Vacuum cut-off valve

A shut-off valve and vacuum technology, which is applied in the field of shut-off valves, can solve the problems that the vacuum shut-off valve is prone to failure and affects the passage of fluid semi-solid fluids, etc., so as to improve contact reliability and stability, patency is not affected, and the force is not affected. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

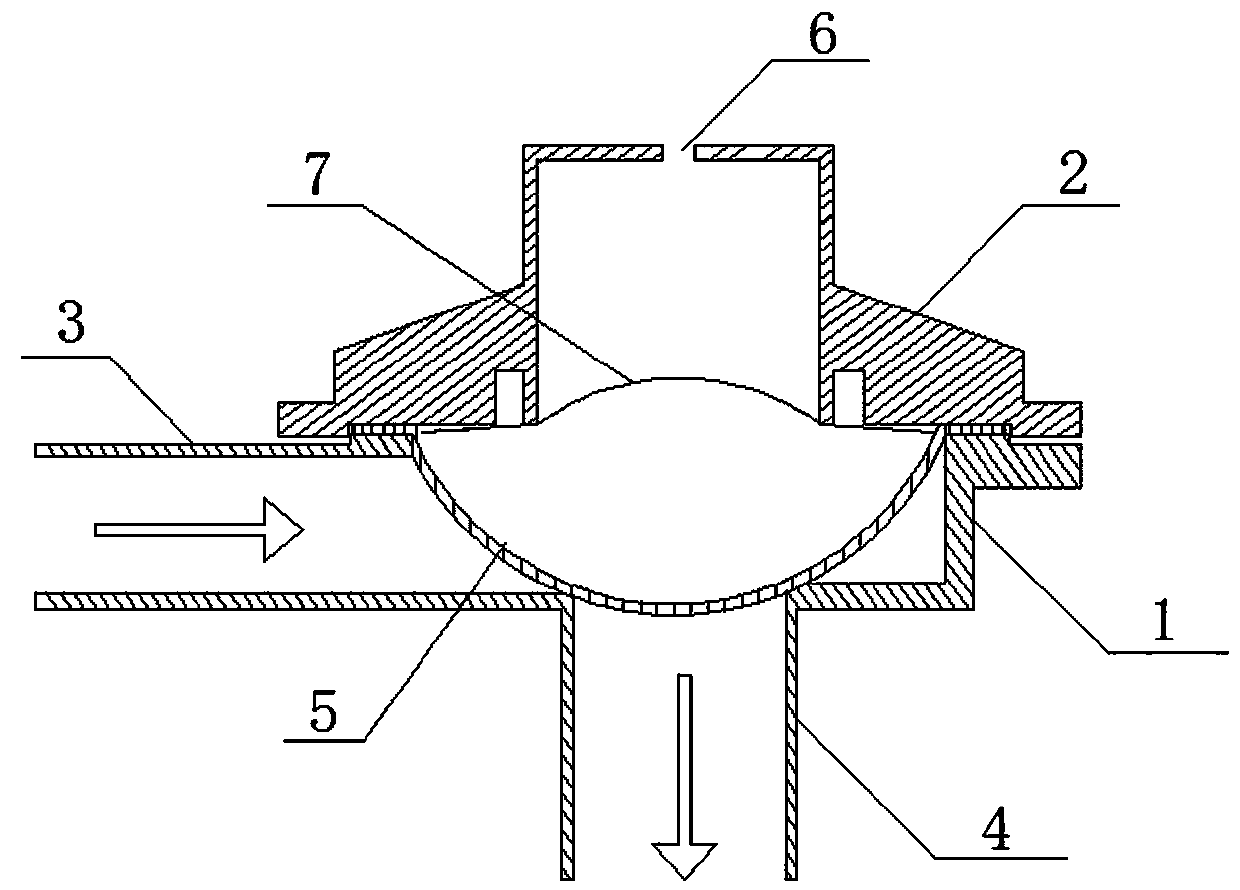

[0031] Such as figure 1 As shown, a vacuum cut-off valve shown in a preferred embodiment of the present invention includes a valve body 1 and a valve cover 2 connected to the valve body 1. The valve body 1 is provided with an inflow channel 3 and an outflow channel 4 communicating with each other. In addition, the inflow channel 3 and the outflow channel 4 are smoothly connected, and the opening of the outflow channel 4 is provided with a deformable partition 5, and the upper space formed by the partition 5 and the valve cover 2 passes through the vacuum negative pressure provided on the top of the valve cover 2. The inlet 6 communicates with the first vacuum source, the first vacuum source is used to control the opening and closing of the partition 5 to the outflow channel 4, the outflow channel 4 communicates with the second vacuum source, and the first vacuum source and the second vacuum source are the same Vacuum source or a different vacuum source.

[0032] The fluid cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com