Vacuum stop valve and hydraulic drive device and vacuumizing device formed by vacuum stop valve and hydraulic drive device

A technology for vacuuming devices and driving devices, which is applied in the direction of valve devices, valve operation/release devices, valve lifts, etc. It can solve problems such as heavy maintenance workload, insufficient flow inertia impact force, and blockage of vacuum stop valve channels. , to achieve the effect of simple structure, not easy to wear and fast closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

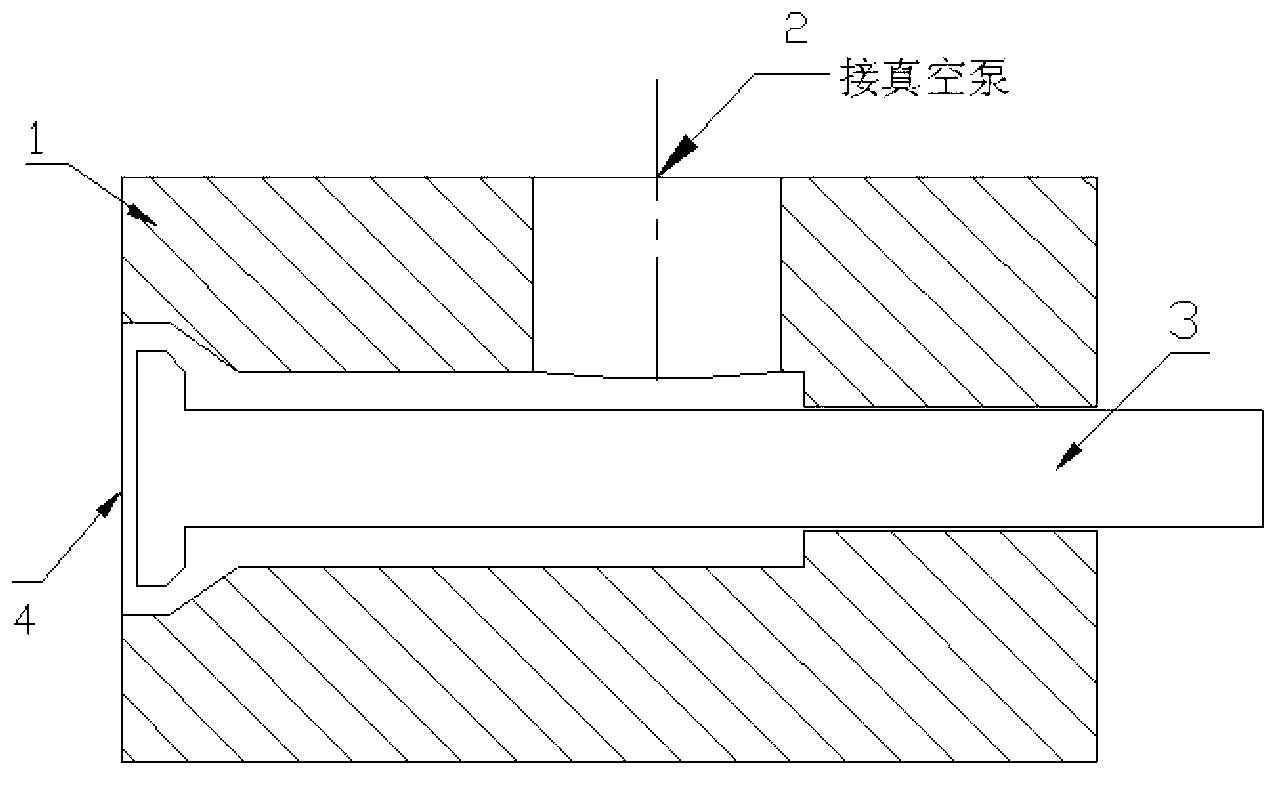

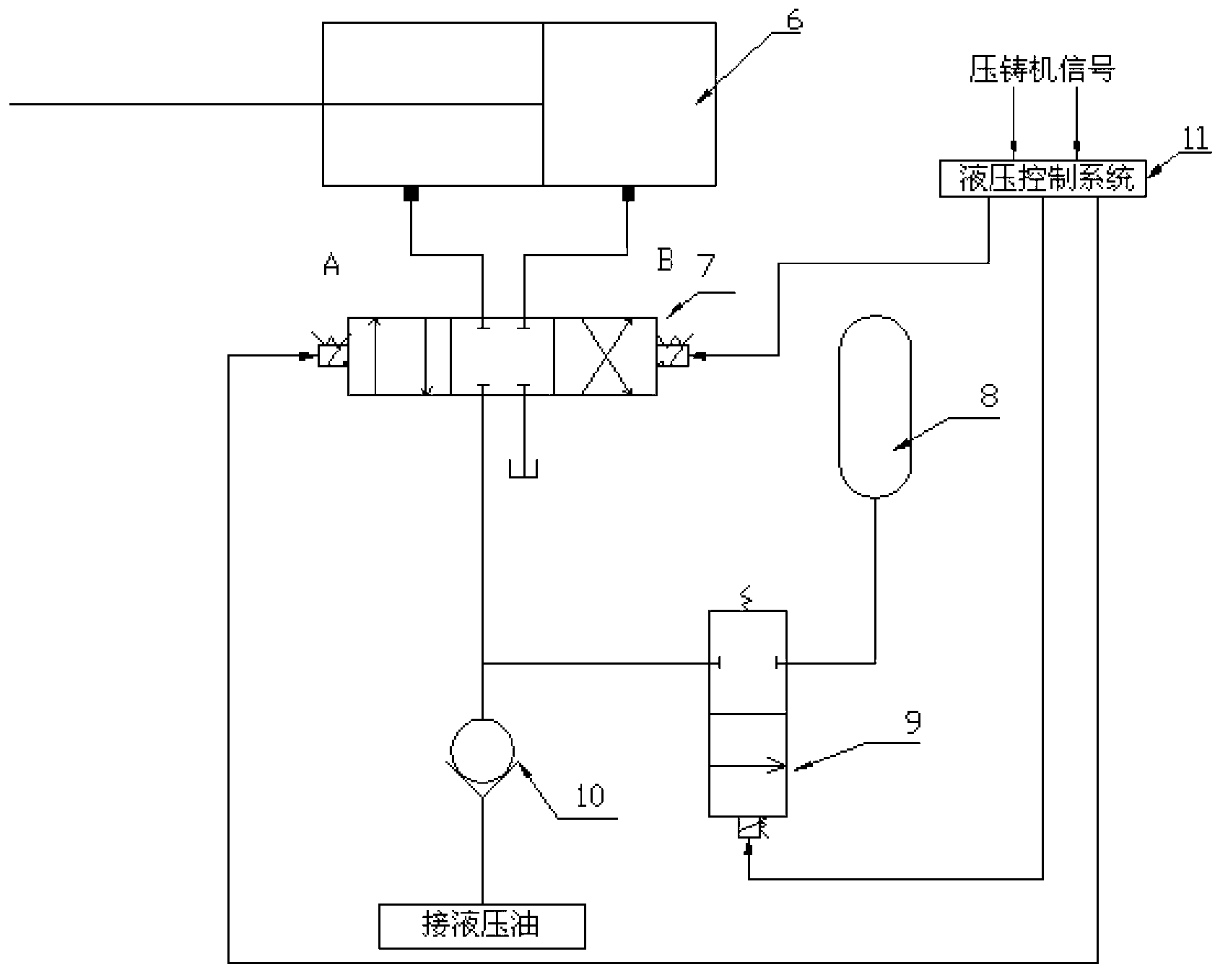

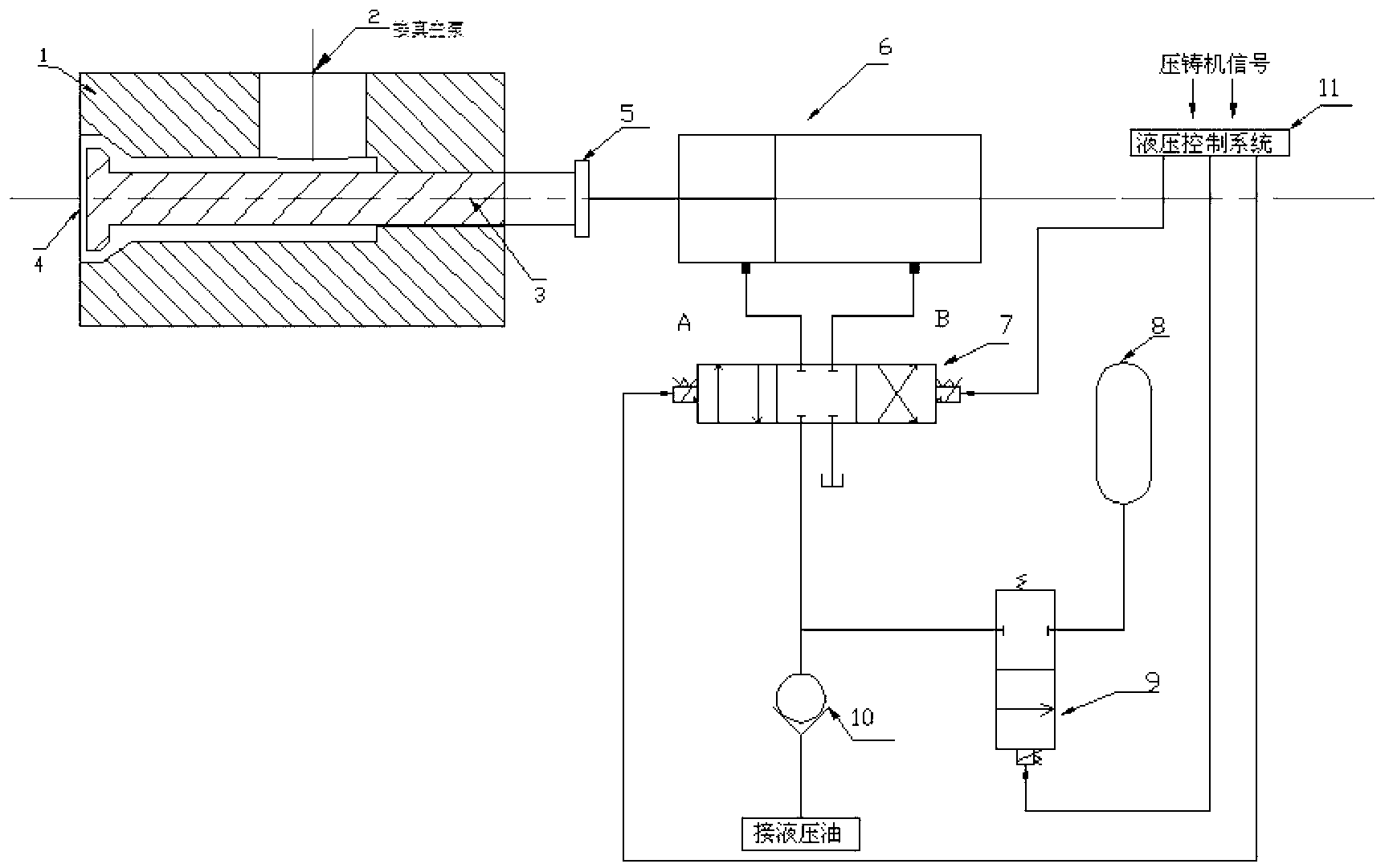

[0015] In order to solve the above-mentioned problems of the passive mechanical vacuum shut-off valve, the present invention proposes the single-piston hydraulically driven vacuum shut-off valve and its driving device. Its working principle is to use hydraulic drive mode to realize intelligent control of the vacuum shut-off valve according to the action signal of the die-casting machine, which can not only meet the high vacuum requirement of the mold cavity, but also effectively prevent the vacuum shut-off valve from being blocked, greatly reducing maintenance work Quantity and later maintenance costs, improve reliability and production efficiency.

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com