Device and method capable of qualitatively and quantitatively analyzing residue in vacuum system

A vacuum system and quantitative analysis technology, which is applied to measurement devices, analytical materials, material separation, etc., can solve problems such as damage to the chromatographic sampling system, damage to chromatographic components, and inability to complete sample gas collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

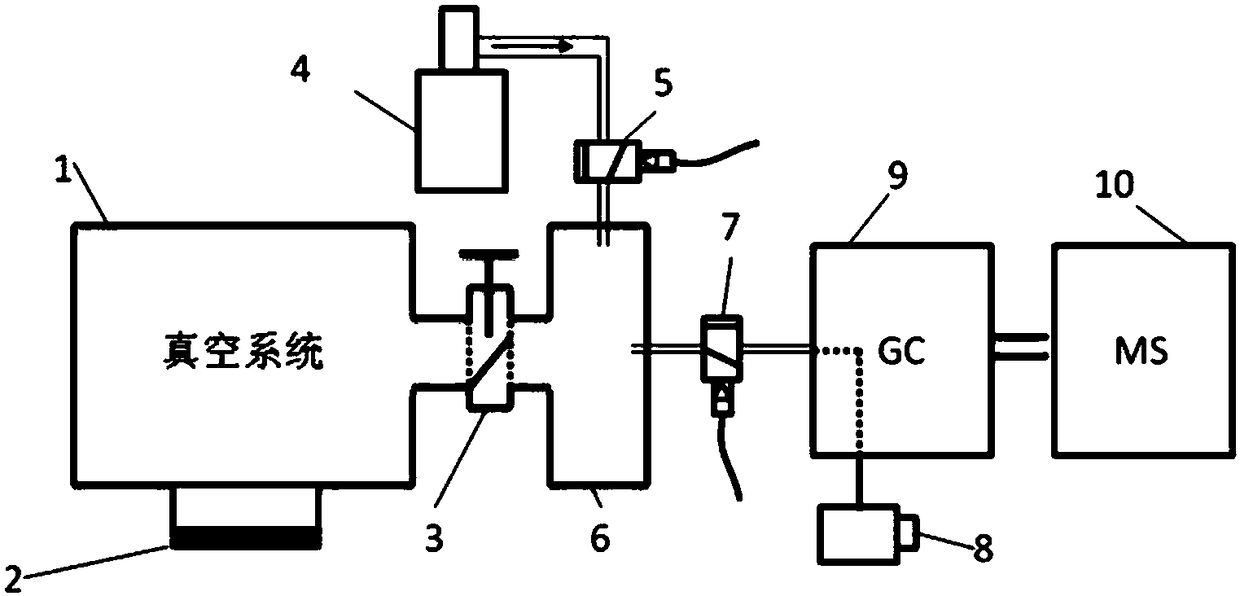

[0026] see figure 1 , figure 1 It is a structural schematic diagram of the present invention.

[0027] The present invention relates to a device and method for qualitative and quantitative analysis of residues in a vacuum system, comprising a vacuum system to be tested 1, a vacuum stop valve 2, first and second vacuum solenoid valves 5 and 7, a gas buffer chamber 6, and a gas source 4. Sampling pump 8, chromatograph 9 and mass spectrometer 10, the vacuum system 1 to be tested and the gas buffer chamber 6 are connected or cut off through the vacuum shut-off valve 3, and the gas source 4 and the gas buffer chamber 6 are connected through the first vacuum The solenoid valve 5 realizes the connection or cutoff of the gas, and the chromatograph 9 and the gas buffer chamber 6 are connected or cut off through the second vacuum solenoid valve 7 .

[0028] Further, the gas buffer chamber 6 is communicated with the quantitative loop 11 through the first three-way valve 15, and the qua...

no. 2 example

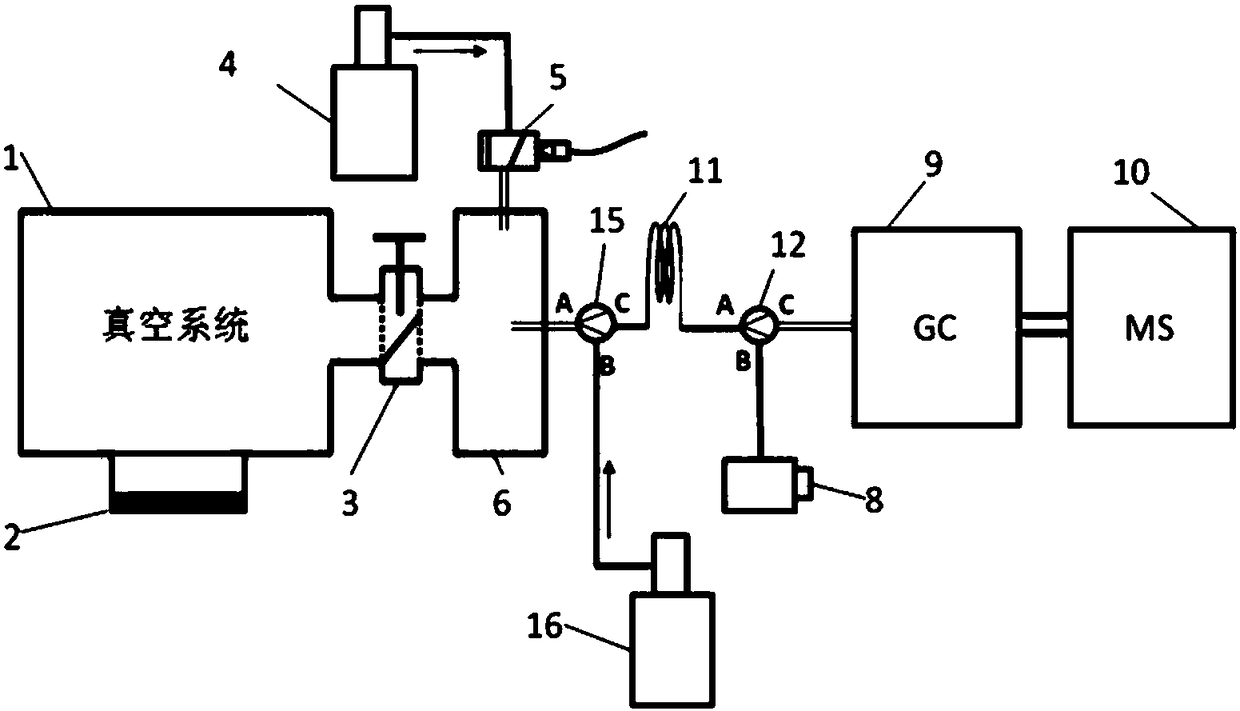

[0036] refer to figure 2 , figure 2 It is a schematic structural diagram of the second embodiment of the present invention;

[0037] Schematic diagram of a device for qualitative and quantitative analysis of complex residues in vacuum systems. The device consists of a vacuum system to be tested 1, a vacuum stop valve 3, a vacuum solenoid valve 5, a gas buffer chamber 6, the first and second gas sources 4 and 16, the first and second three-way valves 15 and 12, and a quantitative loop 11. , a sampling pump 8, a gas chromatograph 9 and a mass spectrometer 10. The vacuum shut-off valve 3 is used to connect the vacuum system 1 to be tested and the gas buffer chamber 6, and is used to control the communication and cut-off between the two; the vacuum solenoid valve 5 is used to connect the first gas source 4 and the gas buffer chamber chamber 6, and is used for on-off of the first gas; the first three-way valve 15 is used to connect the quantitative loop 11, the gas buffer cham...

no. 3 example

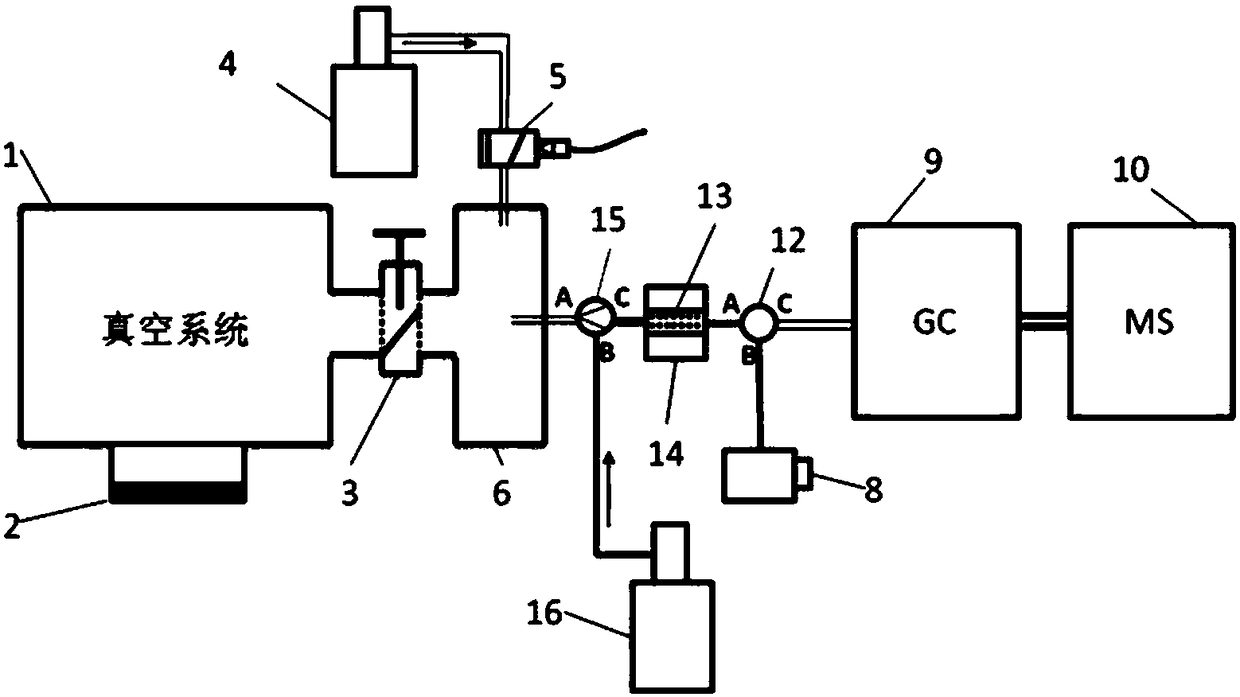

[0043] refer to image 3 , image 3 It is a structural schematic diagram of the third embodiment of the present invention.

[0044] Schematic diagram of a device for qualitative and quantitative analysis of complex residues in a vacuum system. The device consists of a vacuum system to be tested 1, a vacuum stop valve 3, a vacuum solenoid valve 5, a gas buffer chamber 6, the first and second gas sources 4 and 16, the first and second three-way valves 15 and 12, and the enricher 13. Composed of a sampling pump 8, a gas chromatograph 9 and a mass spectrometer 10. The vacuum shut-off valve 3 is used to connect the vacuum system 1 to be tested and the gas buffer chamber 6, and is used to control the communication and cut-off between the two; the vacuum solenoid valve 5 is used to connect the first gas source 4 and the gas buffer chamber The first three-way valve 15 is used to connect the enricher 13, the gas buffer chamber 6 and the second gas source 16, and is used to control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com