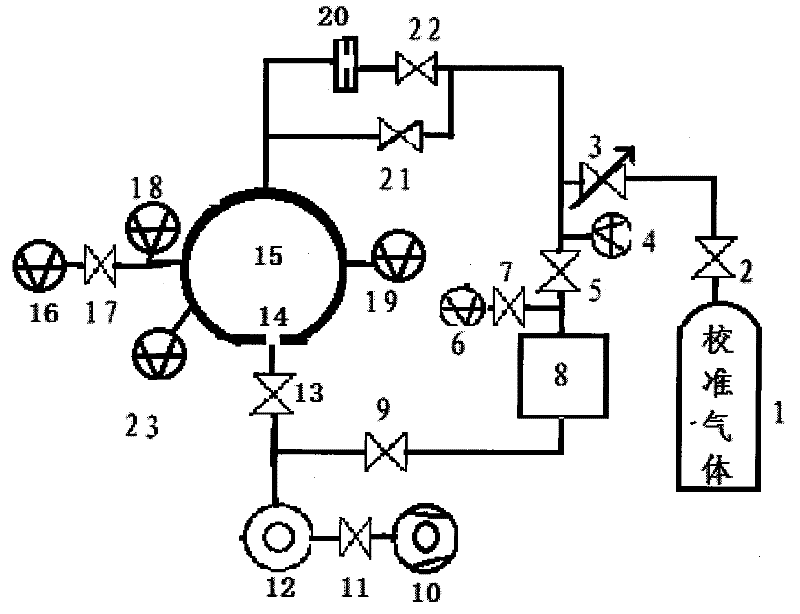

Vacuum gauge calibration apparatus capable of calibrating and testing without displacement and operating method thereof

InactiveUS20090064756A1Semiconductor/solid-state device testing/measurementVacuum gauge using heat conductivity variationVacuum pressureVacuum chamber

The present invention provides a vacuum gauge calibration apparatus capable of calibrating and testing a vacuum gauge without displacement or separation of the vacuum gauge, the vacuum gauge being attached to a vacuum device under operation together with developing a movable vacuum gauge calibration device, and an operating method thereof. According to the present invention, there is provided an apparatus for calibrating and testing a vacuum gauge to be calibrated without displacement, the vacuum gauge being connected to a vacuum device, the apparatus comprising: a vacuum shut-off valve for opening and closing a piping for connecting the vacuum device to the to-be-calibrated vacuum gauge; and a movable vacuum gauge calibration device connected to the to-be-calibrated vacuum gauge, wherein the movable vacuum gauge calibration device includes: a reference vacuum gauge, a vacuum connection valve, a vacuum chamber, a gate valve, and an exhaust device which are connected to the to-be-calibrated vacuum gauge side in series; a gas supply source connected to the vacuum chamber for generating pressure in the vacuum chamber; a leak valve for controlling gas flow in the gas supply source and supplying the gas the vacuum chamber; and a vacuum gauge for the vacuum chamber for measuring vacuum pressure in the vacuum chamber.

Owner:KOREA RES INST OF STANDARDS & SCI

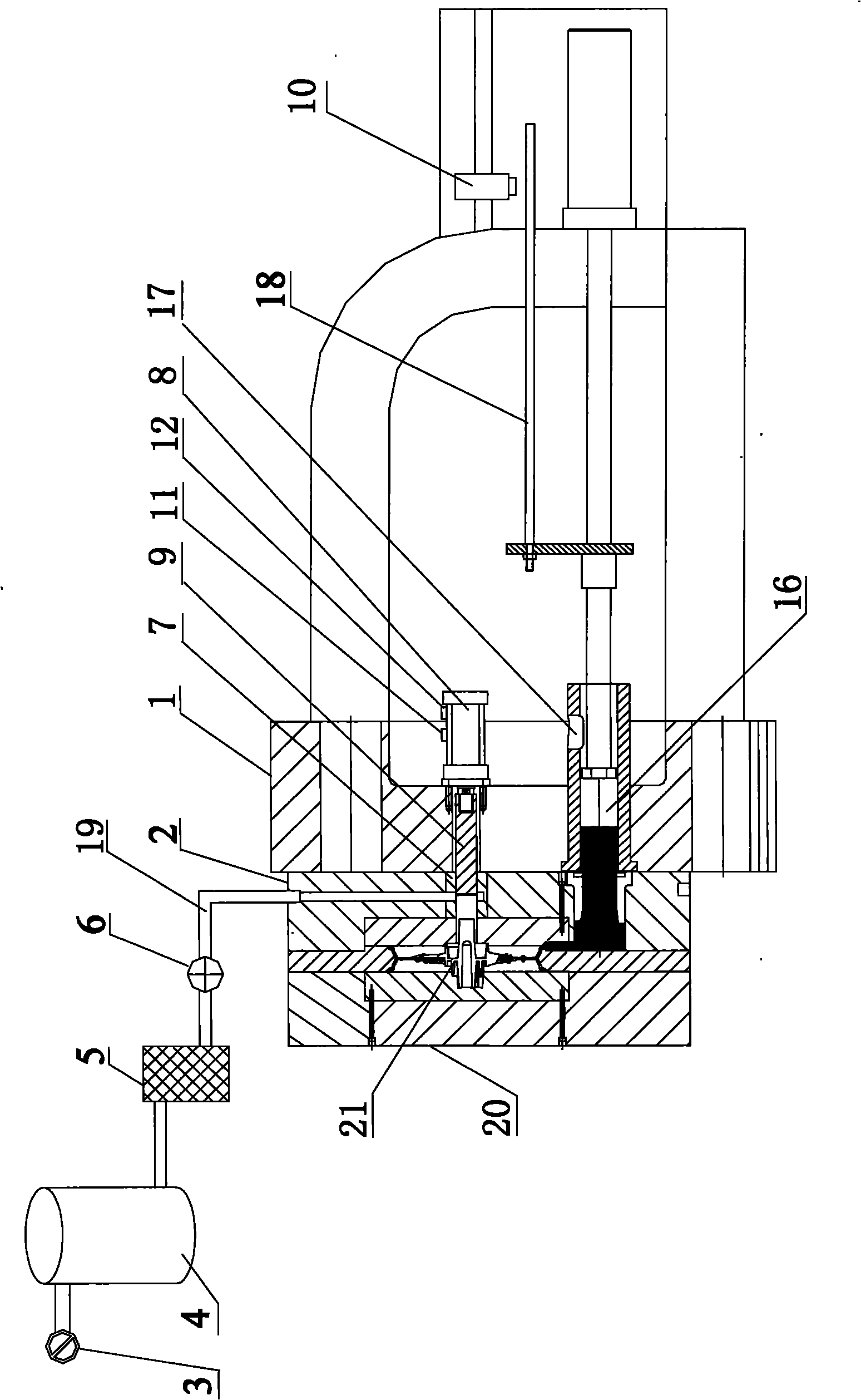

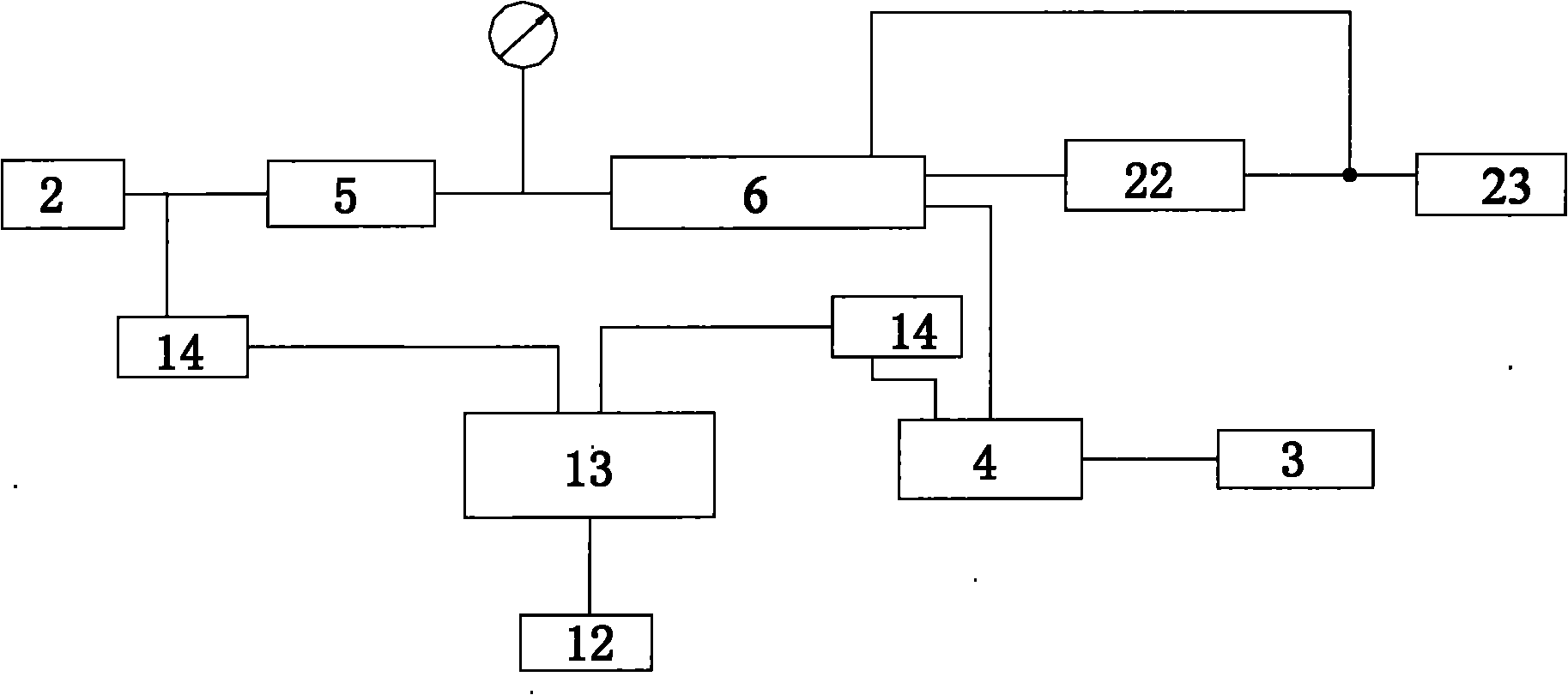

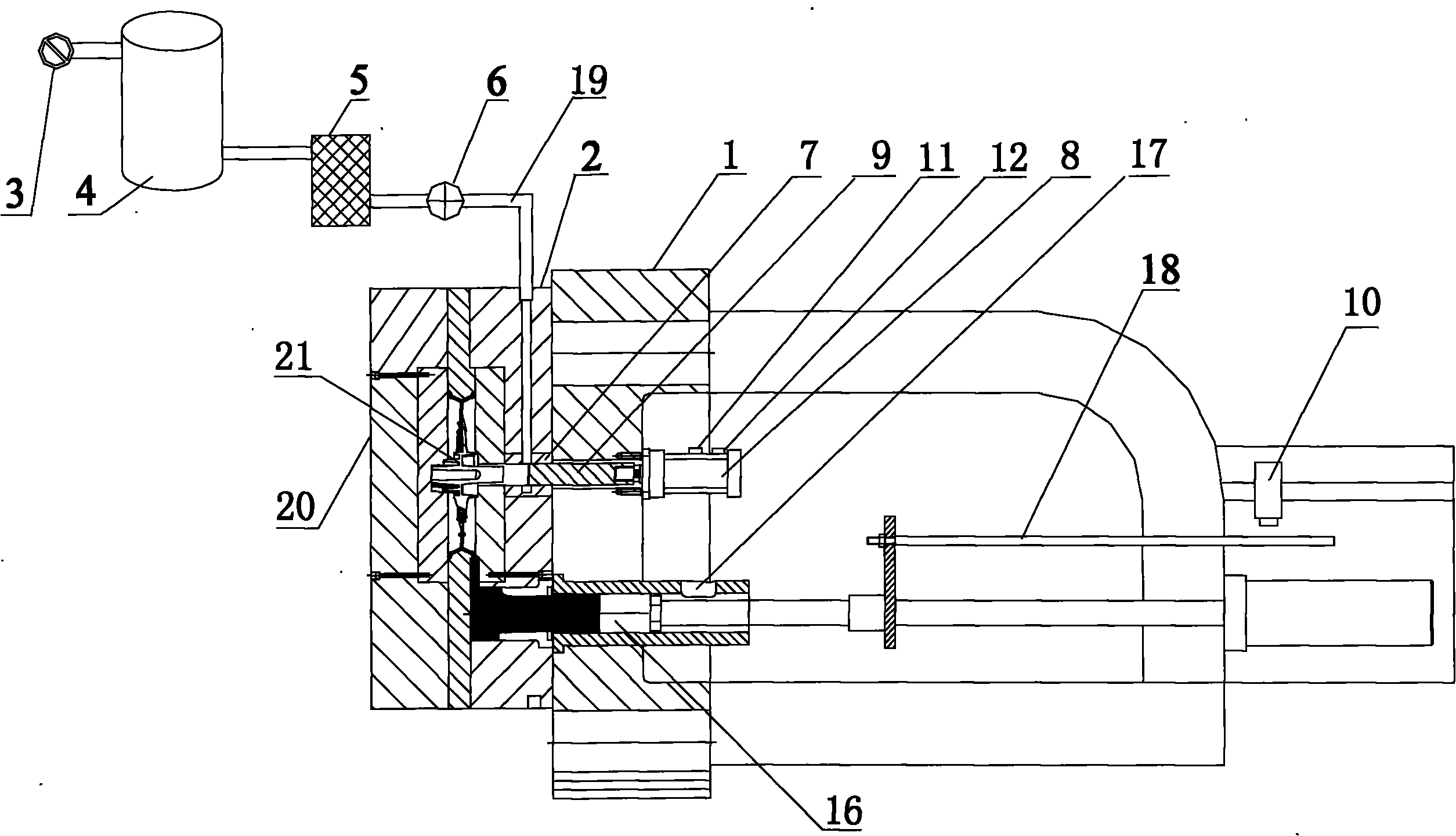

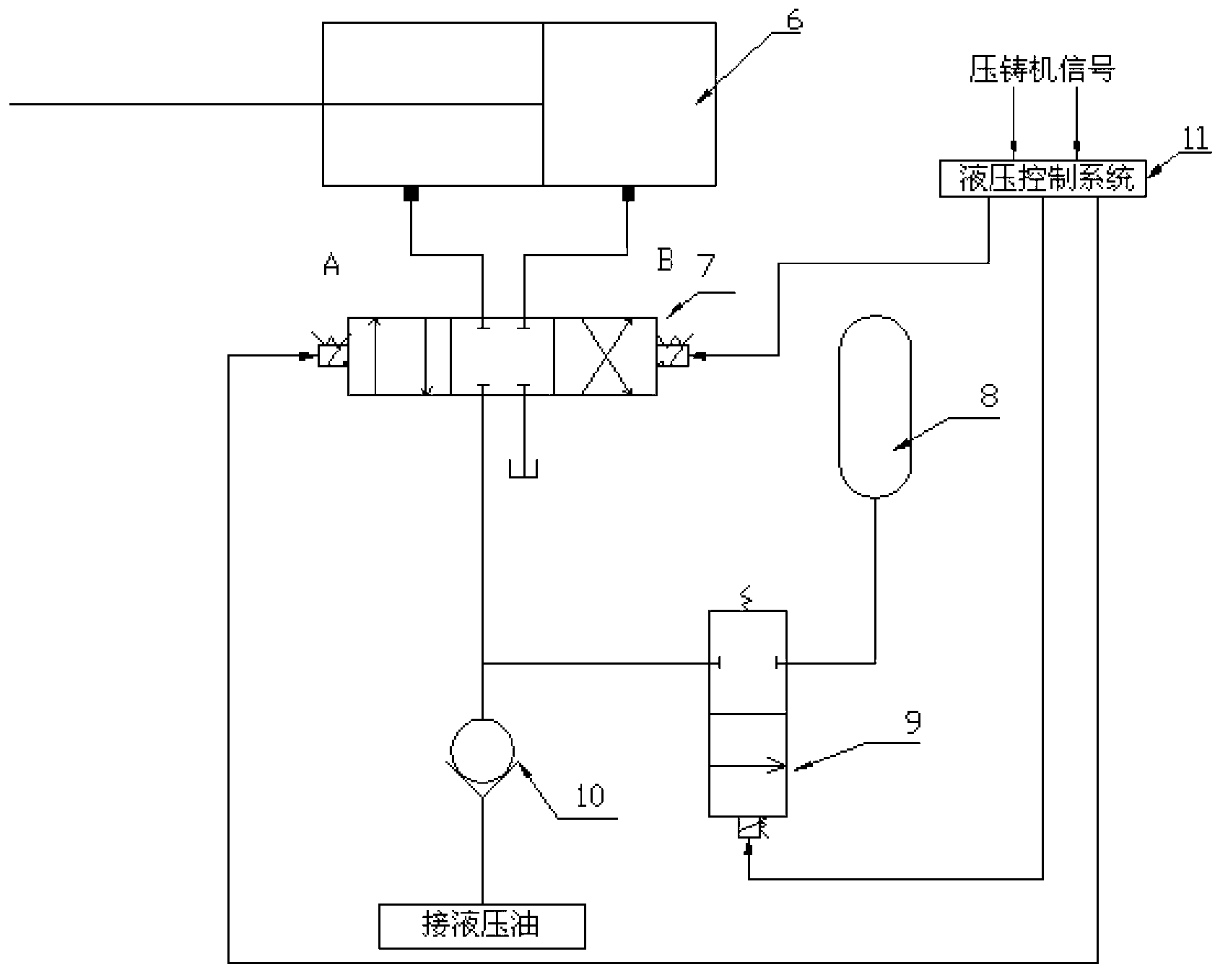

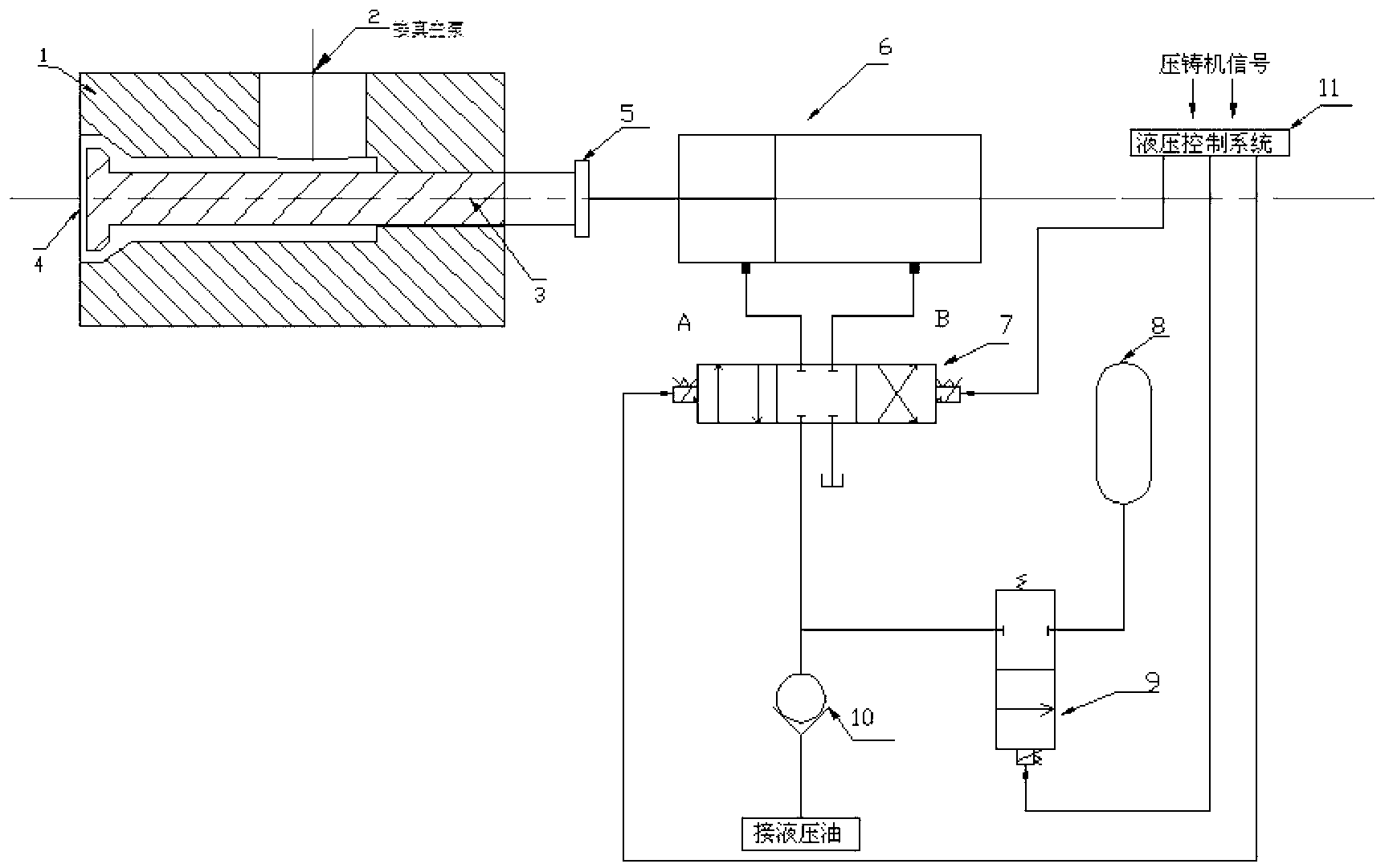

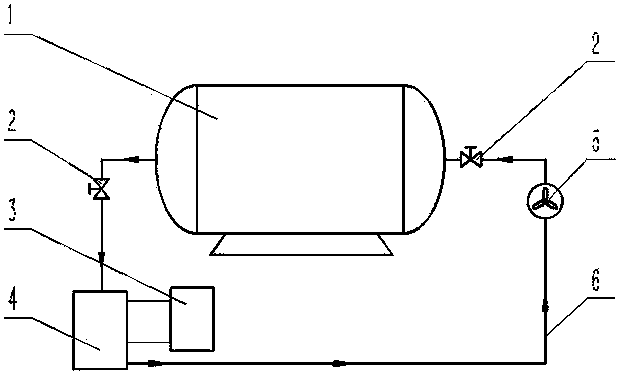

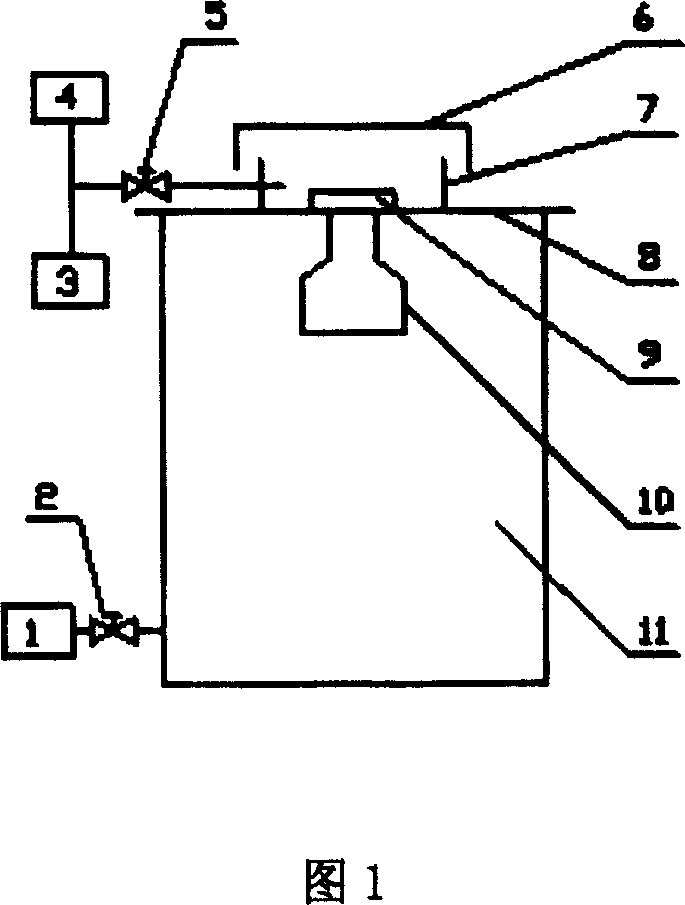

Vacuum die-casting system of die-casting machine

The invention discloses a vacuum die-casting system of a die-casting machine, which comprises the die-casting machine, a fixed-mold wallboard of a die casting mold, and a vacuum program control device of a die-casting system, wherein the vacuum die-casting system of the die-casting machine is arranged on the fixed-mold wallboard, the template of the fixed-mold wallboard of the die casting mold is provided with a channel, the outlet of the channel is connected with a vacuumizing device consisting of a vacuum pump, a negative pressure tank, a filter and a vacuum shut-off valve of the die casting mold by pipes; a channel leading to the center of the template of the die casting mold is connected with a casing pipe, the inner end of the casing pipe is communicated with a cavity of the template of the die casting mold, and a valve rod connected with a piston rod of an oil cylinder on the fixed-mold wallboard is arranged in a hole arranged at the outer end of the casing pipe. When carrying out die assembling on the die casting mold of the die-casting machine, by aid of the negative pressure produced by the vacuum pump of the vacuum die-casting system, the invention instantaneously extracts gases in the cavity and the pipe of the template of the mold, and closes the channel timely when the cavity is filled with molten metals, thereby preventing the molten metals from entering the vacuum pipelines so as to carry out die-casting molding on the molten metals in a vacuum.

Owner:DONGGUAN EONTEC CO LTD

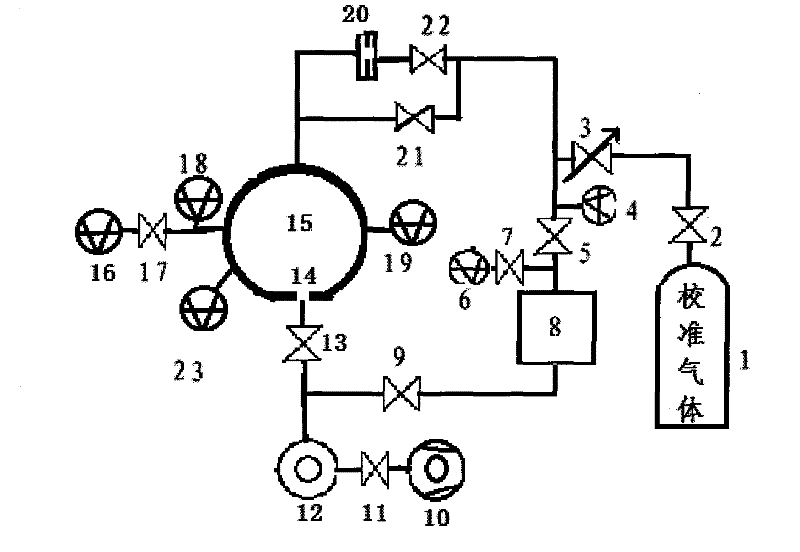

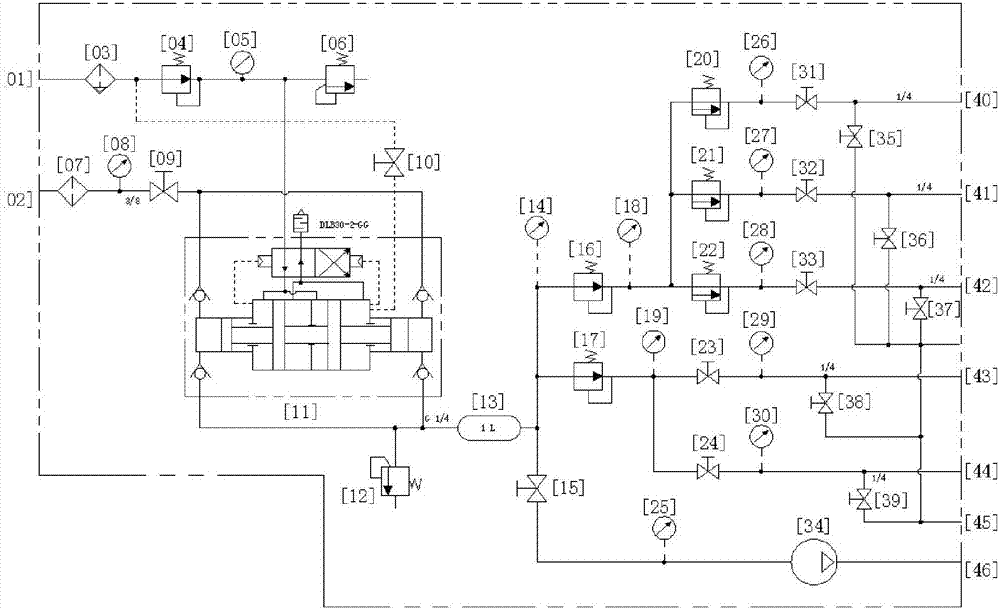

Calibration apparatus of on-site wide-range vacuum gauge and method thereof

InactiveCN102393275ALarge rangeHigh precisionFluid pressure measurementCapacitanceStandard uncertainty

The invention, which belongs to the measurement technology field, relates to a calibration apparatus of an on-site wide-range vacuum gauge and a method thereof. The calibration apparatus comprises: an air source, a pressure-reducing valve, a micro-adjustable valve, a monitoring vacuum meter, five vacuum stop valves, three capacitance film gauges, a pressure stabilizing chamber, a first stop valve, a mechanical pump, a second solenoid valve, a molecular pump, an all-metal angle valve, a vacuum chamber, a calibrated vacuum gauge, and a vacuum monitoring vacuum gauge. Besides, a current limitingair exhaust micropore is arranged in the vacuum chamber; and an air inlet micropore is arranged in the fifth vacuum stop valve. In addition, according to the method, a calibration range of the vacuumgauge is in a pressure intensity rang of from 10 <5> to 10 <-7> Pa; a standard uncertainty within the pressure intensity range of from 10 <5> to 10 < -1> Pa is 1.5%; a standard uncertainty within therange of from 10 <-2> to 10 <-6> Pa is 2.0%; and when the pressure intensity is 10 <-7> Pa, a standard uncertainty is 5 %; and the method has advantages of wide measuring range and high precision andis suitable for on-site operation. Moreover, the apparatus has advantages of small volume and light weight.

Owner:江苏东方航天校准检测有限公司

Gas distribution method and device for spacecraft leak rate detection

InactiveCN108007651AHigh degree of automationTroubleshoot specific pressure inflation problemsDetection of fluid at leakage pointMeasurement of fluid loss/gain rateTurbochargerEngineering

The invention discloses a gas distribution device for spacecraft leak rate detection, including a gas turbocharger, a pressure transmitter, a filter, a pressure stabilizing chamber, a high pressure reducing valve, a medium pressure reducing valve, a driving air pressure reducing valve, a driving air stop valve, an air intake stop valve, a vacuum stop valve, a safety valve, an unloading valve, a vacuum pump, a pressure gauge and a stainless steel pipe. A gas source inlet is connected with a leak indication gas for leak rate detection. A driver inlet is connected with compressed air to drive thegas turbocharger. The leak indication gas is pressurized through the gas turbocharger, and then enters the pressure stabilizing chamber and a corresponding gas transmission loop. Two channels of highpressure and three channels of low-pressure gas are output through devices such as the pressure reducing valves, a high pressure stop value and the pressure transmitter. The vacuum pump is used for pumping out the gas in a gas transmission pipe to improve the purity of the leak indication gas. The gas distribution device of the invention meets the requirement of spacecraft service life and reliability detection, and can improve the reliability of the charging and discharging process of the leak indication gas, shorten the gas charging and discharging time and reduce the cost of leak rate detection.

Owner:SHANGHAI INST OF SATELLITE EQUIP

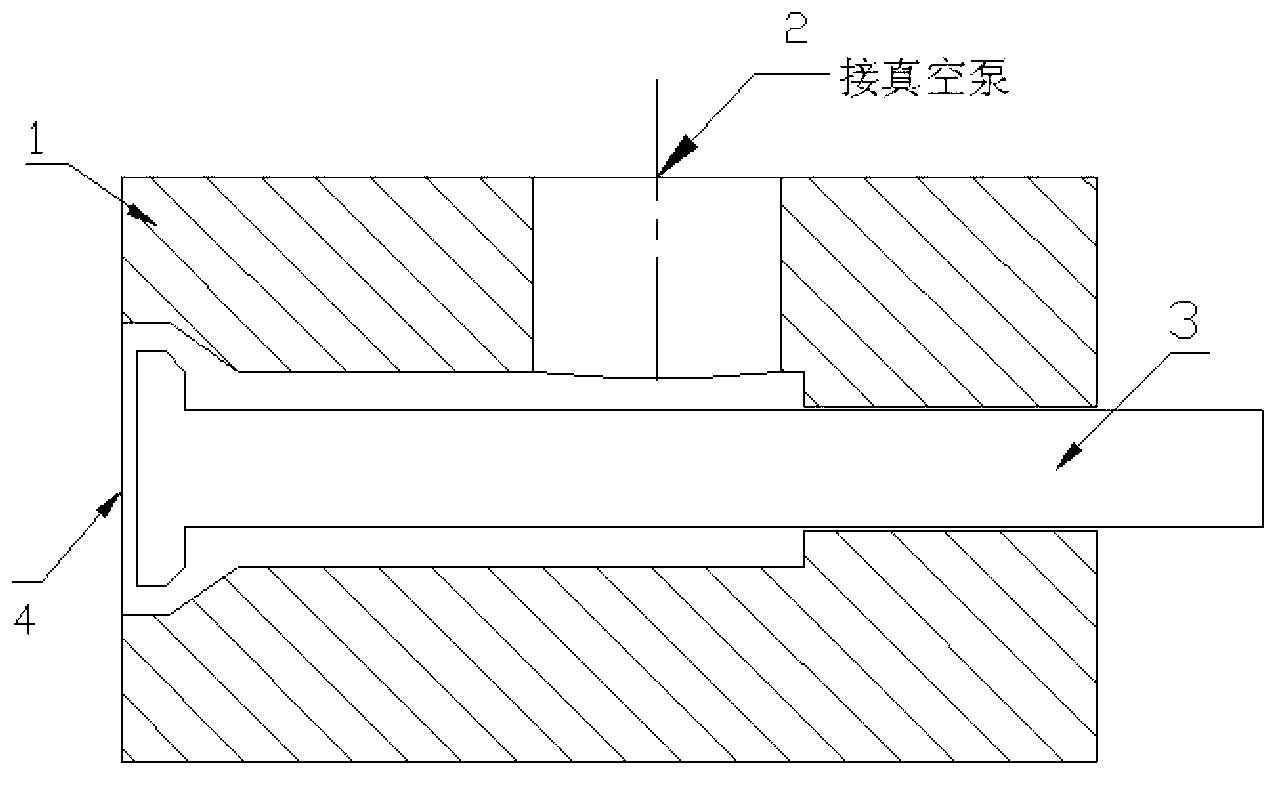

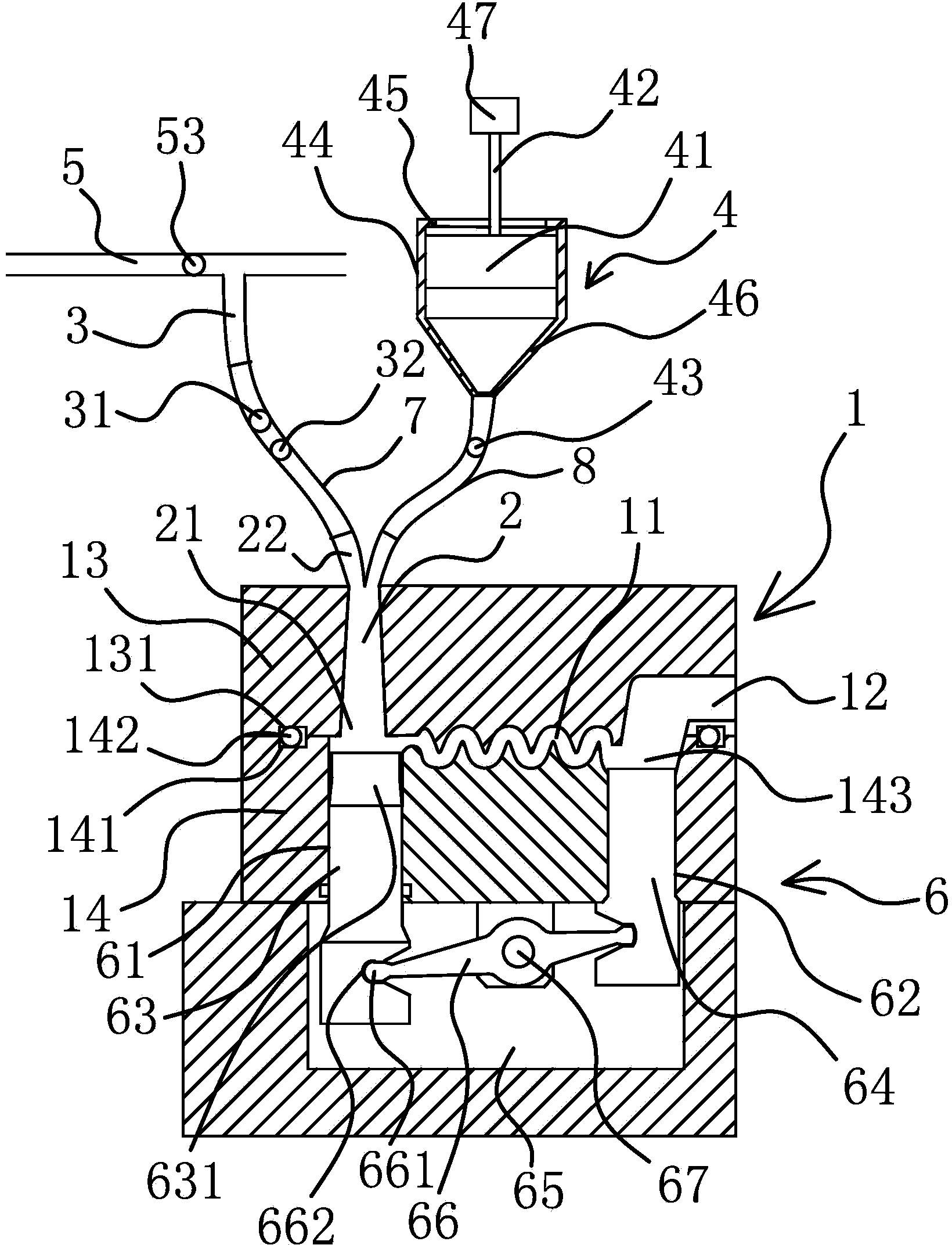

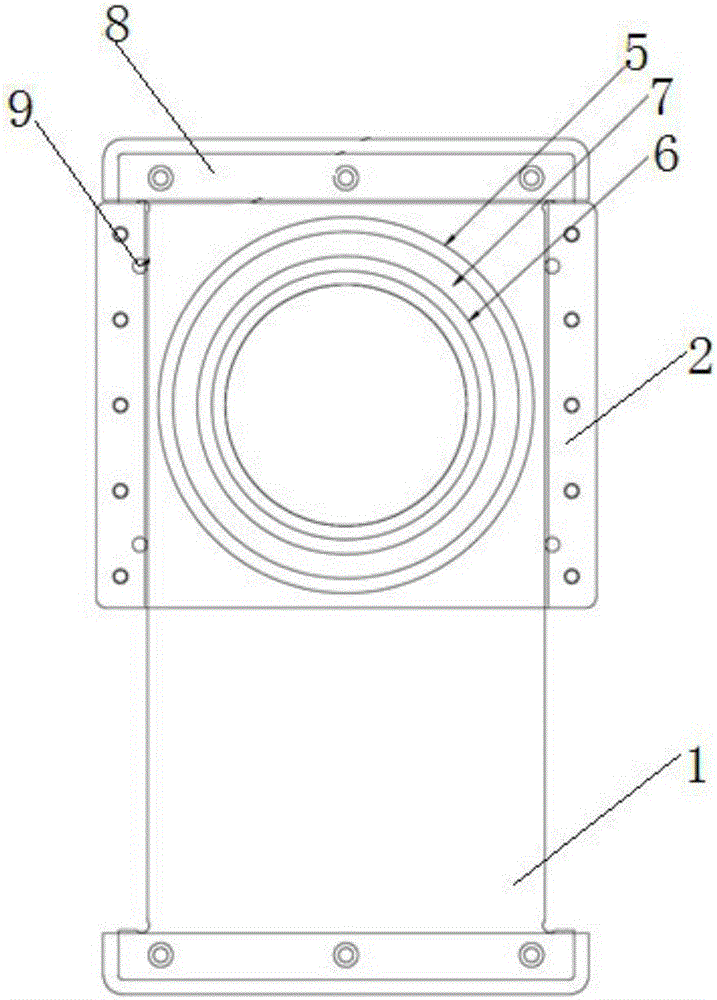

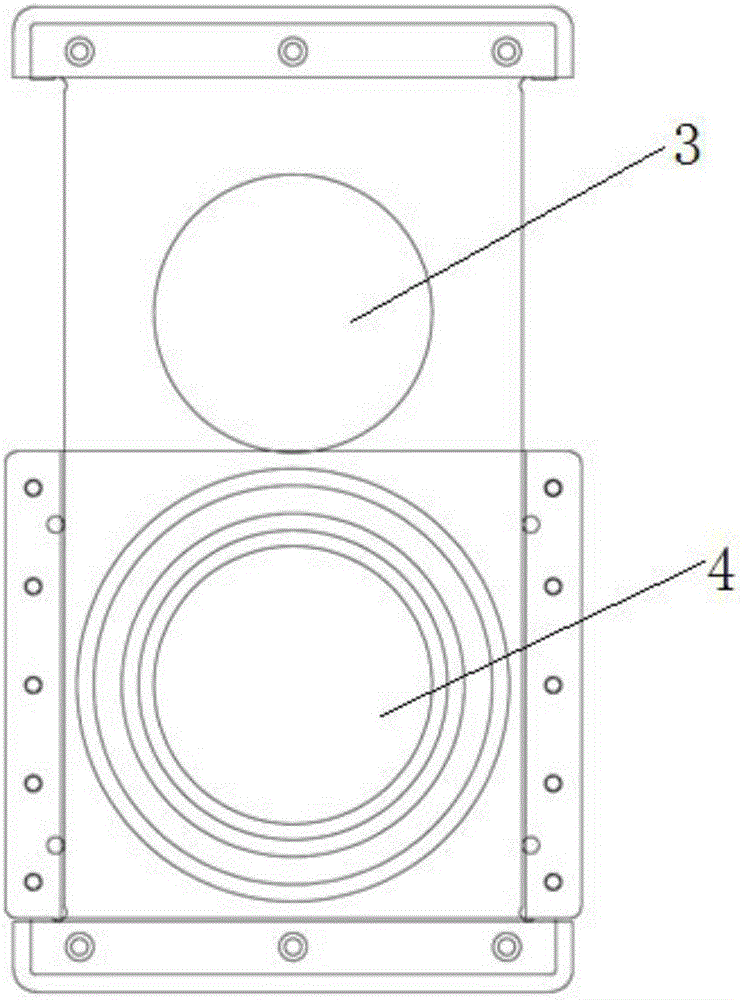

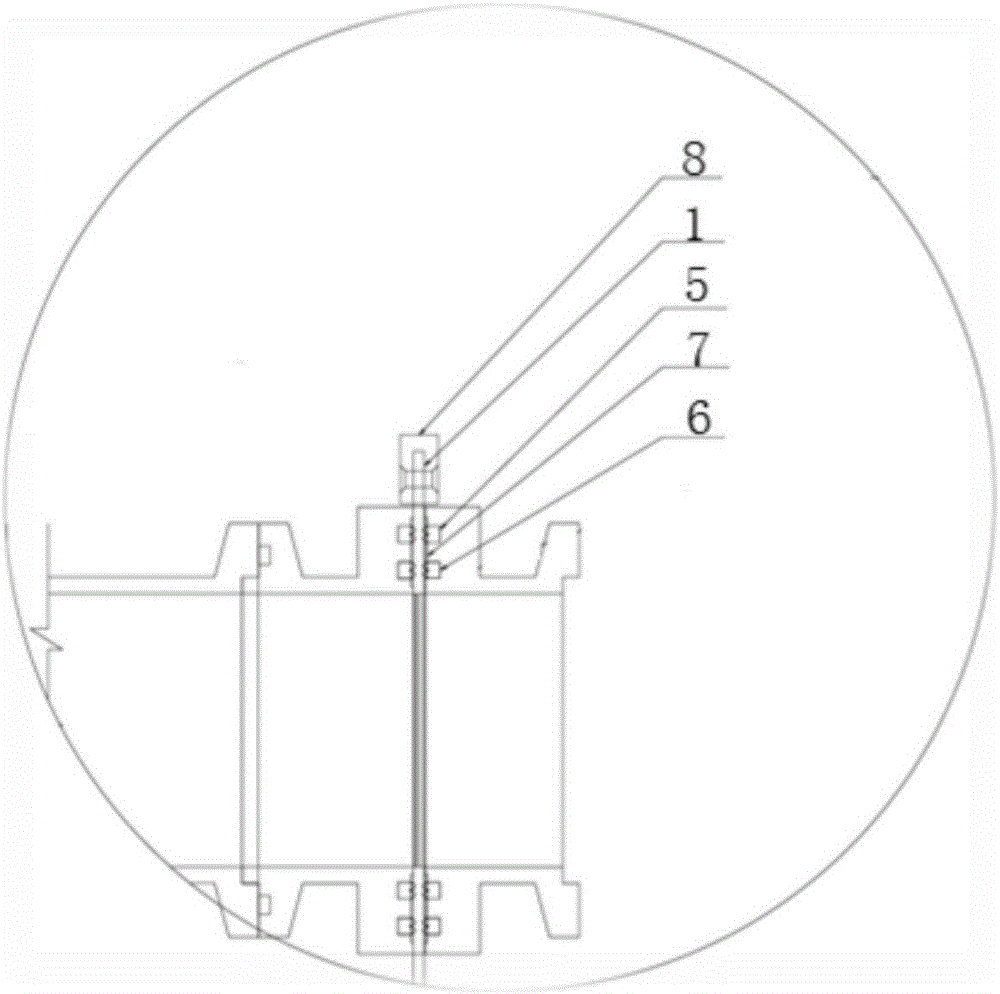

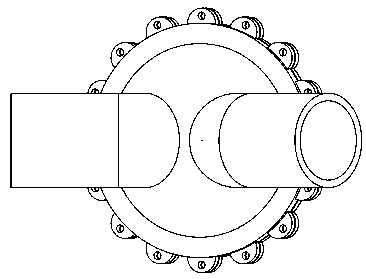

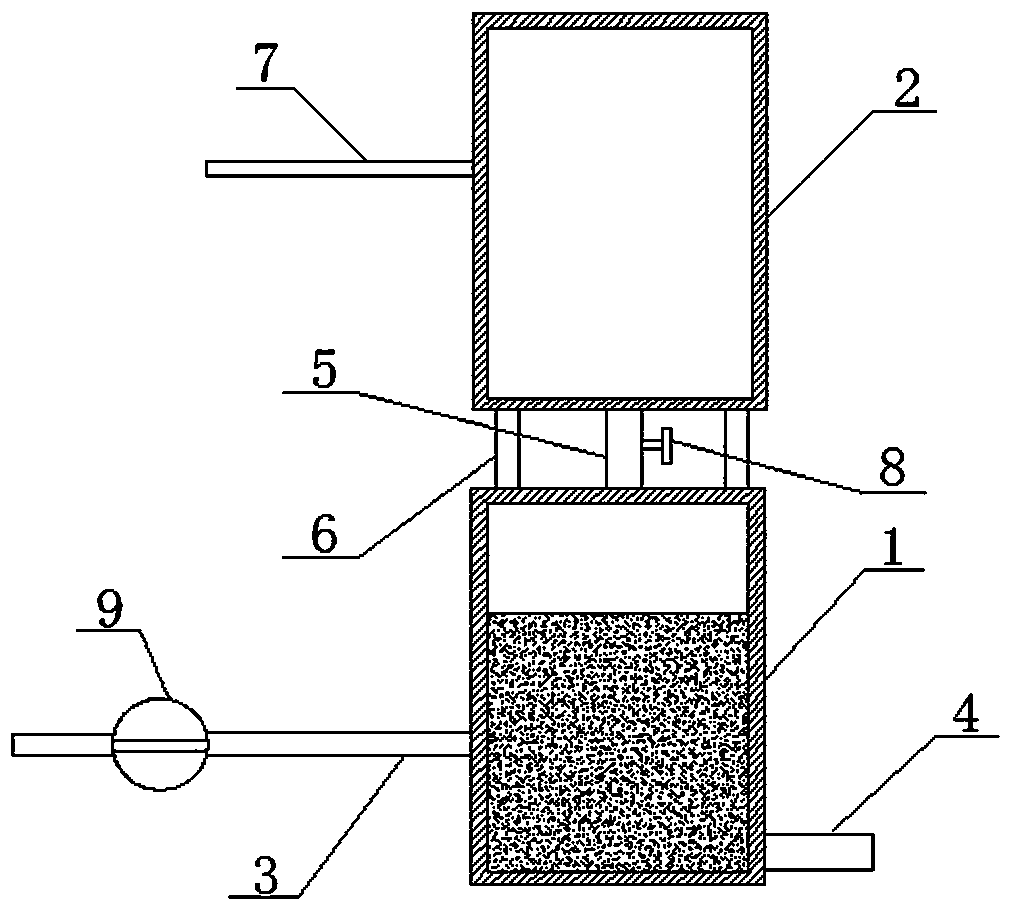

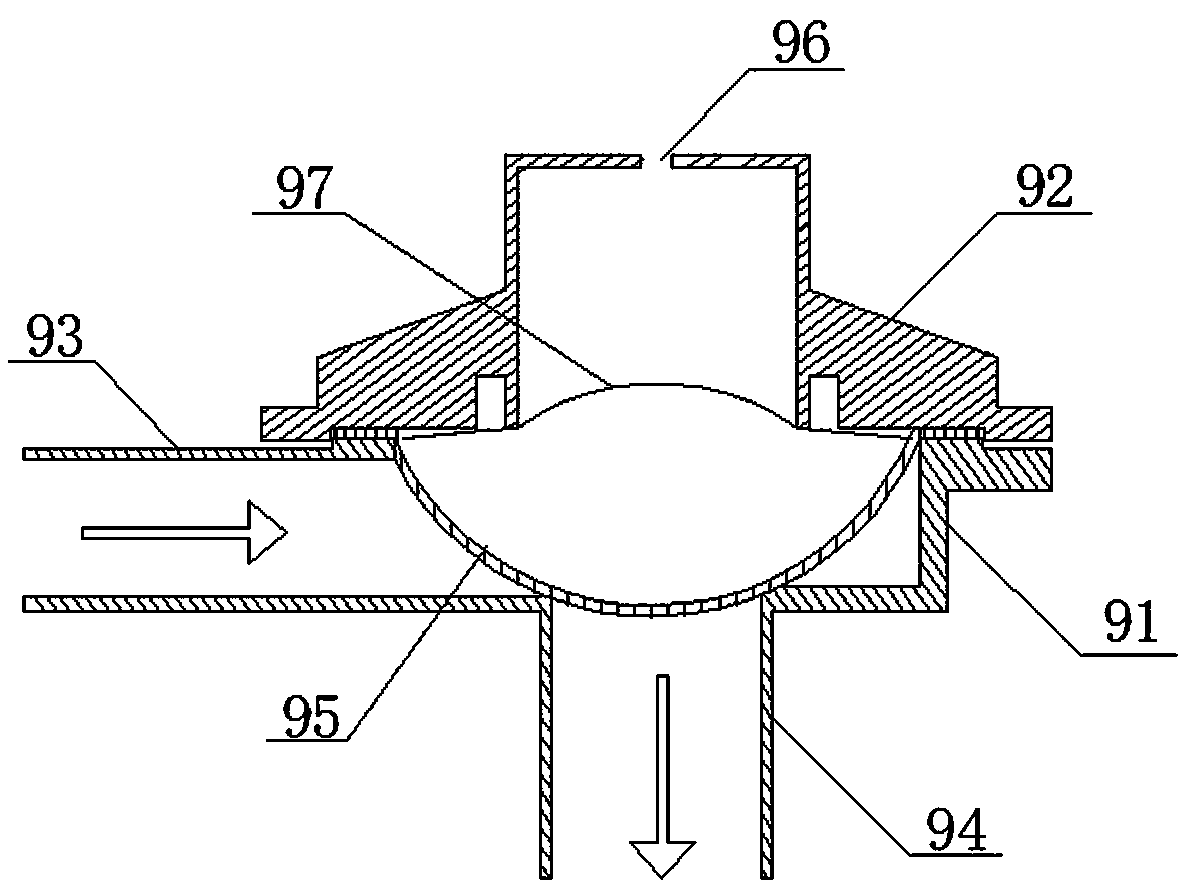

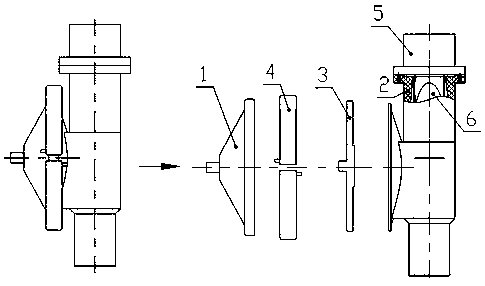

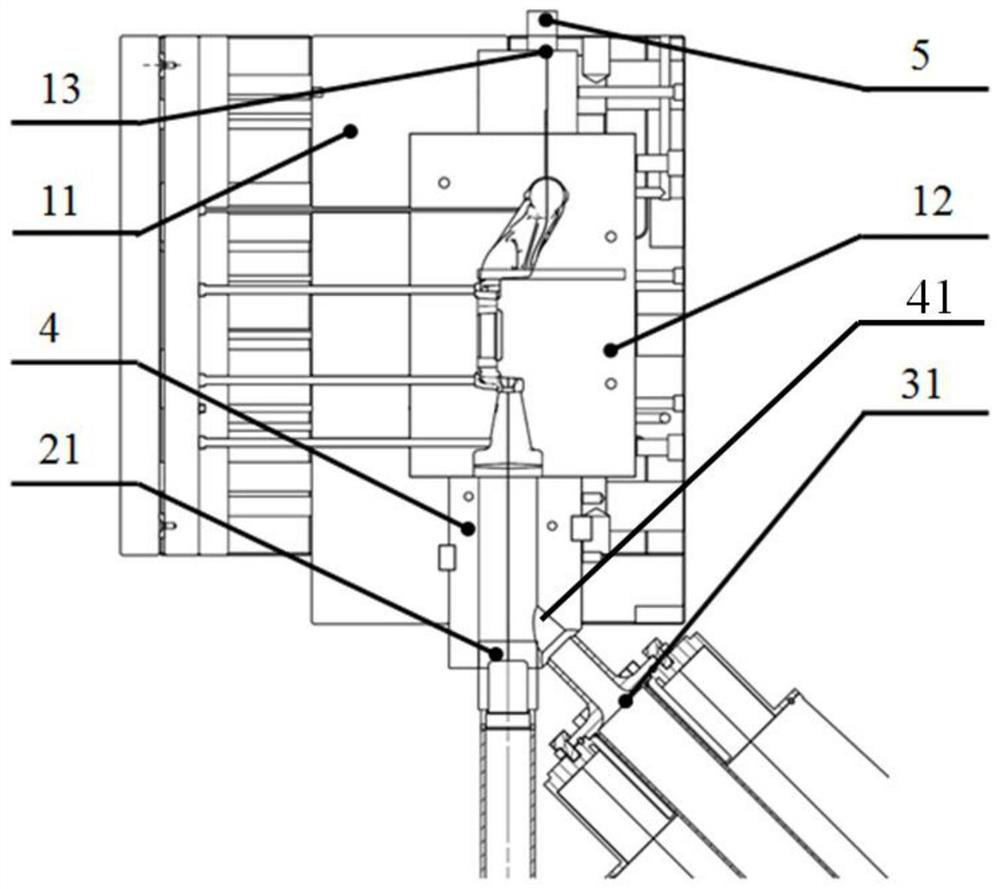

Vacuum stop valve and hydraulic drive device and vacuumizing device formed by vacuum stop valve and hydraulic drive device

InactiveCN102979917ASimple structureEasy to disassembleOperating means/releasing devices for valvesLift valveHydraulic cylinderDevice form

The invention discloses a vacuum stop valve and a hydraulic drive device and a vacuumizing device formed by the vacuum stop valve and the hydraulic drive device. The stop valve comprises a valve body and a valve core. The hydraulic drive device comprises a hydraulic cylinder, a three-position four-way magnetic valve, an energy storage device, a two-position two-way magnetic valve, a one-way valve and a hydraulic control device. The vacuumizing device comprises the vacuum stop valve and the hydraulic drive device. A single valve core type is adopted in the vacuum stop valve, and therefore structure is simple, disassembly is convenient, abrasion can not happen easily, maintenance work amount in later stages is reduced greatly, and use cost is reduced. By adopting hydraulic drive, drive force is large, and motion reliability of the valve core is improved. By adopting a hydraulic high-speed drive circuit, the problem that hydraulic transmission is slow in response speed is solved, response speed of the vacuum stop valve is improved, quick closing is achieved, and blockage due to the fact that molten metal enters into the valve body is effectively prevented.

Owner:HUAZHONG UNIV OF SCI & TECH

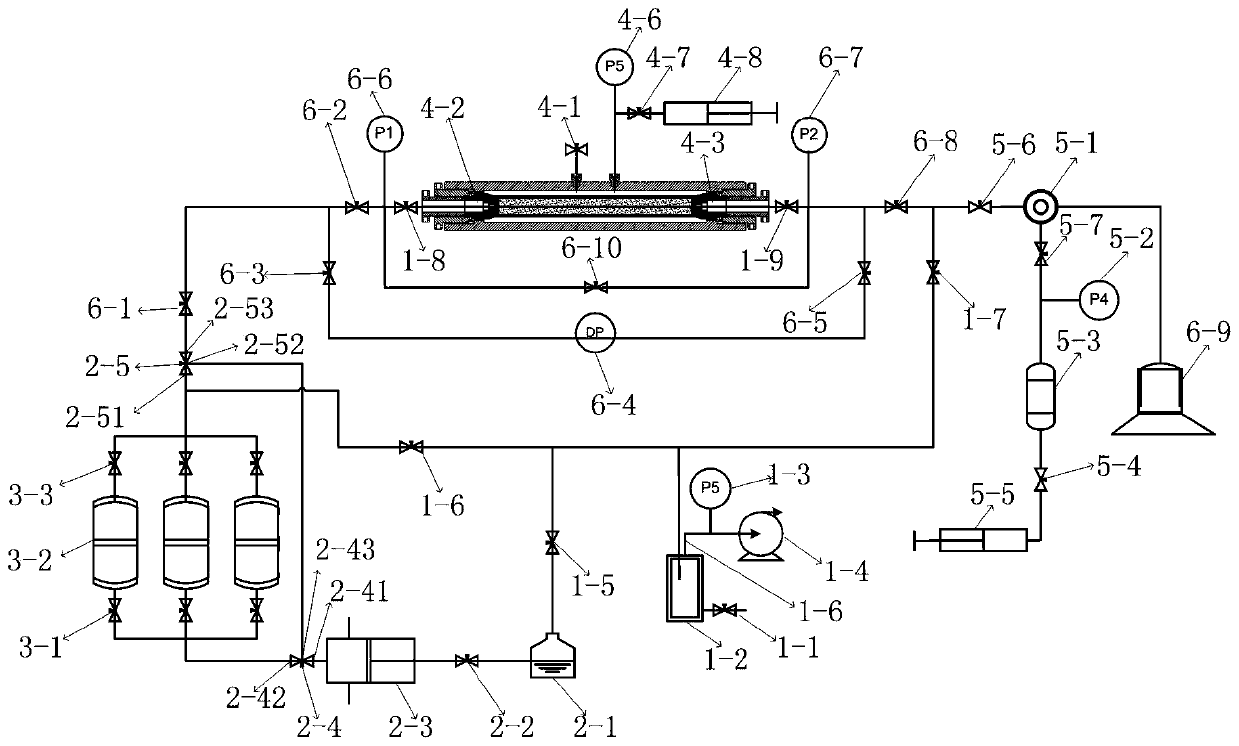

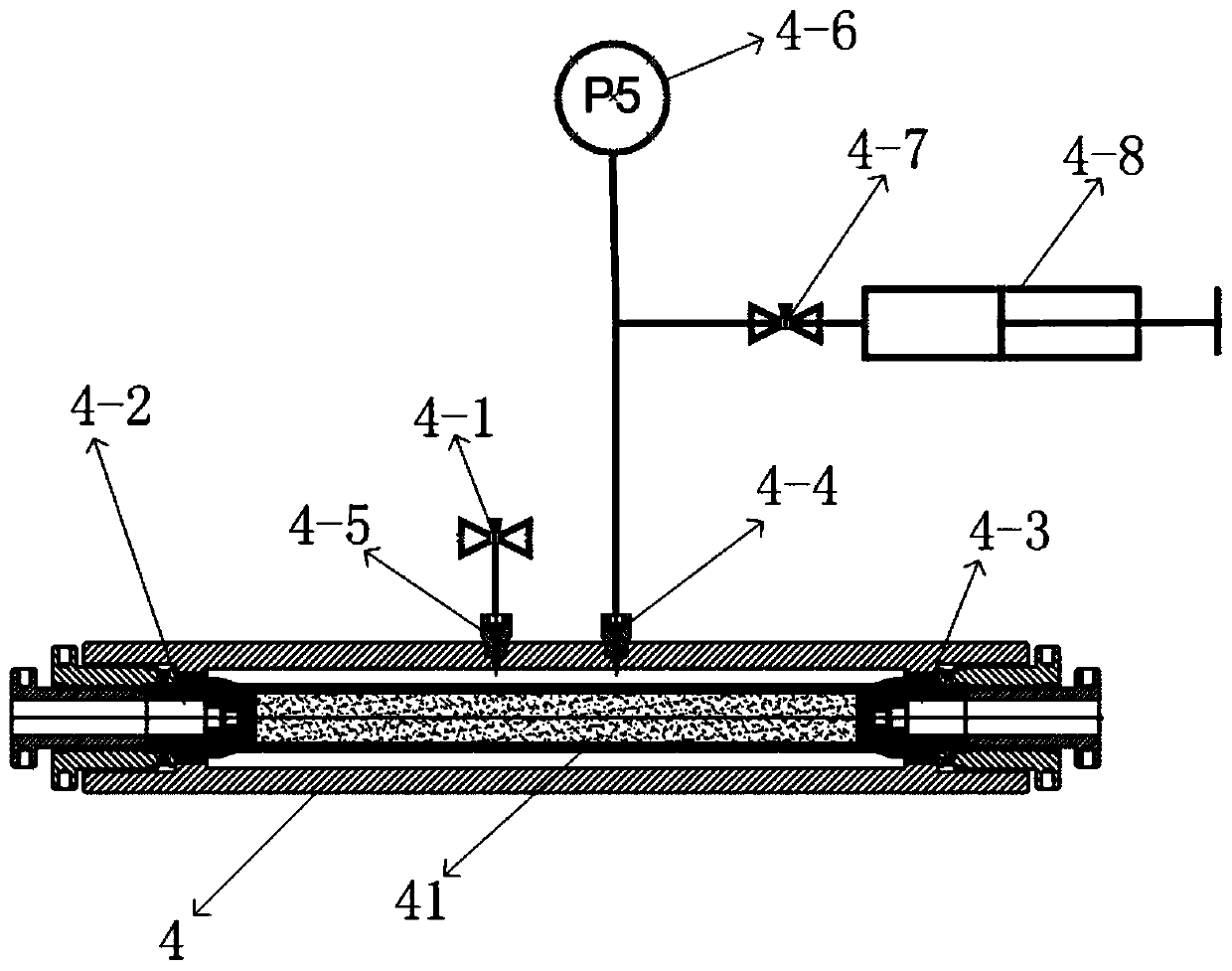

Device and method for testing displacement, steady-state permeability and transient permeability of low-permeability rock

The invention relates to a device and method for testing displacement, steady-state and transient-state permeability of a low-permeability rock. In the device, an outlet of a power pump is connected with an inlet of the clamping chamber through piston containers, an upstream stop valve, a pulse stop valve, an upstream pressure sensor and an upstream vacuum stop valve which are sequentially arranged on a pipeline. An outlet of the clamping chamber is connected with a flow meter through a downstream vacuum stop valve, a downstream pressure sensor, a downstream stop valve and a return pressure upstream stop valve which are sequentially arranged on the pipeline; the plurality of piston containers are arranged in the device to store different fluids; the displacement test can be carried out byusing the different fluids by selecting different piston containers, and during the steady-state permeability test and the transient permeability test, the steady-state permeability and the transientpermeability of corresponding rocks can be calculated by only reading parameters detected by corresponding sensors.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

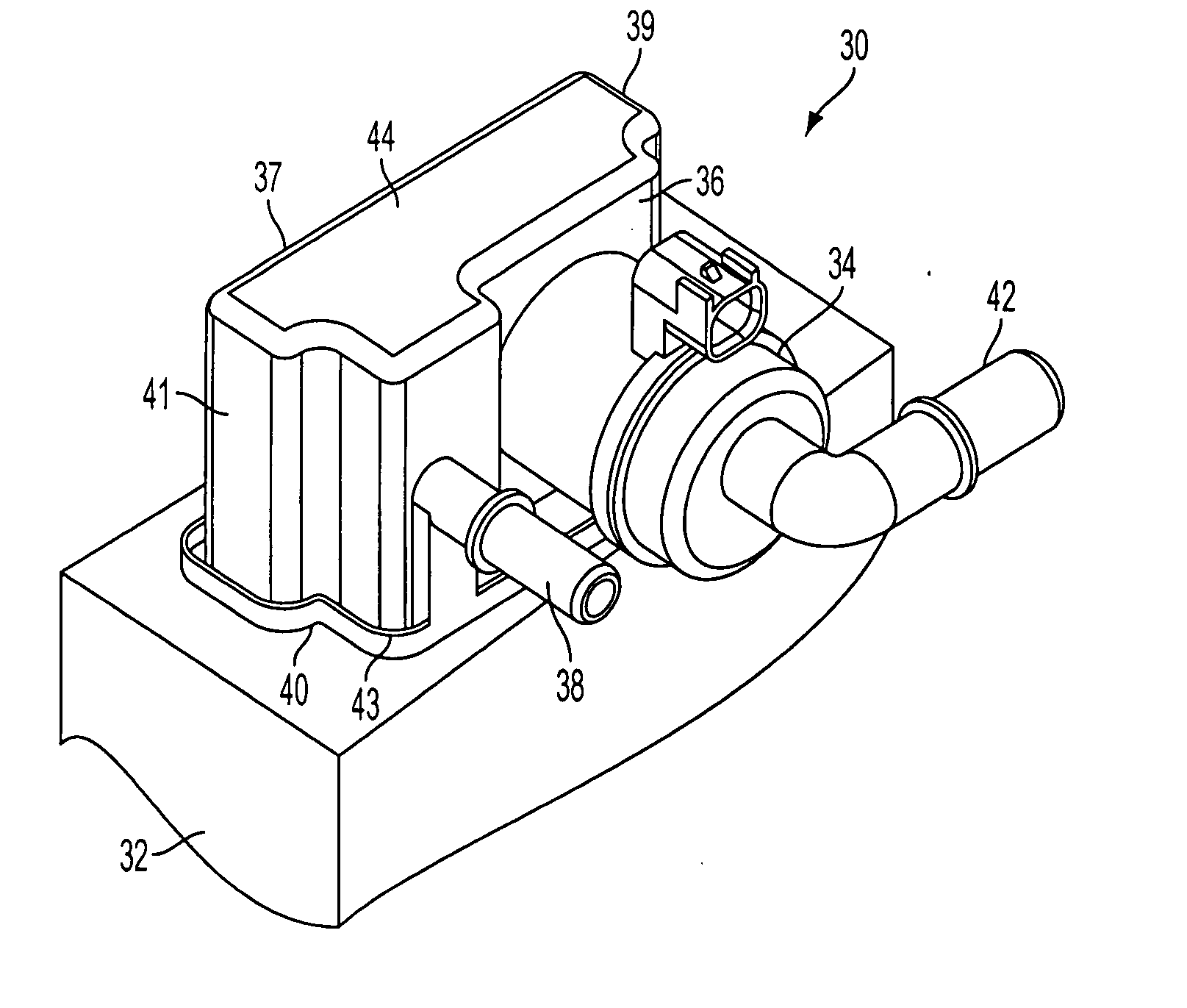

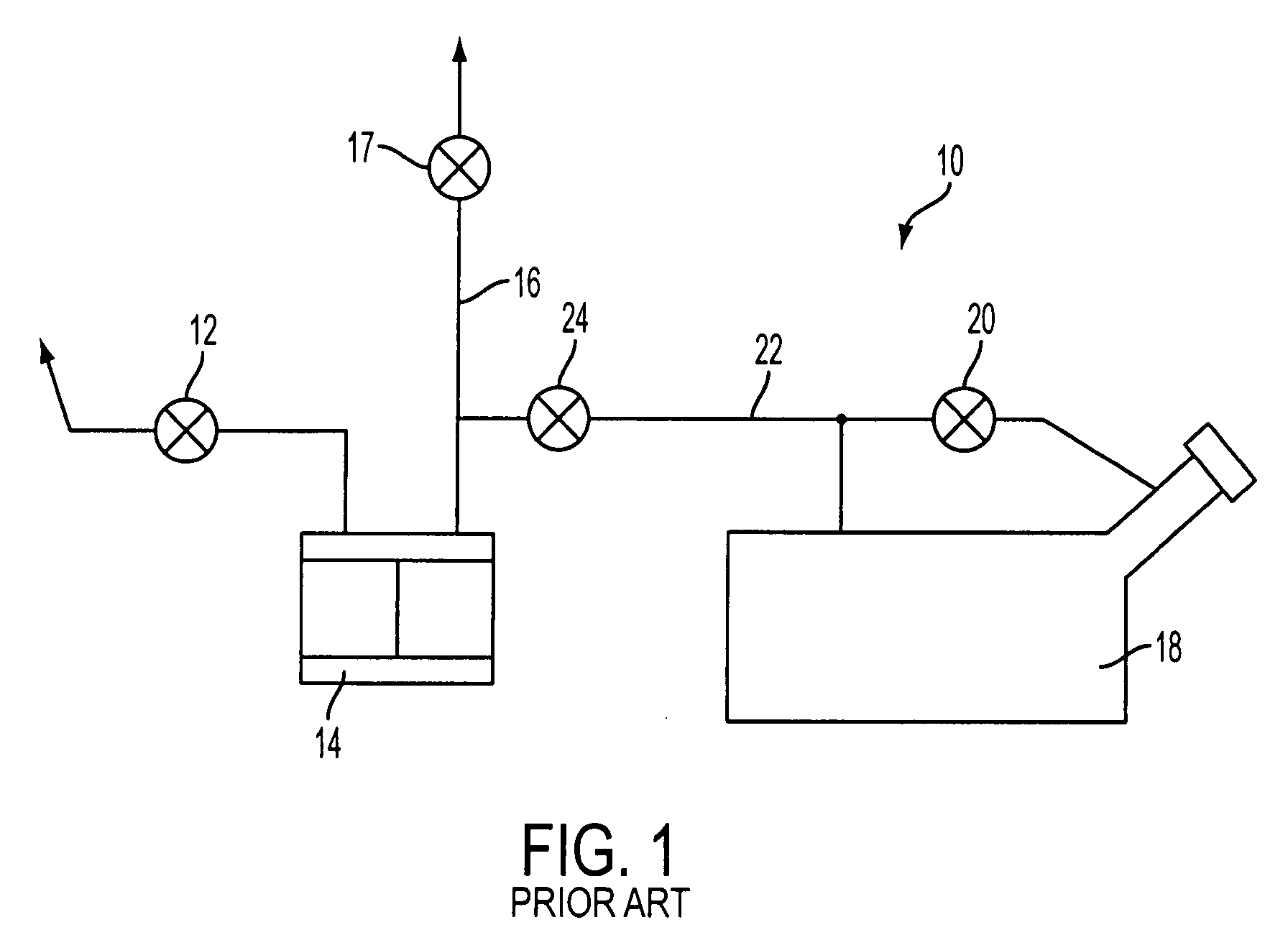

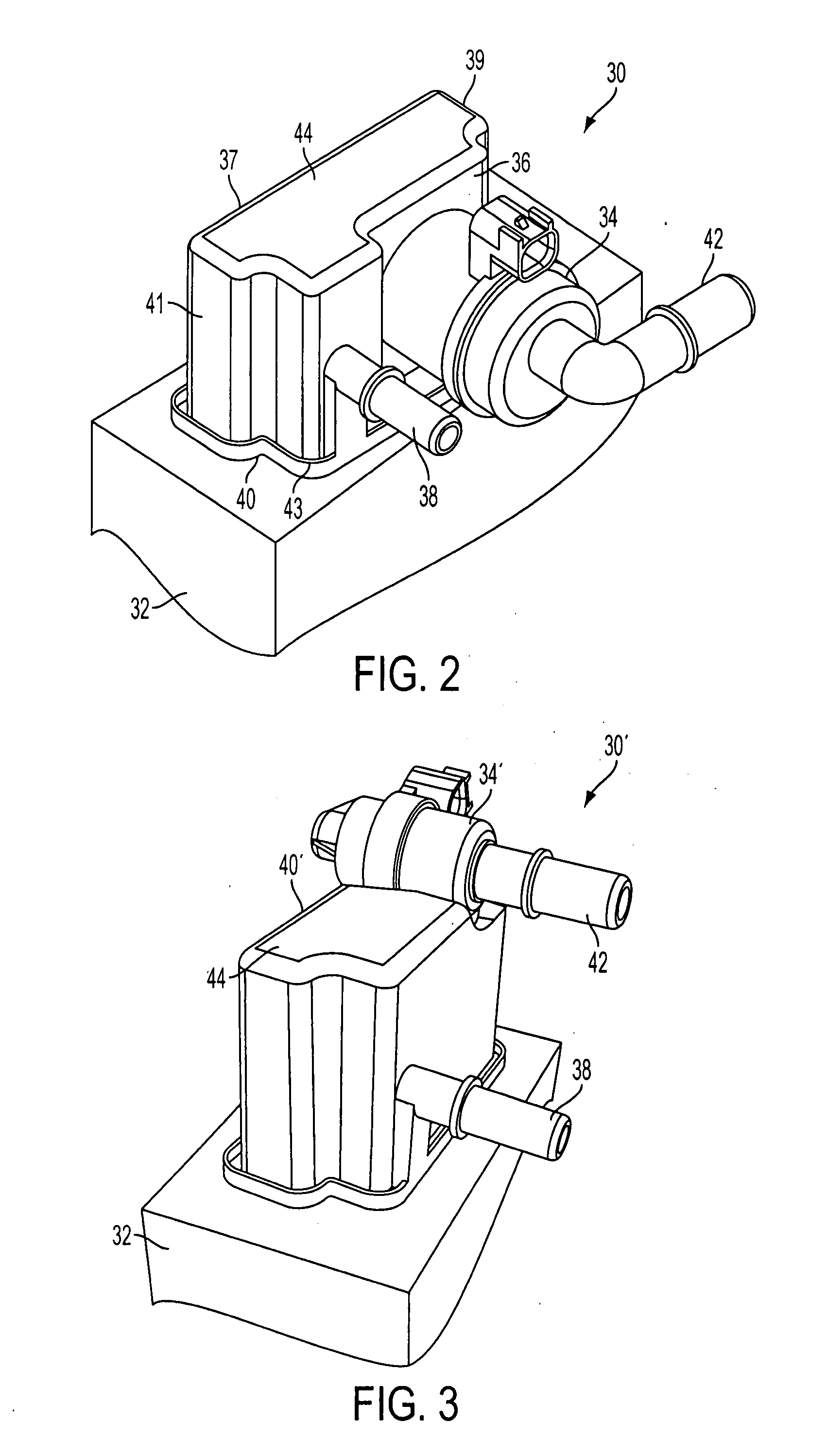

Integrated vacuum blocking valve

A canister assembly (30) is provided for canister purge system of a vehicle. The assembly includes a canister (32) constructed and arranged to adsorb hydrocarbon vapor. A vapor blocking valve (34) is integral with the canister and is in fluid communication therewith. The vapor blocking valve has a port (42) constructed and arranged to fluidly communicate with a fuel tank of the vehicle. The vapor blocking valve is constructed and arranged to permit communication between the fuel tank and canister and, under certain conditions, to isolate the fuel tank from the canister. Since the vapor blocking valve is integral with the canister, additional hoses and mounting brackets are not required.

Owner:SIEMENS CANADA LTD

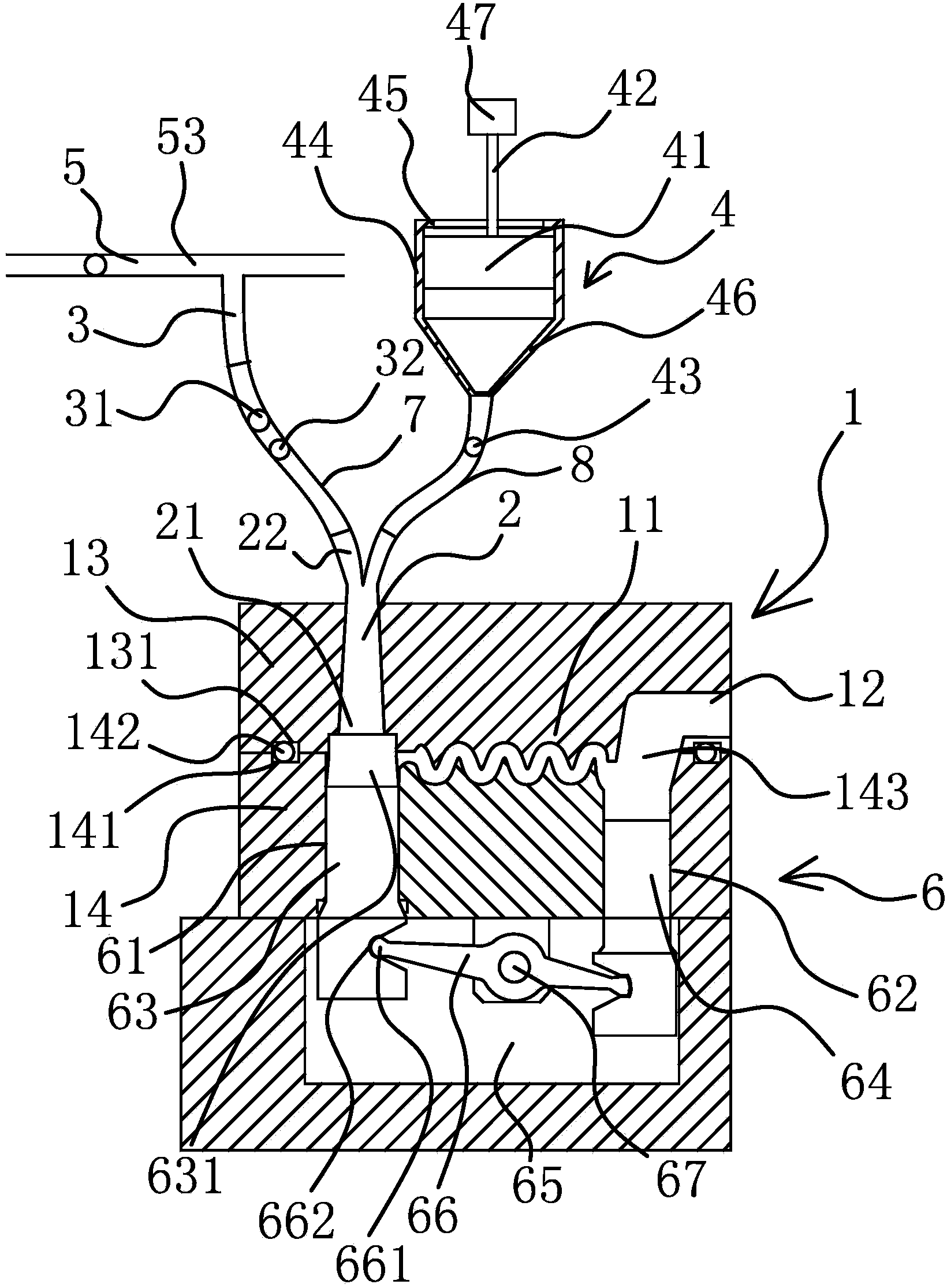

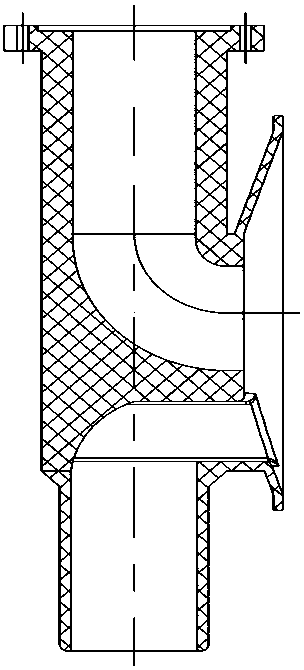

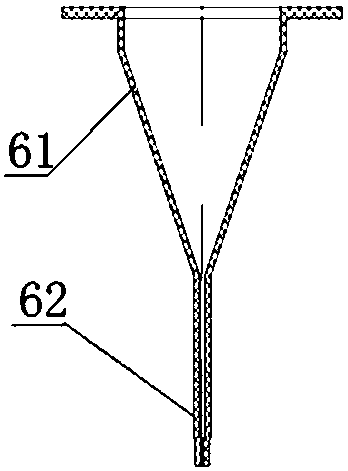

Vacuum pumping system for die cavities of die-casting dies

The invention relates to a vacuum pumping system for die cavities of die-casting dies. The vacuum pumping system solves the technical problem that the vacuum pumping cost of an existing die cavity is high. The vacuum pumping system comprises a plurality of die-casting dies, wherein a feeding passage, a Y-shaped vacuum pumping passage, a branch pipe, a vacuum cylinder barrel, a main pipe, a vacuum tank and a vacuum pumping device are arranged on each die-casting die, a piston body is arranged in each vacuum pumping cylinder barrel in a sliding mode, each piston rod is connected with a driving mechanism, a vacuum stop valve is arranged between each vacuum pumping passage and the corresponding feeding passage, a main pipe electronic control valve is connected onto each main pipe, a branch pipe electronic control valve and a first one-way valve are respectively connected onto each branch pipe, and a second one-way valve is arranged between each die cavity and the corresponding vacuum pumping cylinder barrel. The vacuum pumping system for the die cavities of the die-casting dies has the advantages that the cost is low, one vacuum pump can realize vacuum pumping of a plurality of die cavities, the vacuum is pumped in a double-choice mode, the vacuum pumping difficulty is low, and molten metal is unlikely to enter vacuum pipelines.

Owner:诸暨市海禾金属制品有限公司

Thermocouple device for polycrystal ingot furnace

InactiveCN102703967AExtended service lifePolycrystalline material growthThermometers using electric/magnetic elementsOxide ceramicFurnace temperature

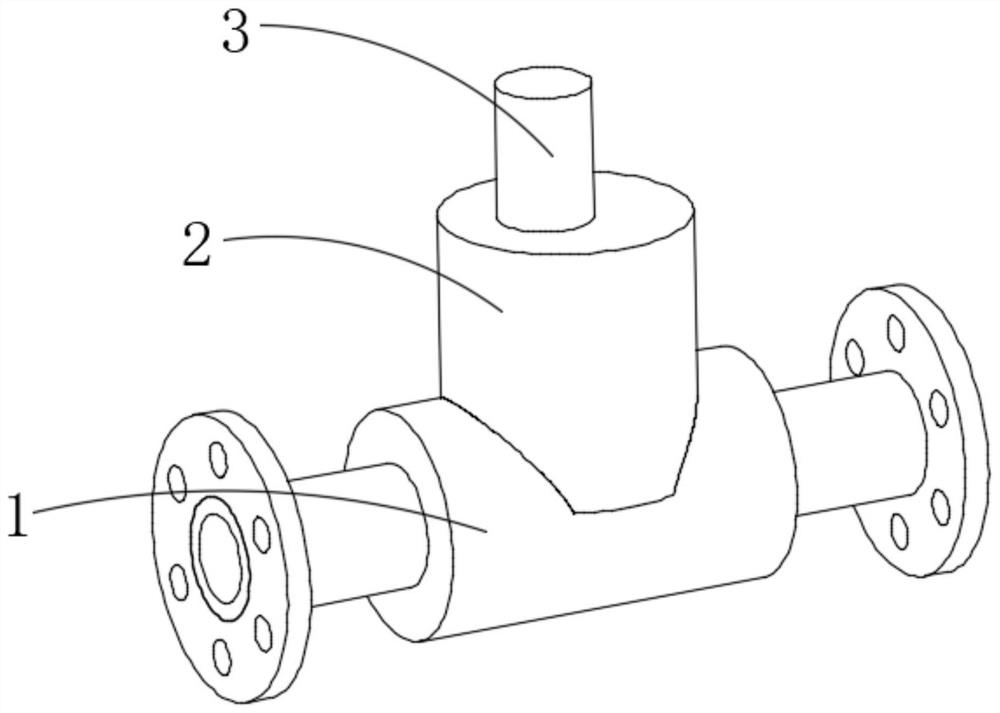

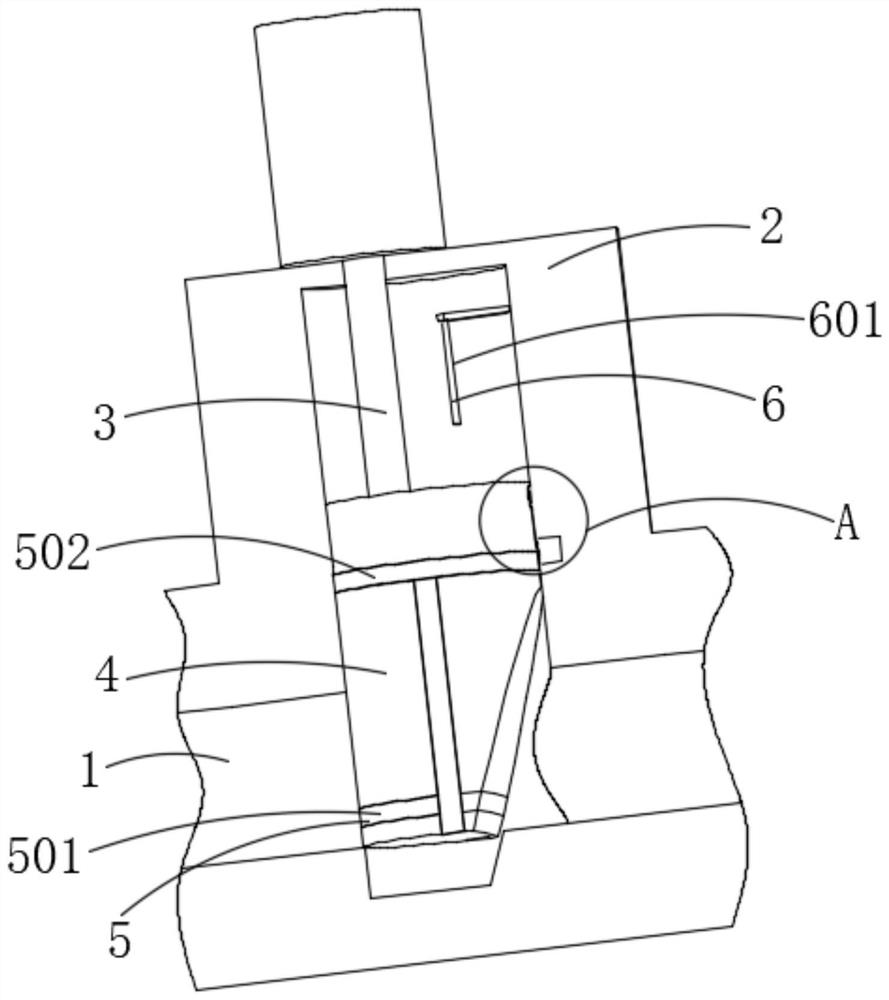

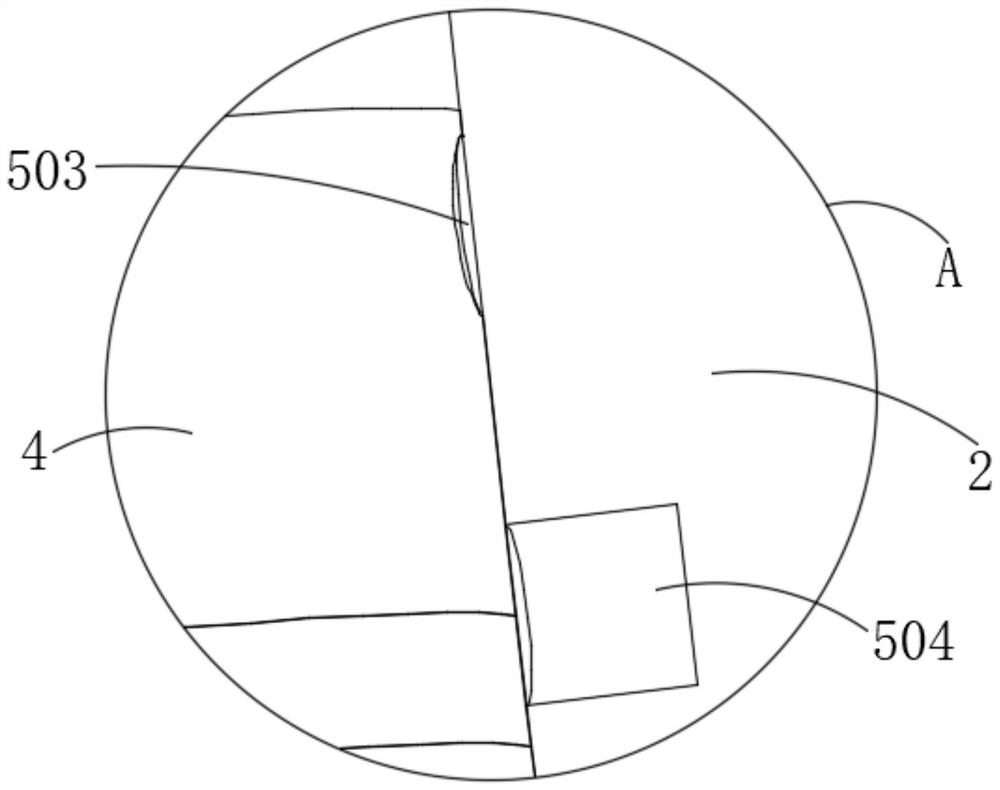

The invention discloses a thermocouple device for a polycrystal ingot furnace. The thermocouple device is a constituent part of a polycrystal ingot furnace temperature control system, and comprises a thermocouple cabin, wherein the thermocouple cabin comprises a reducing T-joint, a thermocouple joint, an aluminum oxide ceramic tube and a thermocouple, wherein the thermocouple joint is hermetically fixed at one end of the reducing T-joint; the aluminum oxide ceramic tube is hermetically fixed in the reducing T-joint through a ceramic tube fixing base; the thermocouple is fixed in the aluminum oxide ceramic tube through the thermocouple fixing base, and is connected with the thermocouple joint; the reducing T-joint is connected with a pipeline branch tube fitting; the pipeline branch tube fitting is connected with a three-way tube through a vacuum hose; the three-way tube is connected with a vacuum cutoff valve; the vacuum cutoff valve is connected with a vacuum unit; and a vacuum deflation valve is connected to the pipeline branch tube fitting. Due to the adoption of the device disclosed by the invention, the service life of the thermocouple can be prolonged greatly, and a hearth is protected when the aluminum oxide ceramic tube is fractured and leaks air accidentally.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

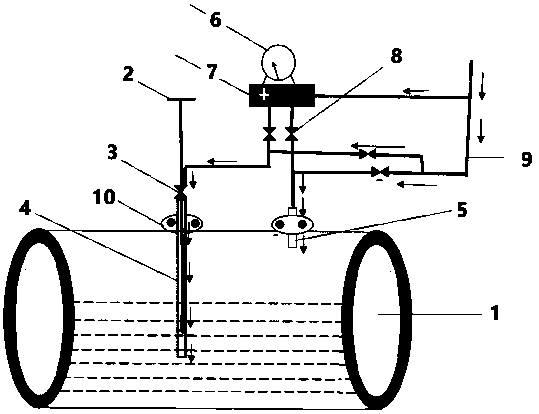

Maintenance system and method for air blowing type level gauge

PendingCN109357731ASolve abnormal liquid levelSolve the problem of clogged measuring tubeTesting/calibration apparatusLevel indicators by pressure measurementPositive pressureDifferential pressure

The invention relates to a maintenance system and method for an air blowing type level gauge. The maintenance system includes a reaction kettle, an air blowing type level gauge, a vacuum stop valve, and a nitrogen gas delivery pipe. The air blowing type level gauge is composed of a positive pressure measuring tube needle, a special blowing valve, a level gauge positive pressure measuring tube, a level gauge negative pressure measuring tube, a differential pressure transmitter, a blowing two-way base, and flanges. The air blowing type level gauge is mounted at the top of the reaction kettle. The level gauge positive pressure measuring tube is mounted at a position of at least half of the reaction kettle through a flange. The positive pressure measuring tube needle is mounted in the level gauge positive pressure measuring tube. The special blowing valve is mounted on the nozzle of the level gauge positive pressure measuring tube and is in contact with the positive pressure measuring tubeneedle. The negative pressure measuring tube is mounted on the top of the reaction kettle through a flange. The nitrogen gas delivery pipe is respectively connected to the level gauge positive pressure measuring tube and the level gauge negative pressure measuring tube through the differential pressure transmitter, the blowing two-way base and the vacuum stop valve in sequence. According to the maintenance system and method for the air blowing type level gauge, the dredging of the needle is performed by the level gauge positive pressure measuring tube and the negative pressure measuring tube,so the operation is simple and convenient, and the operation risk and labor intensity are also reduced.

Owner:JIANGSU GUOWANG HIGH TECH FIBER CO LTD +1

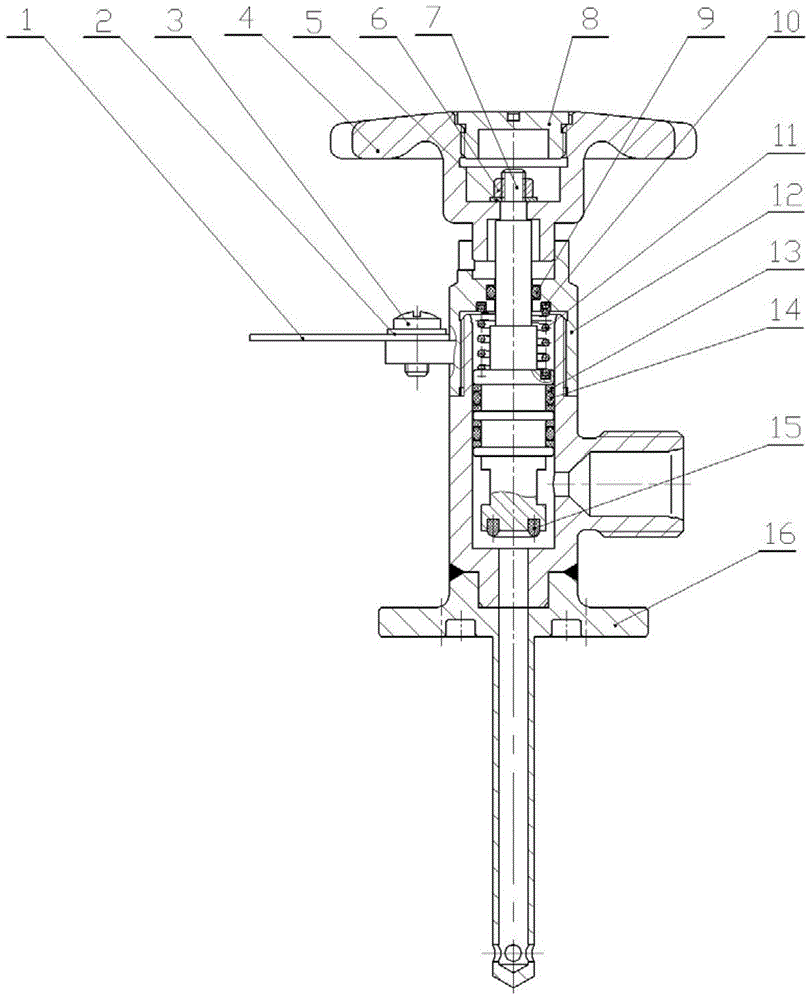

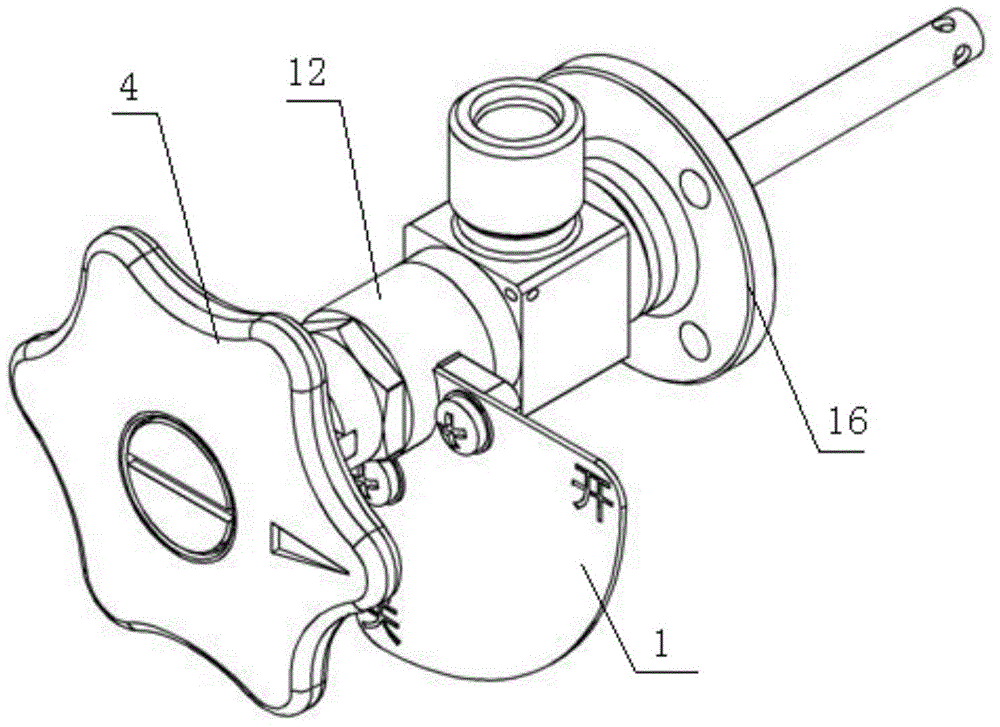

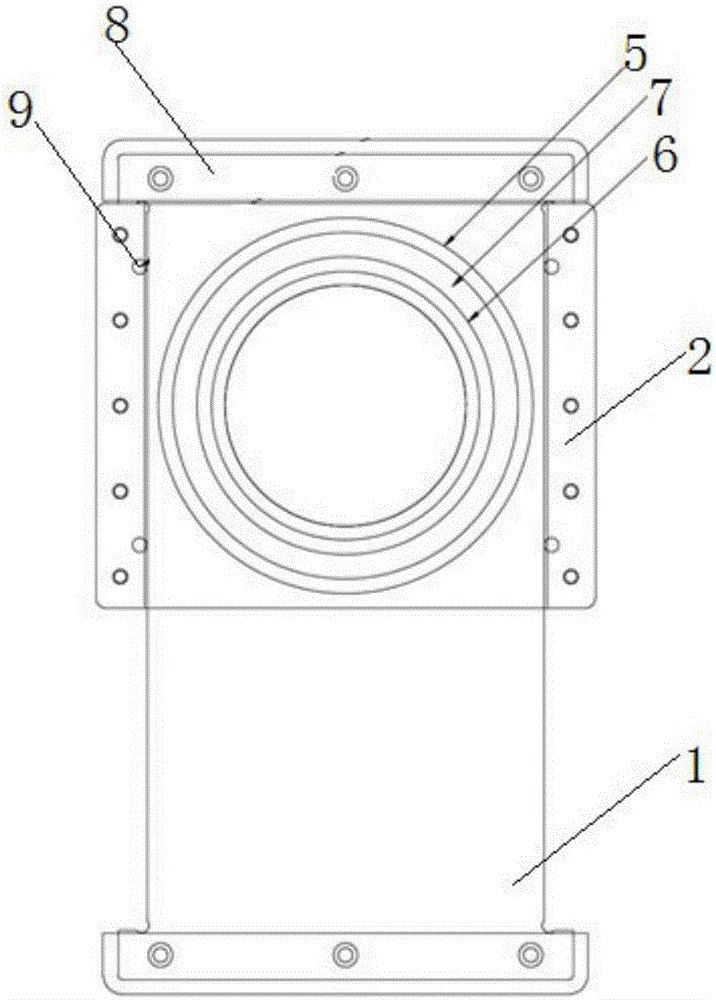

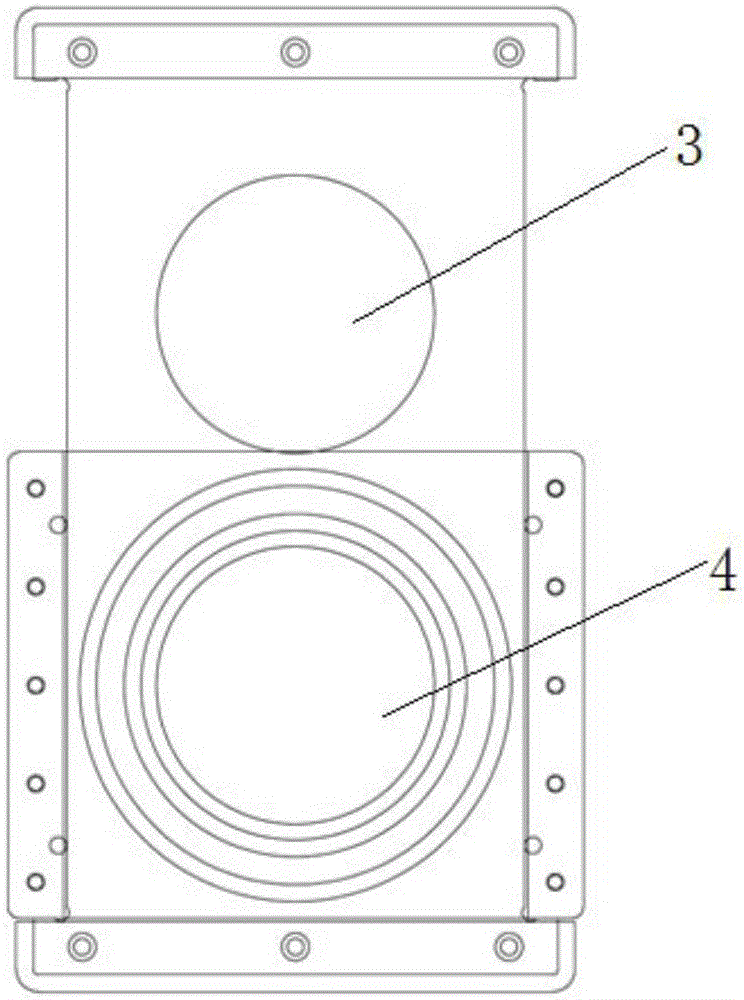

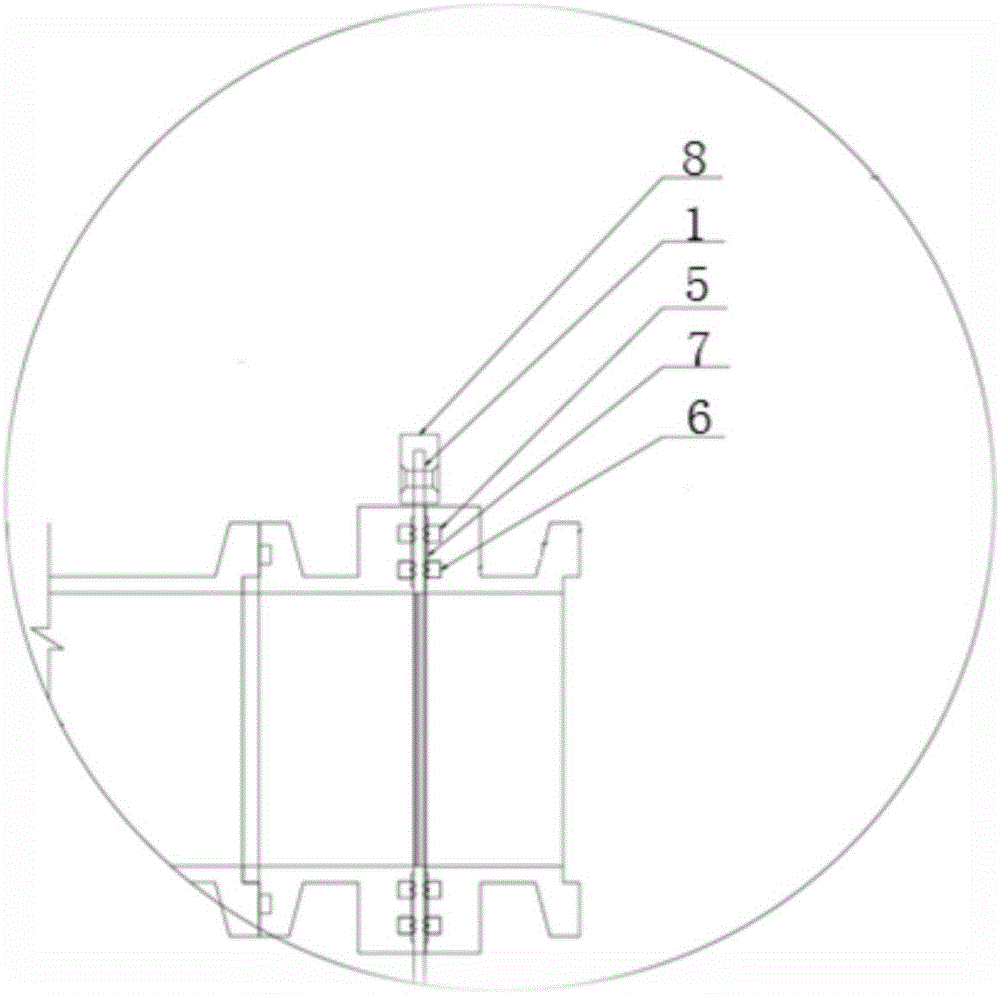

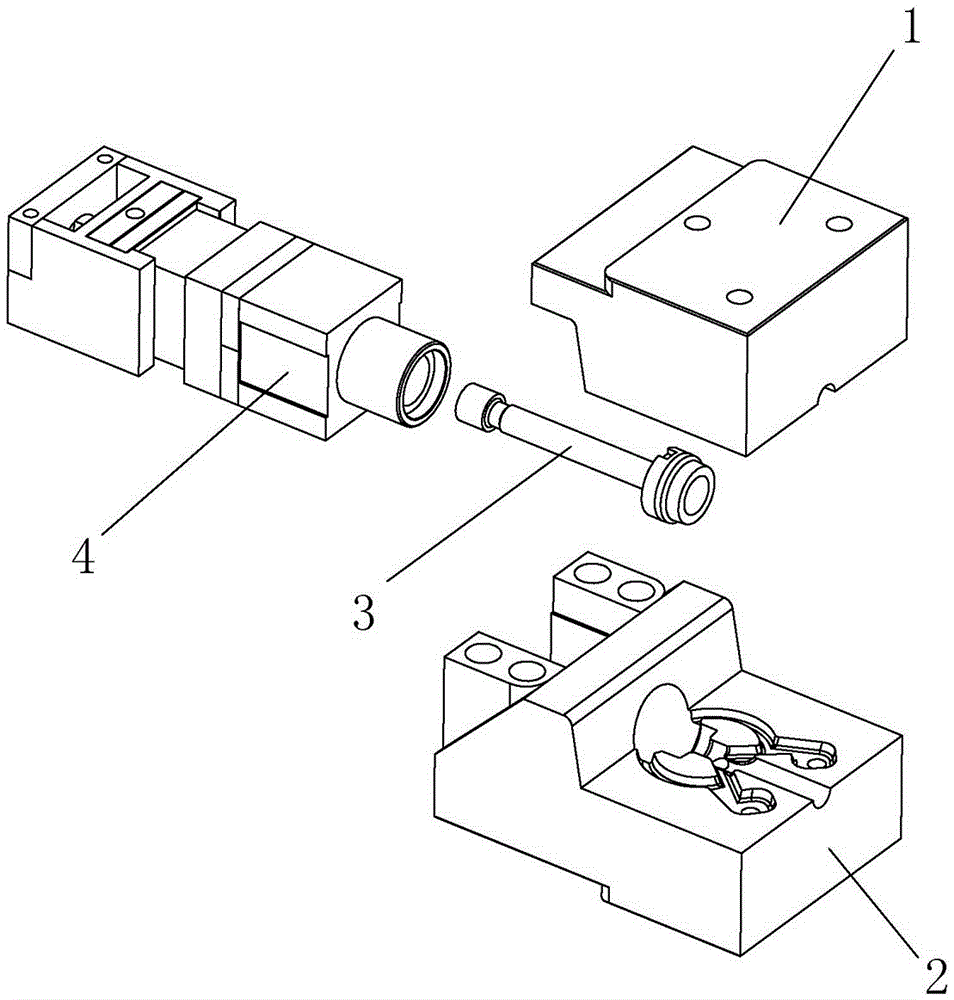

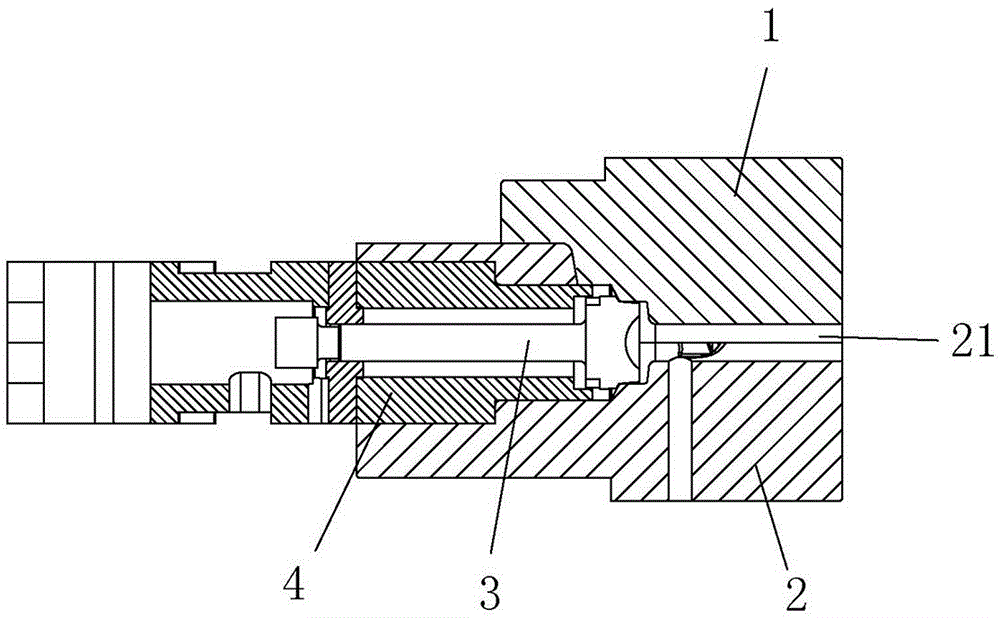

Vacuum stop valve under zero gravity

ActiveCN104613181AImprove reliabilityImprove sealingSpindle sealingsEqualizing valvesEngineeringZero gravity

The invention discloses a vacuum stop valve under zero gravity. The vacuum stop valve comprises a handle, a valve element, a spring, a valve cap and a valve body. The valve element and the spring are installed in the valve body through the valve cap. One end of the valve cap is in threaded connection with the valve body and is provided with a deep groove and a shallow groove. One end of the handle provided with tenons is placed in the grooves and is used in cooperation with the valve cap. A positioning groove is formed in the bottom end face of a threaded hole in the valve cap and is used for installation of the spring. An annular sealing groove is formed in the inner wall of a through hole of the valve cap and is used for installation of a small radial seal ring. The small radial seal ring plays a role in guiding and dust prevention and prevents the valve element from waggling in the radial direction in the axial moving process. Axial soft seat sealing is adopted for internal sealing of the vacuum stop valve, sealing force is provided by the spring, and therefore reliable sealing of multiple times of opening and closing operations can be achieved; a plunger type bi-radial seal ring and a sealing retainer ring are adopted for external sealing, the two rings are mutual backups, and therefore the reliability of the valve is improved.

Owner:BEIJING SATELLITE MFG FACTORY

Slope double-seal vacuum stop valve structure

PendingCN114738510AImprove sealingEasy resetOperating means/releasing devices for valvesSlide valveGas passingEngineering

The invention discloses a slope double-seal vacuum stop valve structure, which relates to the technical field of vacuum stop valves, and comprises a valve body and a connecting shell, and a sealing mechanism penetrating into a sealing stop block is arranged on the outer wall of the sealing stop block and the output end of an air cylinder. By arranging the sealing mechanism, the output end of the air cylinder pushes the sealing piston block to drive the sealing check block to move downwards, when the sealing check block plugs the interior of the valve body, the first spring pushes the fixing rod to reset, the fixing rod is inserted into the fixing hole, the sealing check block is fixed to the connecting shell, and meanwhile the fixing rod is separated from the sealing piston block; then the output end of the air cylinder continues to push the sealing piston block to move in the sealing bin, and air in the sealing bin is conveyed into the first air bag through a first air guide pipe and conveyed into the second air bag through a second air guide pipe; and the first air bag and the second air bag are expanded to block the gaps of the contact parts of the sealing check block, the valve body and the connecting shell, so that the overall sealing performance of the device is improved.

Owner:合肥品炙装备科技有限公司

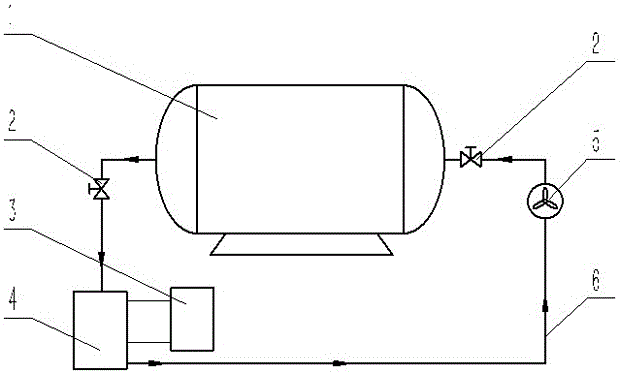

Back pressure turbine vacuum deaerator system and condensation water circulation method

ActiveCN105910092AHigh thermal efficiencySave resourcesLiquid degasificationEngineeringWater circulation

Provided are a back pressure turbine vacuum deaerator system and a condensation water circulation method. The system mainly comprises: a vacuum deaerator, a condensate pump, a deironing filter, a shaft-sealing condenser, and a vacuum pump. A low-pressure steam source is used as deoxidized steam and is connected with one end of an electric check valve, and the other end converges into a path and is connected with an electric control valve. The other end of the electric control valve is connected with a check valve. The other end of the check valve is connected with a vacuum stop valve. The vacuum stop valve is connected with the deoxidizing connector of the vacuum deaerator. One end of a vacuum electric valve is connected with the condensed water outlet of the vacuum deaerator, and the other end is connected with the inlet side of the condensate pump. One end of the check valve is connected with the outlet side of the condensate pump, and the other end is connected with an electric sluice valve. The other end of the electric sluice valve is connected with a deironing filter. One end of an electric cut-off valve is connected with a bypass electric cut-off valve, and the other end is connected with the inlet of the shaft-sealing condenser. One end of the electric cut-off valve is connected with the outlet of the shaft-sealing condenser, and the other end is connected with one end of the bypass electric cut-off valve.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST +1

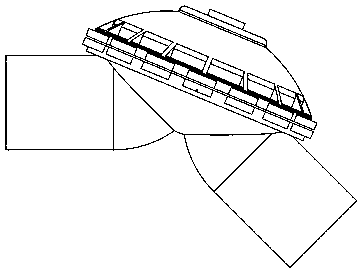

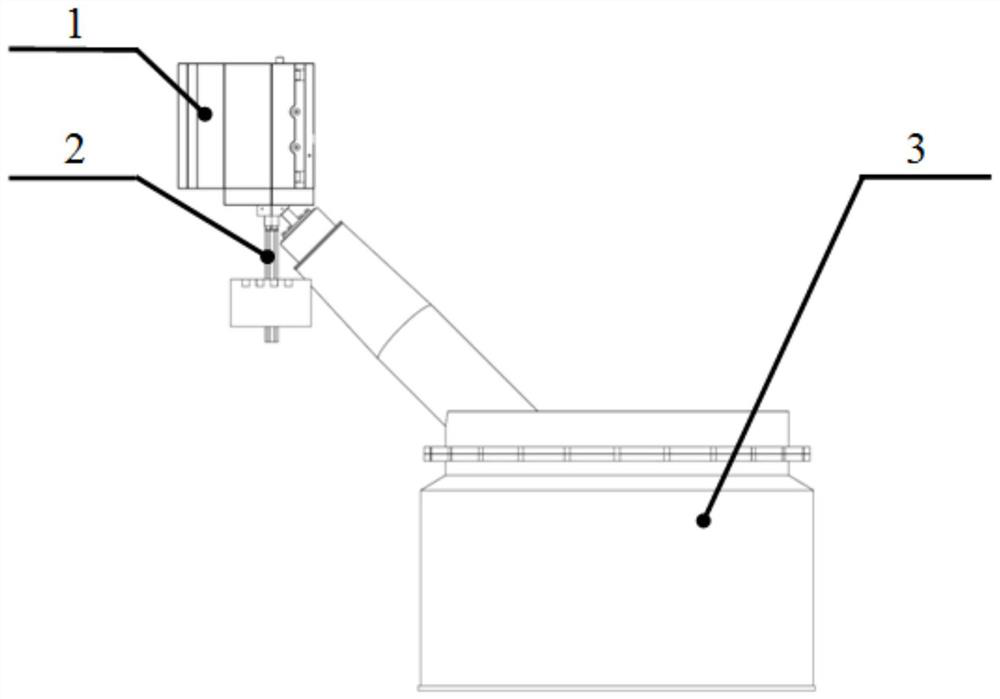

Device and method for increasing high-power microwave transmission device breakdown threshold value

InactiveCN106848497AIncrease vacuumRaise the breakdown thresholdVacuum evaporation coatingSputtering coatingMicrowave - actionSurface plasmon

The invention discloses a high-power microwave transmission device and method for a high breakdown threshold value. The device comprises a circular waveguide with the inner surface plated with a nanometer porous alloy material, and movable gate type vacuum stop valves are arranged at the two ends of the circular waveguide; the circular waveguide is internally plated with the nanometer porous alloy material, the waveguide and gas in the microwave system can be adsorbed, surface plasma formation under the high-power microwave action is inhibited, and the high-power microwave system breakdown threshold value is increased. For the movable gate type vacuum stop valves, an innovative dynamic vacuum seal technology is used, the internal vacuum degree of a microwave system or the circular guide can be kept, the phenomenon that due to the fact that the nanometer porous alloy material plated on the inner surface is exposed in the atmosphere, passivation is caused, the problem that the nanometer porous alloy material plated on the surface is passivated and repeatedly activated is avoided, and the service life of the equipment under the high breakthrough threshold value is prolonged.

Owner:NORTHWEST INST OF NUCLEAR TECH

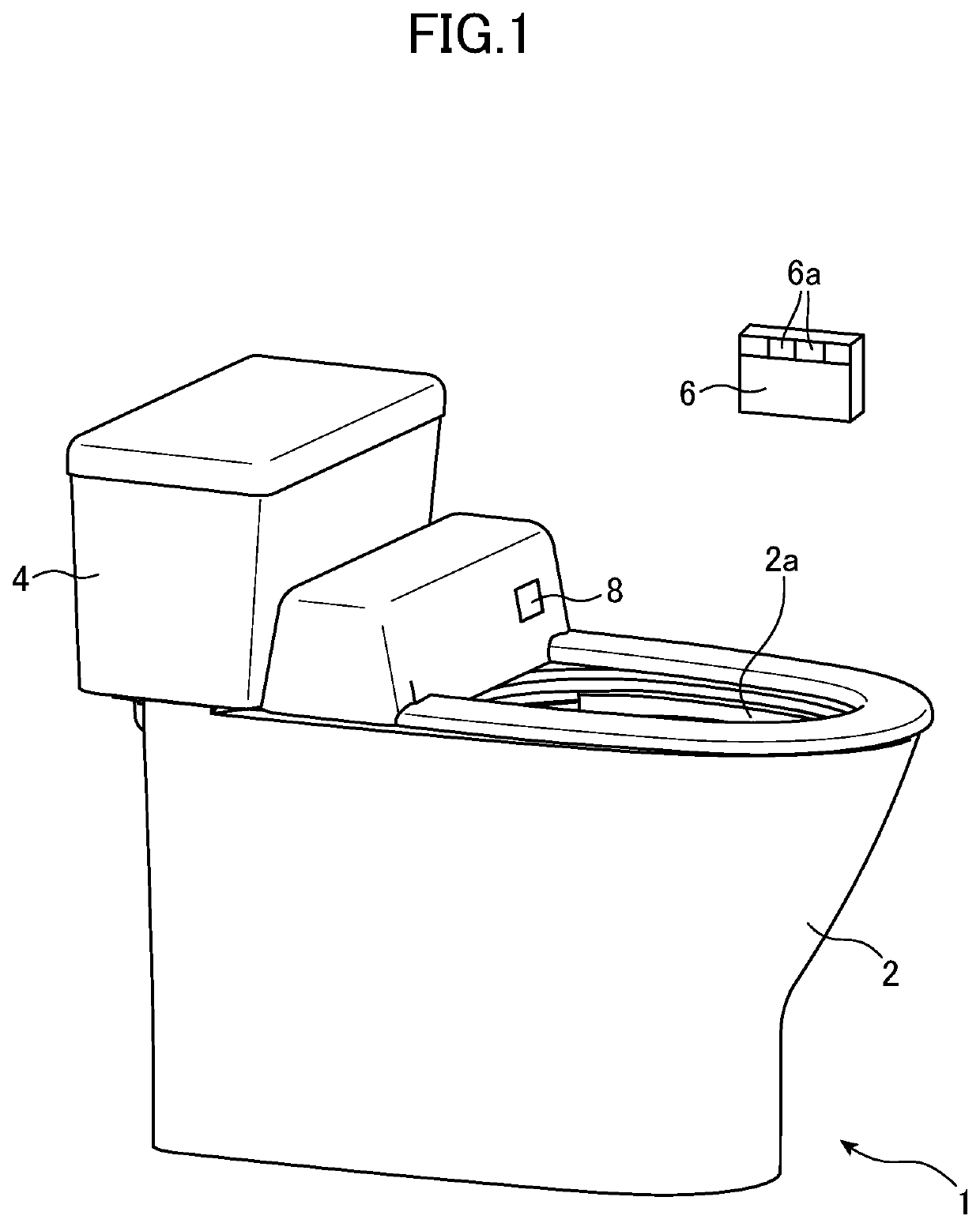

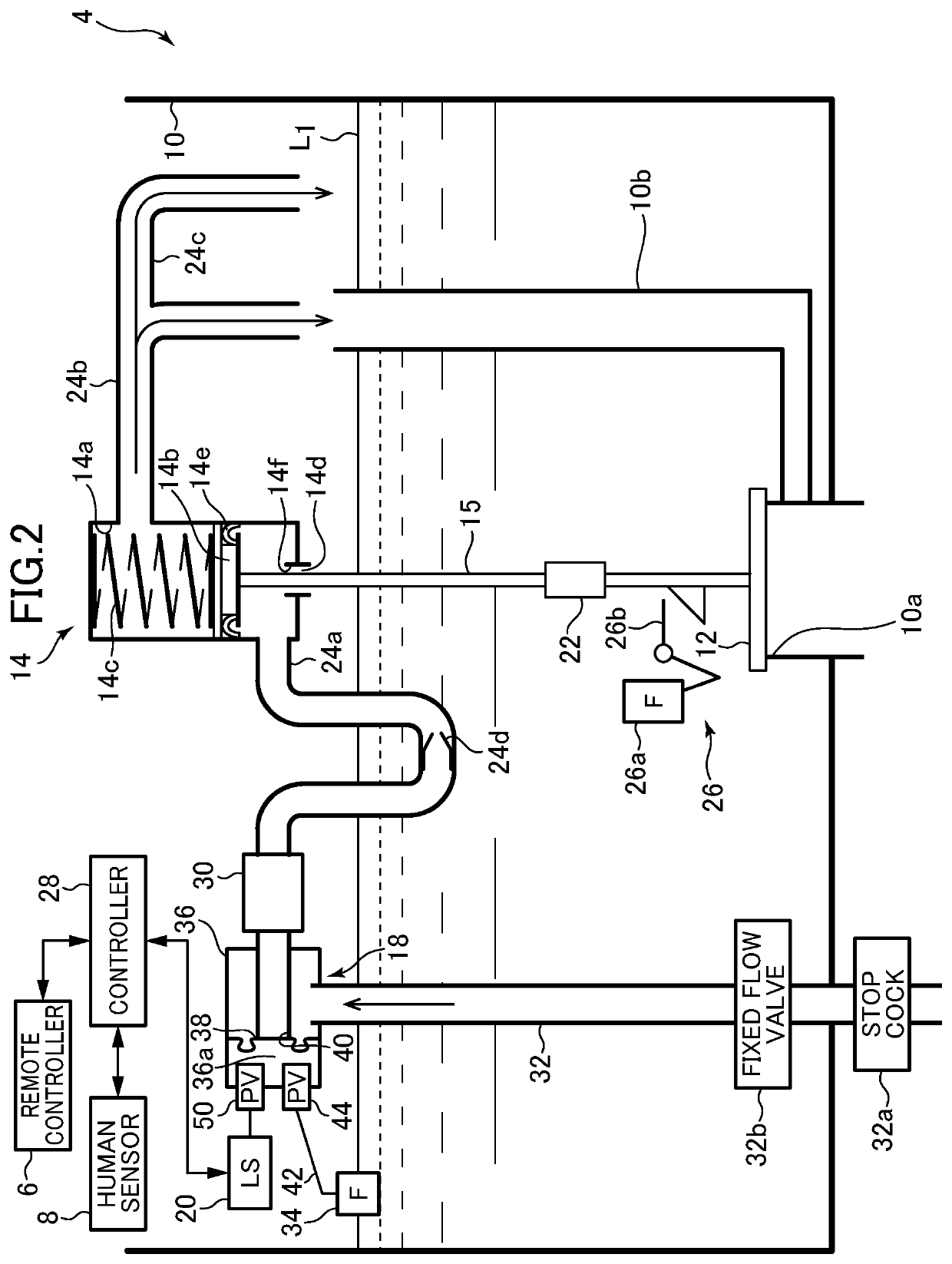

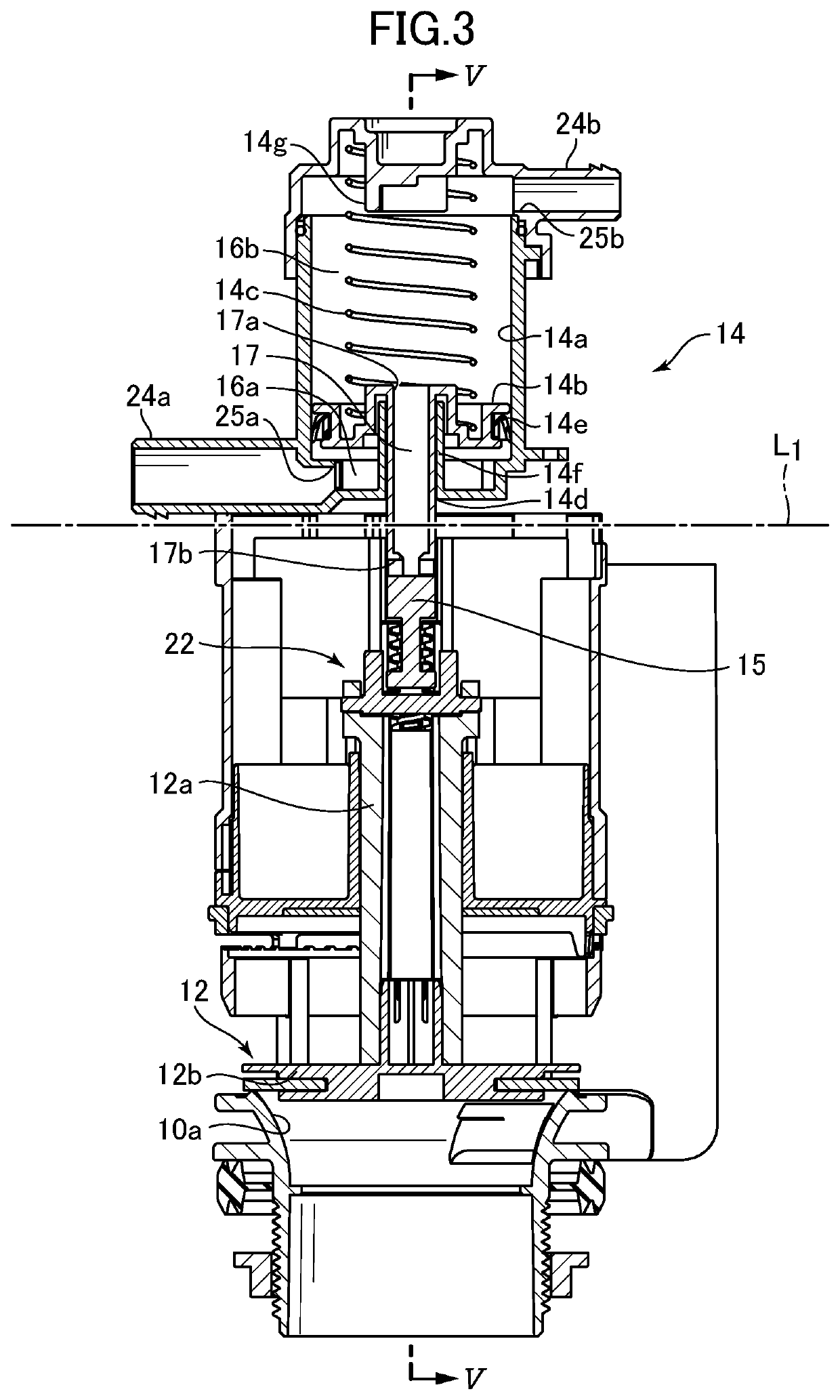

Flush water tank apparatus and flush toilet apparatus provided with the same

PendingUS20220074181A1Easy dischargeOptimization mechanismFlushing devicesWater storage tankToilet flushing

There is provided a flush water tank apparatus capable of returning to a state where next toilet flush operation can be started in a short time while opening a discharge valve using a water supply pressure. A flush water tank apparatus (4) includes a reservoir tank (10), a discharge valve (12), a discharge valve hydraulic drive portion (14) configured to drive the discharge valve using a water supply pressure, and a discharge / vacuum break valve device (30) provided on an upstream side of the discharge valve hydraulic drive portion and configured to supply the water supplied from the upstream side to the discharge valve hydraulic drive portion on a downstream side. The discharge valve hydraulic drive portion includes a cylinder (14a) into which the water from the discharge / vacuum break valve device flows, and a piston (14b) configured to be moved by a pressure of the water flowing into the cylinder to move the discharge valve. The discharge / vacuum break valve device includes a valve body that operates to discharge the water flowing backward from the discharge valve hydraulic drive portion while opening the upstream side to an atmosphere when the supply of the water from the upstream side is stopped.

Owner:TOTO LTD

Quick cooling structure of large high-temperature resistance furnace

The invention discloses a quick cooling structure of a large high-temperature resistance furnace. The quick cooling structure comprises a freezing tower, at least two vacuum stop valves and a high-temperature pipeline fan, wherein the freezing tower, the high-temperature pipeline fan and the large high-temperature resistance furnace are sequentially communicated through pipes to form a closed loop, at least one vacuum stop valve is arranged on the pipe between the freezing tower and the large high-temperature resistance furnace, and at least one vacuum stop valve is arranged on the pipe between the high-temperature pipeline fan and the large high-temperature resistance furnace. The problem that at present, the large high-temperature resistance furnace is too long in temperature reduction time and accordingly influences a workpiece or a material production period and hinders improvement of enterprises' capacity is solved by means of the quick cooling structure of the large high-temperature resistance furnace.

Owner:湖南省鑫源新材料股份有限公司

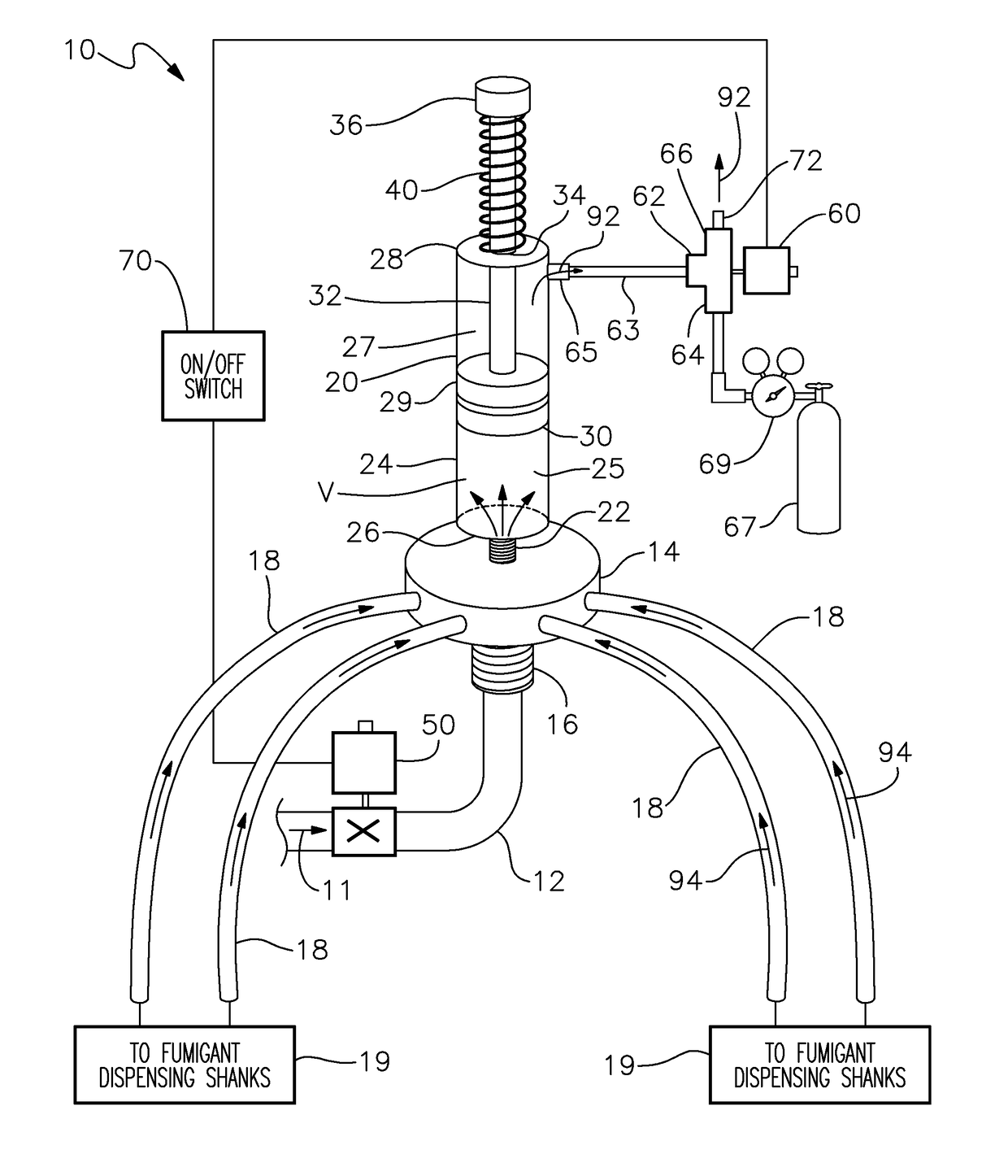

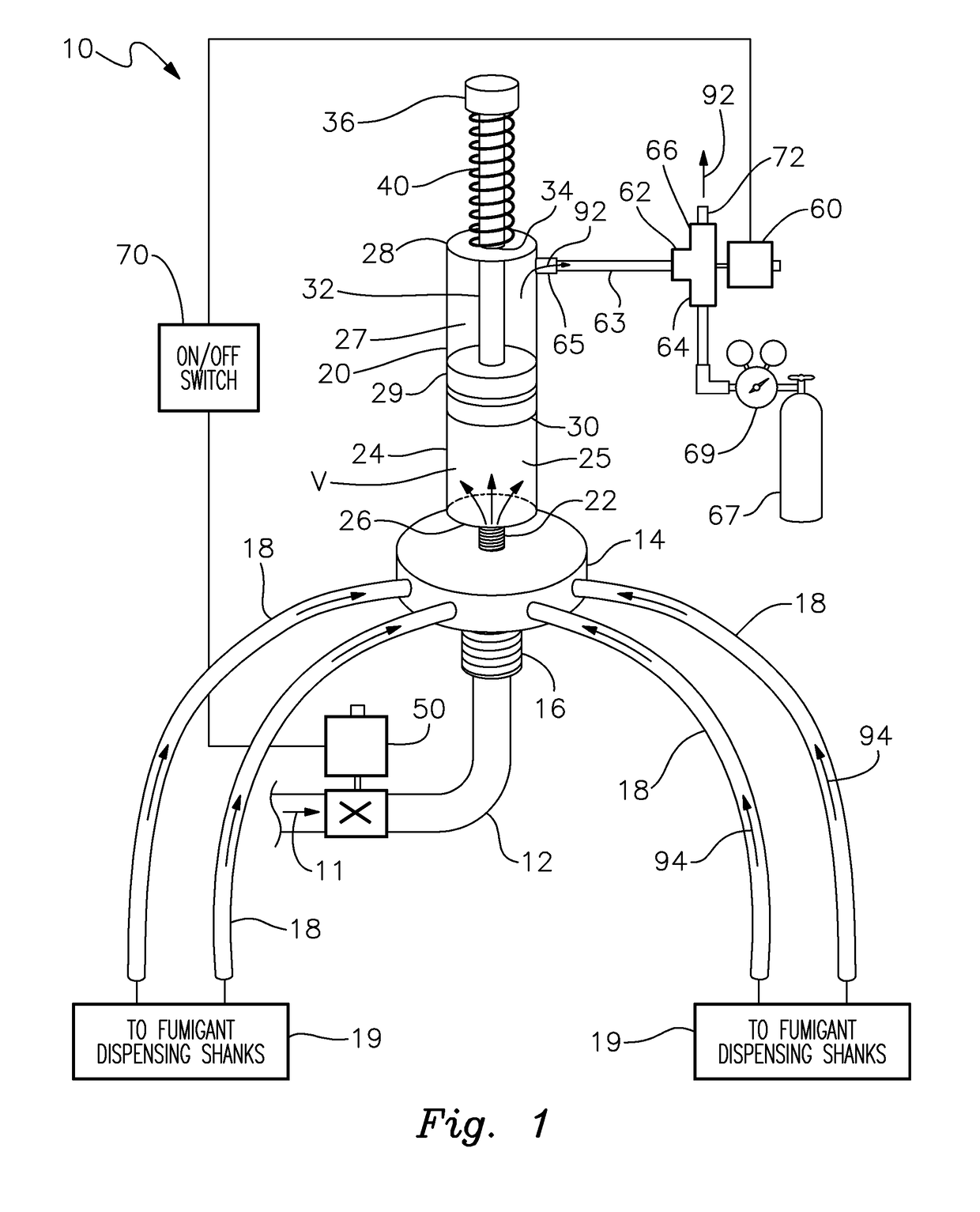

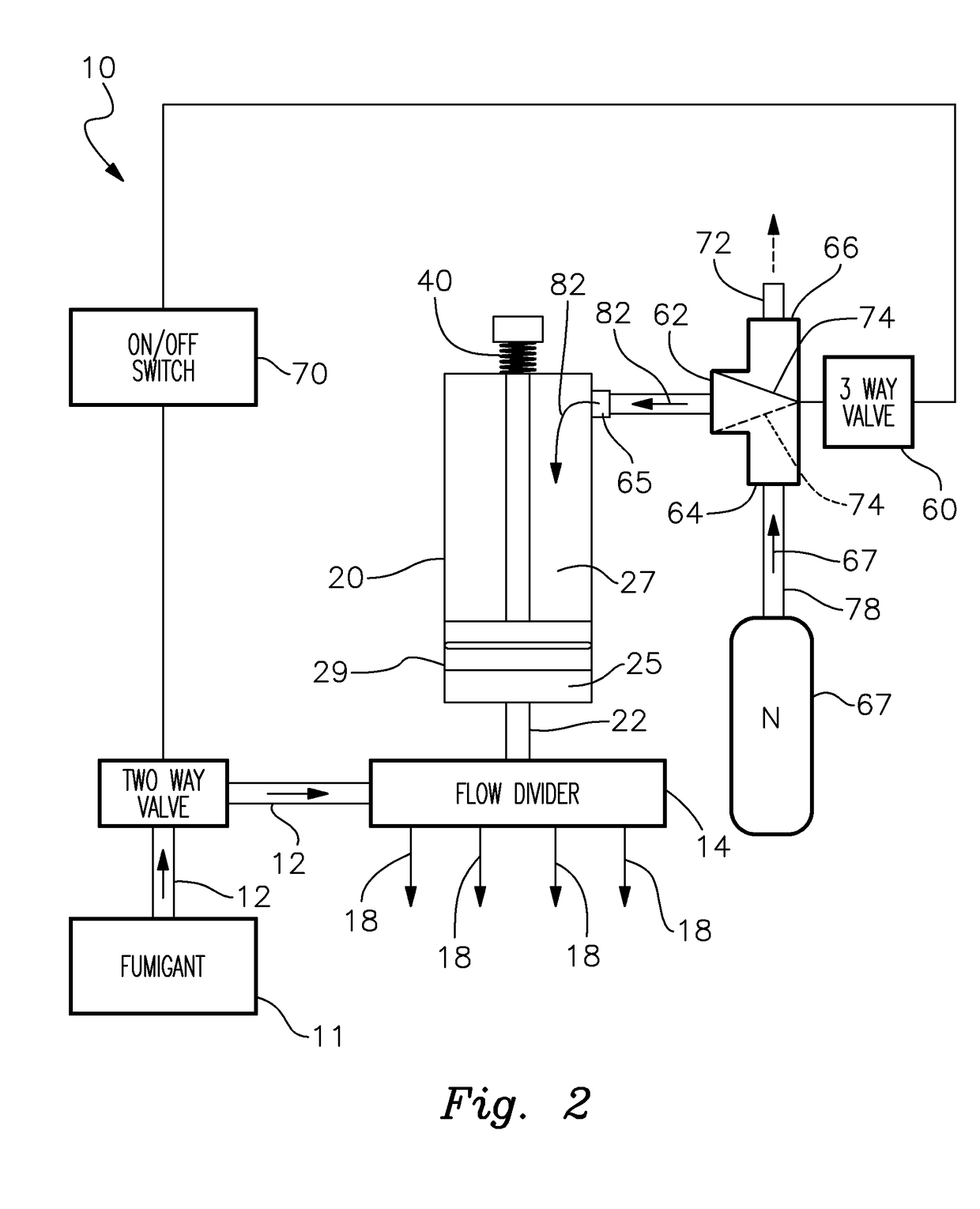

Vacuum Shut Off Valve Mechanism For A Soil Fumigant Applicator Rig

InactiveUS20180243786A1Effectively controlling undesirableEffective controlLiquid surface applicatorsFumigatorsFlow dividerPneumatic cylinder

A vacuum shut off valve mechanism for a soil fumigant applicator includes a pneumatic cylinder that is operably connected to respective fumigant dispensing tubes and shanks of the applicator through a flow divider. A pair of switch operated valves respectively control the flow of fumigant to the flow divider and operation of the pneumatic cylinder. In a first switch state a first valve is opened to deliver fumigant to the flow divider and a second valve operates the pneumatic cylinder to pressurize the flow divider and allow delivery of the fumigant to the dispensing shanks. In a second state, the first valve is closed and the second valve operates the pneumatic cylinder to draw a vacuum, which restricts dripping and leaking of residual fumigant from the tubes and dispensing shanks.

Owner:TRIEST AG GRP

Special gas accurate controller for cell exposure

InactiveCN103525699ABioreactor/fermenter combinationsBiological substance pretreatmentsGas cylinderCell membrane

The invention provides a special gas accurate controller for cell exposure. The special gas accurate controller comprises a stirring mixer, wherein the stirring mixer is provided with three accurate gas flow controlling valves which are connected with a compressed air cylinder, a carbon dioxide gas cylinder and a special equalization gas cylinder, the outer surface of each of the compressed air cylinder, the carbon dioxide gas cylinder and the special equalization gas cylinder is provided with a temperature controlling sleeve, two ends of the special equalization gas cylinder are provided with a vacuum stop valve and an equalization stop valve, the rear end, provided with an electrically controlled three-way valve, of the equalization stop valve is connected with a vacuum pump, the other end of the equalization stop valve is connected to a special total gas source by virtue of a total gas source stop valve, one end of the special equalization gas cylinder is provided with a swing shaft, the swing shaft is connected to an eccentric gear by virtue of a rocker, an output pipeline of the stirring mixer is connected to an exposure gas hole arranged in an exposure gas bin by virtue of an exposure gas flow controlling valve and carries out a quantitative exposure test on the cell on a cell film plate, and a computer controller is used for controlling all electronic valves, motors and total temperature controllers according to a preparatory program to reach the purpose of accurately controlling the special gas during cell exposure. The special gas accurate controller has the beneficial effect of accurately controlling the special gas to carry out scientific research and scientific experiments of cell exposure.

Owner:中国人民解放军第二一〇医院 +1

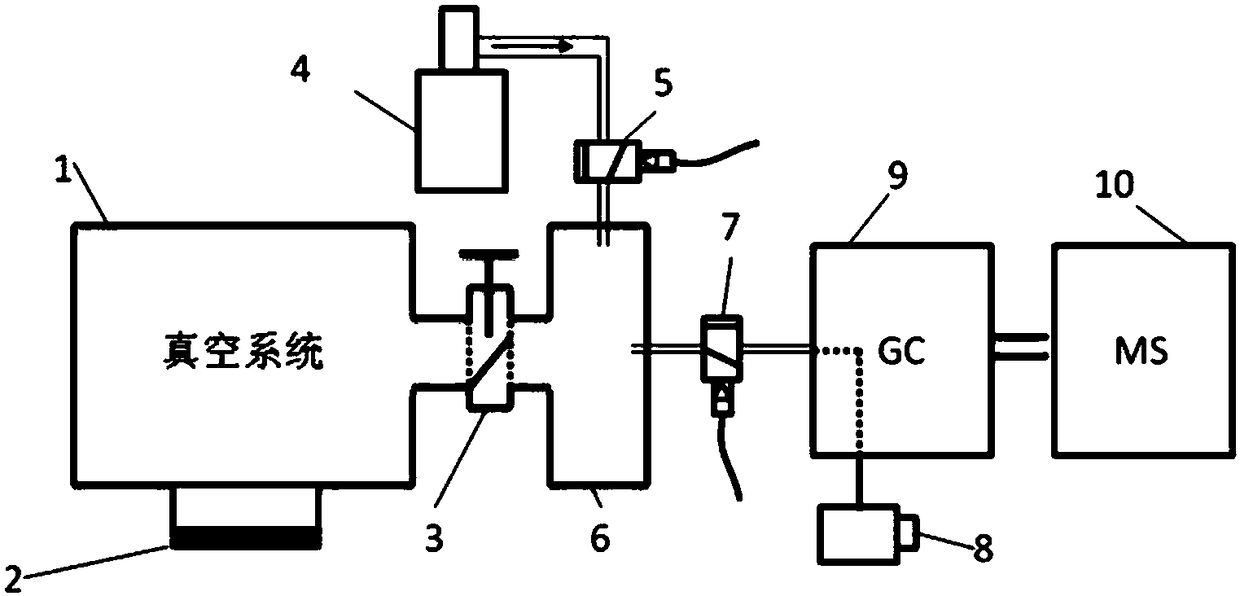

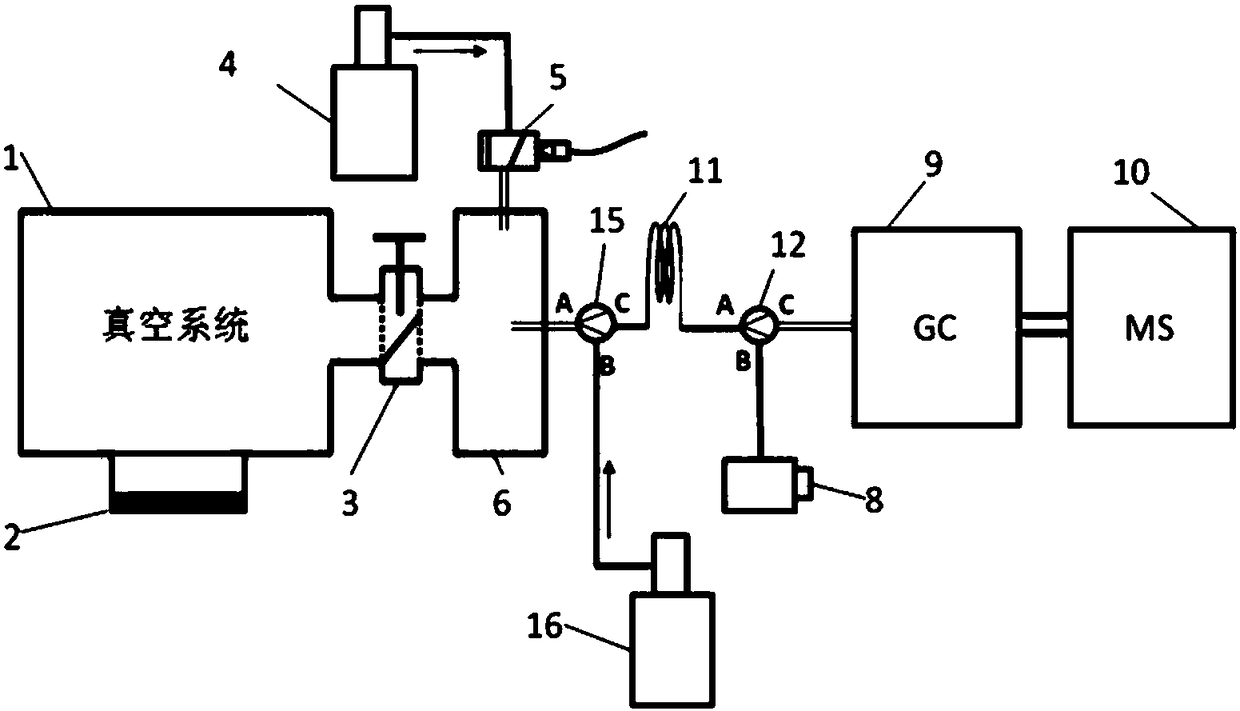

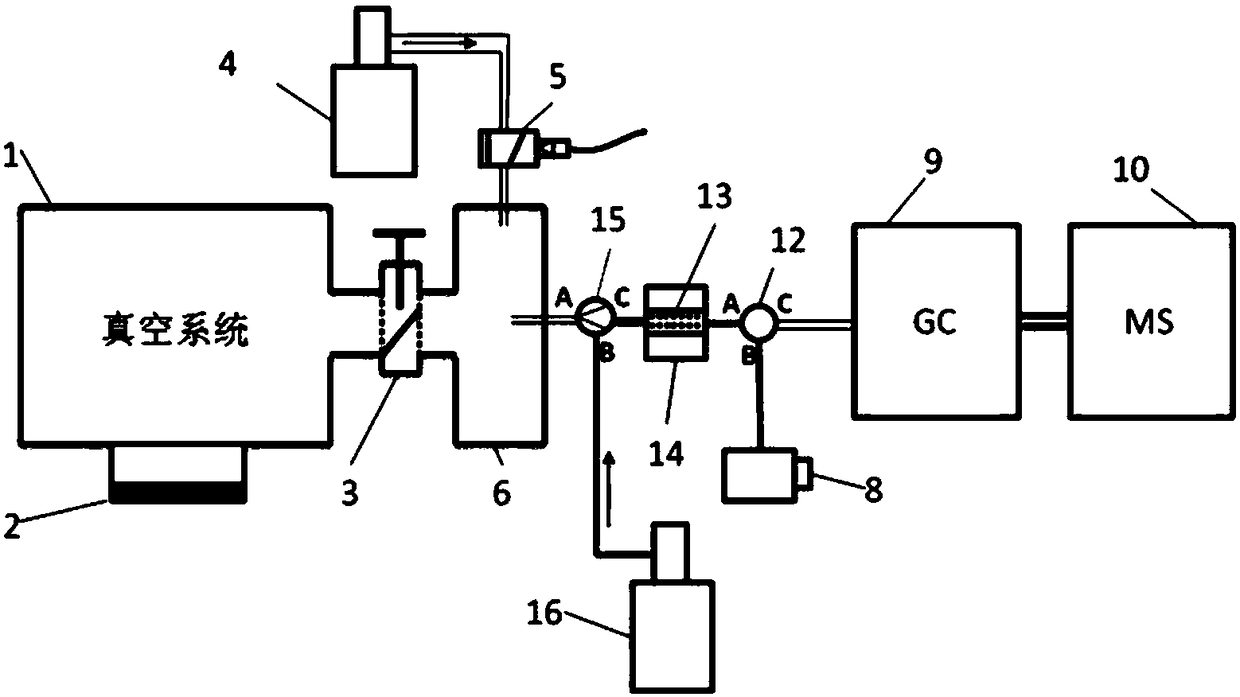

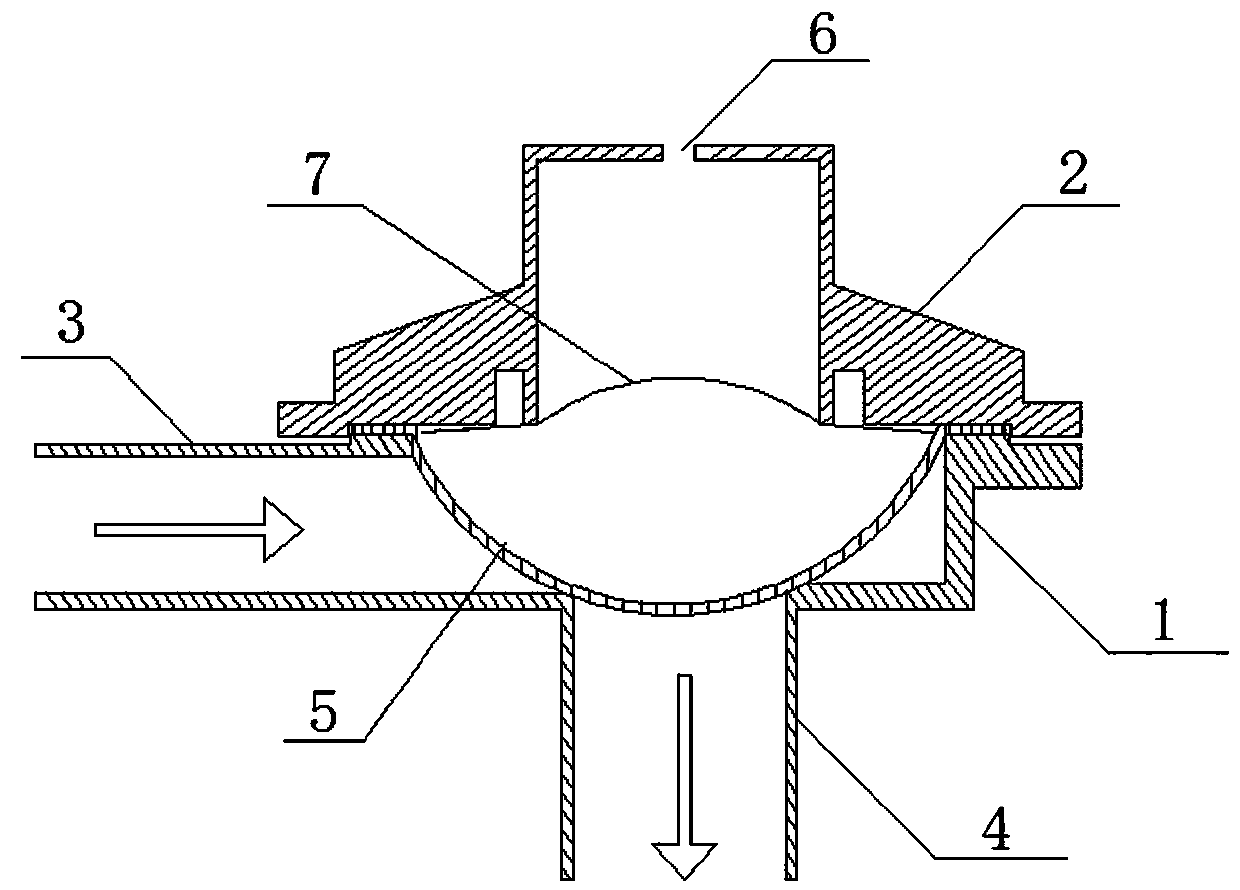

Device and method capable of qualitatively and quantitatively analyzing residue in vacuum system

PendingCN108362801AQualitatively accurateAccurate quantitative analysisComponent separationMaterial defectSimple Organic Compounds

The invention relates to the technical field of vacuum monitoring, in particular to a device and method capable of qualitatively and quantitatively analyzing a residue in a vacuum system. The device comprises a vacuum system to be detected, a vacuum stop valve, a first vacuum electromagnetic valve, a second vacuum electromagnetic valve, a gas buffer chamber, a gas source, a sampling pump, a chromatograph and a mass spectrometer, wherein communication or shutoff between the vacuum system to be detected and the gas buffer chamber is achieved through the vacuum stop valve; gas communication or gas shutoff between the gas source and the gas buffer chamber is achieved through the first vacuum electromagnetic valve; communication or shutoff between the chromatograph and the gas buffer chamber isachieved through the second vacuum electromagnetic valve. The device breaks through a great defect that in the existing residual gas analyzing mass spectrometry, an organic residue with complex components cannot be analyzed, so that an organic matter with the complex components can be accurately analyzed qualitatively and quantitatively. A standard sample experimental test shows that through thedevice and the method, a mixed gas containing 38 organic compounds in the vacuum system can be accurately analyzed qualitatively and quantitatively.

Owner:苏州铭谱源分析仪器有限公司

Vacuum cut-off valve

PendingCN111075950AImprove contact reliabilityImprove contact stabilityDiaphragm valvesEngine diaphragmsAir tightnessMechanics

The invention discloses a vacuum cut-off valve. The vacuum cut-off valve comprises a valve body and a valve cover connected to the valve body; the valve body is provided with an inflow channel and anoutflow channel communicating with each other; the inflow channel is smoothly connected with the outflow channel; a channel opening of the outflow channel is provided with a deformable partition; an upper space formed by the partition and the valve cover communicates with a first vacuum source through a vacuum negative pressure inlet formed in the top of the valve cover; the first vacuum source isused for controlling the opening and closing of the outflow channel by the partition; the outflow channel is in communication with a second vacuum source; and the first vacuum source and the second vacuum source are the same vacuum source or different vacuum sources. The vacuum cut-off valve can improve the passability of a fluid, especially a semi-solid fluid, the airtightness of the vacuum cut-off valve is ensured, and the service life of the vacuum cut-off valve is prolonged.

Owner:CHENGDU QIANJI ENTERPRISE MANAGEMENT CONSULTING CO LTD

A device and method for increasing the breakdown threshold of a high-power microwave transmission device

InactiveCN106848497BIncrease vacuumRaise the breakdown thresholdVacuum evaporation coatingSputtering coatingMicrowave - actionSurface plasmon

The invention discloses a high-power microwave transmission device and method for a high breakdown threshold value. The device comprises a circular waveguide with the inner surface plated with a nanometer porous alloy material, and movable gate type vacuum stop valves are arranged at the two ends of the circular waveguide; the circular waveguide is internally plated with the nanometer porous alloy material, the waveguide and gas in the microwave system can be adsorbed, surface plasma formation under the high-power microwave action is inhibited, and the high-power microwave system breakdown threshold value is increased. For the movable gate type vacuum stop valves, an innovative dynamic vacuum seal technology is used, the internal vacuum degree of a microwave system or the circular guide can be kept, the phenomenon that due to the fact that the nanometer porous alloy material plated on the inner surface is exposed in the atmosphere, passivation is caused, the problem that the nanometer porous alloy material plated on the surface is passivated and repeatedly activated is avoided, and the service life of the equipment under the high breakthrough threshold value is prolonged.

Owner:NORTHWEST INST OF NUCLEAR TECH

Vacuum sucking cast process of preparing magnesium base composite material

InactiveCN1317093CSolve molding problemsAvoid the defects of easy air entrainmentMagnesium matrix compositeProduct gas

The present invention relates to casting technology. The vacuum sucking casting process of preparing magnesium base composite material includes the following steps: 1. fixing preheated mold casing onto partition with fixing sleeve and introducing mixed protecting gas; 2. opening the cut-off valve to vacuum pump the sealed cavity and maintaining the vacuum; 3. eliminating vacuum for refined magnesium base composite material melt to be poured into the mold cavity fast, opening the vacuum cut-off valve while pouring to the pouring head of the mold casing for the magnesium base composite material liquid to fill the cavity, and maintaining vacuum unit complete solidification. The present invention proposes new method of vacuum sucking casting and applies vacuum sucking casting method in preparing magnesium base composite material and magnesium alloy part, to form thin-wall complicated magnesium base composite material casting successfully.

Owner:SHANGHAI JIAOTONG UNIV

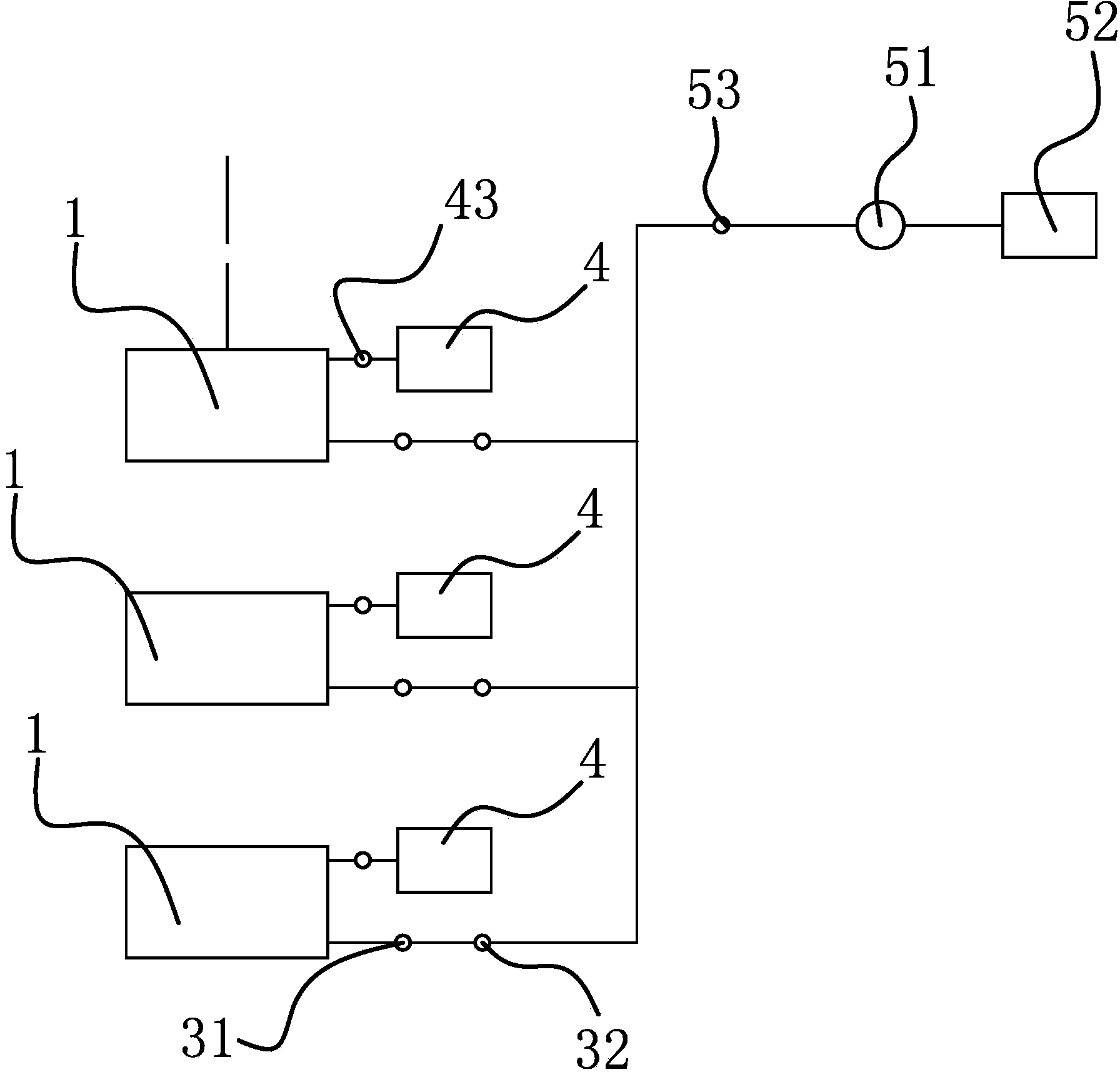

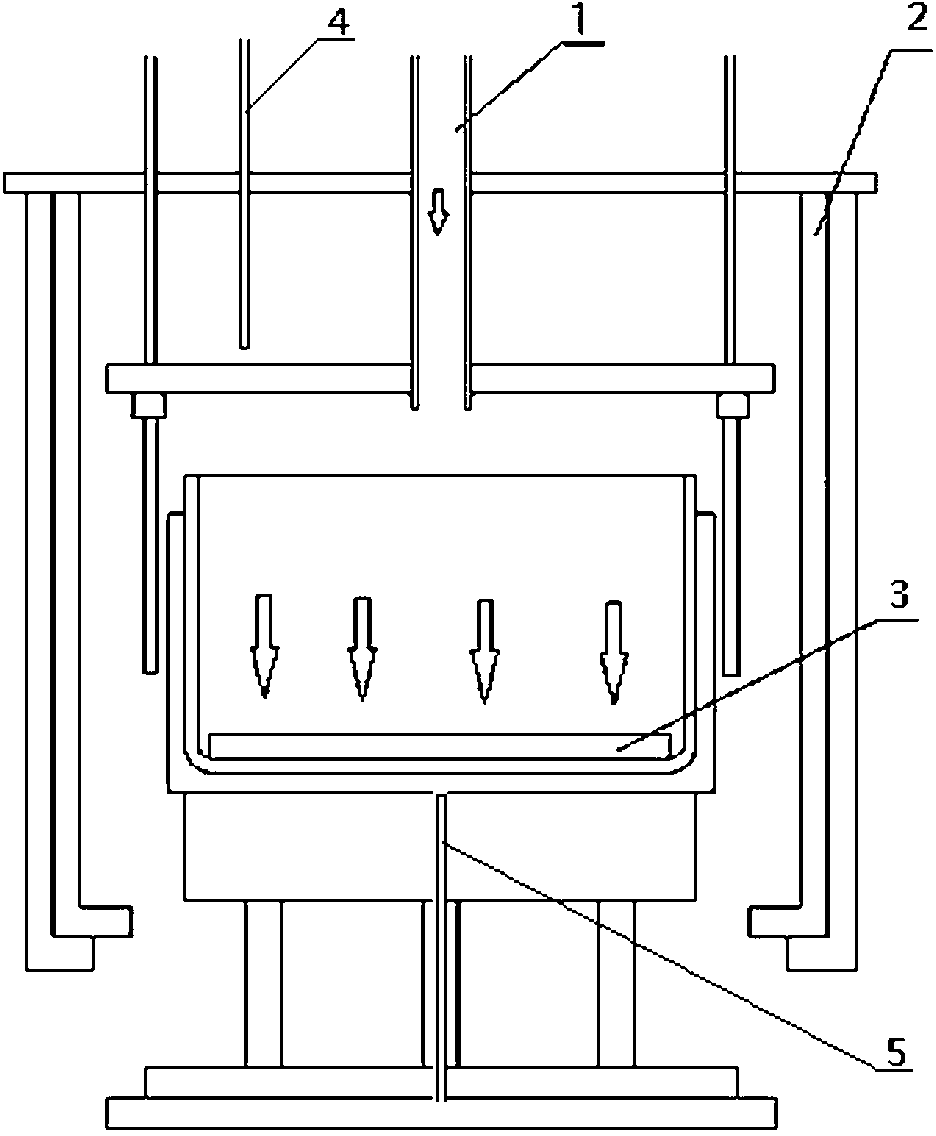

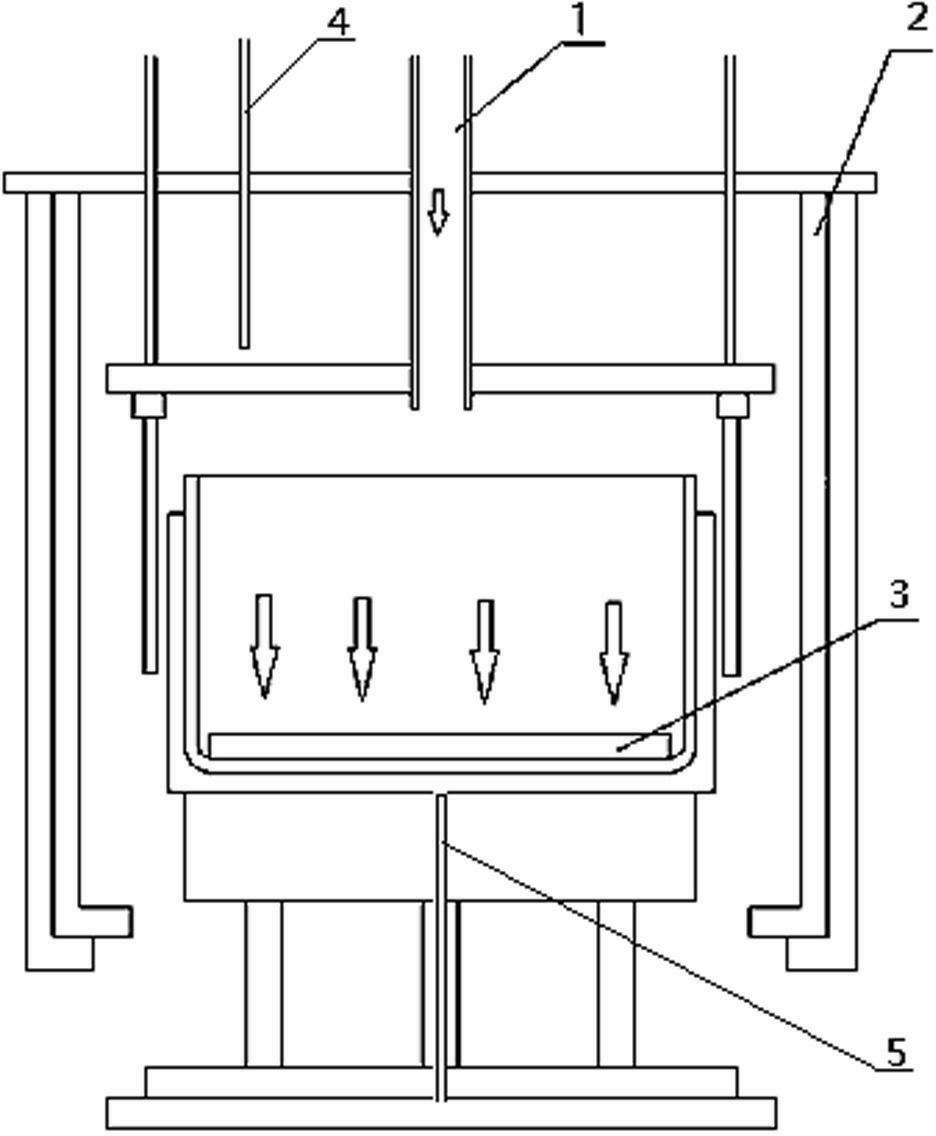

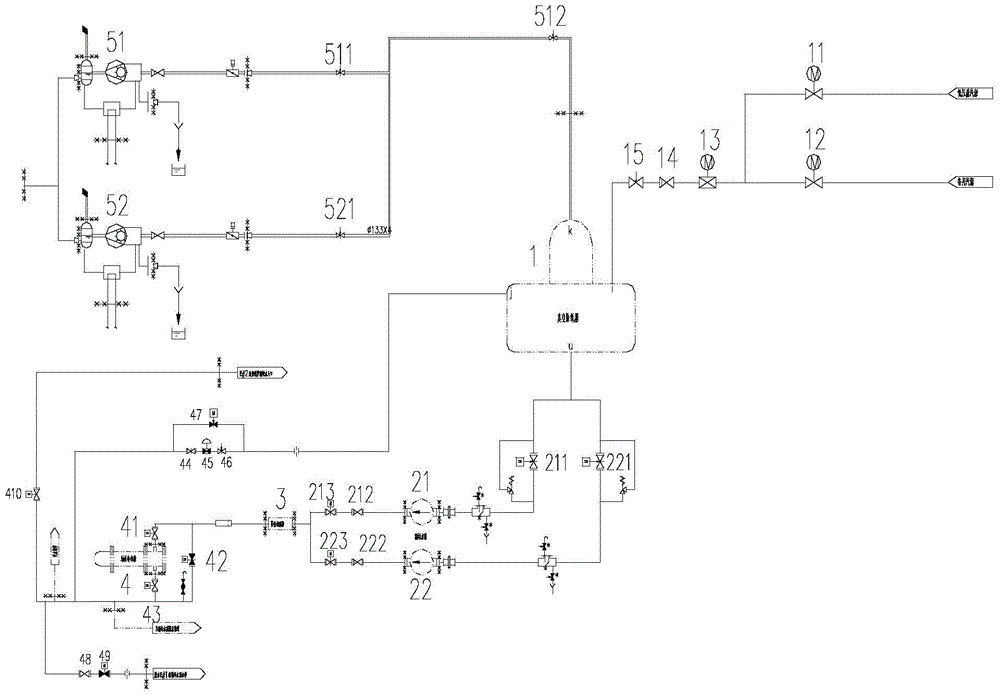

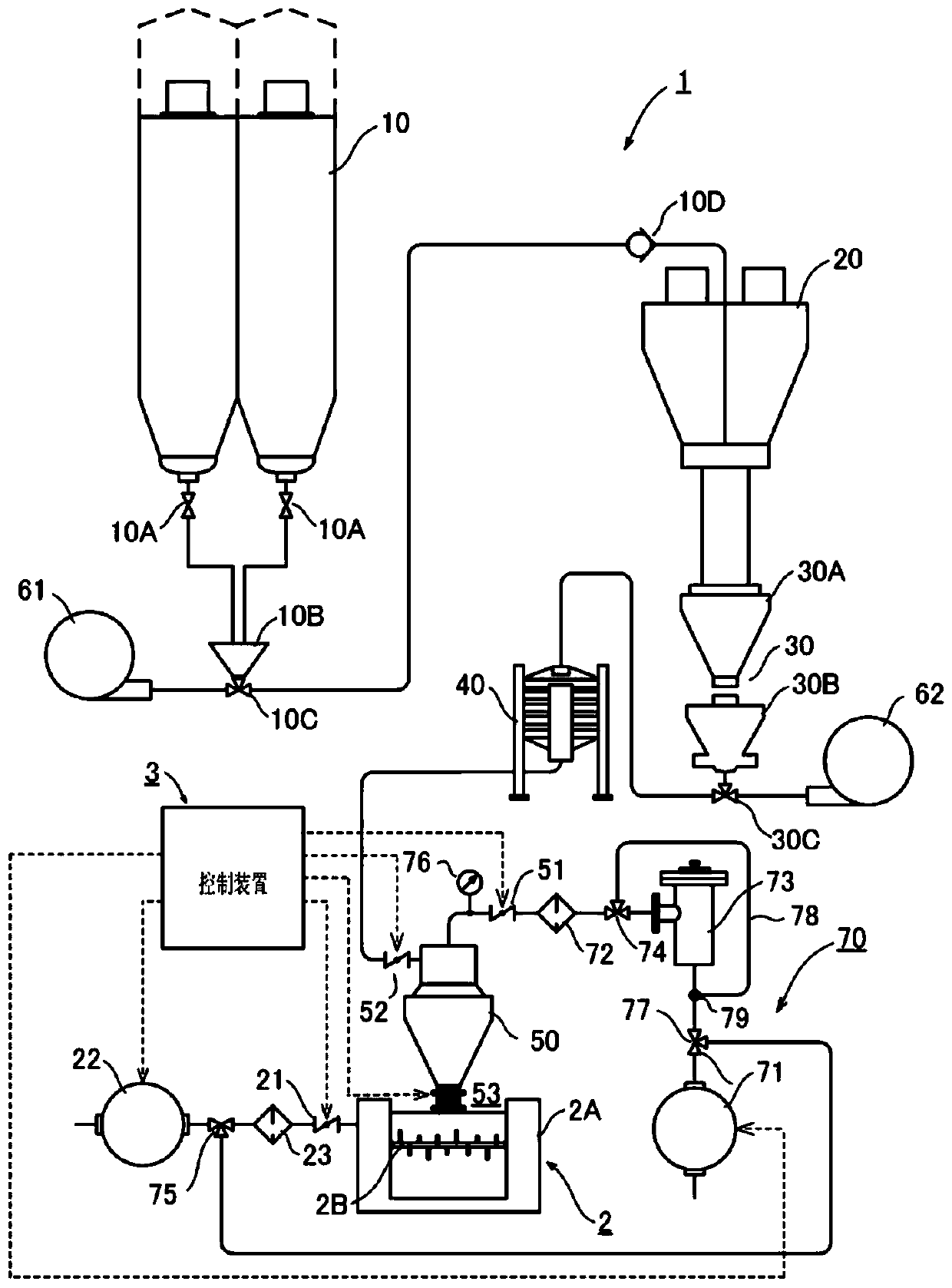

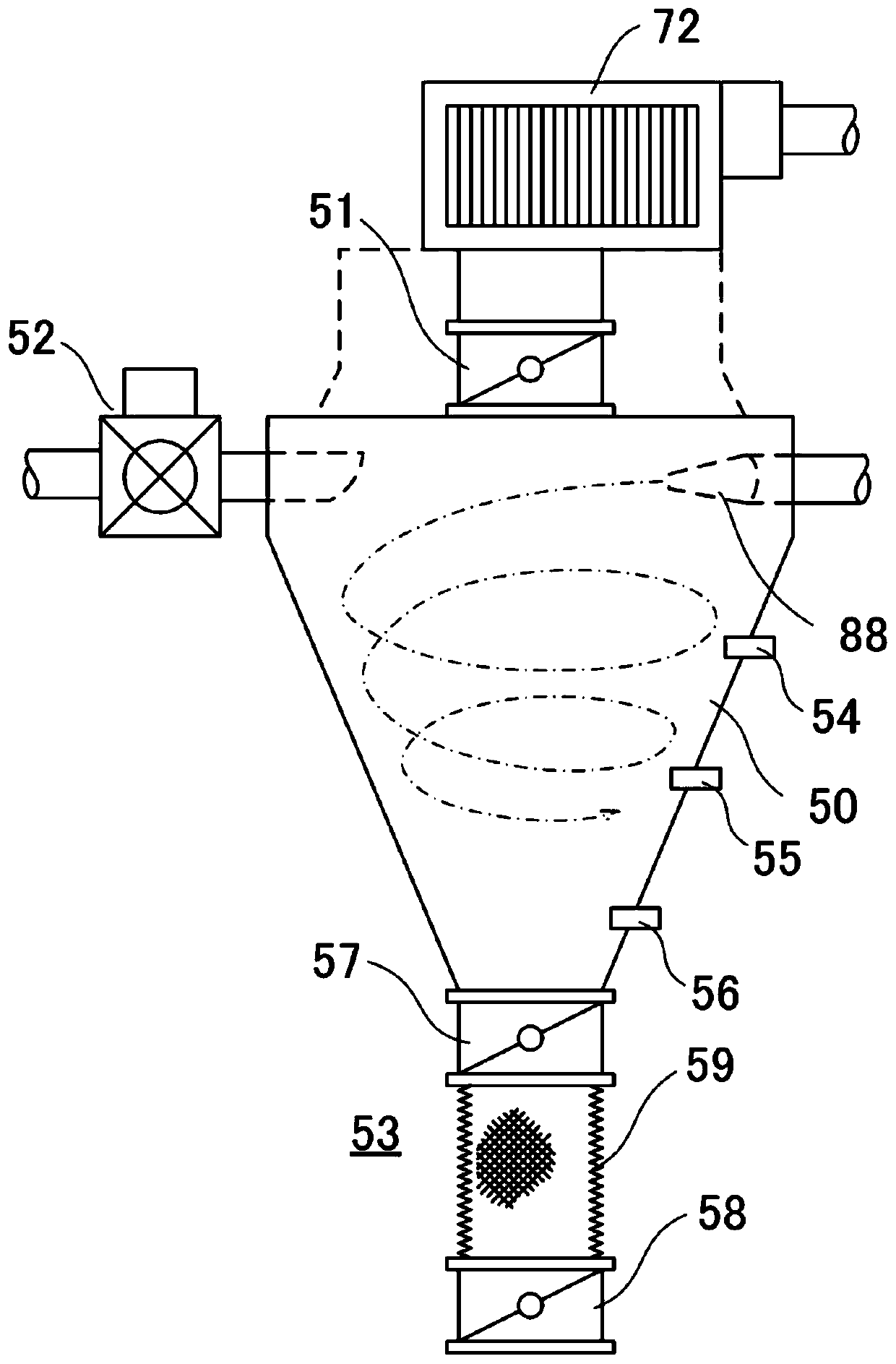

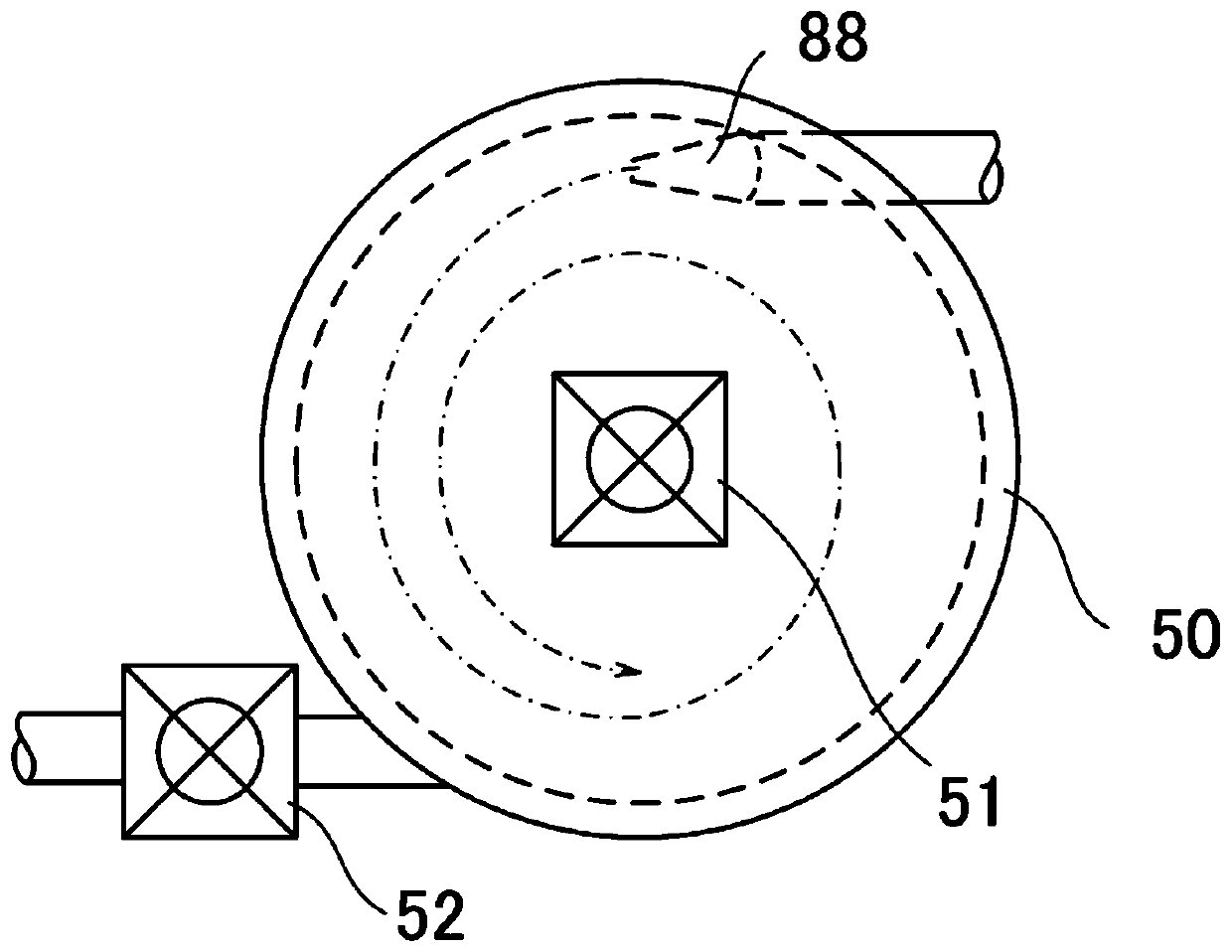

Powder supply device for supplying powder to container of food processing machine

The present invention provides a powder supply device for supplying powder to a container of a food processing machine. The powder supply device comprises a storage cylinder (50) which is arranged above the container and is provided with an exhaust port for exhausting gas, an introduction port for introducing powder and a supply port for supplying the powder into the container; a first vacuum shutoff valve (51) that opens and closes the exhaust port; a second vacuum shutoff valve (52) that opens and closes the introduction port; a third vacuum shutoff valve (53) that opens and closes the supply port; temperature sensors (54, 55, 56) for measuring the temperature in the storage cylinder; and a vacuum device (70) that vacuumizes the inside of the storage cylinder. A control device reduces the pressure in the storage cylinder to a pressure lower than or equal to a pressure at which the temperature of the powder begins to decrease by latent heat of evaporation. And before the measured temperature in the storage cylinder is reduced to be lower than the target temperature, the vacuum device is operated in a state that the first vacuum stop valve is opened and the second vacuum stop valveand the third vacuum stop valve are closed.

Owner:SODICK CO LTD

Pollutant suction system applied to vacuum toilet

The invention discloses a pollutant suction system applied to a vacuum toilet. The system comprises two vacuum negative pressure tanks which are in air pressure communication through a connecting pipe, one vacuum negative pressure tank is an adsorption tank used for sucking pollutants and temporarily storing the pollutants, the other vacuum negative pressure tank is a pressure supply tank for supplying vacuum negative pressure to the adsorption tank, a constant pressure device is arranged on the connecting pipe, a pollutant inlet pipe used for sucking the pollutants and a pollutant dischargingpipe used for discharging pollutants are arranged on the adsorption tank, a vacuum stop valve is arranged on a pollutant inlet pipe, and an exhausting pipe used for extracting air is arranged on thepressure supply tank. With the adoption of the structure, the adsorption tank can always keep higher pollutant adsorption capability, requirements for the power supply environment are reduced, and thevacuum toilet can be really promoted and popularized.

Owner:CHENGDU QIANJI ENTERPRISE MANAGEMENT CONSULTING CO LTD

A Rapid Cooling Structure of Large High Temperature Resistance Furnace

The invention discloses a quick cooling structure of a large high-temperature resistance furnace. The quick cooling structure comprises a freezing tower, at least two vacuum stop valves and a high-temperature pipeline fan, wherein the freezing tower, the high-temperature pipeline fan and the large high-temperature resistance furnace are sequentially communicated through pipes to form a closed loop, at least one vacuum stop valve is arranged on the pipe between the freezing tower and the large high-temperature resistance furnace, and at least one vacuum stop valve is arranged on the pipe between the high-temperature pipeline fan and the large high-temperature resistance furnace. The problem that at present, the large high-temperature resistance furnace is too long in temperature reduction time and accordingly influences a workpiece or a material production period and hinders improvement of enterprises' capacity is solved by means of the quick cooling structure of the large high-temperature resistance furnace.

Owner:湖南省鑫源新材料股份有限公司

A vacuum cut-off valve used in toilets of railway vehicles

The invention discloses a vacuum shut-off valve for railway vehicle toilets, which relates to the technical field of water supply and drainage sanitary equipment for railway vehicles, and includes a valve cover, a valve body, a leather bowl, a curved clamp, a gland and a rubber duckbill. The valve body The upper and lower ends and one side of the valve body are provided with openings and communicate with each other, the gland bolt is connected to the upper end of the valve body, the leather cup is connected to the opening on the side of the valve body, the valve cover is installed on the leather cup, and the valve cover The rubber duckbill is set in the valve body and communicated with the opening at the upper end of the valve body. The invention meets the requirements of the operation of railway vehicles, so that the vehicle can be stationary and the sewage can be discharged smoothly. , When the vehicle moves at high speed and generates negative pressure, it can effectively isolate the air from entering the vehicle toilet. At the same time, the product has a simple structure, reasonable layout, easy installation and disassembly, and is conducive to later maintenance and maintenance.

Owner:吉林大学重庆研究院

Pressure-regulating and mold-filling high-pressure solidification casting device and casting method

The invention discloses a pressure-regulating and mold-filling high-pressure solidification casting device and casting method. The device comprises a smelting furnace, an injection rod, a riser tube,a hammer head, a charging barrel, a mold, a vacuum tube and a vacuum stop valve. By means of the device, a high-quality aluminum alloy melt can be taken from the center of molten aluminum in a smelting furnace, the molten aluminum is conveyed into a mold cavity through the closed liquid riser tube and a charging barrel by controlling a pressure difference between the interior of the smelting furnace and a mold cavity by a computer, and the molten aluminum level stably rises in the whole process, so that the contact area between molten aluminum and air in the conveying and mold filling stages is greatly reduced, oxidizing slag is reduced, and meanwhile, a certain vacuum condition is formed in the mold cavity, so that the air content of the molten aluminum is reduced, and the mold filling capacity of the molten aluminum in the mold cavity is improved. After mold filling is completed, a casting is solidified under a high pressure, the casting is compact in structure and fine in grain, theforming probability of casting defects such as shrinkage porosity, shrinkage cavities and pinholes is greatly reduced, and finally the internal quality of the casting and the mechanical property of abody are greatly improved.

Owner:SHENYANG RES INST OF FOUNDRY

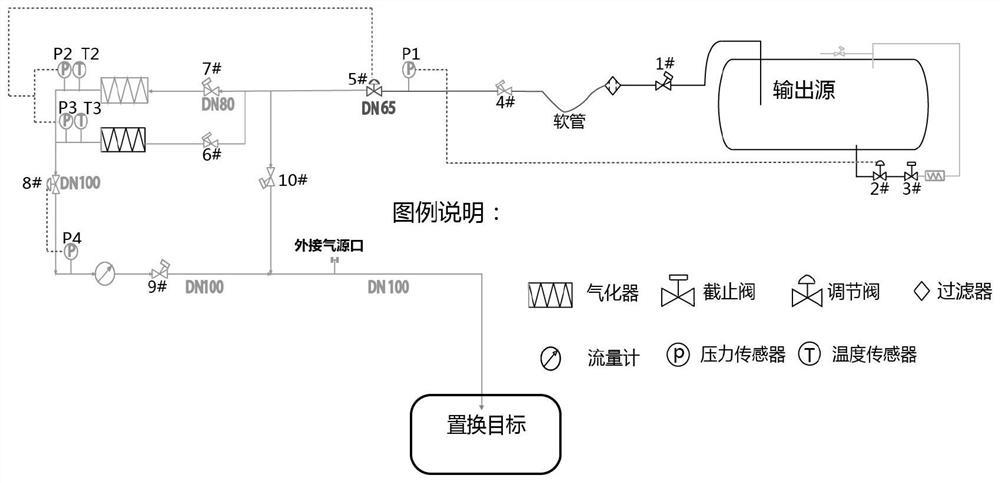

Large-flow low-pressure online gas supply system

PendingCN113217817AIncrease gasificationGuaranteed amount of vaporizationPipeline systemsThermodynamicsEngineering

The invention relates to a high-flow low-pressure online gas supply system, and belongs to the field of industrial nitrogen production. The online gas supply system comprises a liquid nitrogen output source, a first vacuum stop valve, a filter, a third vacuum stop valve and an online gas supply structure, and the online gas supply structure comprises a fourth vacuum stop valve, a P1 pressure sensor, a gasification channel composed of a seventh vacuum stop valve, a gasifier, a T2 temperature sensor and a P2 pressure sensor, a gasification channel composed of a sixth vacuum stop valve, a gasifier, a T3 temperature sensor and a P3 pressure sensor, a P4 pressure sensor, a flowmeter, a ninth vacuum stop valve, an external gas source port and a replacement target. The online gas supply system is large in gasification amount, low in pressure and high in temperature, sufficient heat exchange between nitrogen and air is guaranteed, adjustment and control are convenient, and safety is higher.

Owner:中国人民解放军63796部队

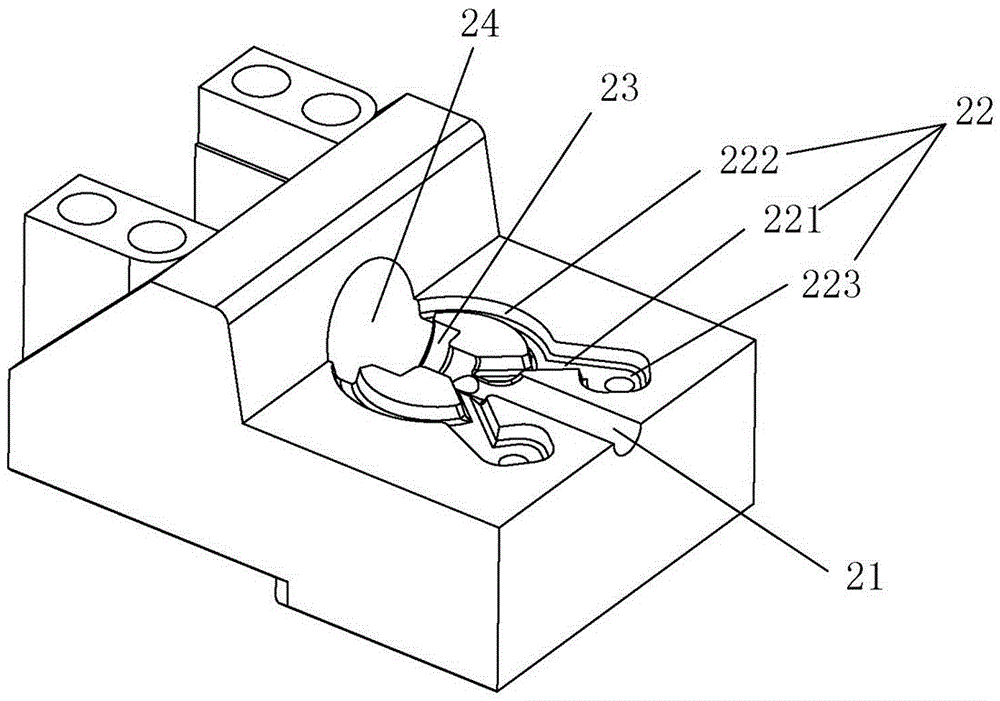

Vacuum stop valve for mold

The invention relates to the technical field of vacuum valves, in particular to a vacuum stop valve for a mold. The vacuum stop valve for the mold comprises valve bodies and a valve element. The valve body is provided with a buffer loop, an air inlet channel and an air outlet channel. The buffer loop communicates with the air inlet channel and the air outlet channel. The vacuum stop valve for the mold further comprises a piston. The end of the piston is arranged in the air outlet channel in a sleeved manner, and the piston and the fixed valve body move relatively. The piston is provided with an air channel. The valve element is movably inserted into the air channel and comprises an element bar and an element head. The element head is located at one end of the air outlet channel. A connecting channel is arranged between the air outlet channel and the air inlet channel. The front end of the element head is inserted into the connecting channel in a connected manner. The element head opens or closes the air channel by moving in the connecting channel. The vacuum stop valve for the mold is simple in structure, convenient to use, capable of smoothly discharging air in the mold, good in air discharge effect and high in safe reliability; and besides, automatic resetting can be achieved, and therefore production efficiency is improved.

Owner:HUZHOU ANDA AUTO PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com