Patents

Literature

125 results about "Gas analyser" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

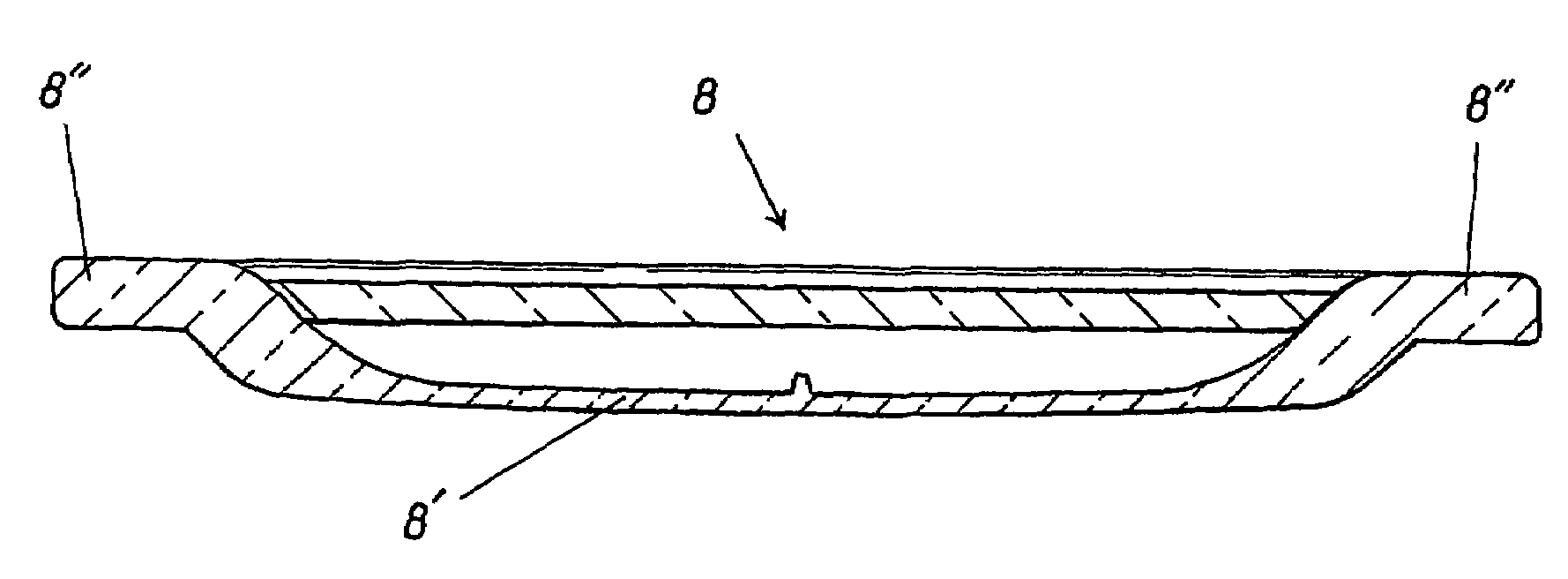

Air gas analyzer window and a method for producing such a window

ActiveUS7629039B2Uniform material thicknessSatisfactory transmission propertyLayered productsRespiratory organ evaluationPlastic materialsLight beam

A window for use in an adapter for an IR gas analyser for analysing breathing gases, where the gases flow through a through-penetrating passageway in the adapter, which includes windows disposed on opposite sides of the passageway so as to enable an IR beam to be sent through the windows and through the passageway containing said breathing gases. Each window is a one-piece structure comprised of plastic material and has a round basic shape that includes a surrounding edge and a central part which is sunken in relation to the surrounding edge and which forms the window through which the IR beams or rays shall be able to pass. A method of producing such a window, by injection moulding a thermoplastic material in a mould where injection of the plastic material is also disclosed.

Owner:PHASEIN

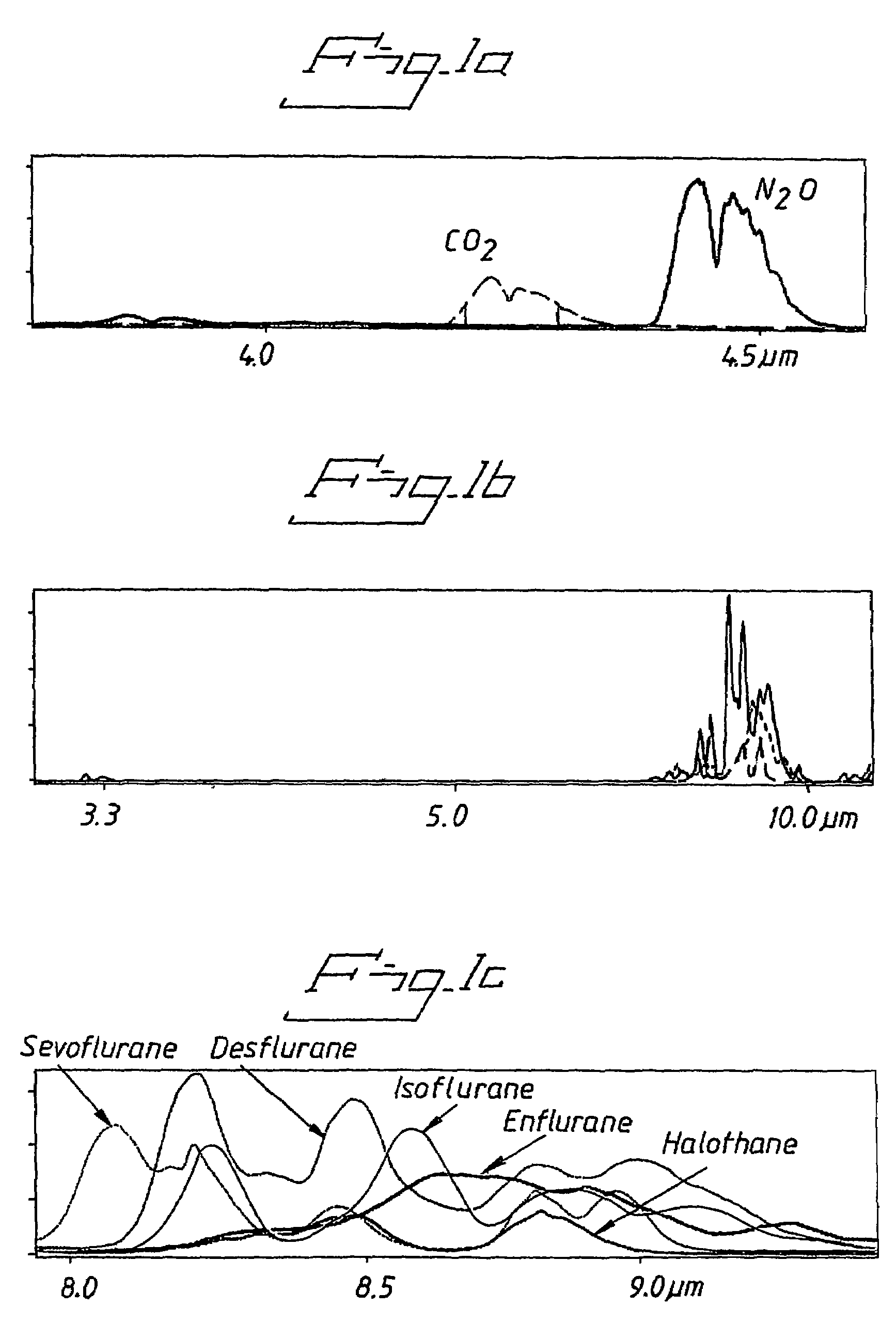

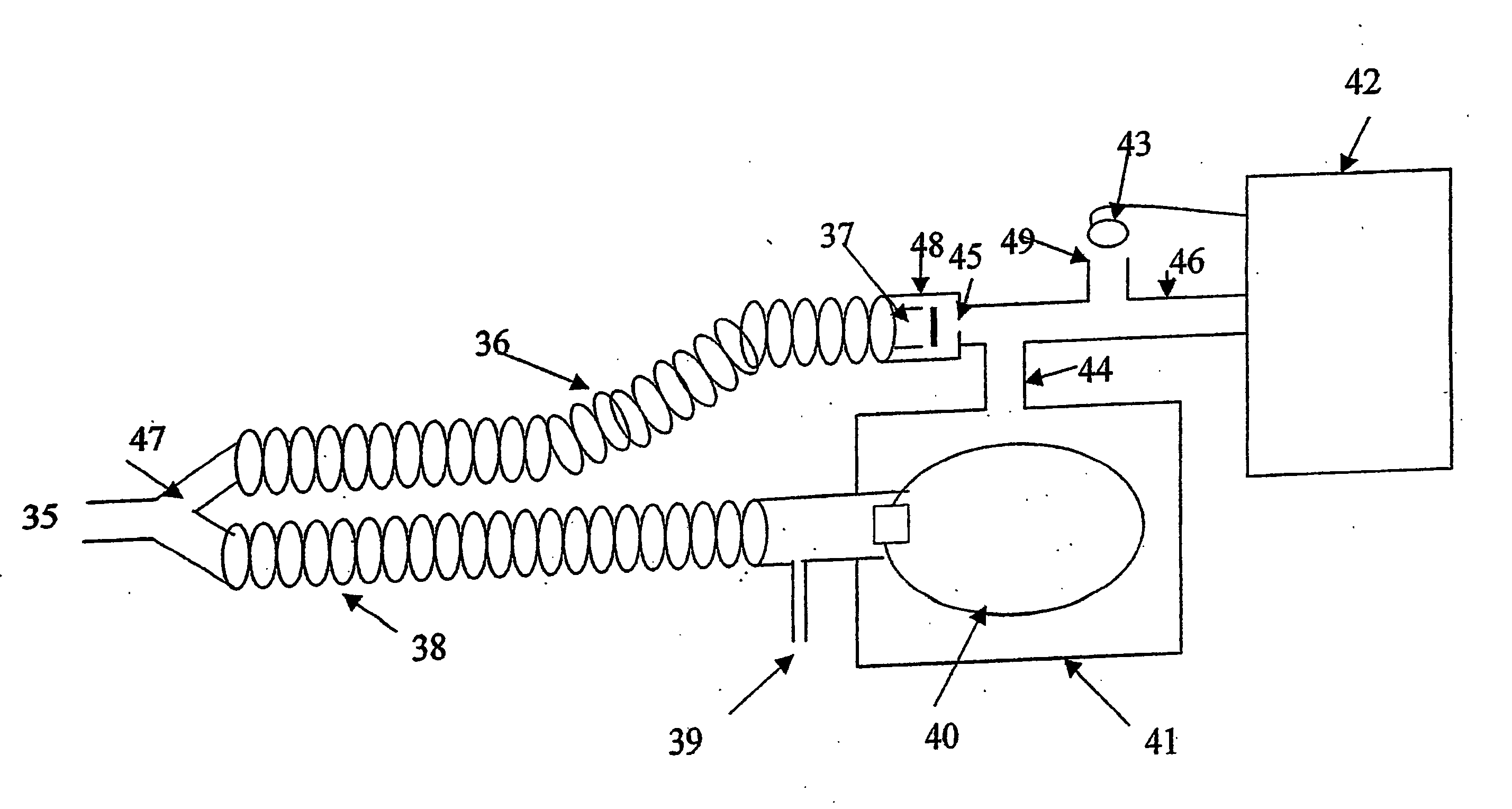

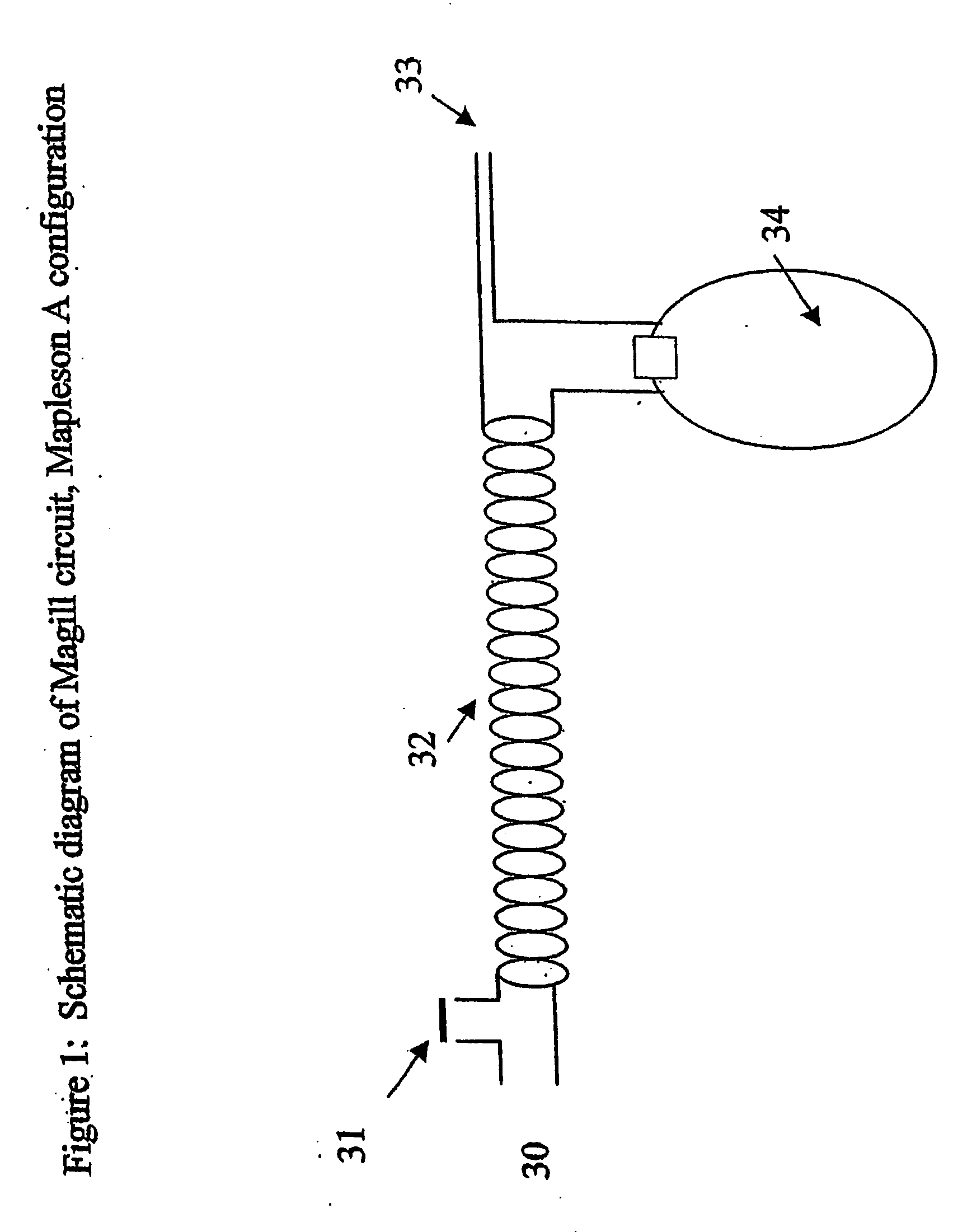

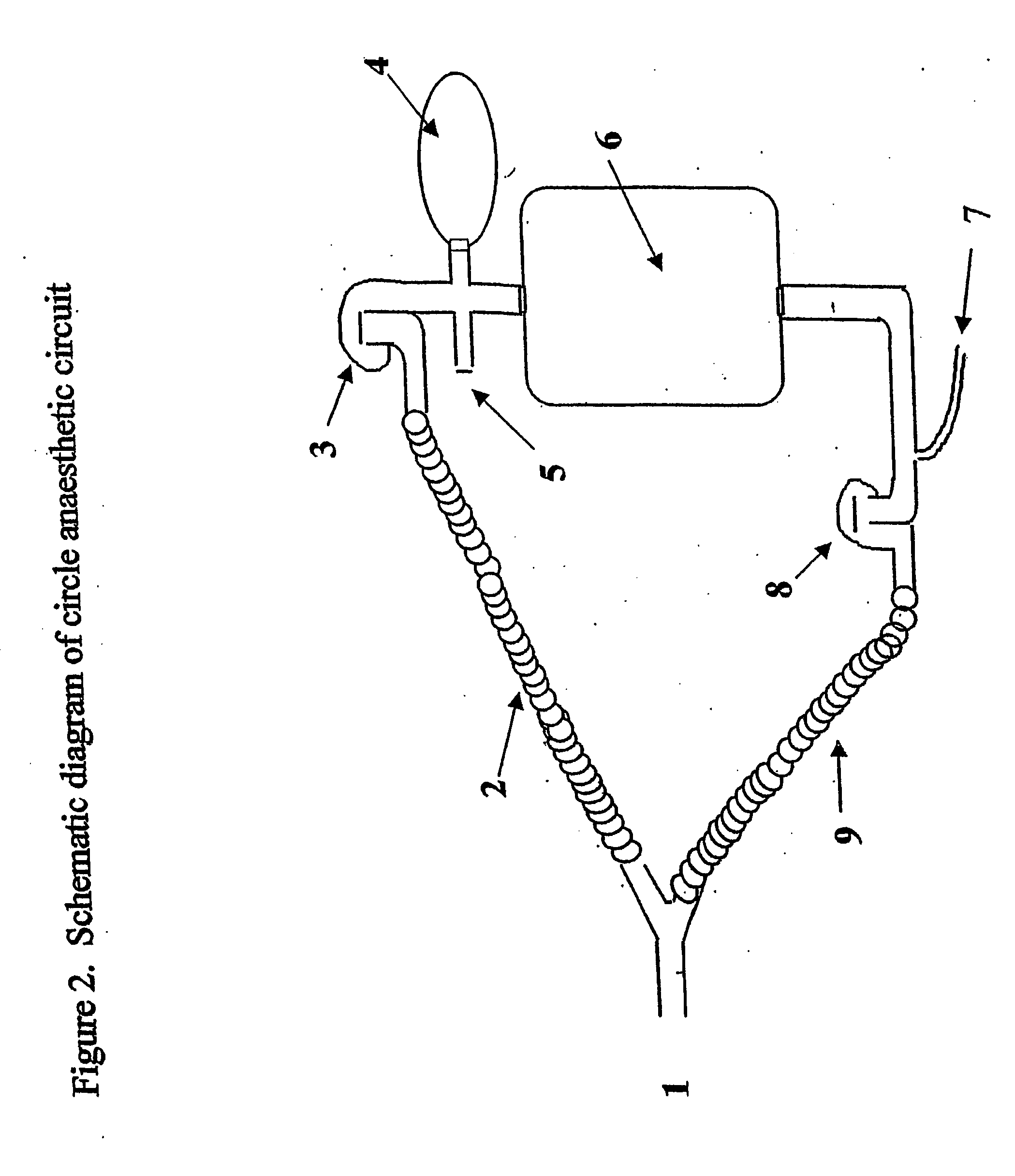

Method for continuous measurement of flux of gases in the lungs during breathing

ActiveUS20050217671A1RespiratorsOperating means/releasing devices for valvesAutonomous breathingEngineering

A method of calculating the flux of any gas (x) in a CBC circuit for a ventilated or a spontaneous breathing subject, for example said gas(x) being; a) an anesthetic such as but limited to; i)N2O; ii) sevoflurane; iii) isoflurane; iv) halothane; v) desflurame; or the like b) Oxygen; c) Carbon dioxide; or the like utilizing the following relationships; Flux of gas(x)=SGF (FSX−FEX) wherein SGF=Source of gas flow into the breathing circuit (CBC circuit) in liters / minute as read from the gas flow meter as set by the anesthesiologist; FSX=Fractional concentration of gas X in the source gas (which is set by the anesthesiologist); FEX=Fractional concentration of gas X in the end expired gas as determined by a portable gas analyzer, or the like.

Owner:THORNHILL SCI INC

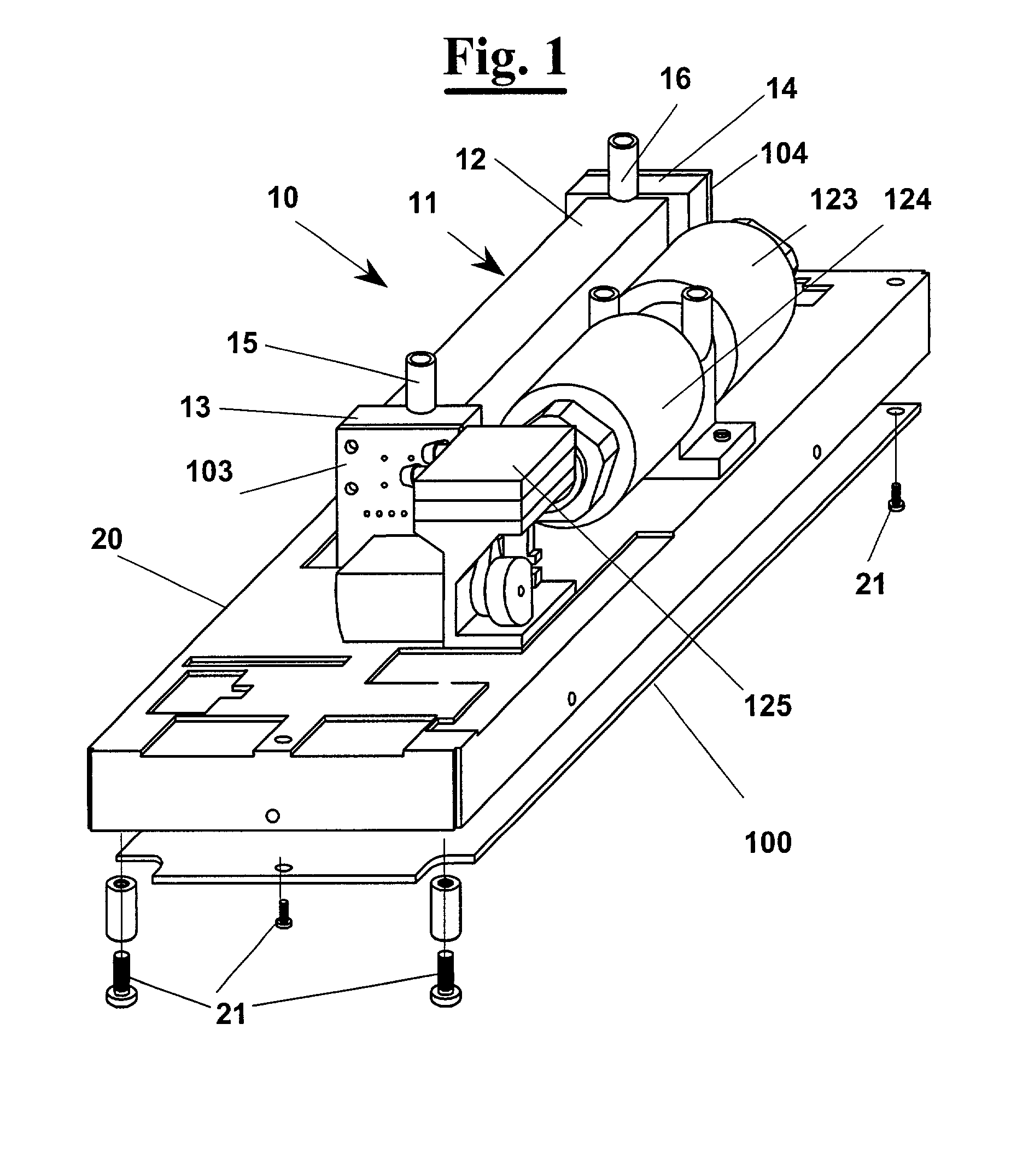

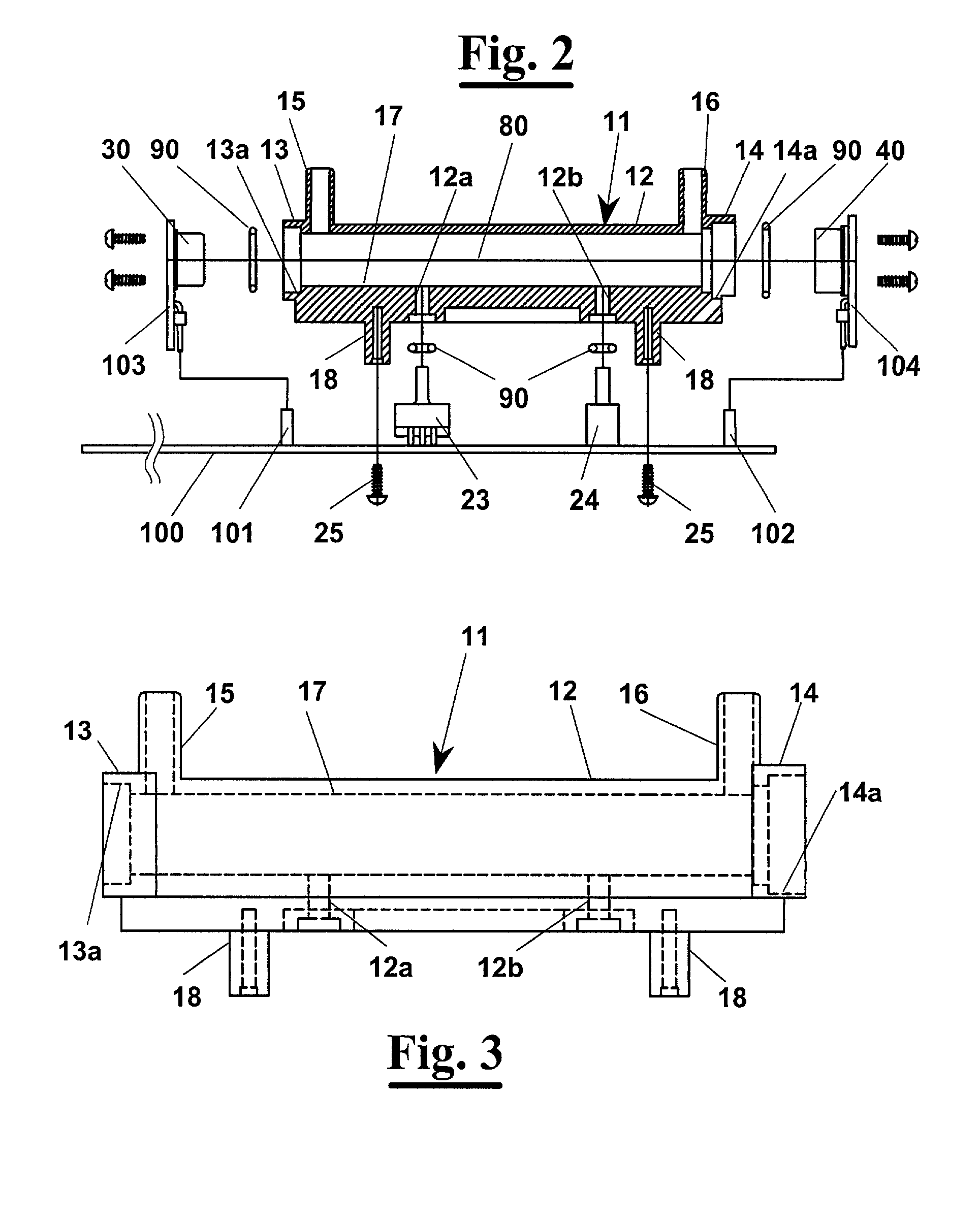

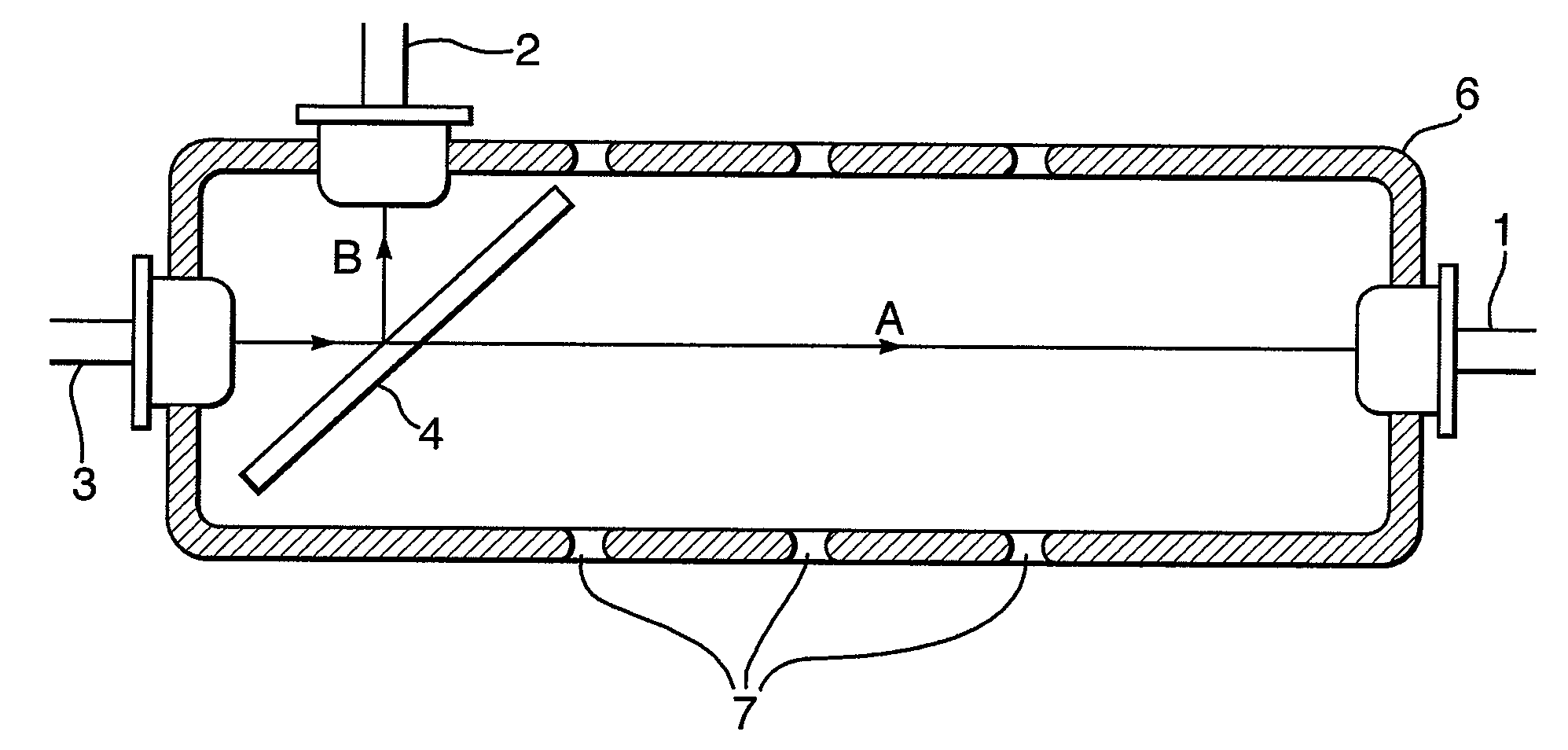

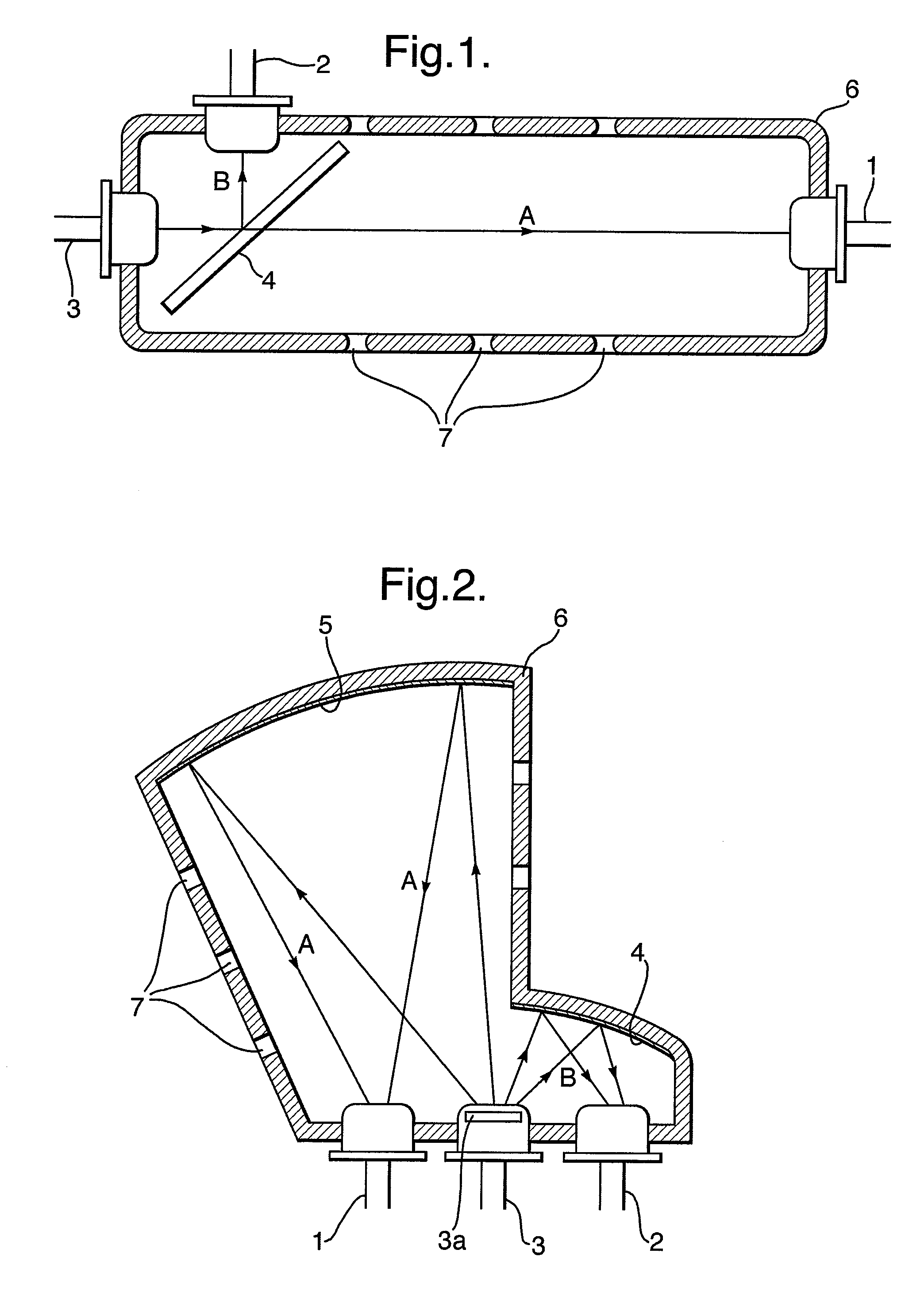

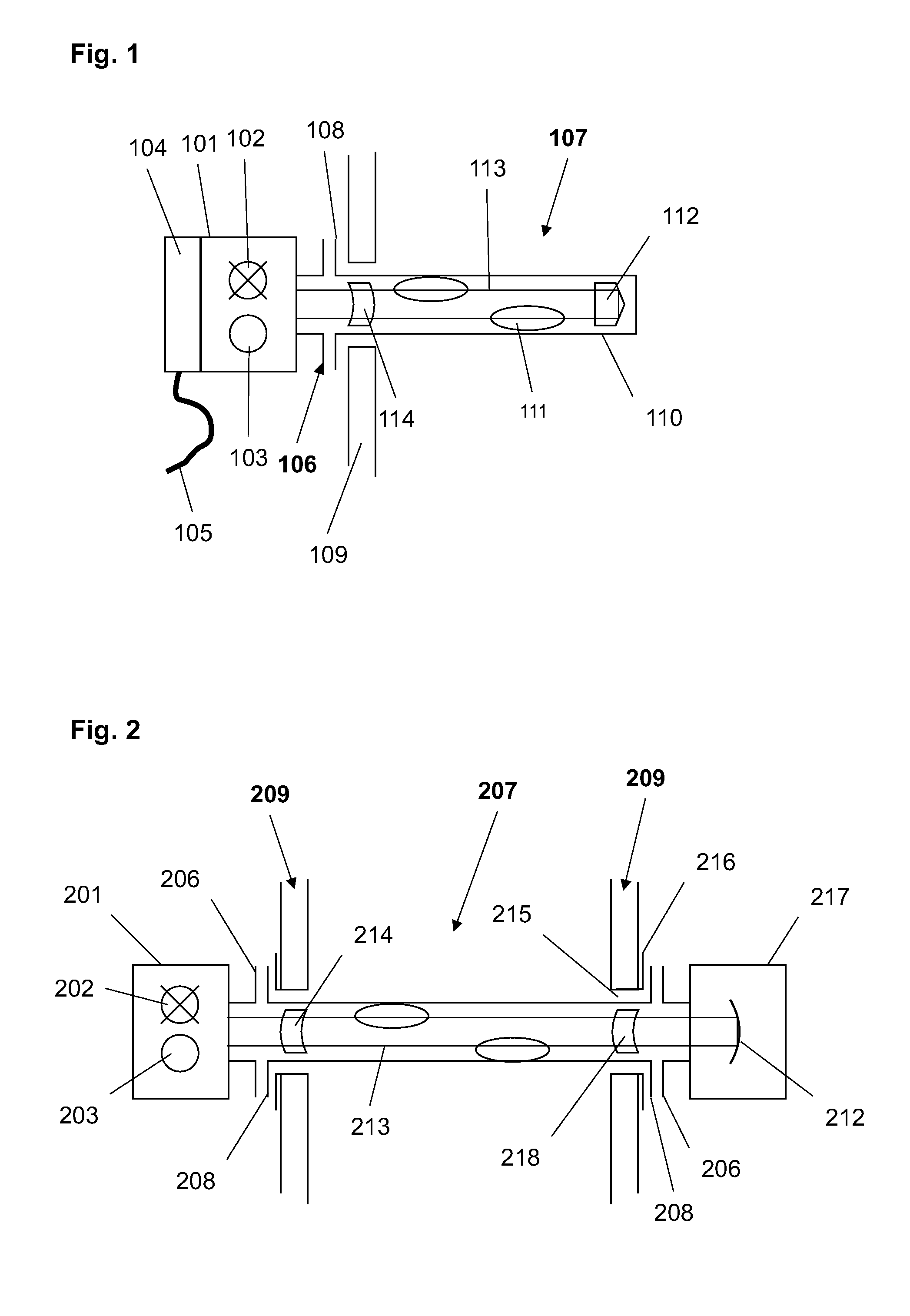

Non-dispersive infrared cell for gas analysis

InactiveUS20010048079A1Complex structureReduce measurement efficiencyRadiation pyrometryTransmissivity measurementsGas analyserPrinted circuit board

A method non-dispersive infrared (NDIR) gas analysis, which can be carried out by a gas analyser comprising a cell (10) containing of gas, a sender (30) of IR waves and at least a receiver (40) of such waves. The transmission of IR waves and / or the reception of IR waves after the passage of the gas occur directly in the cell (10) same wherein the gas is fed. The analyser has a body (11) defining the cell (10), a sender (30) of IR waves and at least a receiver (40) of such waves, that are located opposite to each other with respect to the cell (10). The IR sender (30) and the receiver (40) are both arranged in the cell (10) at its end (13,14). The body (11) has inlet (15) and outlet (16) channels for the gas and a cavity (17), which can be metal coated inside and that defines the optical path (80) for the IR waves. The body (11) is directly mounted on a printed circuit board (100) that has the electronic control unit for transmission of the IR waves and for analysis of the signals coming from the receiver (40).

Owner:BRUNAMOTI MASSIMO +2

Optical absorption gas analyser

ActiveUS20090268204A1Save battery powerImprove efficiencyMaterial analysis by optical meansGas analyserRadiation emission

An optical absorption gas analyser for determining the concentration of a target gas in a sample is disclosed. The analyser comprises a chamber for containing the sample in use; a radiation source assembly arranged to emit radiation into the chamber; a first radiation detector assembly arranged to detect radiation transmitted along a first optical path through the chamber and a second radiation detector assembly arranged to detect radiation transmitted along a second optical path through the chamber, wherein the length of the second optical path which the sample can intercept is shorter than that of the first optical path. The analyser further comprises a processor adapted to generate a sensing signal SS based on the detected radiation transmitted along the first optical path and a reference signal SR based on the detected radiation transmitted along the second optical path. The processor determines the concentration of the target gas in the sample based on a comparison of the sensing signal with the reference signal.

Owner:BAH HLDG

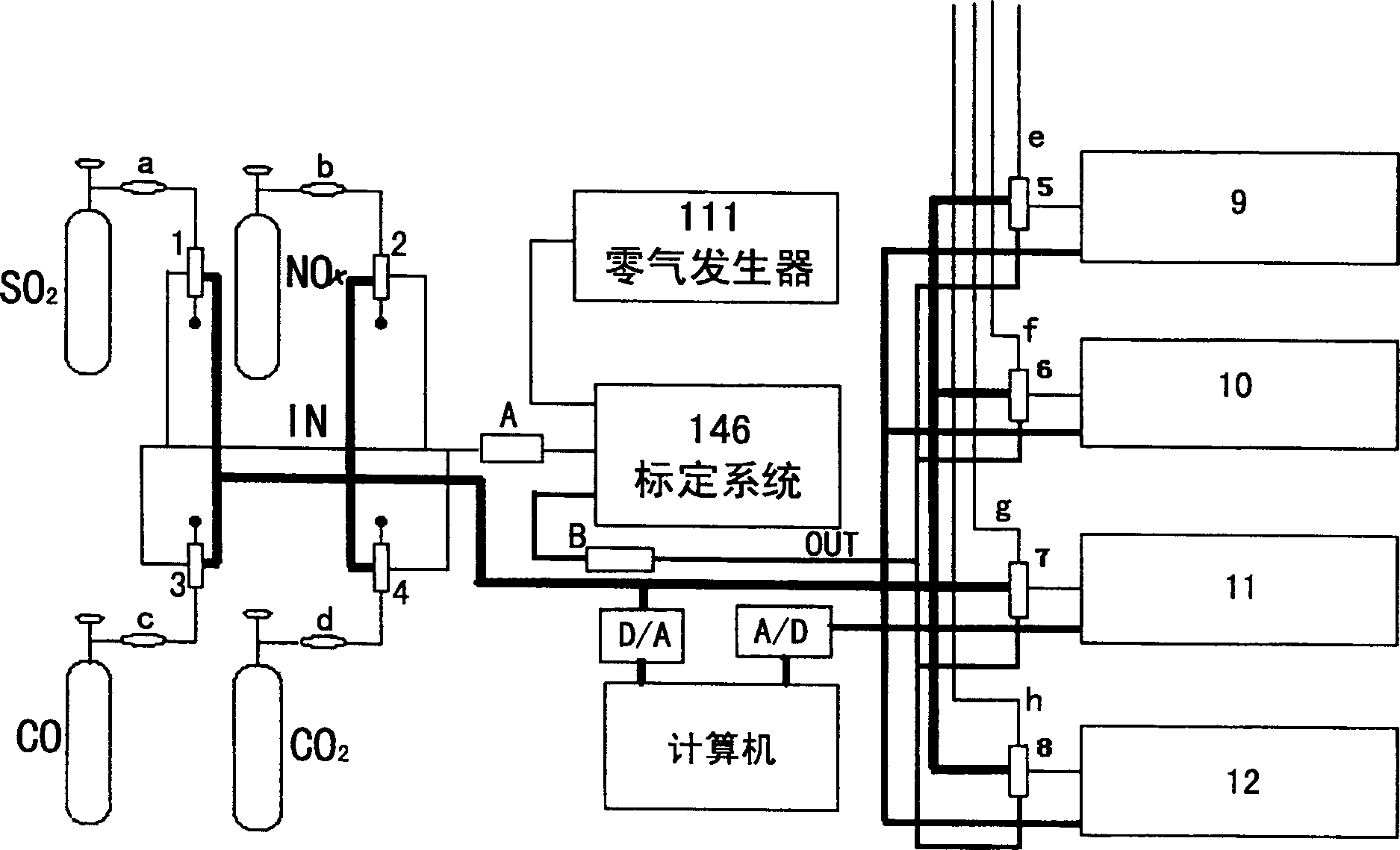

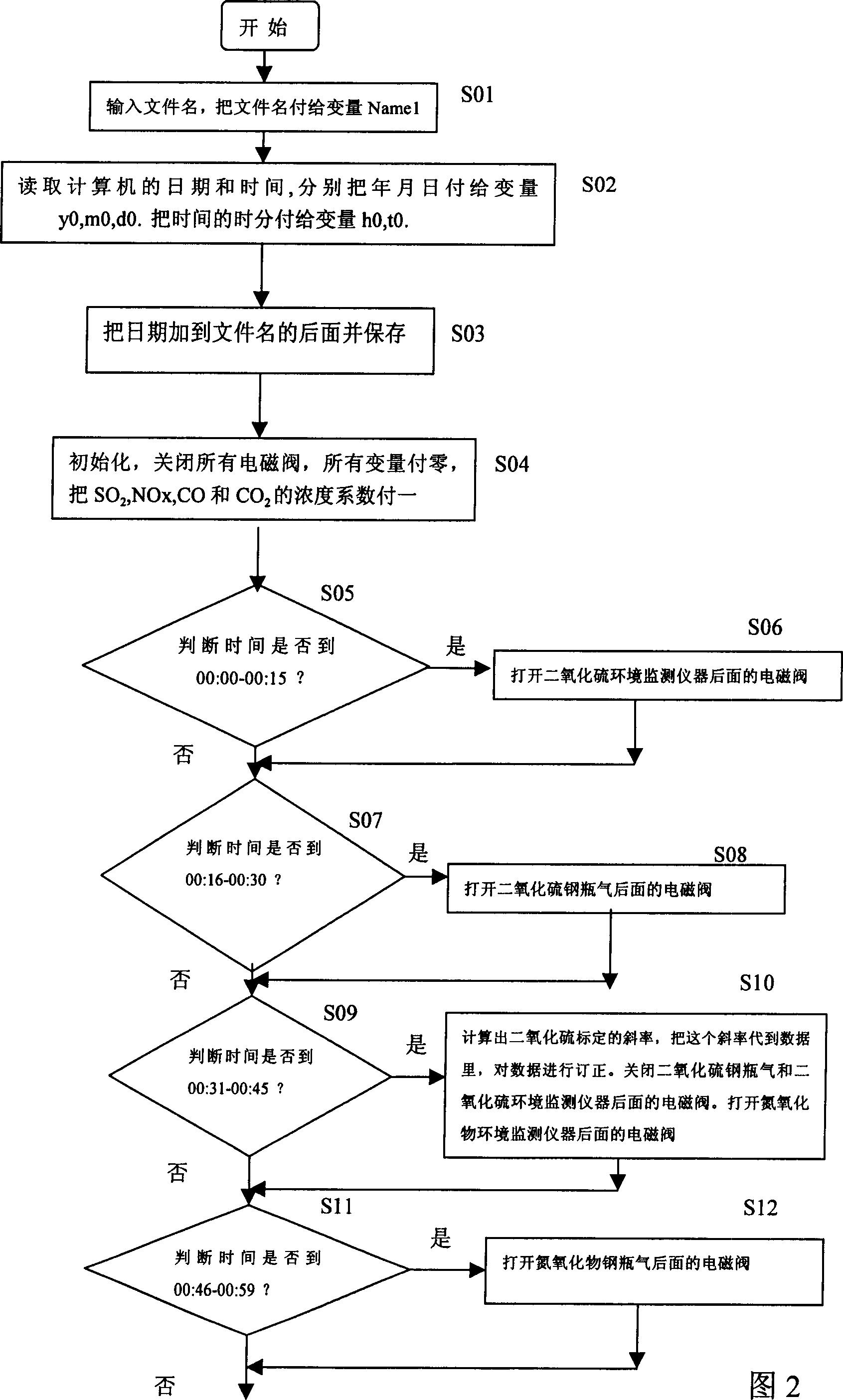

A gas analyser calibrating device and calibrating method

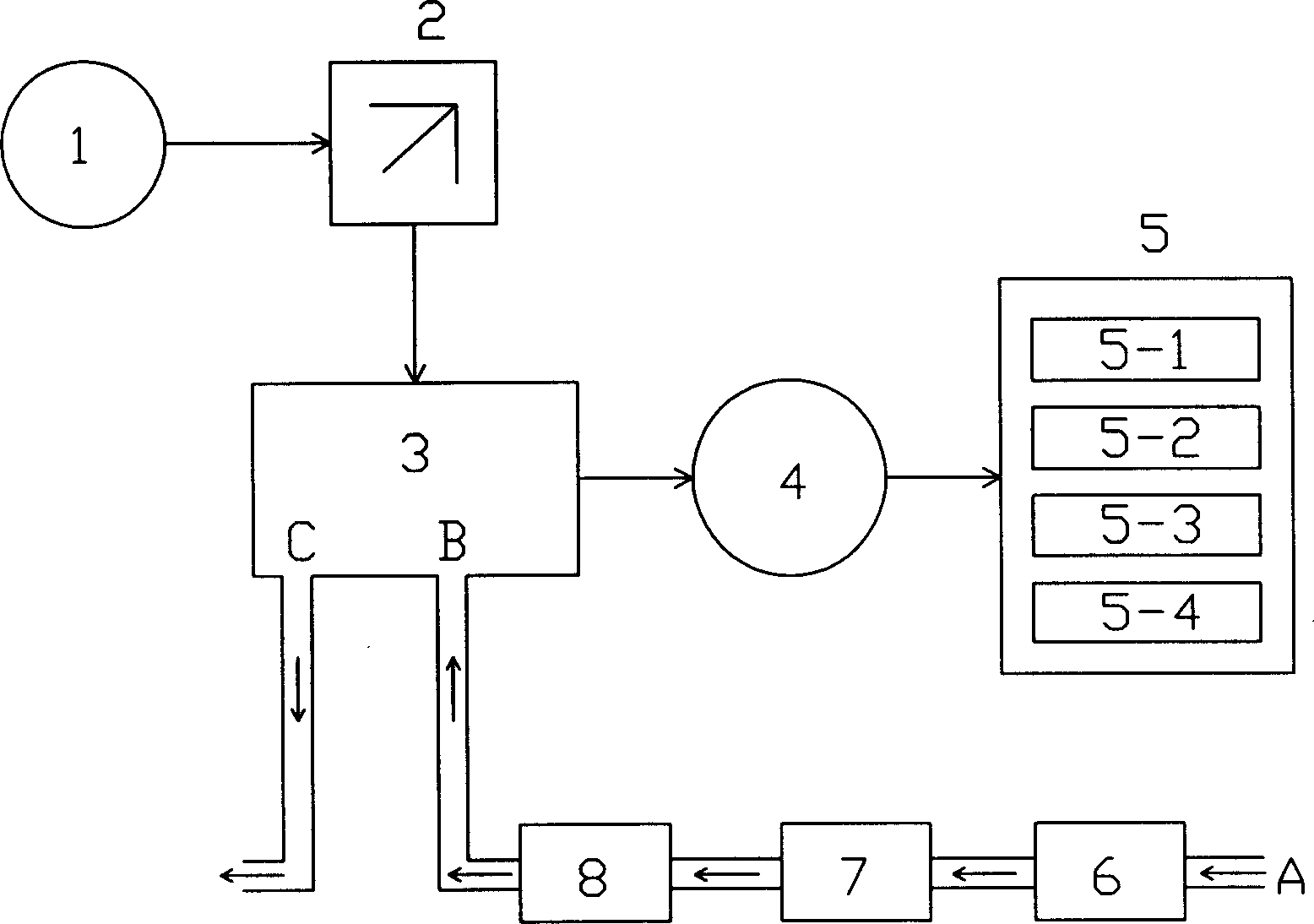

The gas analyzer calibrating equipment includes zero gas generator, calibration system and various kinds of gas analyzers. One gas inlet of the calibration system has one total gas intake pipe connected and the total gas intake pipe is connected to several standard gas cylinders via solenoid valve; and the gas outlet of the calibration system has one total gas outlet pipe connected and the total gas outlet pipe has the other end connected to analyzer via one three-way solenoid valve, which has normally closed port connected to the total gas outlet pipe, the normally opened port connected to atmosphere, and common port connected to the air intake port of the analyzer. The computer controls these solenoid valves via D / A converter. The equipment may be used to obtain the output slope of the analyzer data for correcting the data the analyzer obtains and obtaining the practical value of the gas component in atmosphere, solving the drift problem of analyzer.

Owner:INST OF ATMOSPHERIC PHYSICS CHINESE ACADEMY SCI

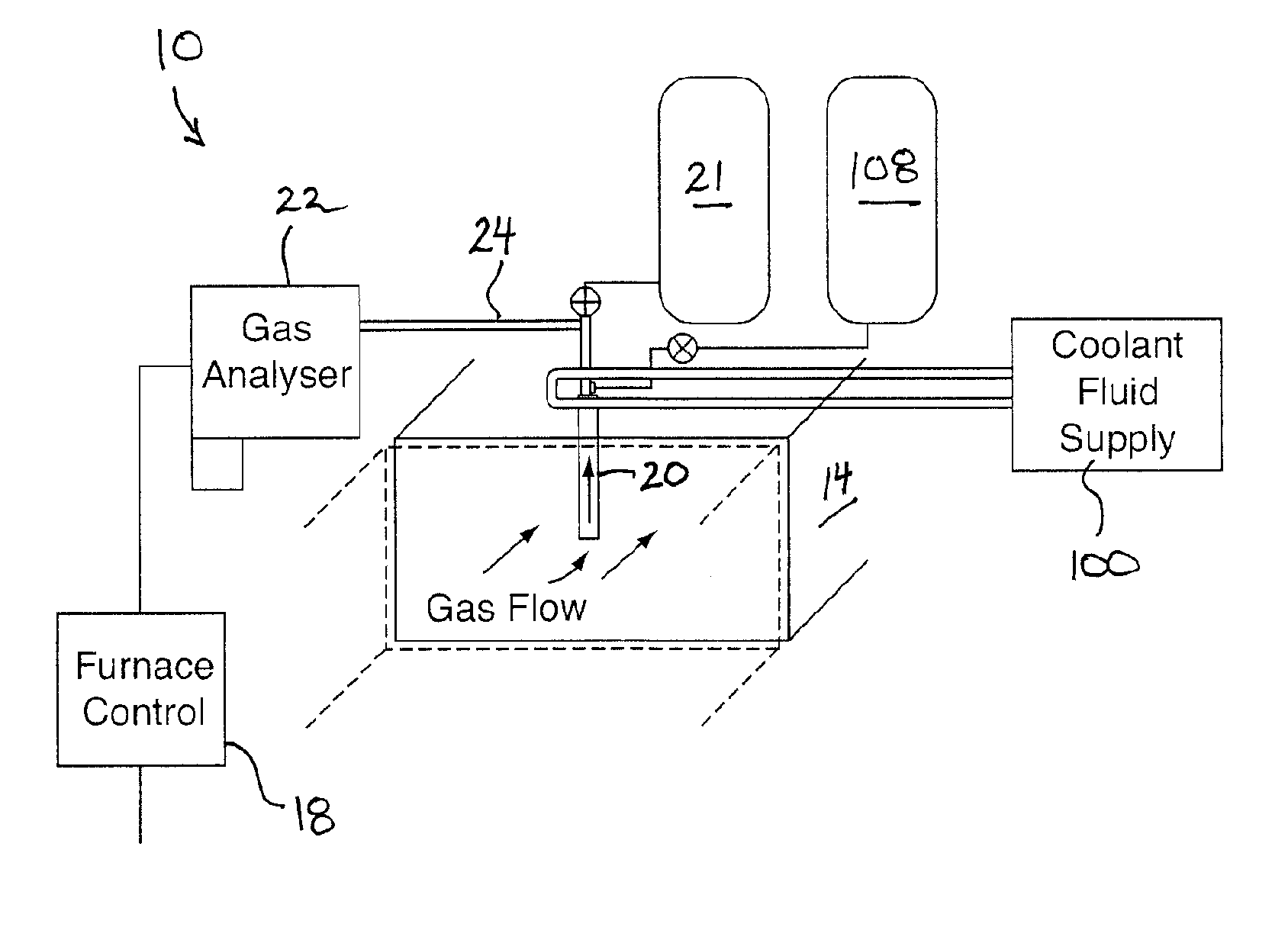

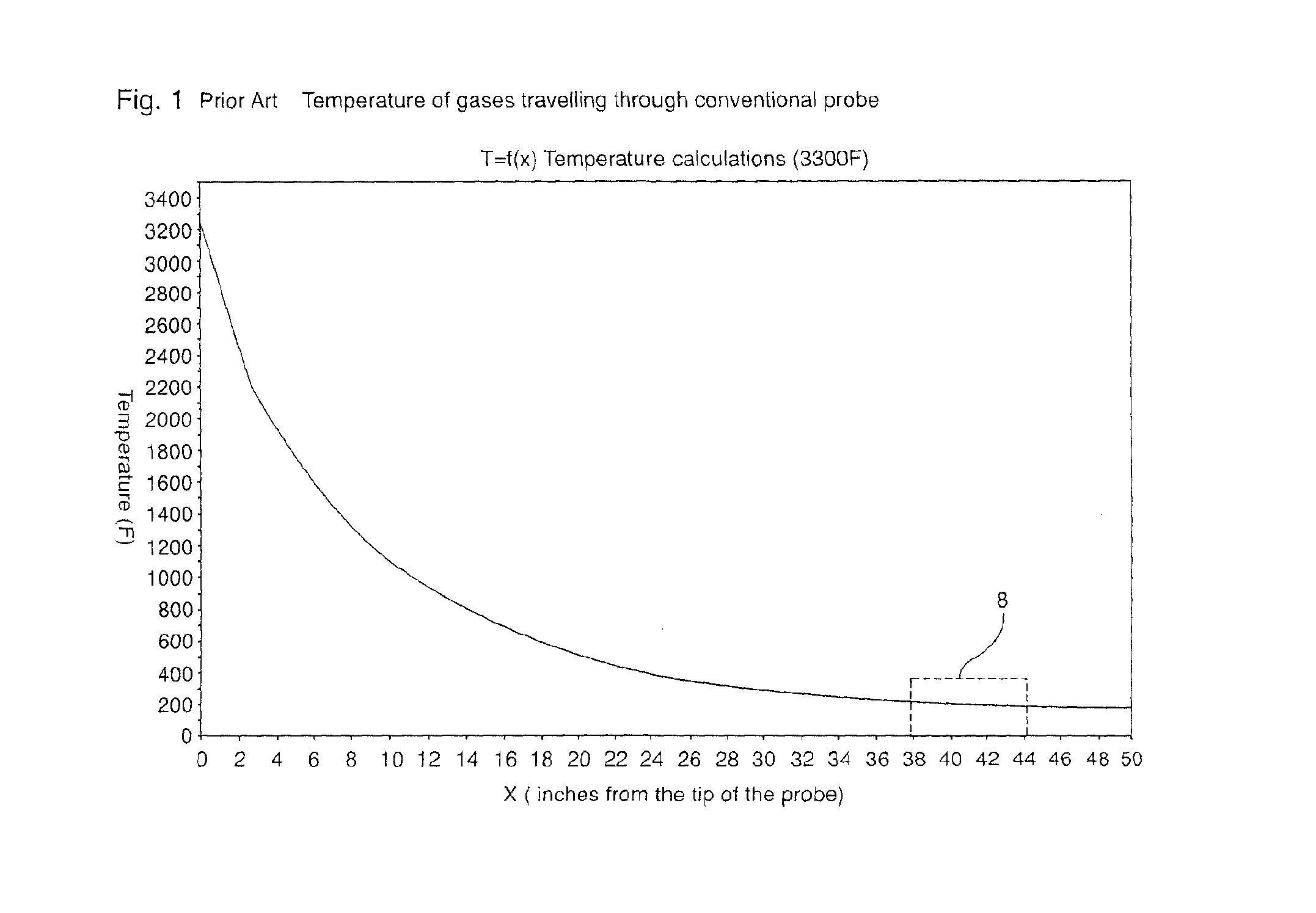

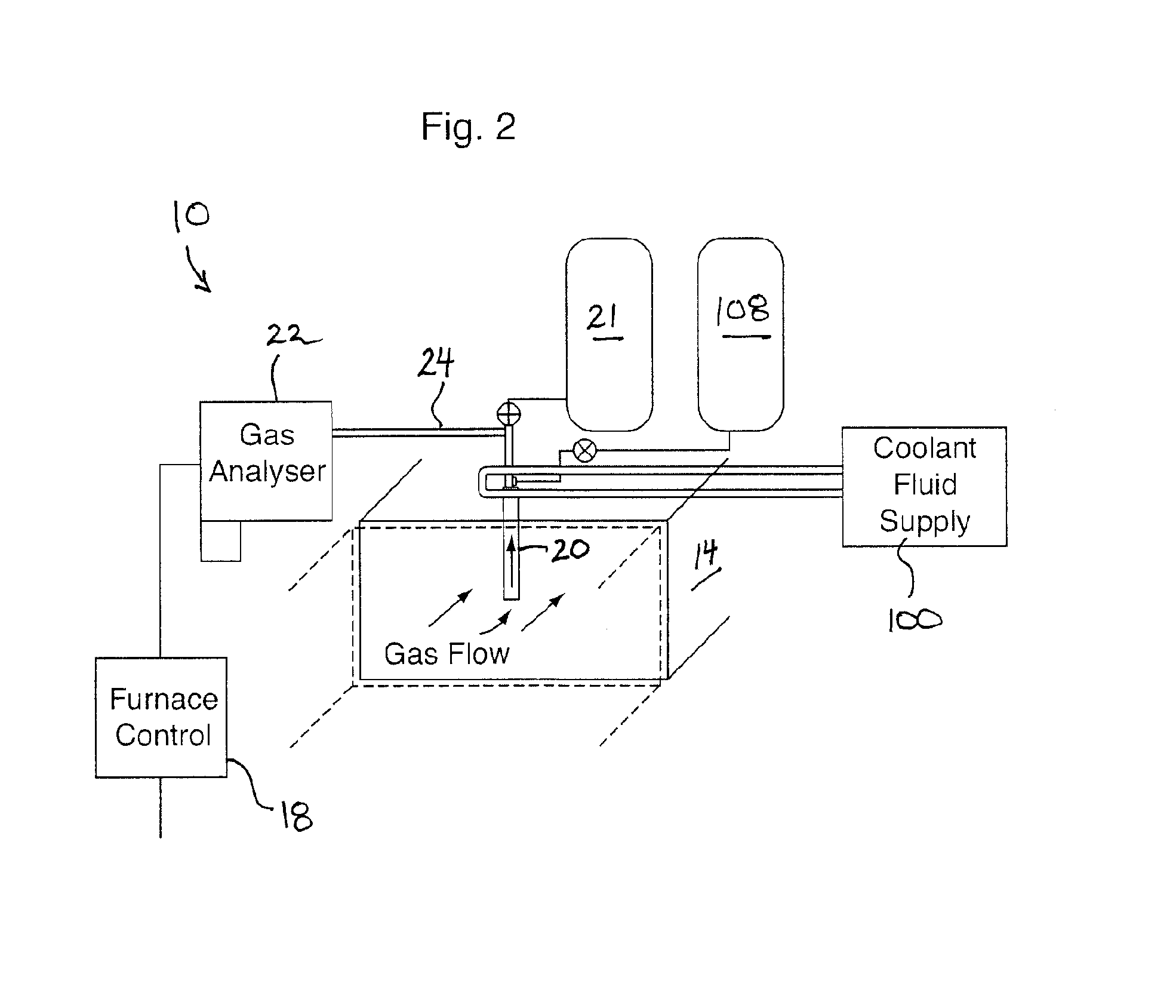

Non-Condensing Gas Sampling Probe System

InactiveUS20150377750A1Preserve integrityEasy to measureWithdrawing sample devicesPreparing sample for investigationGas phaseProduct gas

A system for measuring water and / or gaseous phase content of high temperature process gases includes a probe for gas sample extraction and cooling temperatures below those which probe filter or gas analyzer components degrade. A heated gas extraction tube provided within the probe interior operates to maintain the thermal stability of the cooled gas sample to preserve chemical integrity.

Owner:TENOVA GOODFELLOW INC

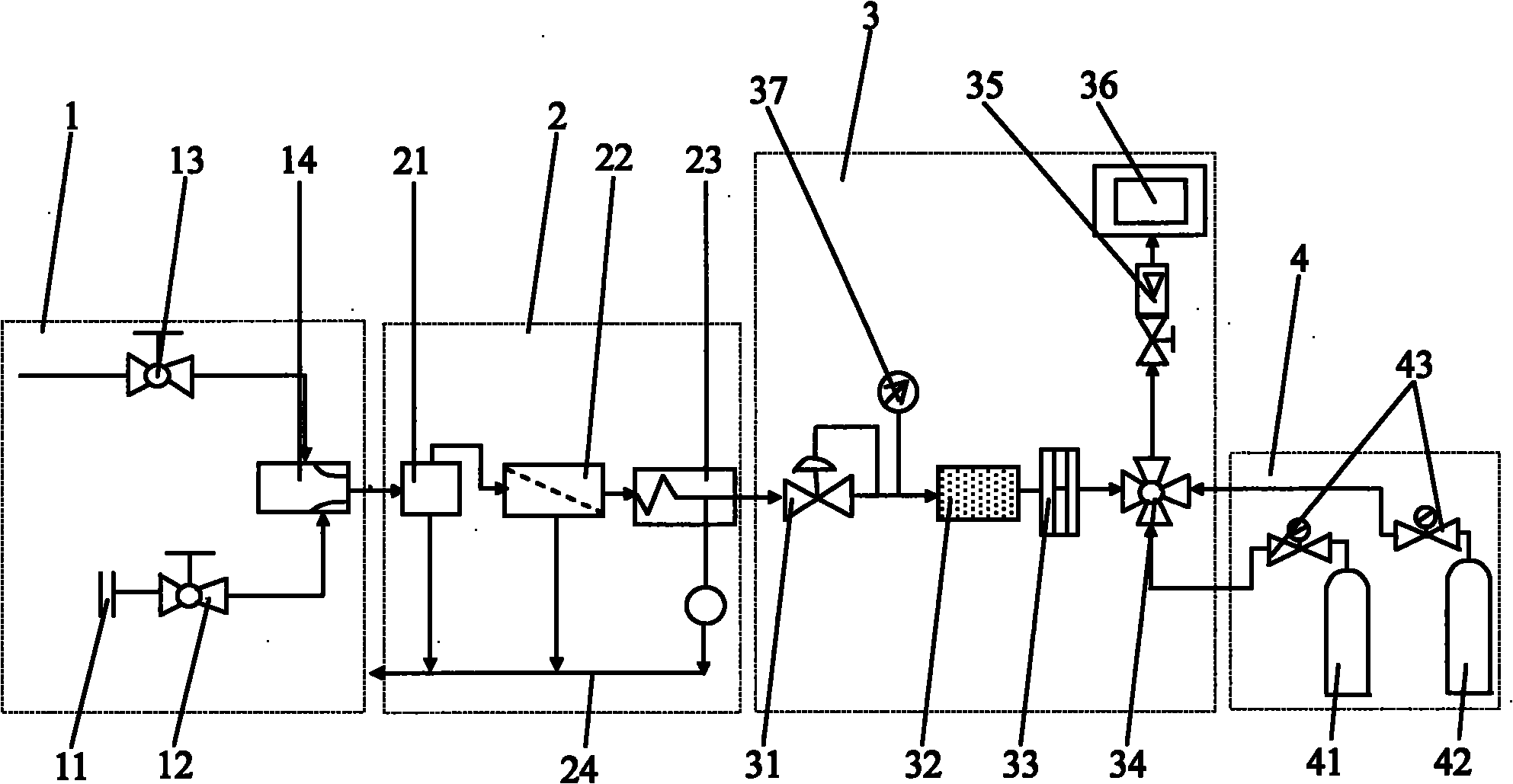

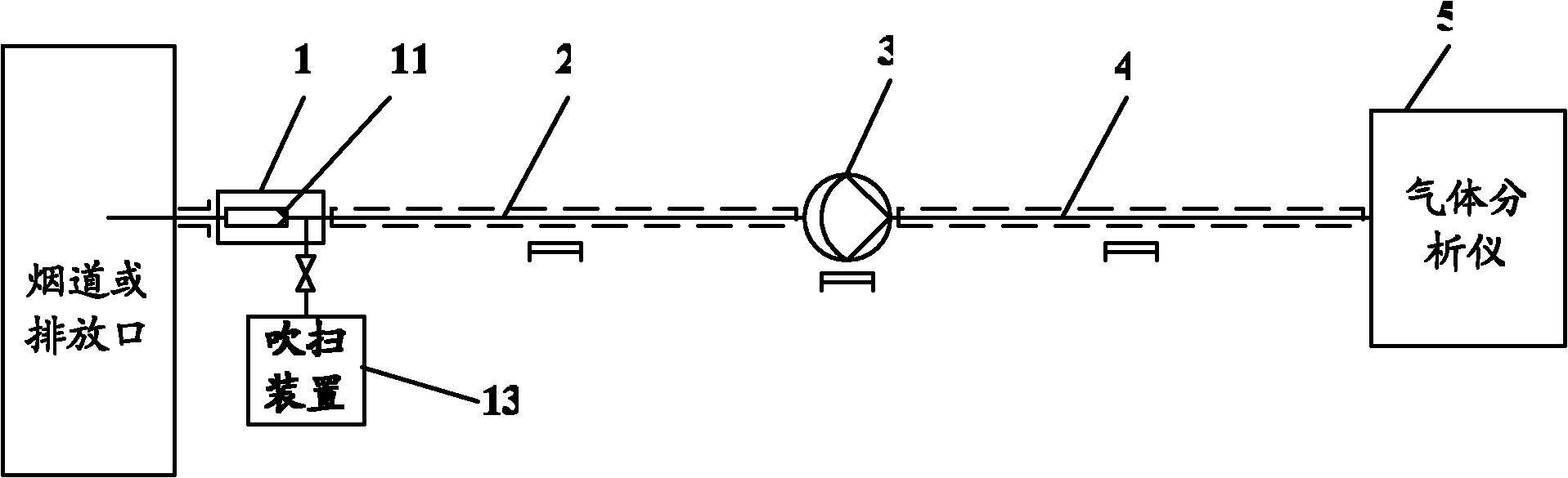

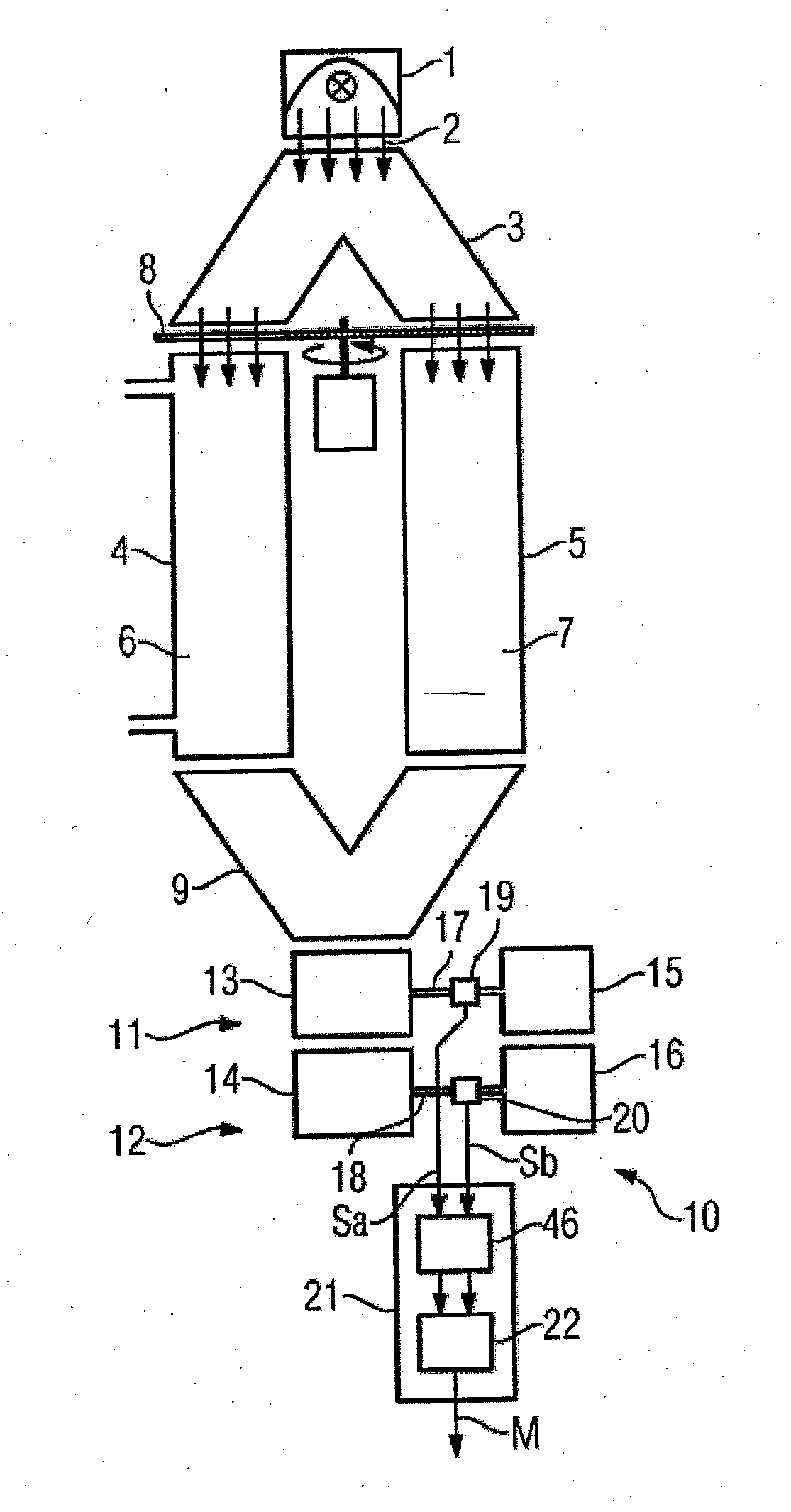

Online analysis system and method for monitoring harmful gases in livestock and poultry farm

InactiveCN101900716ARealize online calibrationAccurate emissionsWithdrawing sample devicesPreparing sample for investigationFiltrationEngineering

The invention discloses an online analysis system for monitoring harmful gases in a livestock and poultry farm. The online analysis system comprises a sampling unit, a purifying unit and an analytic unit connected in turn. Steam with a constant pressure is introduced into the sampling unit, is sent into the purifying unit by an injection pump and then is passed into the gas analytic unit. Through multiple times of filtration and dehumidification treatments, the gasses exhausted by a ventilation opening of the livestock and poultry farm can be stably sampled under various working conditions, and the sampled gasses automatically undergo dust removal, dehumidification drying, pressure and flow stabilization, fine filtration, flow measurement and quantitative analysis. Besides, measurement range calibration and zero point calibration are performed on a gas analyzer through a standard gas connected with the analytic unit to realize online calibration of the analysis system. The invention also discloses an online analysis method for monitoring the harmful gasses in the livestock and poultry farm. Through the online analysis system and the online analysis method, hydrogen sulfide, ammonia gas, carbon dioxide, carbon monoxide and methane exhausted by the ventilation opening of the livestock and poultry farm can be accurately and reliably detected and analyzed online.

Owner:JIAXING UNIV

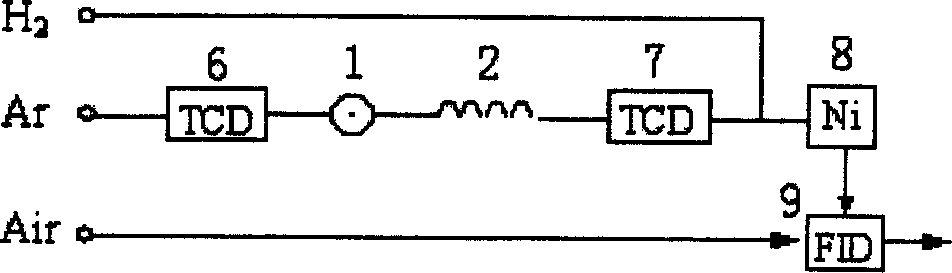

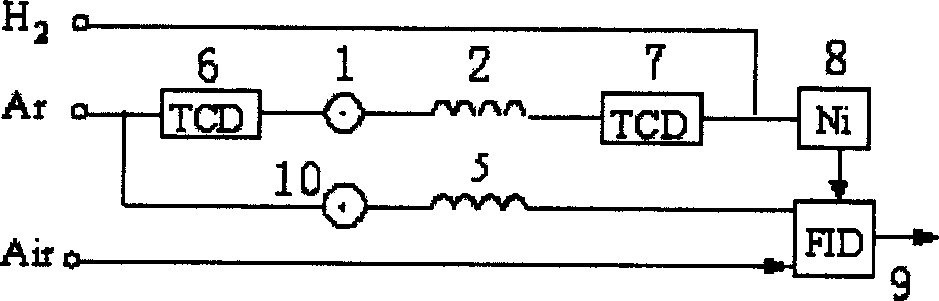

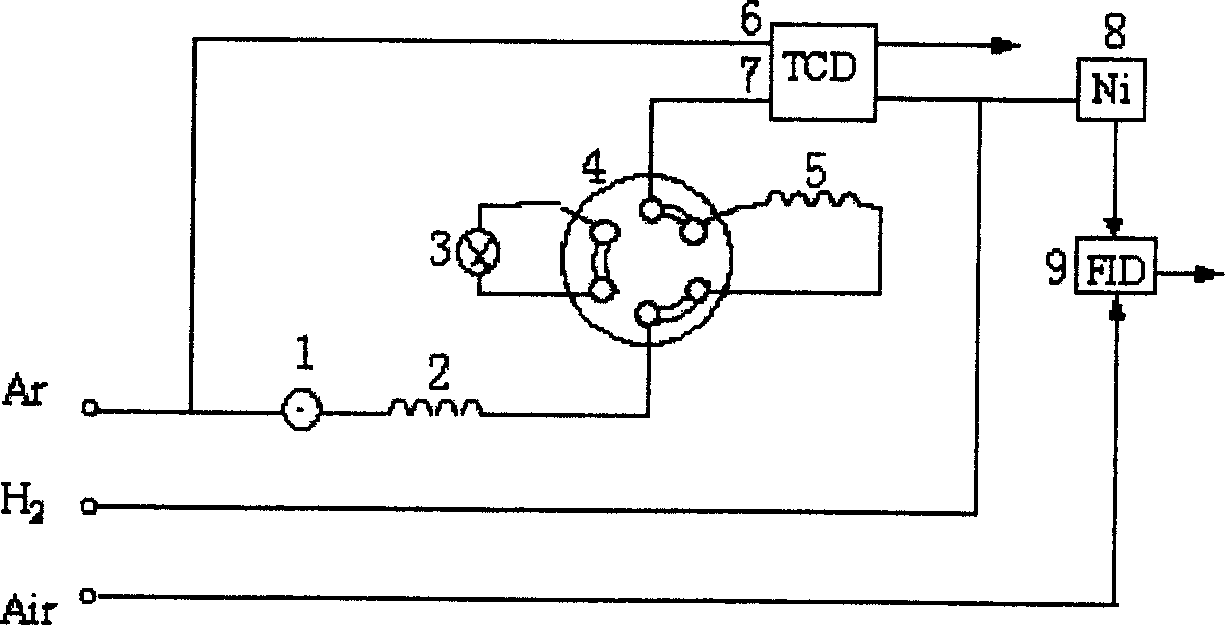

Gas chromatography for measuring gas content and characteristic gas in insulating oil completed at one time of sample injection

This invention publishes a kind of gas phase chromatography method which can measure the air content and the specific gas in the insulating oil with just once sampling. This invention uses Ar as carrier gas. It also uses the packed column sample entrance. What is more, it has six-way value color-spectrum-switching column, heat transmission detector and the H-fire ionization detector. During the process, Ar is divided into 2 parts. One part will directly go out after it goes through the heat transmission detector's reference arm 6, while the other part will go by steps through the sample entrance 1, the first color spectrum column 2, the six-way value 4, the second color spectrum column or gas lock 3, the heat transmission detector 7, the Ni catalysis CH4 converter 8 with H2, and at last the H fire ionization detector 9 with the air. Then it will go out. During the only one sampling, the invention can meanwhile measure the air content and analyze the accident specific gas in the simple oil. To sum up, it operates easily, needs little work and can decrease the analysis error relatively. So it can do the work of analyzing the sample oil which has low degassing ratio well, as it can satisfactorily separate all the groups.

Owner:STATE GRID HUBEI ELECTRIC POWER RES INST +1

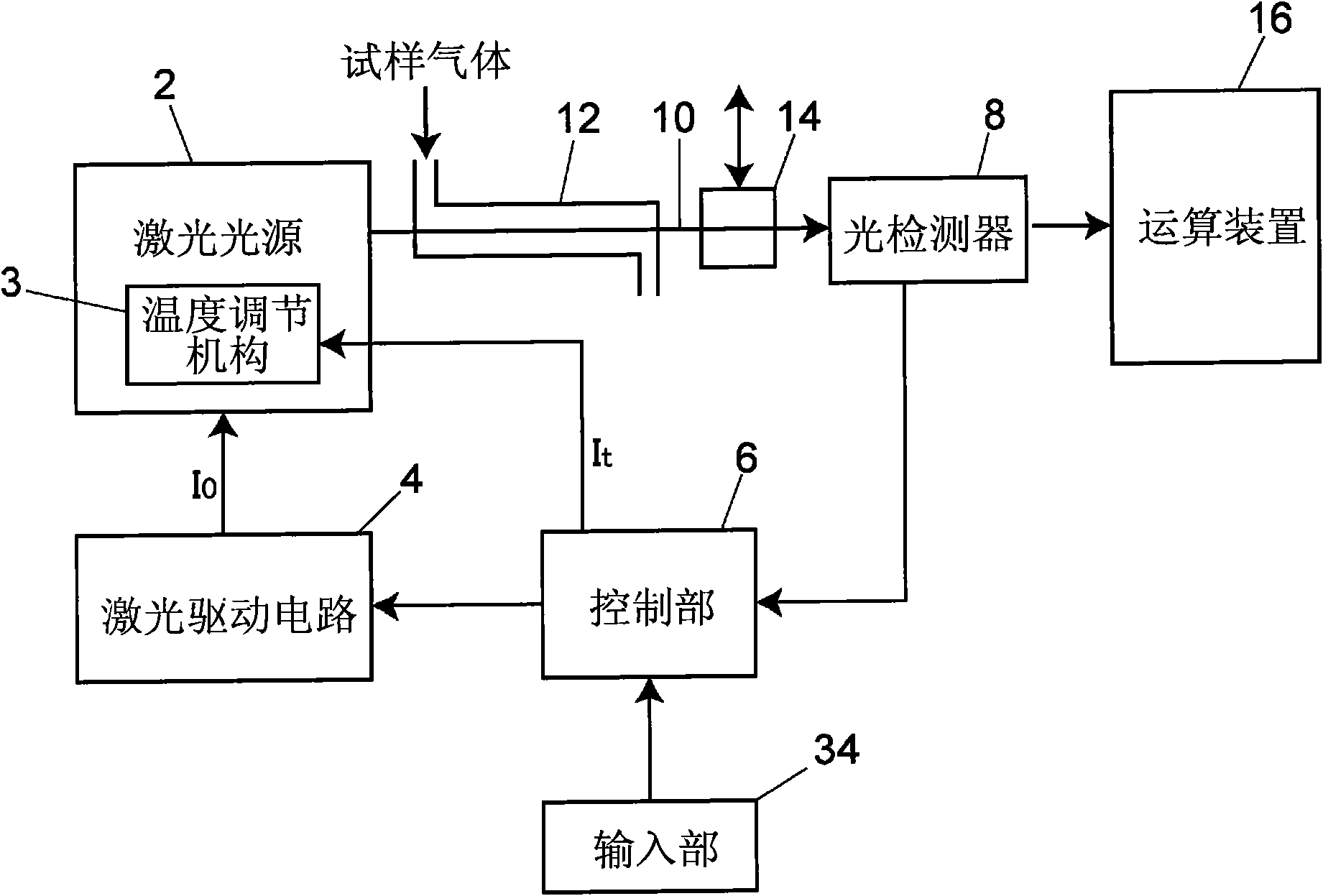

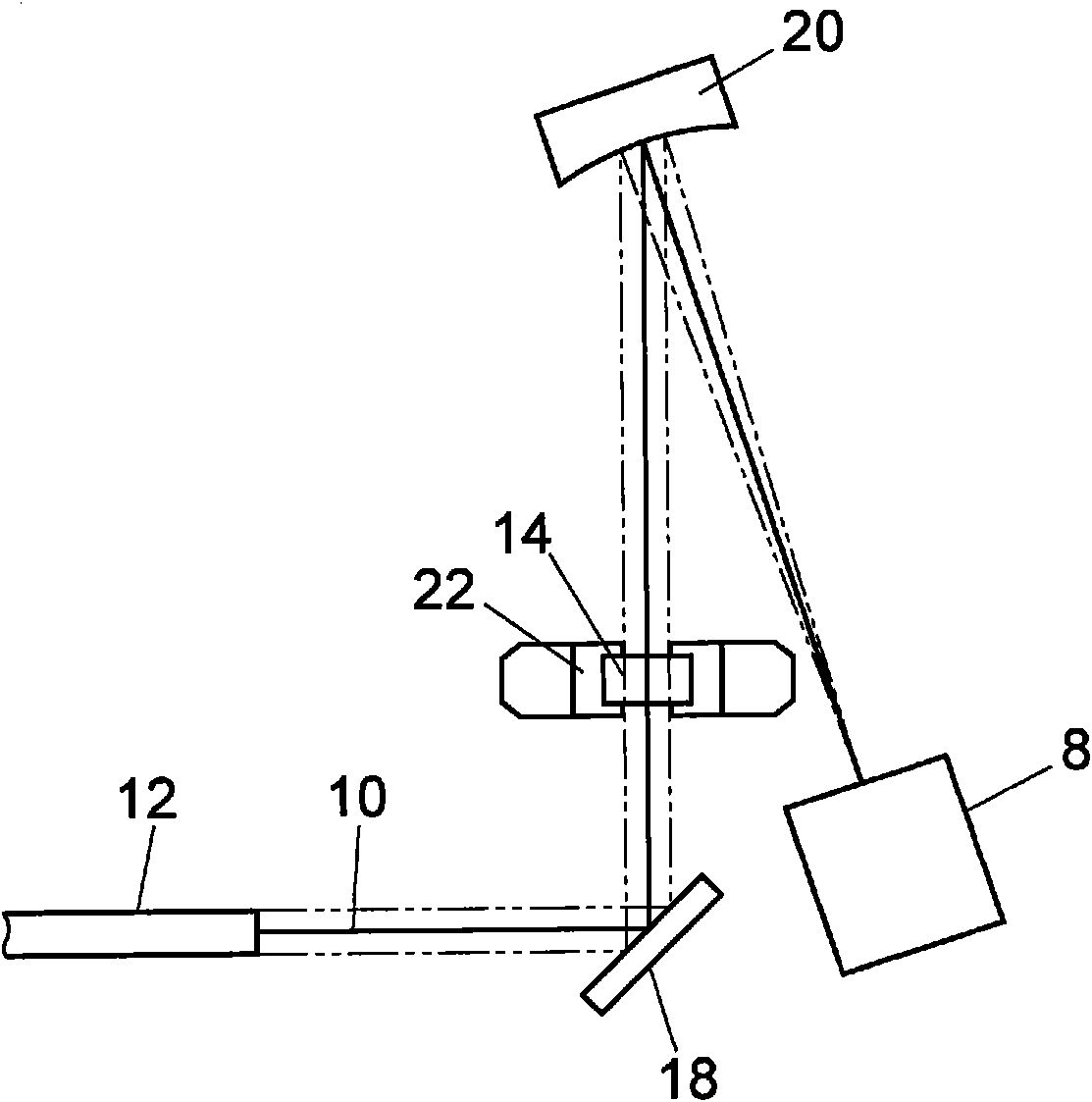

Gas analyzing apparatus with built-in calibration gas cell

A gas analyzing apparatus for laser absorption spectroscopy measurement includes a laser light source to generate laser beam with a specific wavelength absorbed by a component being measured in sample gas, a laser light source drive controller to control driving of the laser light source, an optical detector arranged at a location where the laser beam is received, a gas cell for measurement of the sample gas which is arranged on an optical path of the laser beam going from the laser light source to the optical detector, and a computing unit to calculate a concentration of the component being measured in the sample gas in accordance with a detection signal of the optical detector. Further, the gas analyzing apparatus has at least one calibration gas cell where calibration gas is filled with, and a calibration gas cell mounting mechanism capable of locating one of the calibration gas cells in a removable manner on the optical path of the laser beam.

Owner:SHIMADZU SEISAKUSHO CO LTD

Gas analyzer and method of gas analysis

ActiveUS20100018288A1High sensitivityMaterial analysis using sonic/ultrasonic/infrasonic wavesMaterial analysis using wave/particle radiationBlood gas analysisGas passing

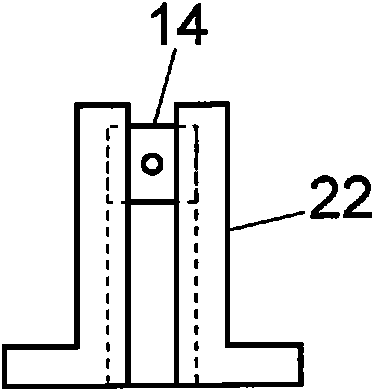

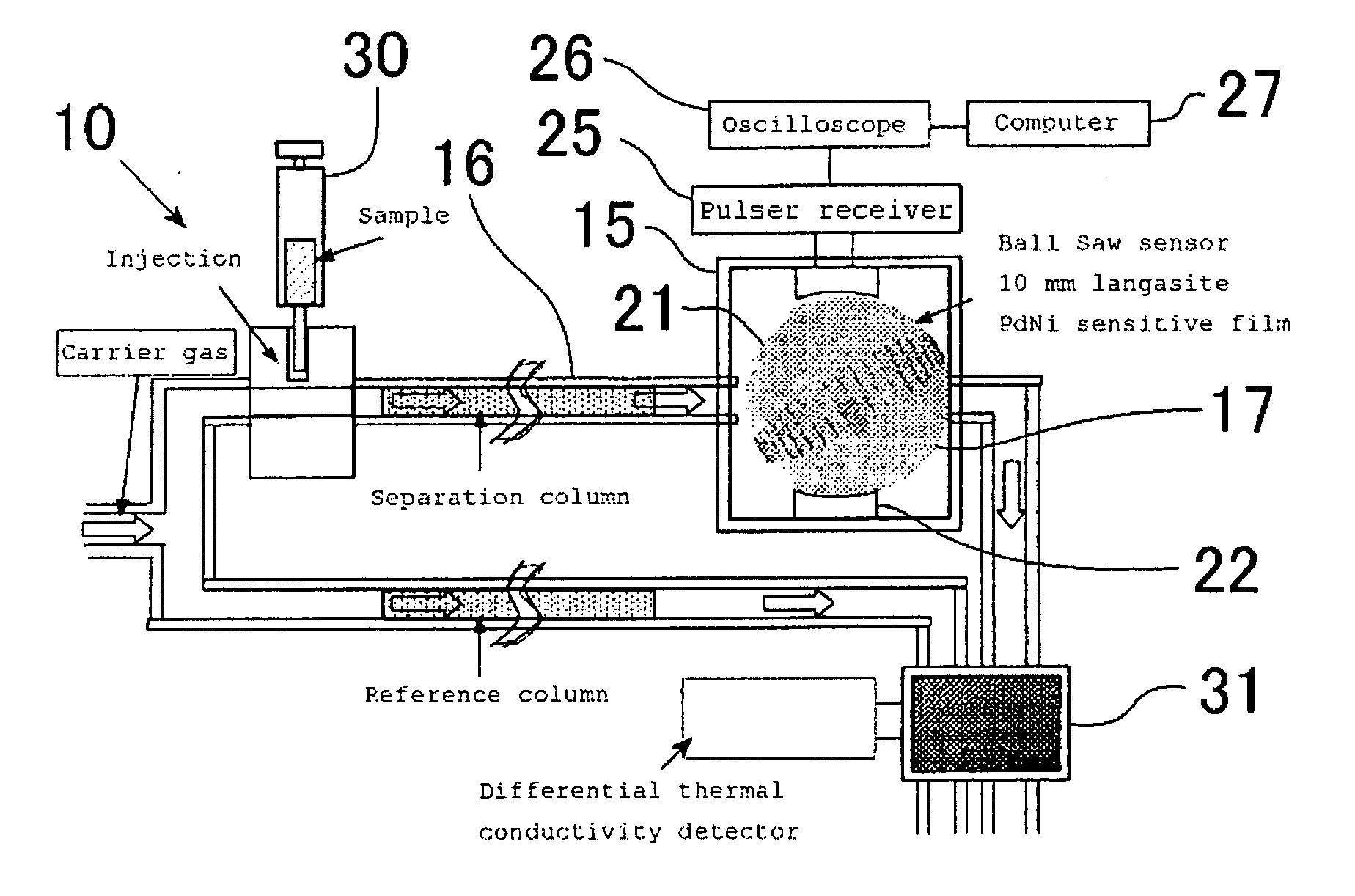

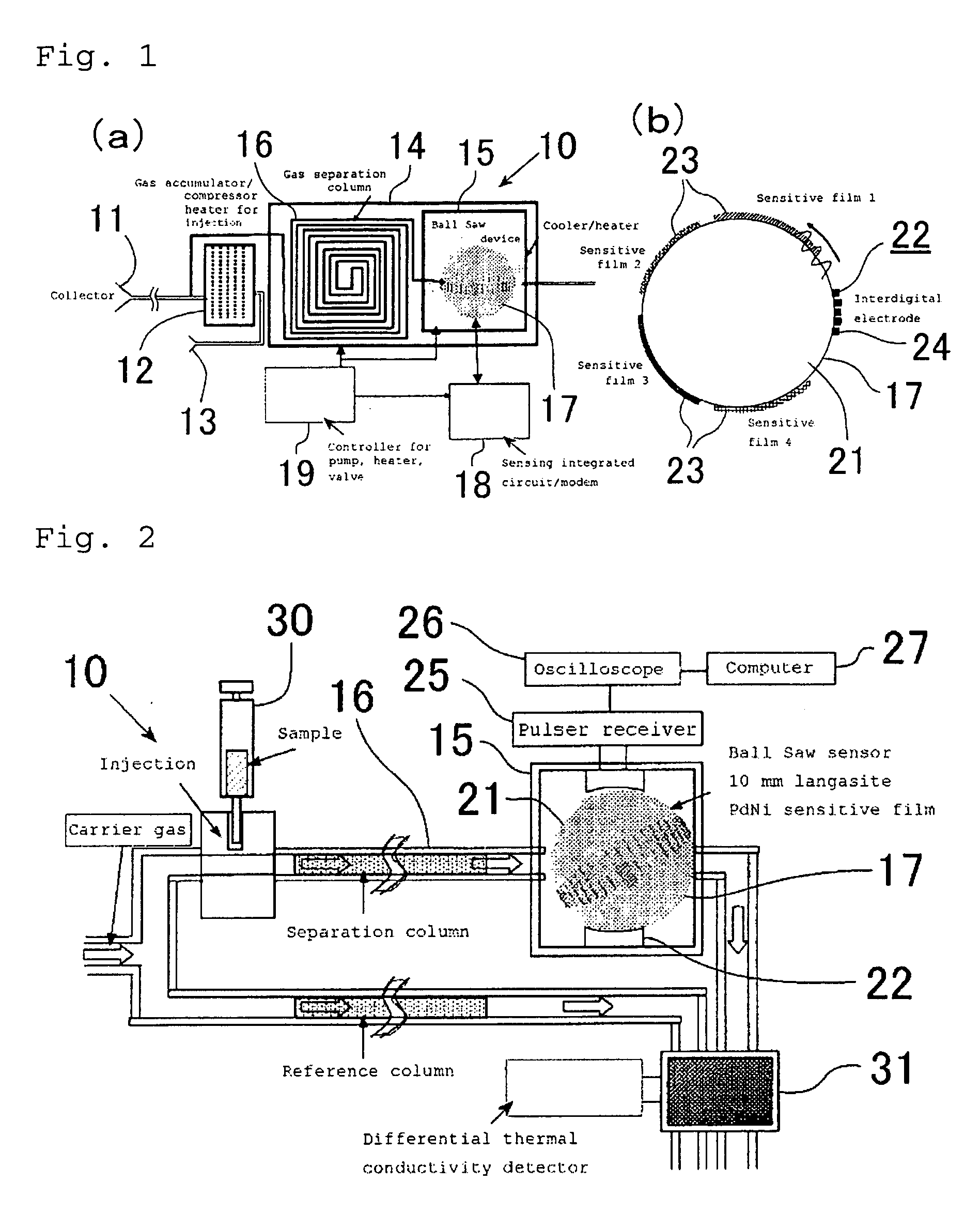

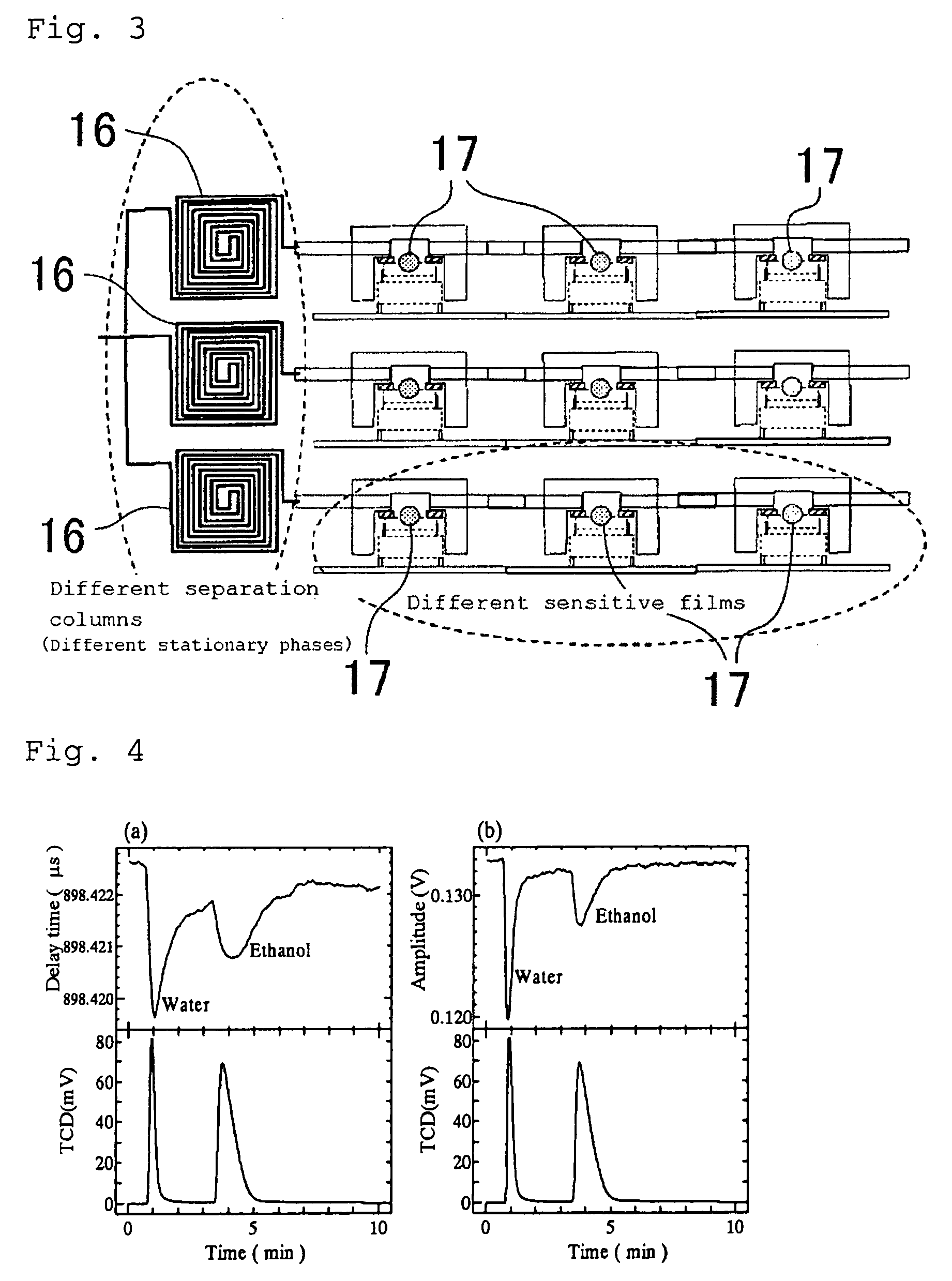

The present invention provides a gas analyzer that can be miniaturized and detect a wide variety of gases with high sensitivity, and a method of gas analysis. A separation column 16 is configured so as to pass a sample gas together with a carrier gas through the inside thereof. A surface acoustic wave device 17 has a base material 21 with an annularly continuous annular surface formed of at least apart of a spherical surface; a surface acoustic wave generating means 22 capable of generating a surface acoustic wave that propagates along the annular surface; and a plurality of reaction parts 23 provided along the annular surface so as to change a predetermined physical quantity of the surface acoustic wave in response to the components of the sample gas. The surface acoustic wave device 17 is arranged so that the sample gas passing through the separation column 16 is reacted with the reaction parts 23. The measuring part 18 can measure a physical quantity of the surface acoustic wave propagating along the annular surface, and the components of the sample gas can be analyzed on the basis of the measured physical quantity.

Owner:BALL WAVE INC

Method for quick quantitative analysis of gas content during the process of petroleum exploration and well drilling by using optical spectrum analyzer

InactiveCN1731147AFast analysisAccurate analysisPhase-affecting property measurementsColor/spectral properties measurementsSpectrum analyzerWell drilling

The invention relates to a method for fast quantity analyzing the gas content during oil exploration by a spectrum analyzer in the field of oil exploration gas log technology. The tested gas enters into the gas flow cell after processing and is radiated by infraction and tested by the detector, it is computed in the spectrum analysis working station to obtain the infrared spectrum of the sample and the content of each group.

Owner:HAICHENG PETRO CHEM INSTR FACTORY

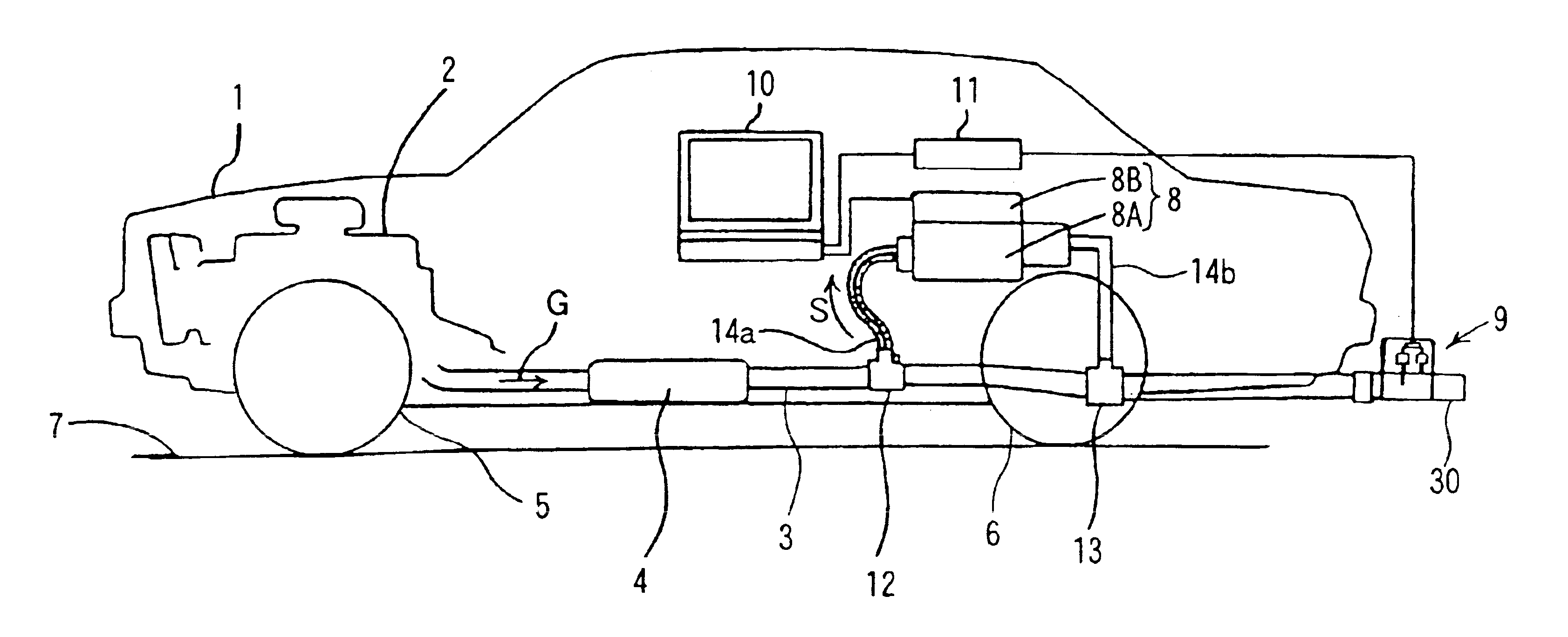

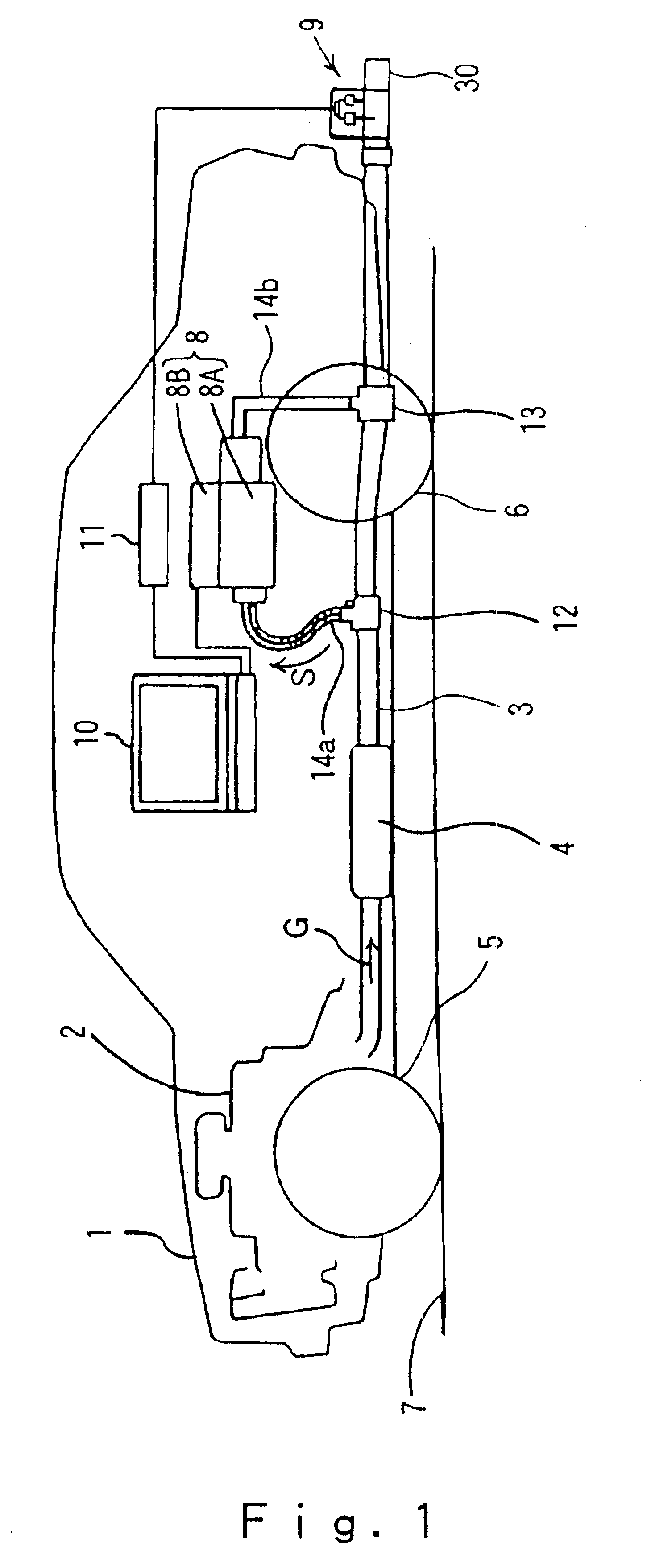

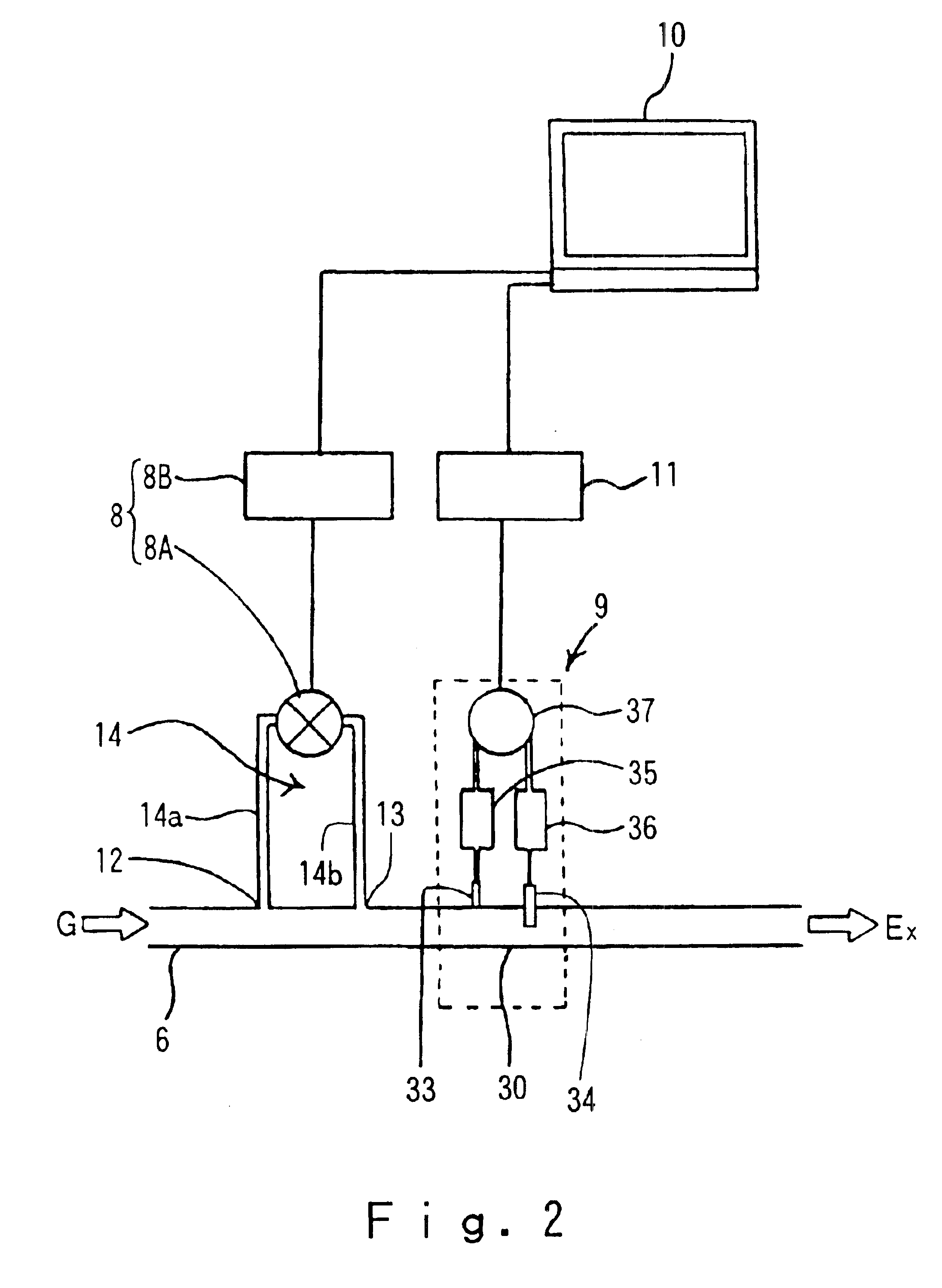

Vehicle-installed exhaust gas analyzing apparatus

InactiveUS6865472B2Reduce noiseImprove accuracyAnalogue computers for vehiclesInternal-combustion engine testingContinuous measurementConversion factor

A vehicle-installed exhaust gas analyzing apparatus includes a nondispersive infrared (NDIR) type gas analyzer for continuously measuring concentration of hydrocarbon (HC) in an exhaust gas flowing through an exhaust pipe which is connected to an engine, an exhaust gas flowmeter for continuously measuring flow rate of the exhaust gas flowing through the exhaust pipe, and an operation processing device for processing outputs from the NDIR type gas analyzer and the exhaust gas flowmeter to continuously calculate mass of total hydrocarbon (THC) contained in the exhaust gas. The components are configured so at to be installable in vehicle. THC concentration is obtained by multiplying a measurement result obtained by the NDIR type analyzer by a predetermined conversion factor.

Owner:HORIBA LTD

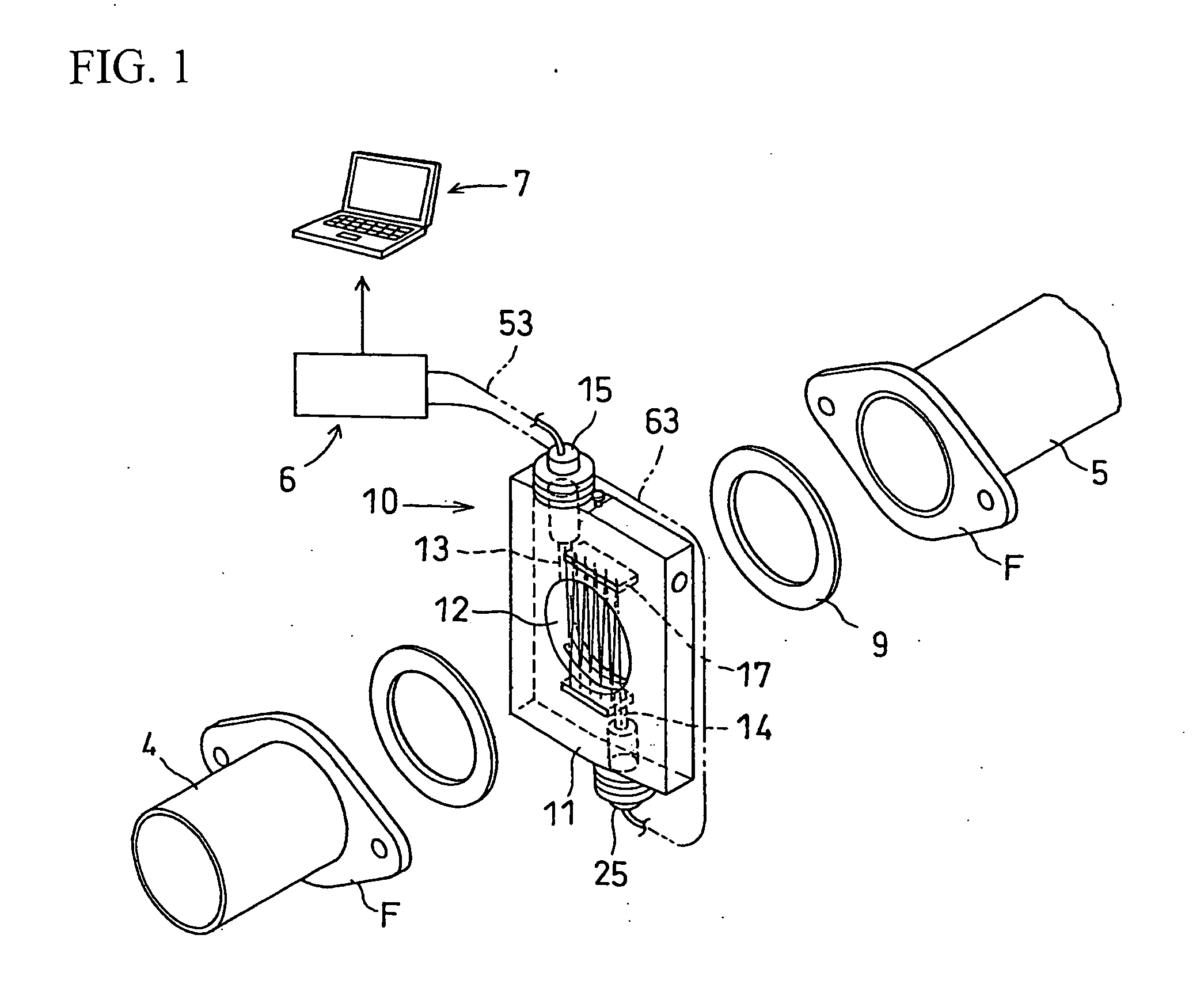

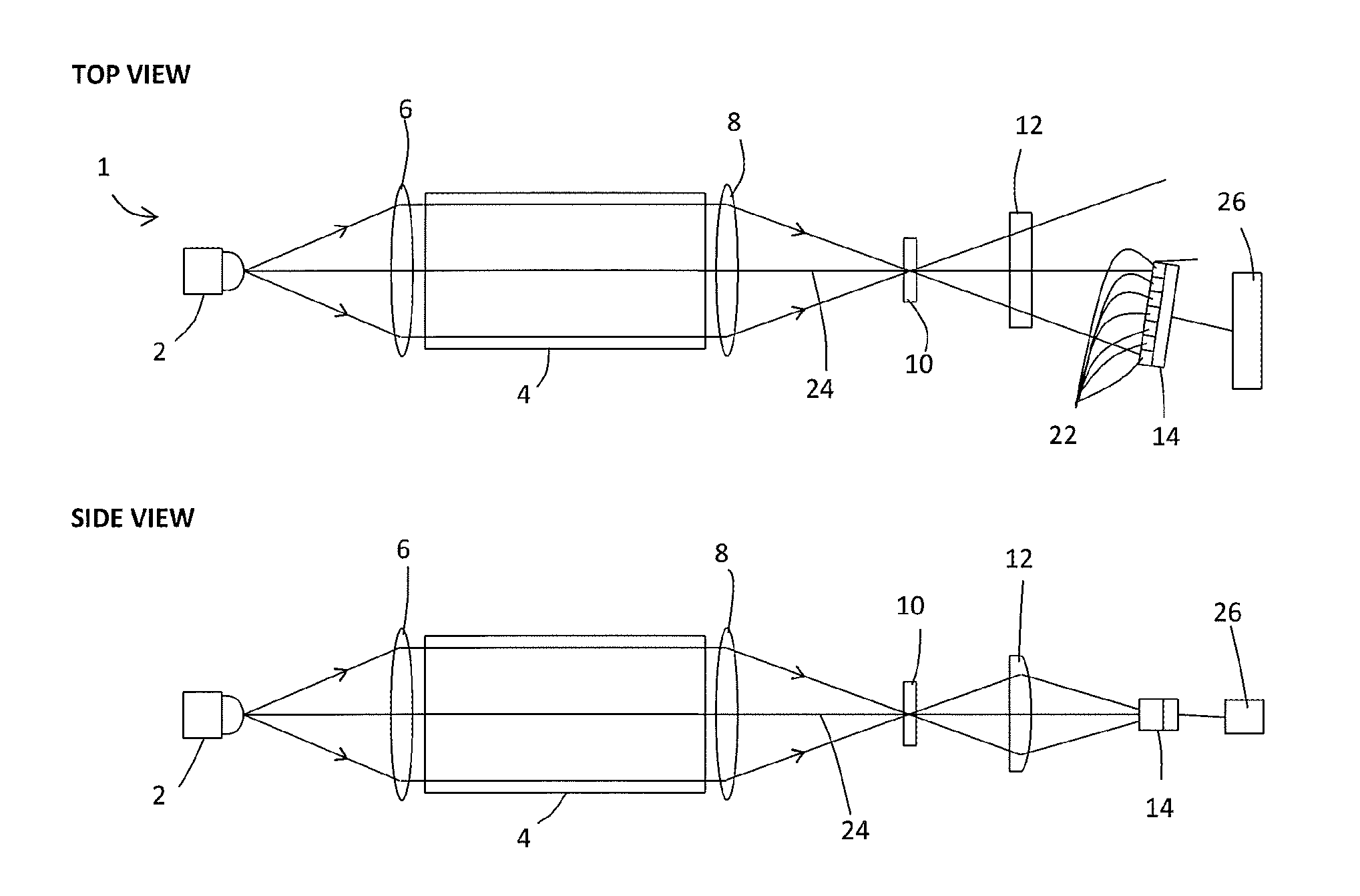

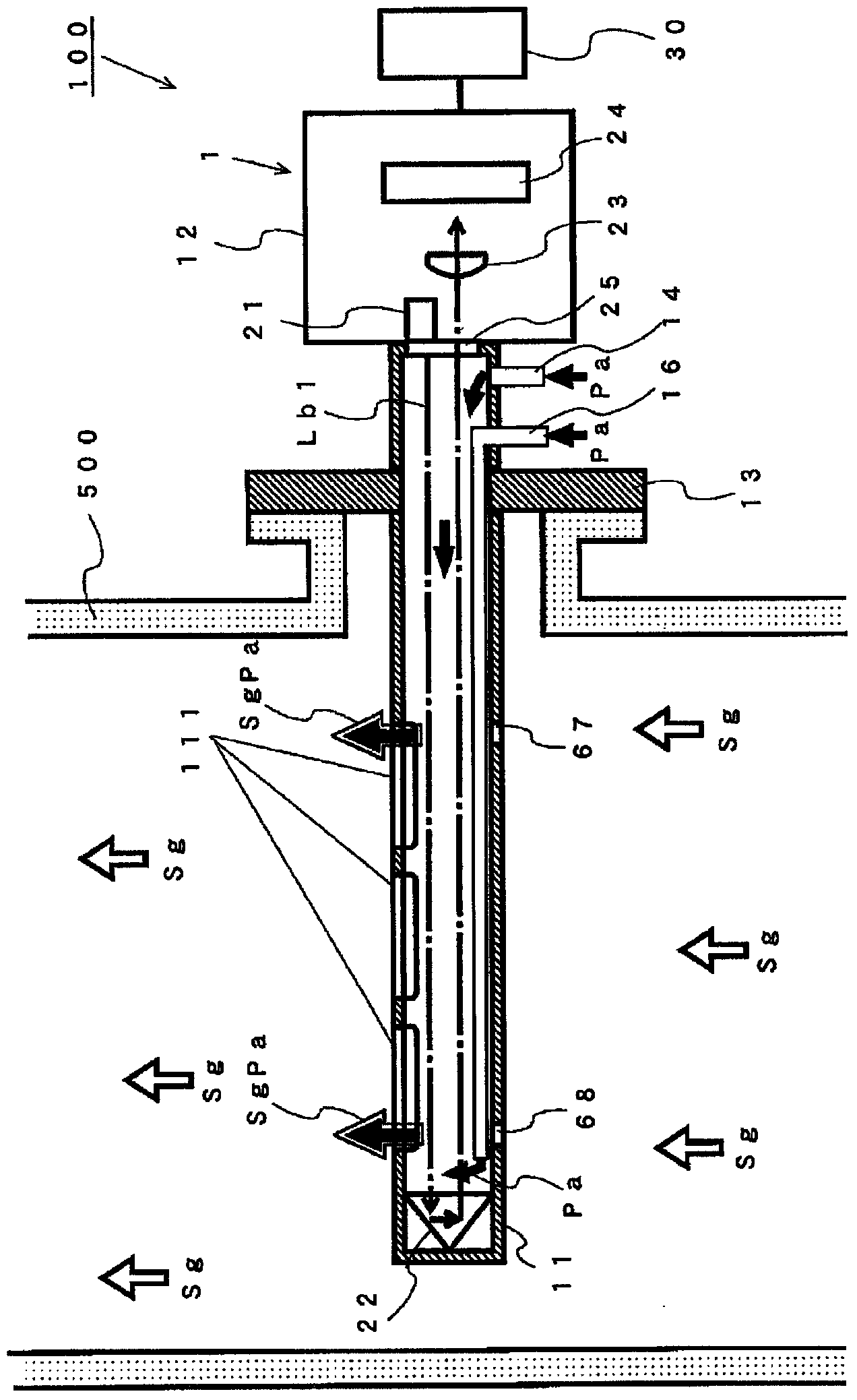

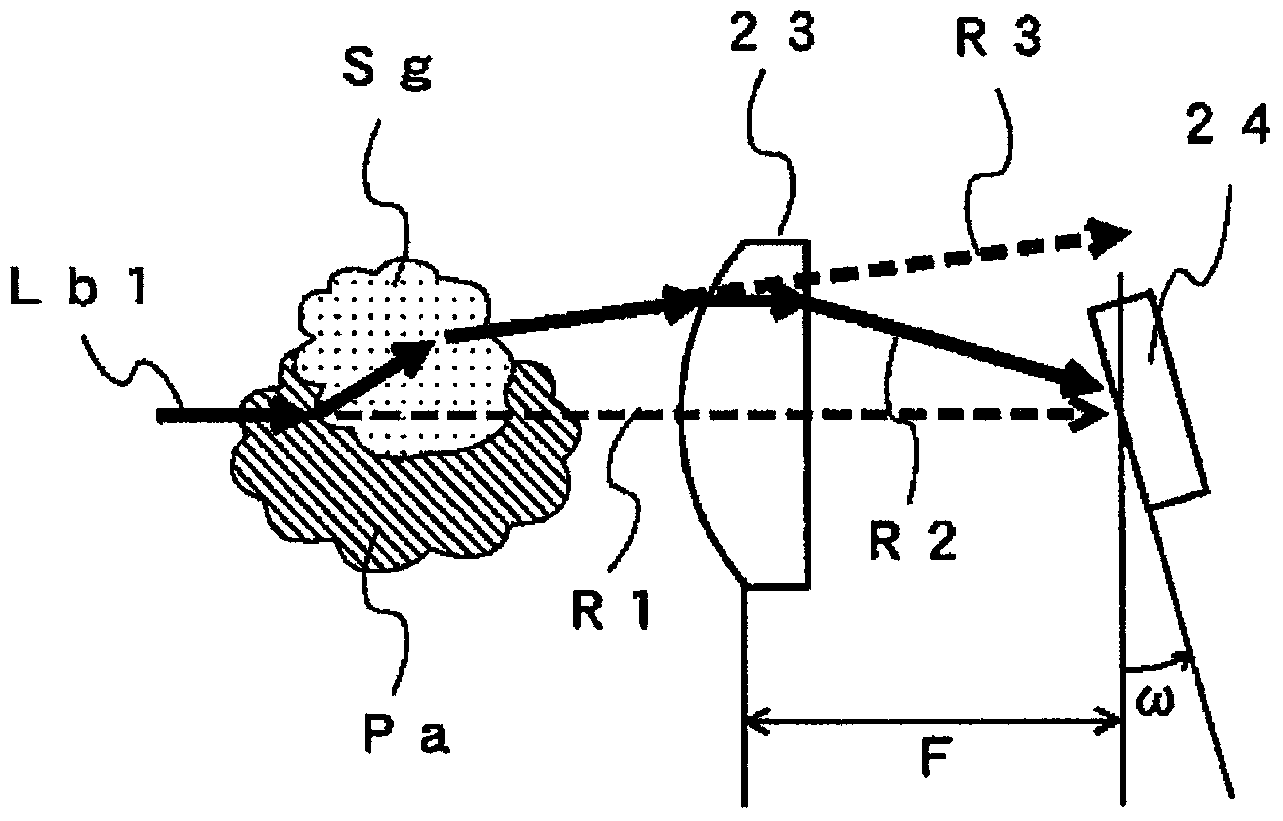

Gas Analyzer and Gas Analyzing Method

InactiveUS20090323068A1Reduce data volumeRadiation pyrometryScattering properties measurementsGas compositionLaser light

A gas analyzer capable of measuring a concentration of a gas component in gas at sensor units provided at a plurality of positions in real time by decreasing the number of signals input from the sensor units to an analyzer so as to reduce a data amount input to the analyzer and a gas analyzing method. The gas analyzing method includes the steps of: demultiplexing laser light by a demultiplexer into measurement laser light and reference laser light; letting the measurement laser light pass through gas to be received by a photoreceiver; finding an absorption spectrum absorbed by a gas component in the gas based on a light intensity of the received measurement laser light and of the reference laser light; and analyzing the absorption spectrum to measure a concentration of the gas component.

Owner:TOYOTA JIDOSHA KK +1

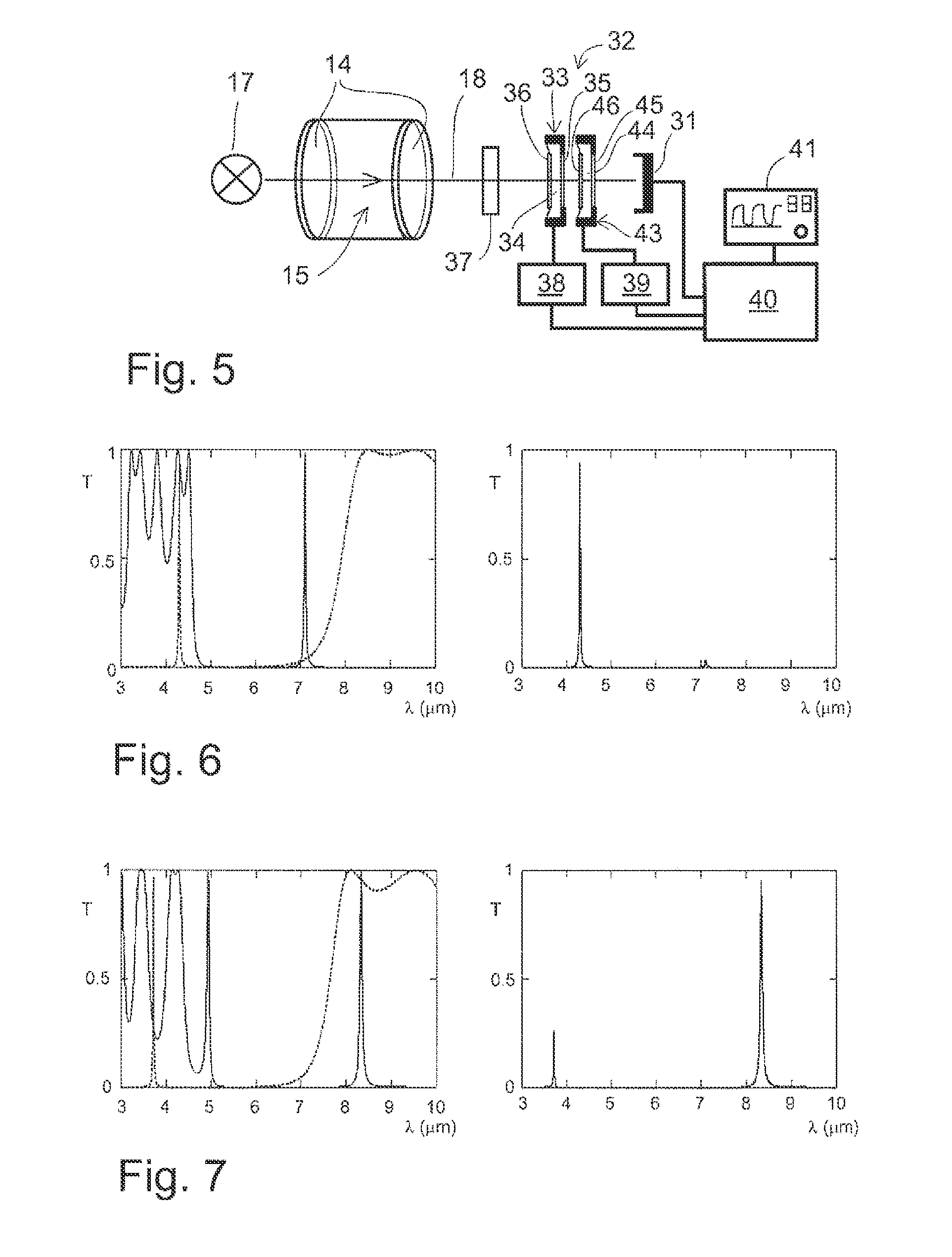

Gas analyzer for measuring at least two components of a gas

ActiveUS20120097852A1Material analysis by optical meansPyrometry using electric radation detectorsGas analyserWavelength

A gas analyzer for measuring at least two components of a gas is disclosed herein. The gas analyzer comprising an emitter configured to emit infrared radiation through the gas, a filter assembly configured to permit a transmission of predetermined wavelengths emitted by the emitter, and a detector configured to receive wavelengths emitted by the emitter and penetrated through the filter assembly. The filter assembly comprises at least two tunable narrowband interference filters in series, each of the filters comprising two dielectric mirrors and an air space between the two dielectric mirrors to tune one of the filters to different transmission band than another of the filters.

Owner:GENERAL ELECTRIC CO

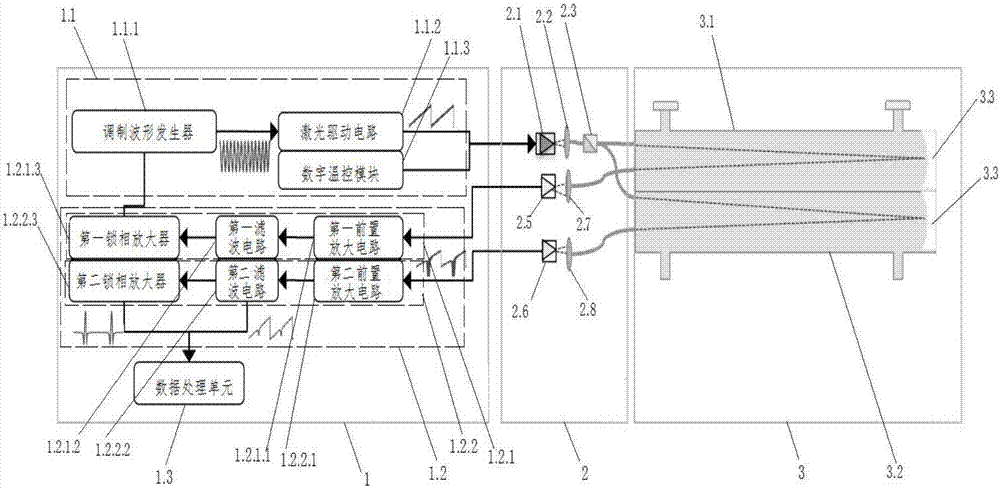

Parallel double-gas chamber trace gas analysis system, and gas concentration calculating method

The invention provides a parallel double-gas chamber trace gas analysis system. The system is characterized in that the system comprises a circuit module, an optical module and a gas passage module, and a laser driving circuit and a digital temperature control module are connected to a laser; the beam splitter divides laser lights into two beams, and the two beams are respectively connected to the laser incident interfaces of a standard gas chamber and a sample gas chamber through optical fibers; laser emitting interfaces which are connected to the standard gas chamber and the sample gas chamber through optical fibers are respectively connected to a second collimating convergence lens and a third collimation convergence lens through optical fibers; and a first photodiode detector is connected to a first preamplifier circuit, and a second photodiode detector is connected to a second preamplifier circuit. The system eliminates the influences of wavelength drift, the temperature pressure change and other unstable factors of the laser in a TDLAS technology, the laser performance error tolerating rate of the system is improved, and the adaptation to environment is improved.

Owner:WUHAN MIZI ENERGY SCI & TECH CO LTD +1

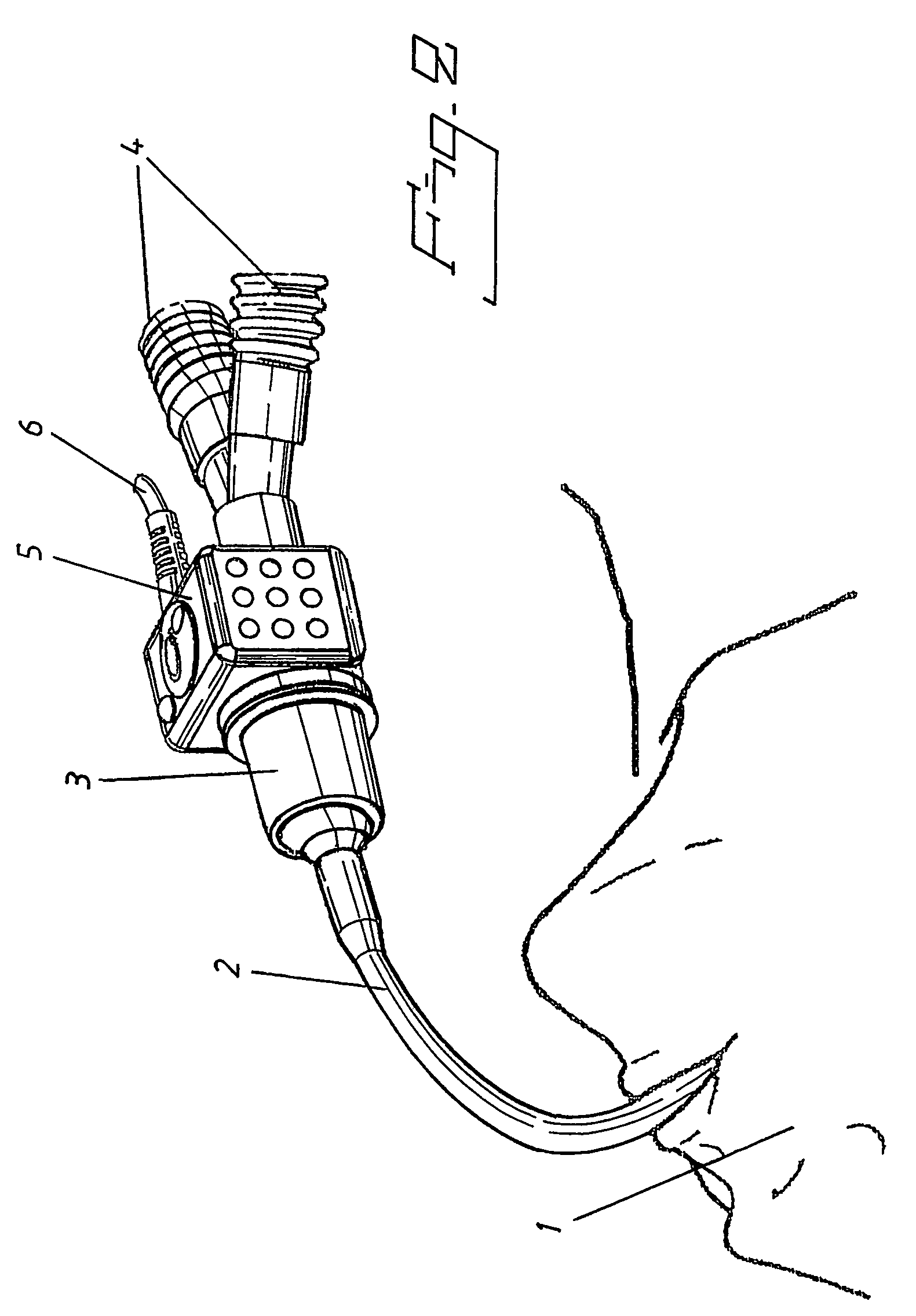

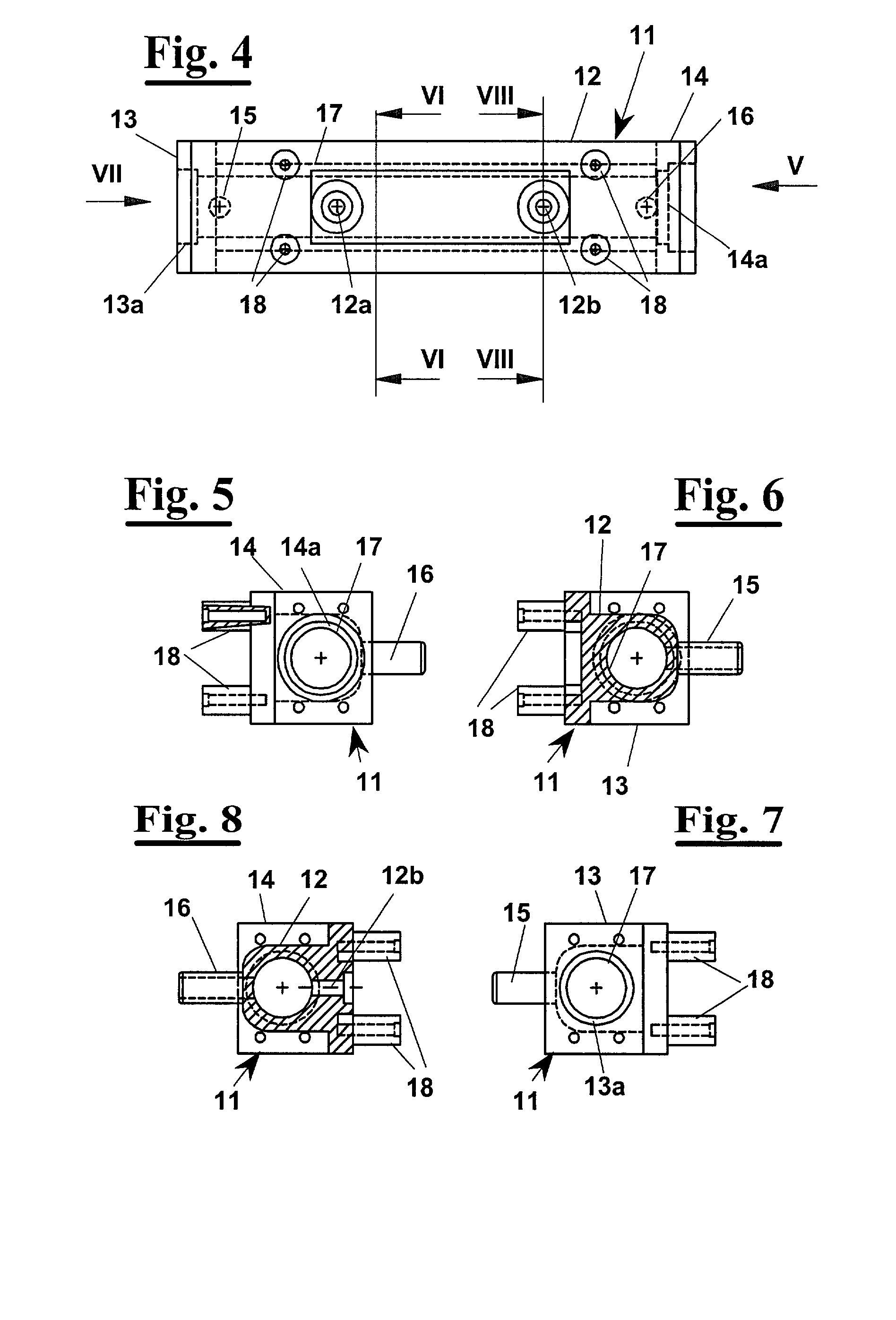

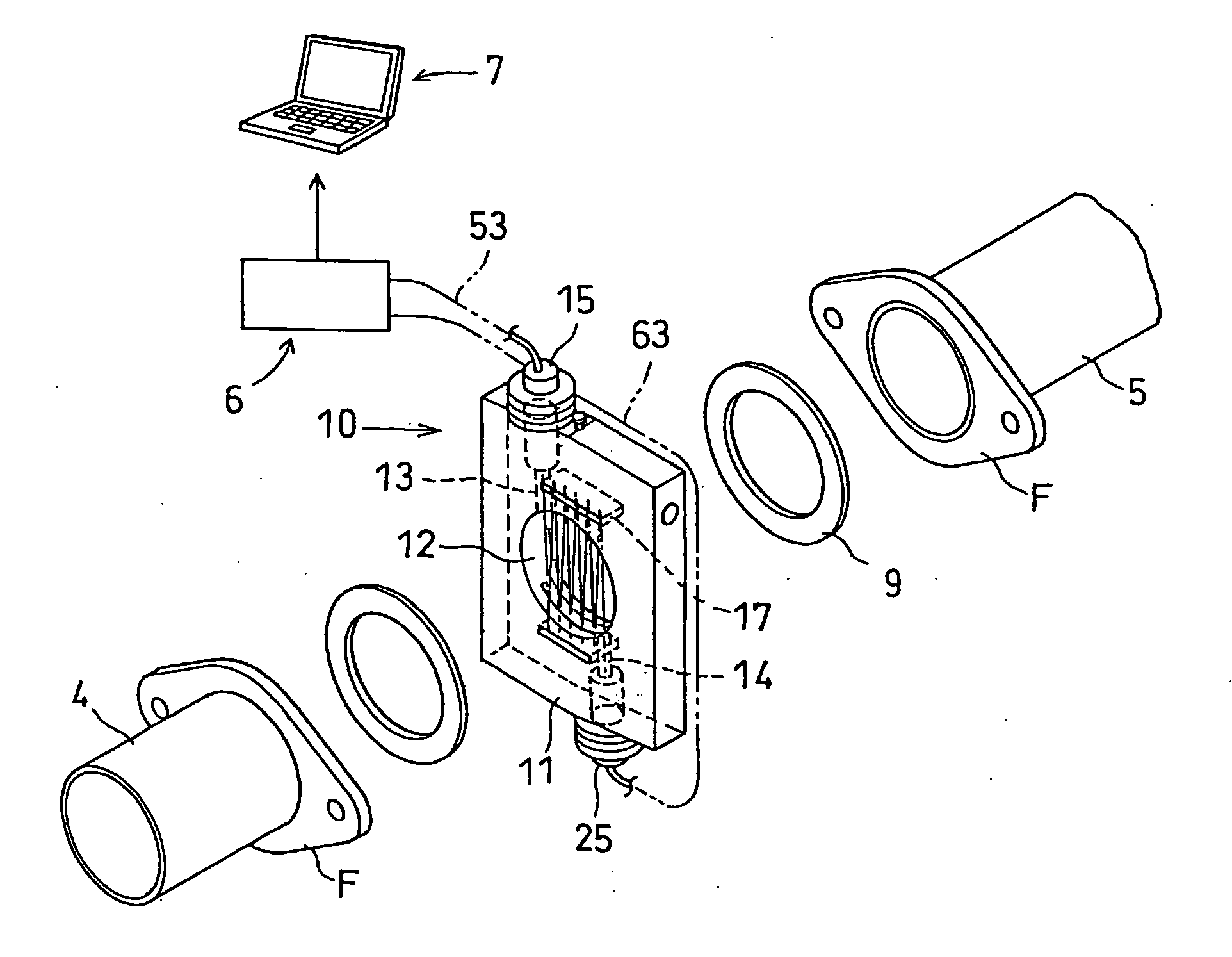

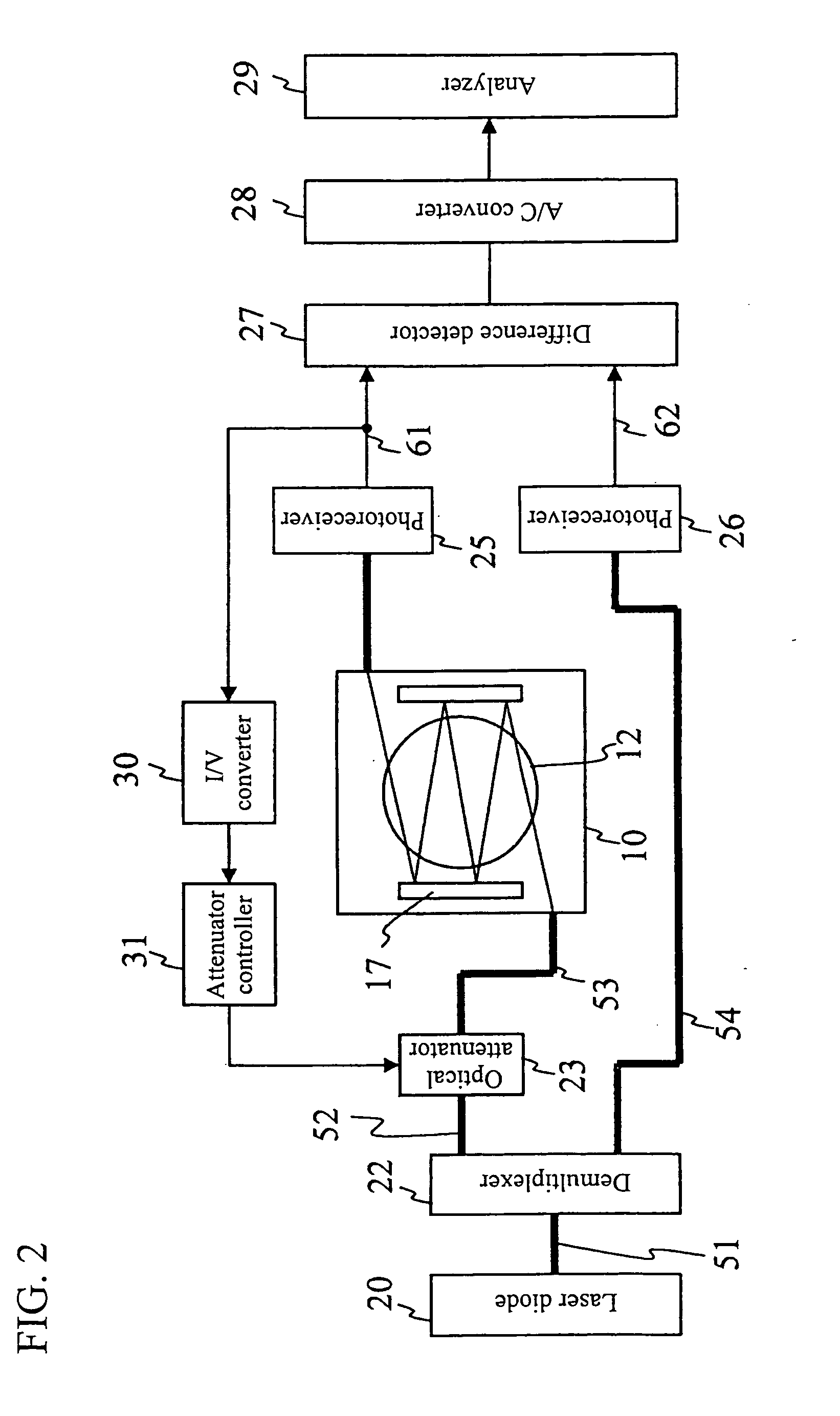

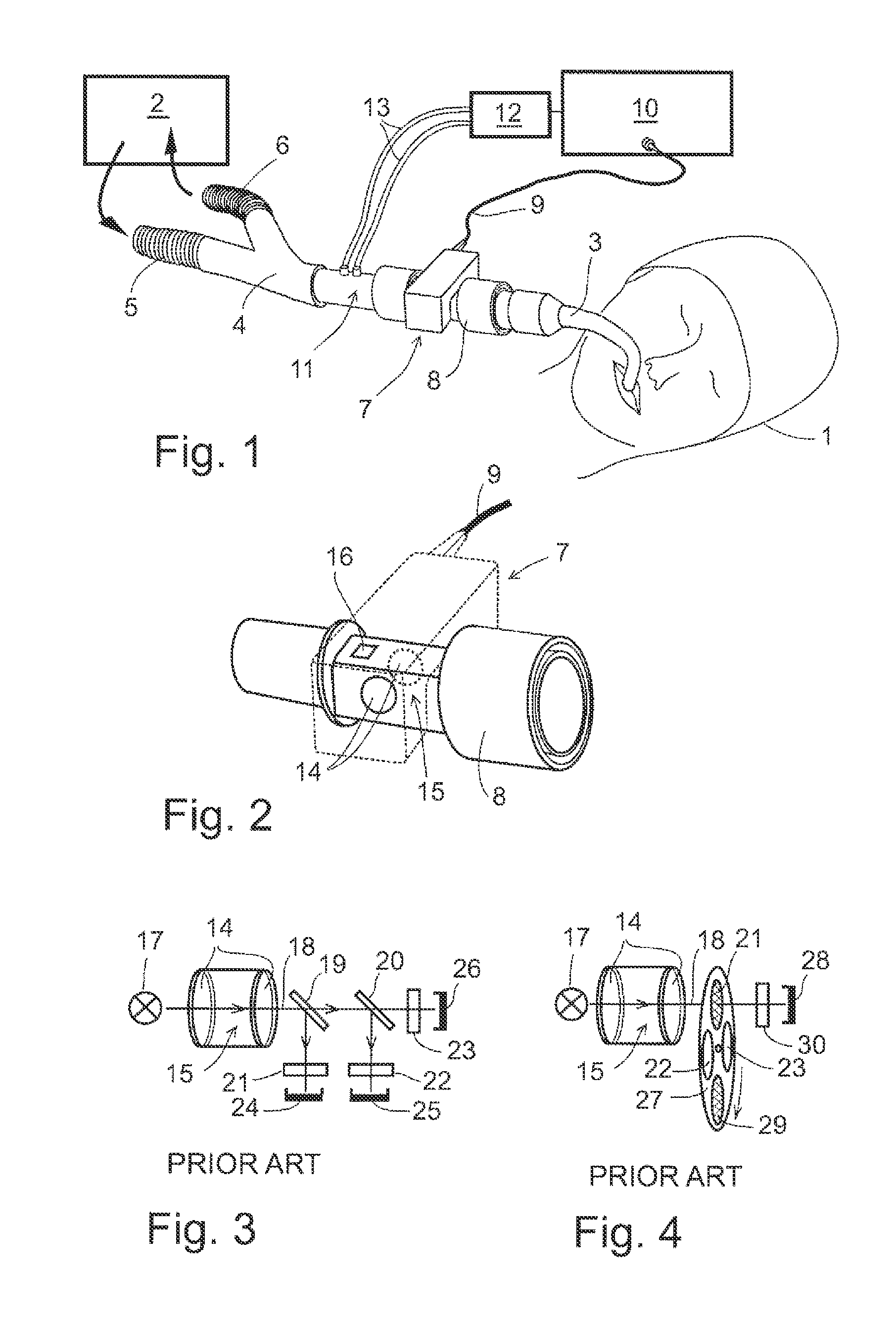

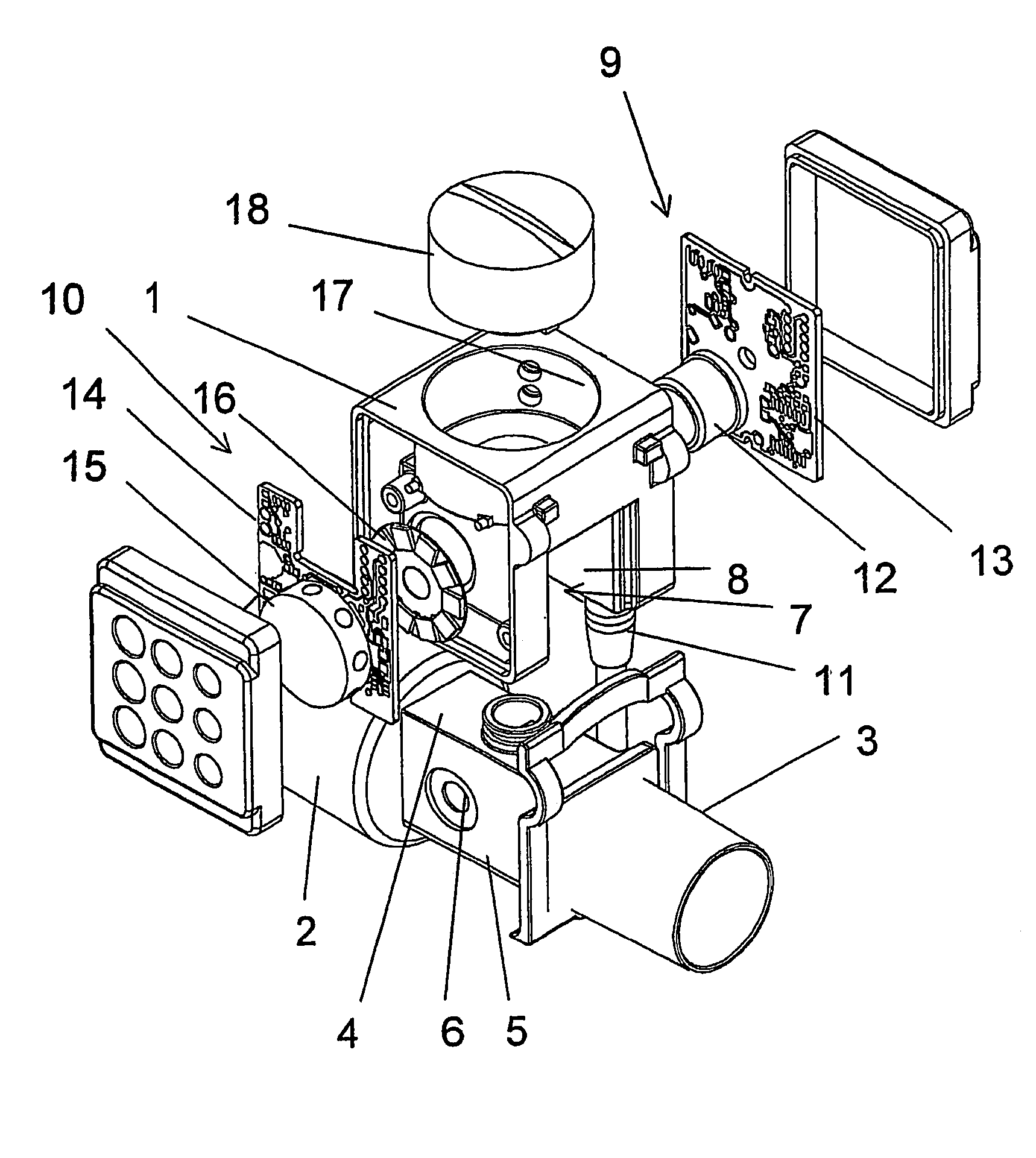

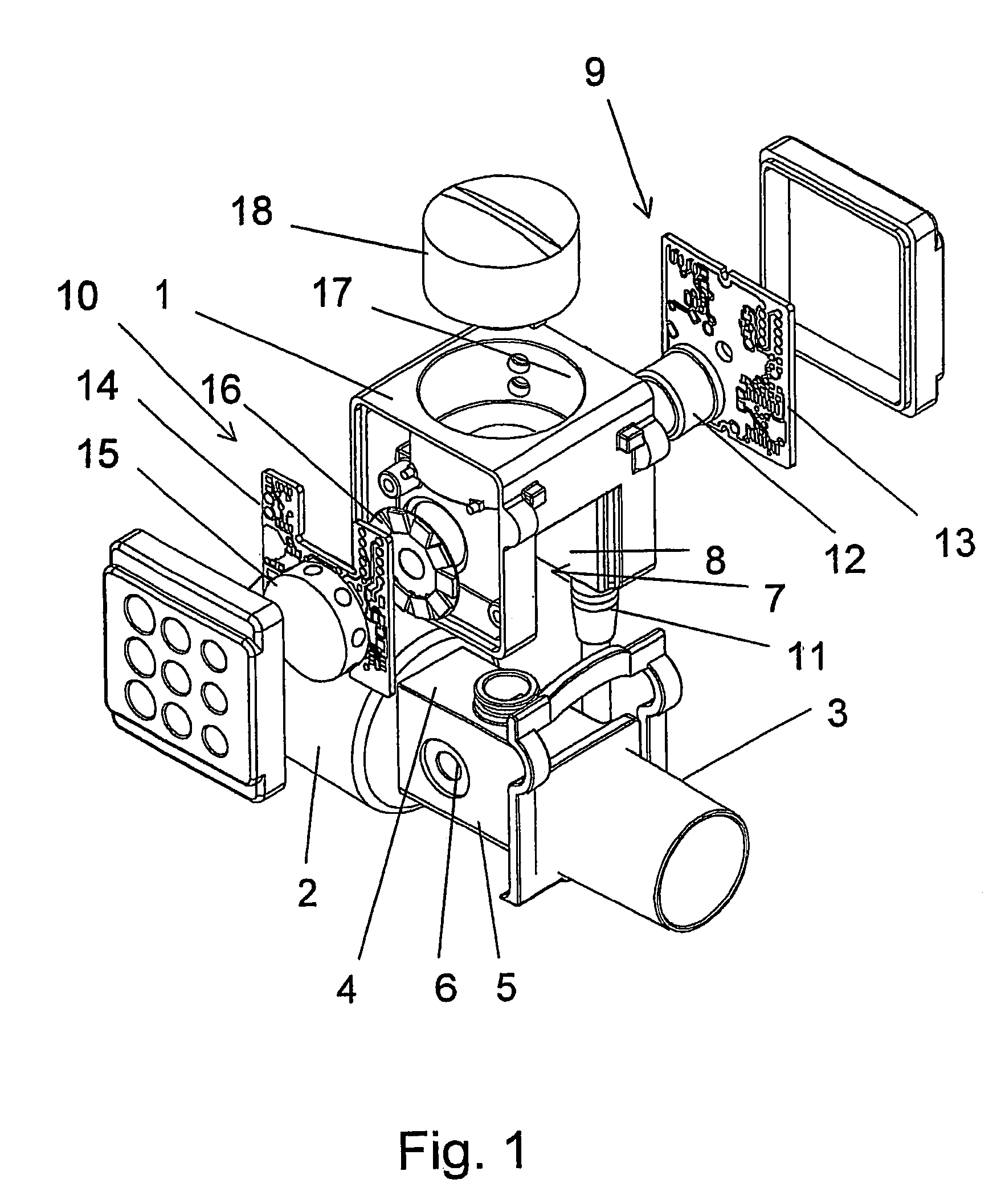

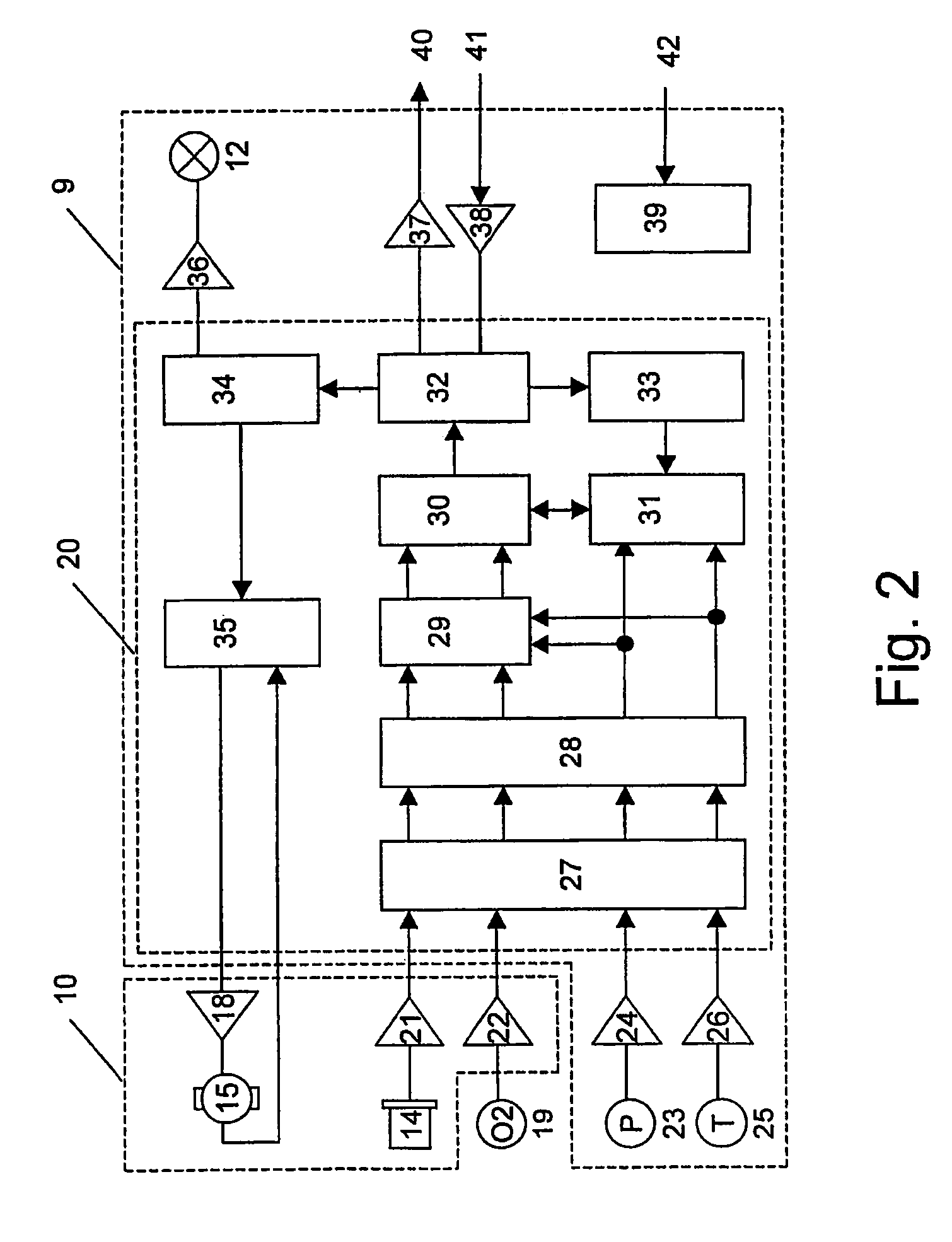

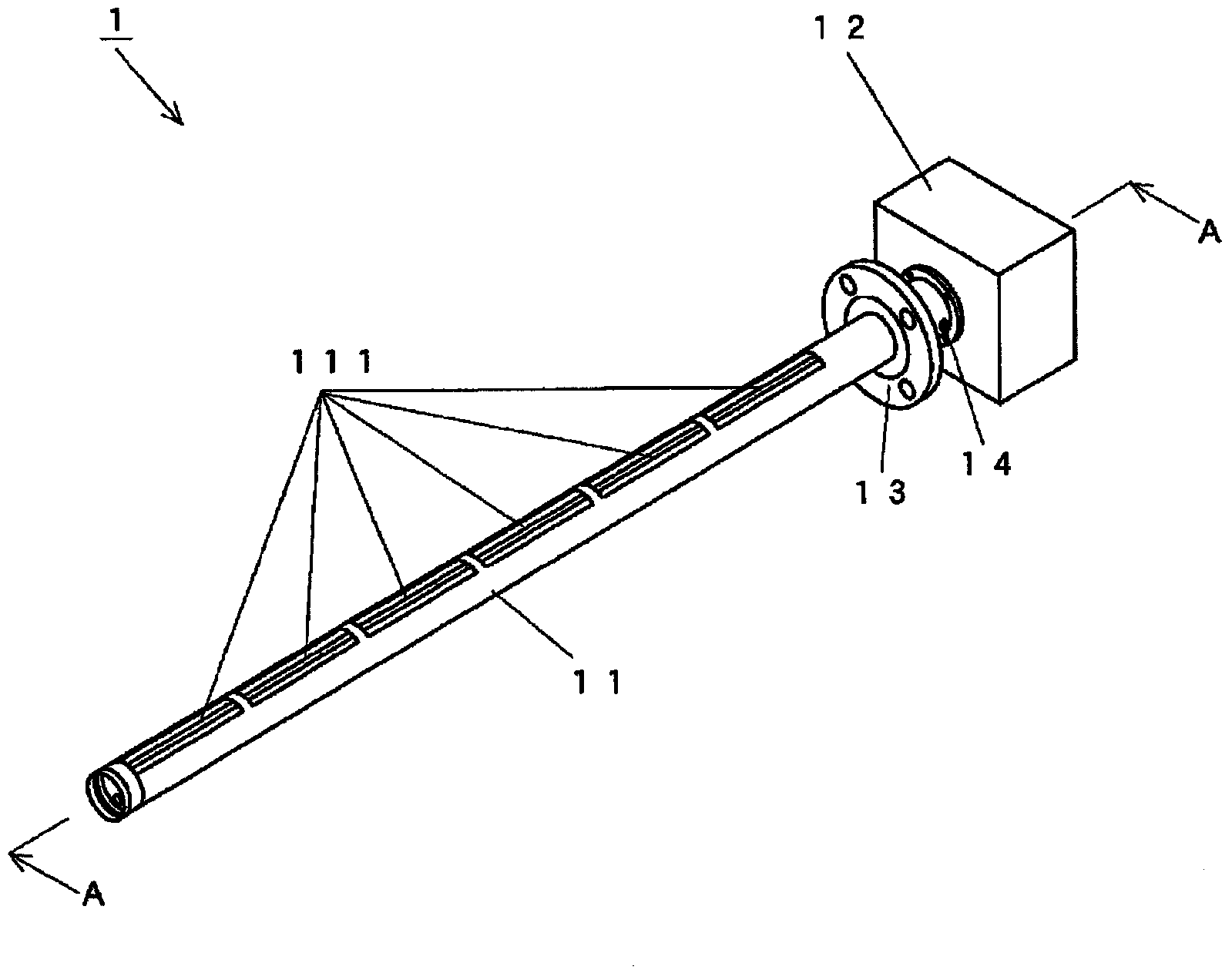

Measuring head for a gas analyser

InactiveUS7235054B2Easy to adaptEasy to switchWithdrawing sample devicesRespiratory organ evaluationRespiratorEngineering

A measuring head for the analysis of respiratory gases to and from a patient connected to a respirator, includes an aperture (7) which is intended to be placed over an adapter (2) through which respiratory gases flow. The measuring head (1) has a light transmitter (9) which includes an IR-emitter (12) on one side of the aperture (7) and a light receiver (10) which includes an IR-detector on the other side of the aperture (7). The measuring head (1) also includes a signal processing unit (20) necessary for the gas analysis.

Owner:PHASE IN

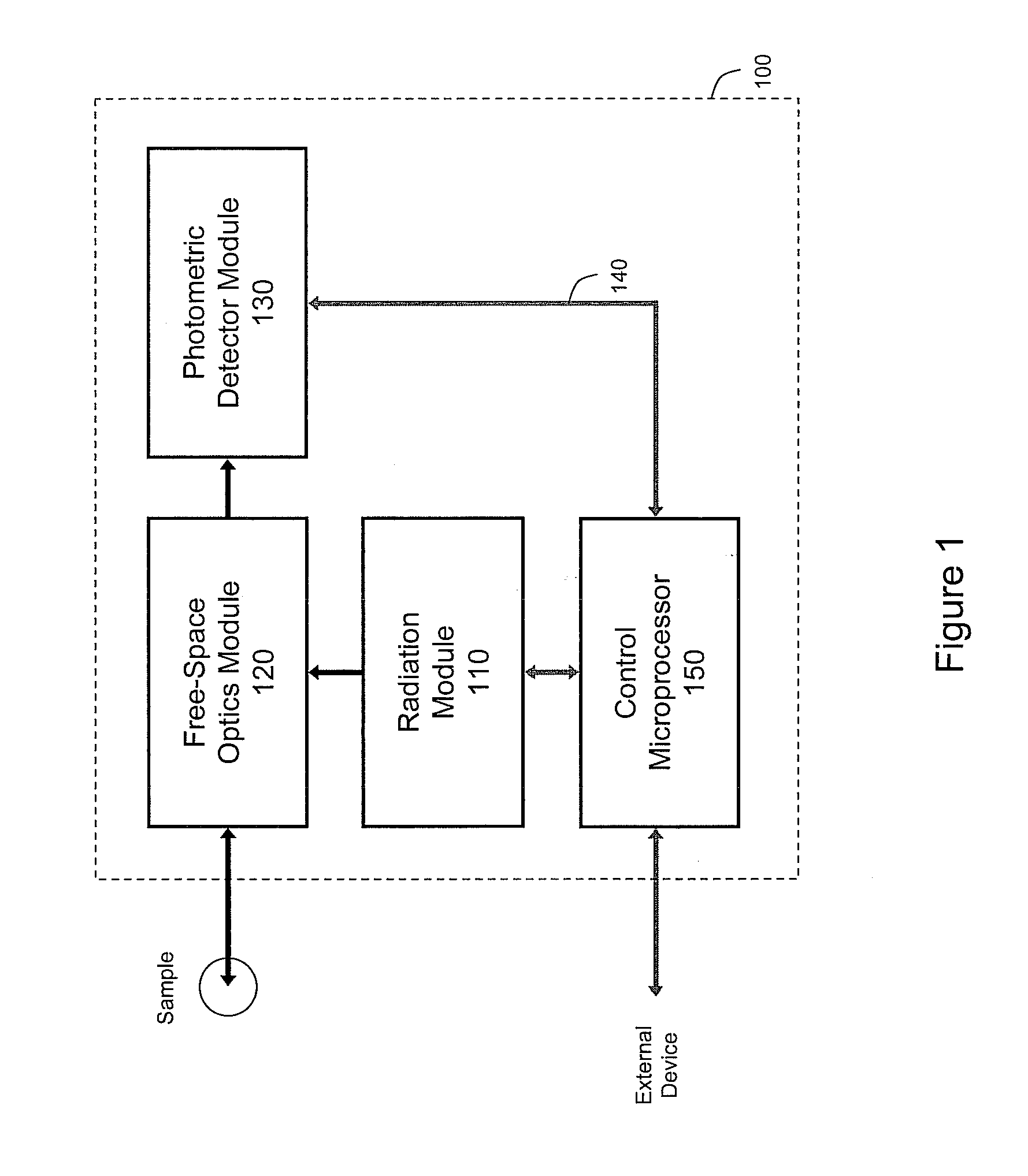

Chemical analyzer for industrial process control

ActiveUS20080180661A1Maximizes optical throughputImprove signal-to-noise ratioRadiation pyrometrySpectrum investigationNon destructiveSolid mass

An optical apparatus for measurement of industrial chemical processes. The analyzer uses Raman scattering and performs measurement of chemical concentrations in continuous or batch processes. The analyzer operates at a standoff distance from the analyte (or analytes) and can measure concentrations through an optical port, facilitating continuous, non-destructive, and non-invasive analysis without extracting the analyte or analytes from the process. The analyzer can measure one or several solid, liquid, or gaseous analytes, or a mixture thereof.

Owner:CAMBRIUS

Gas analyser

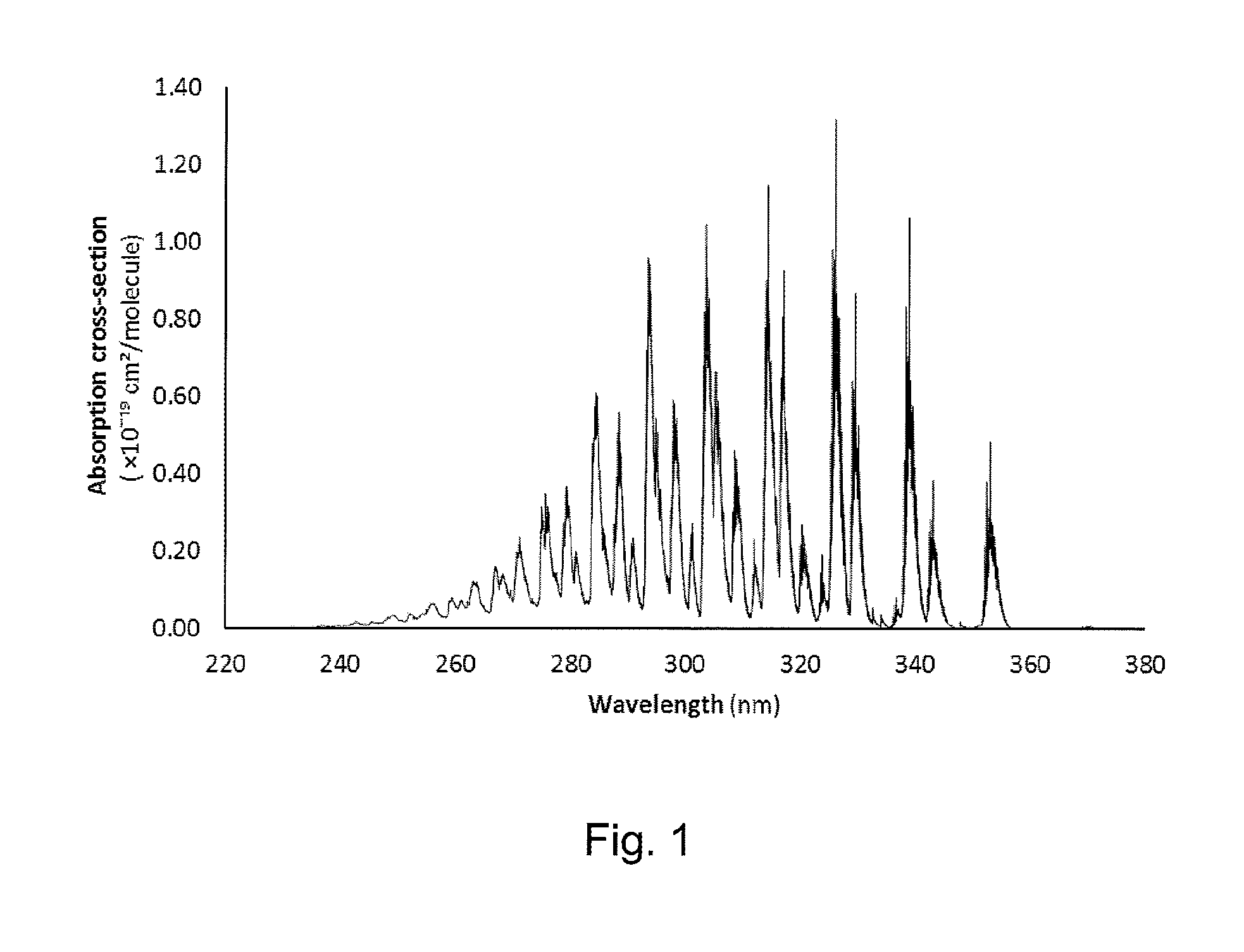

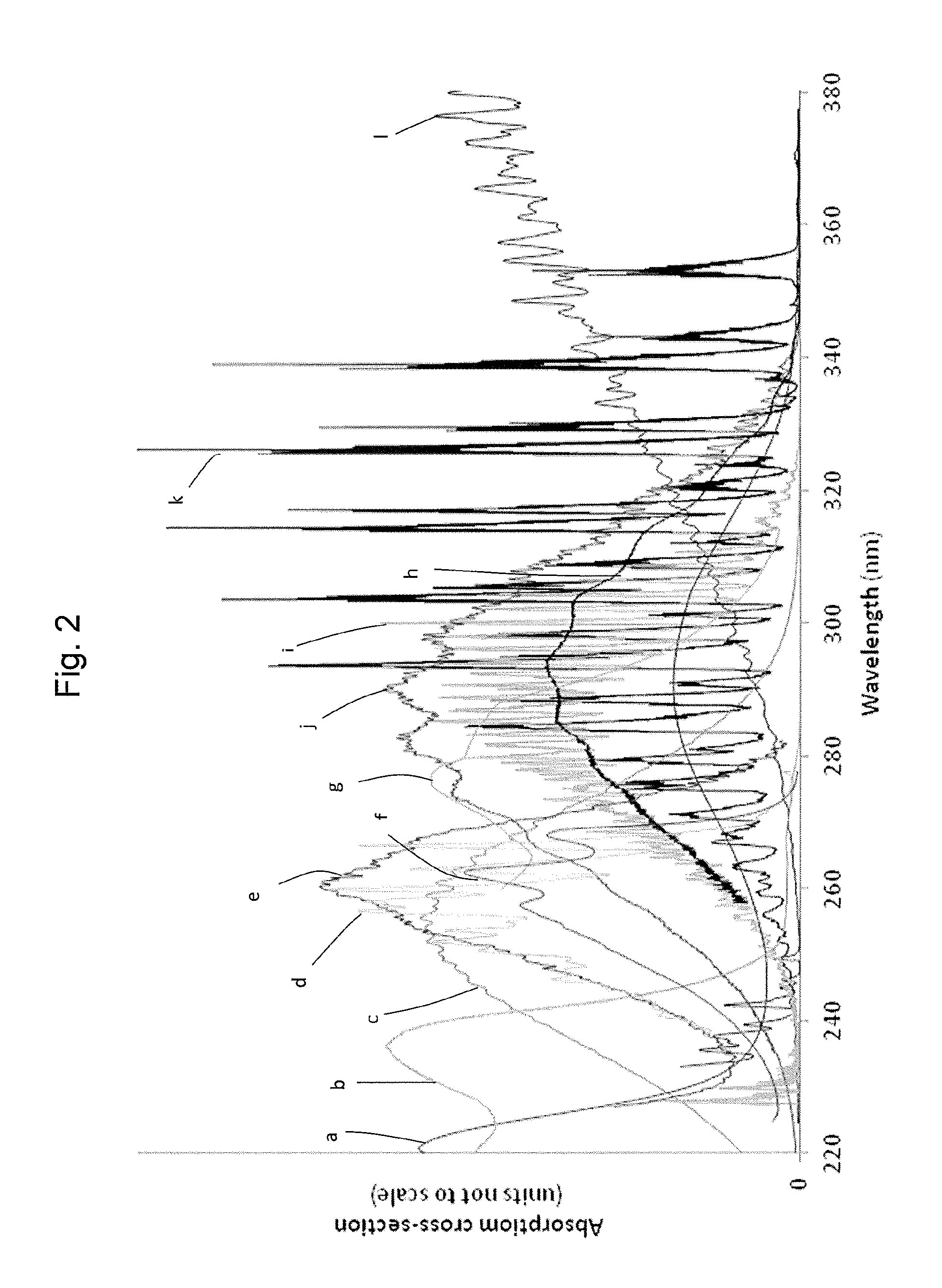

ActiveUS20140034840A1Easy constructionLimited wavelength rangeAbsorption/flicker/reflection spectroscopyColor/spectral properties measurementsNitrogen dioxideUltraviolet lights

A gas analyser is provided to measure the concentration of formaldehyde within enclosed environments such as within buildings comprising an ultraviolet light source, a sample chamber, a detector. The detector measures the intensity of light received by photosensors within a measurement range of wavelengths, and at least one reference range of wavelengths. Advantageously, the concentration of formaldehyde is determined taking into account fluctuations in the intensity of light emitted by the light source, and in the presence of any interferents such as nitrogen dioxide.A method of measuring the concentration of formaldehyde in enclosed environments is also presented.

Owner:ALPHASENSE LTD

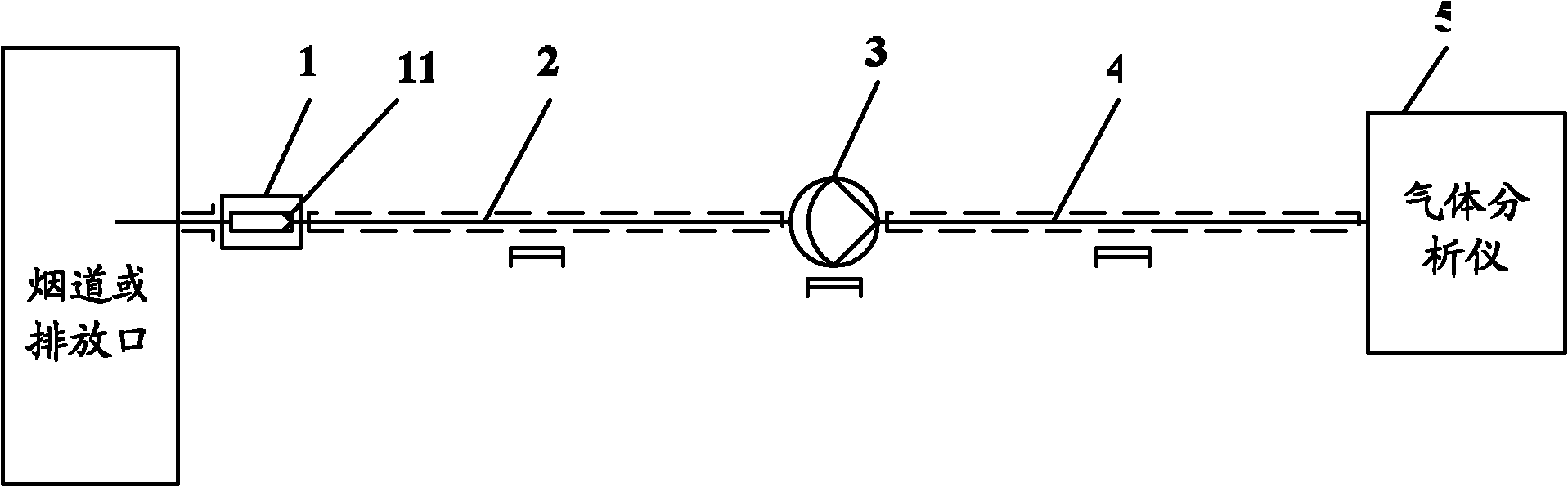

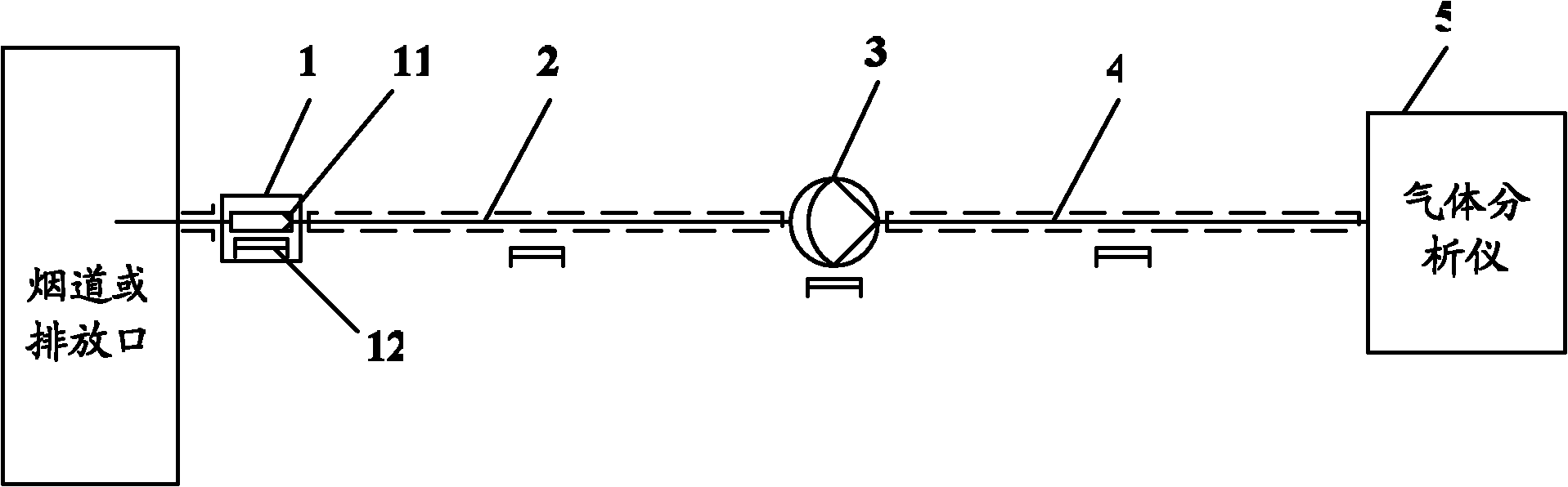

Gas analytical system

InactiveCN102156065AImprove measurement accuracyReduce the number of jointsWithdrawing sample devicesPreparing sample for investigationLine tubingGas analyser

The invention discloses a gas analytical system comprising a sampling probe, an external heat traced sampling pipeline, a sampling pump, an internal heat traced sampling pipeline and a gas analyzer in sequence along the transmission direction of sample gas, wherein the sampling probe comprises a sample gas filter used for removing dust out of the sample gas; the sampling pump is accompanied with a heater which can keep the temperature of the sample gas; the gas analyzer is suitable for analyzing and detecting the high-temperature sample gas up to 200 DEG C; after being collected by the sampling probe, the sample gas is transmitted to the gas analyzer through the external heat traced sampling pipeline, the sampling pump and the internal heat traced sampling pipeline; and when entering the gas analyzer, the sample gas is consistent with the sample gas collected by the sampling probe, thus improving the measurement accuracy of the content of each component in the high-temperature sample gas.

Owner:BEIJING SDL TECH

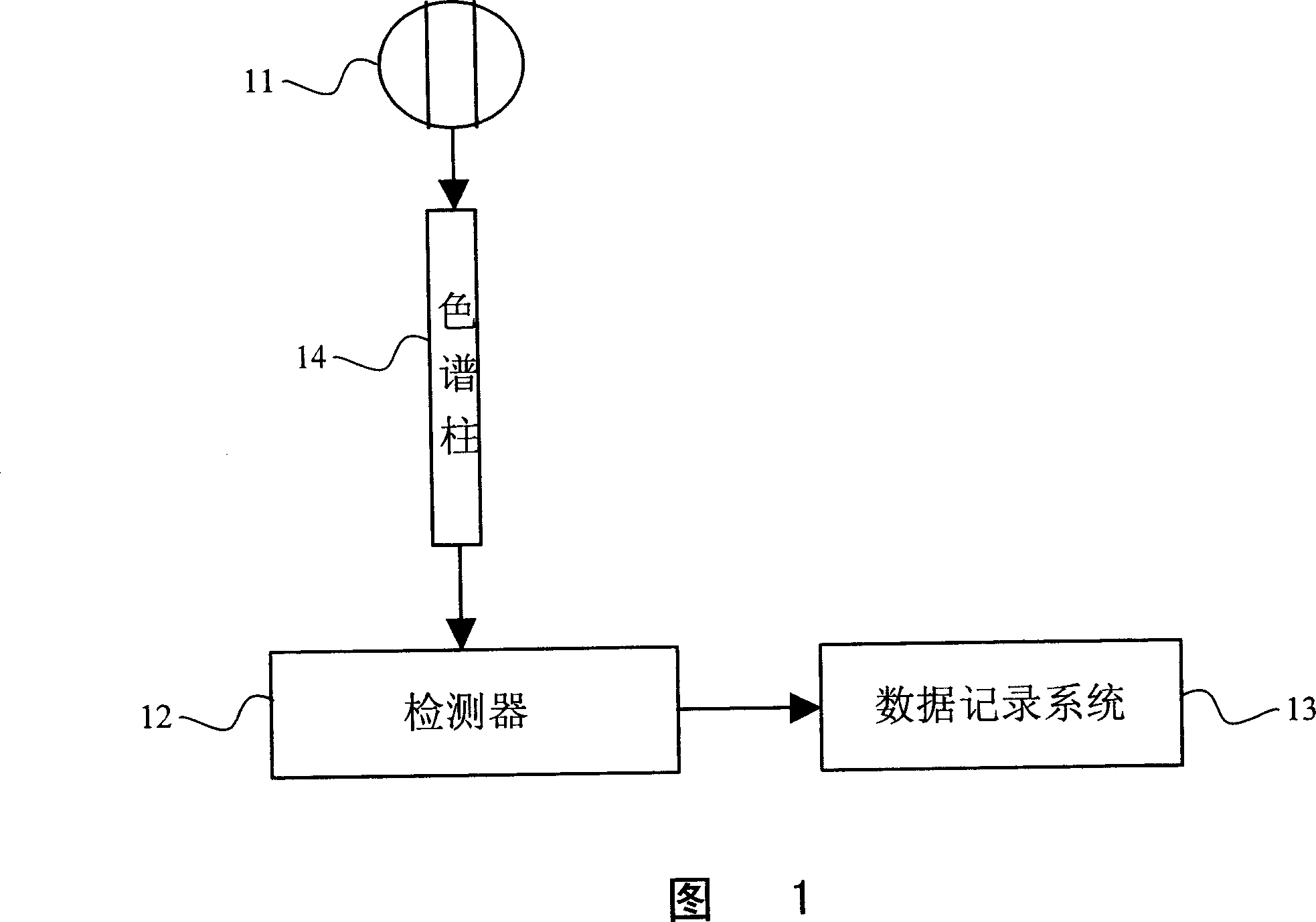

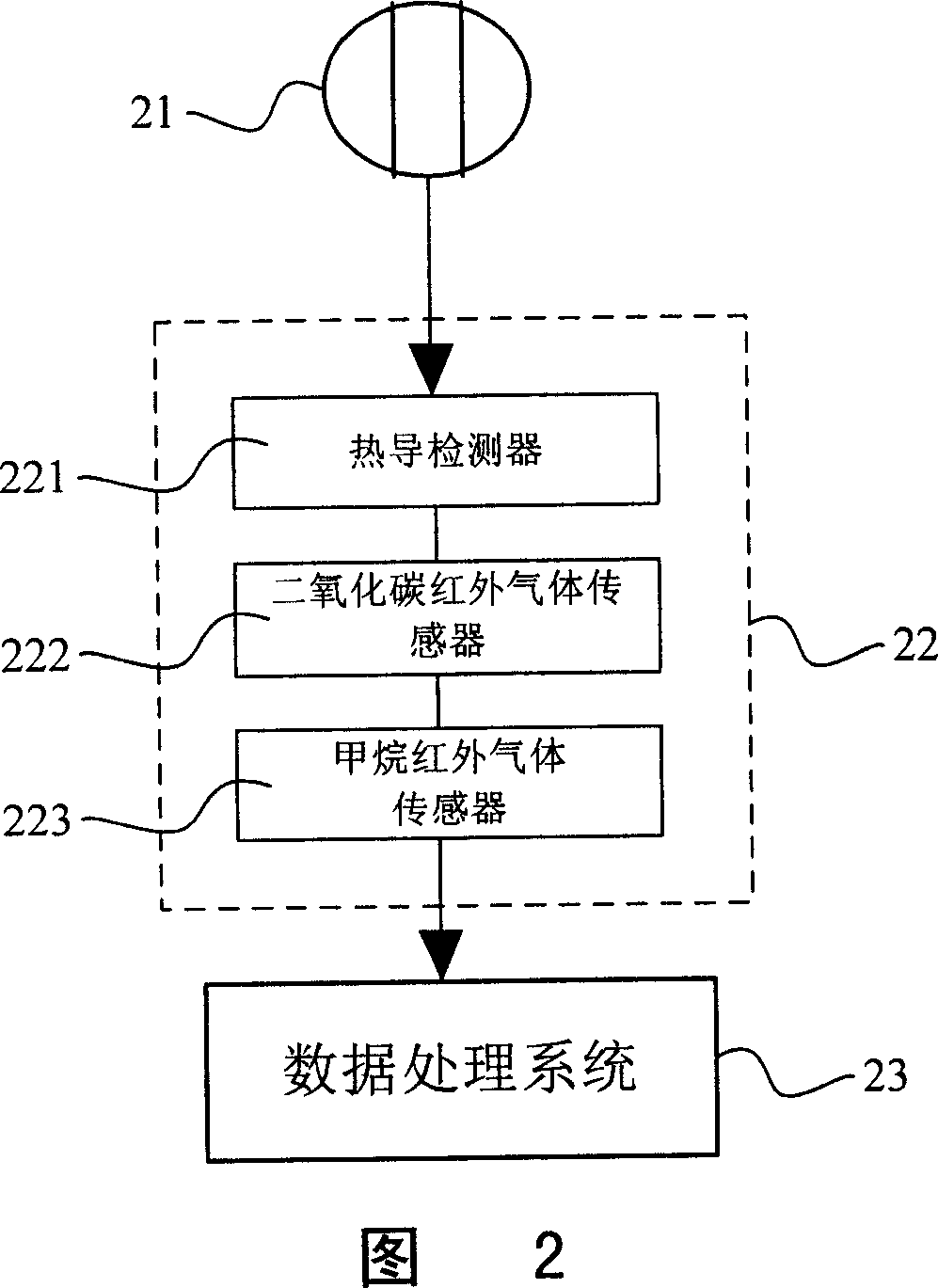

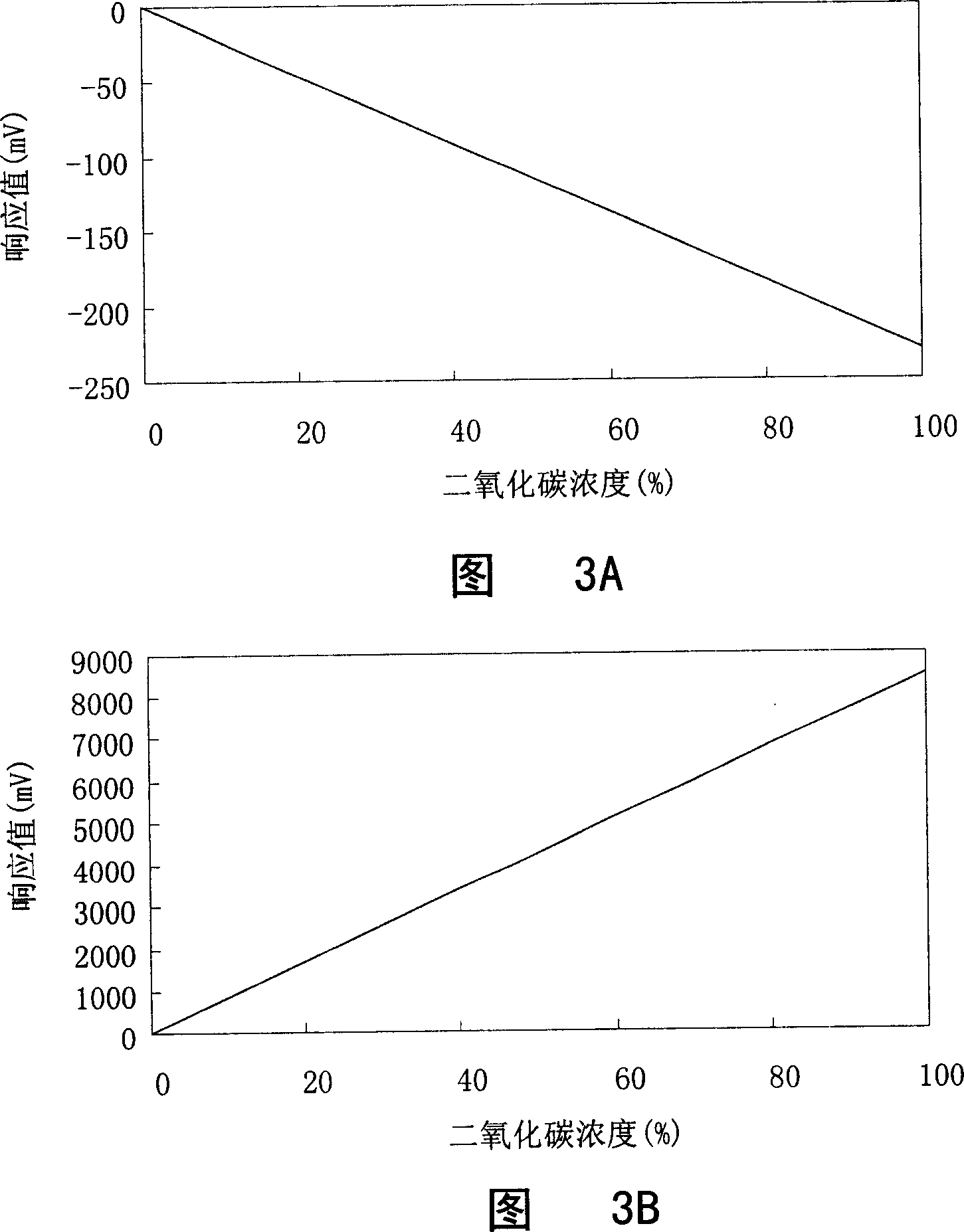

Gas analyzing method and apparatus

InactiveCN1979172AAccurate and reliable measurement resultsMaterial analysisProcess systemsData processing system

The invention relates to a gas analyzing method that could test the thickness of hydrogen, methane and carbon dioxide in mix gas. It includes the following steps: determining the responding curve of detecting instruments, testing the gas thickness in mixed gas. The gas analyzing instrument includes filling valve, and data process system. The advantages of the invention are that it could test the thickness of mix gas at same time and the result is accurate and reliable.

Owner:SHANGHAI GASOLINEEUM & CHEM EQUIP +1

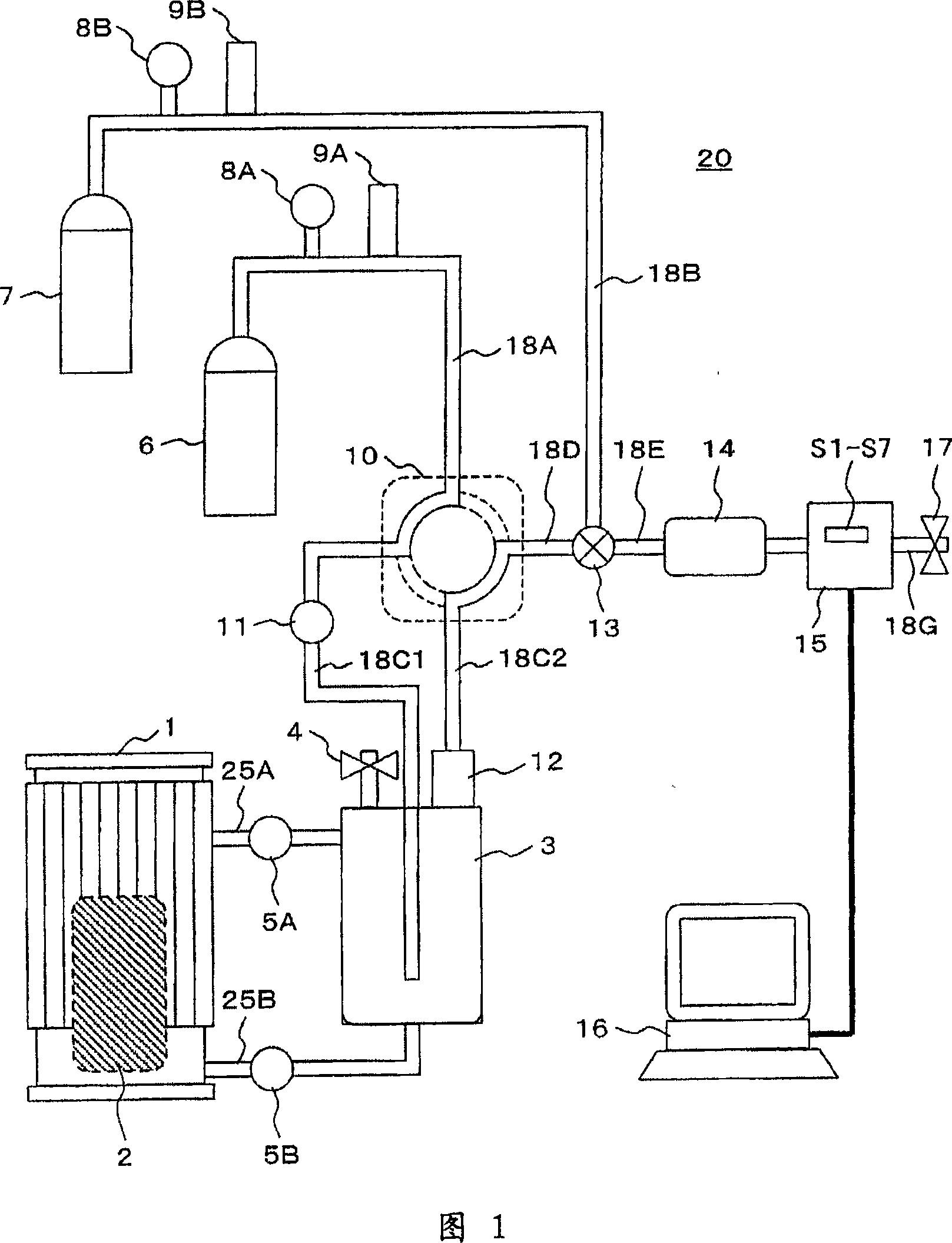

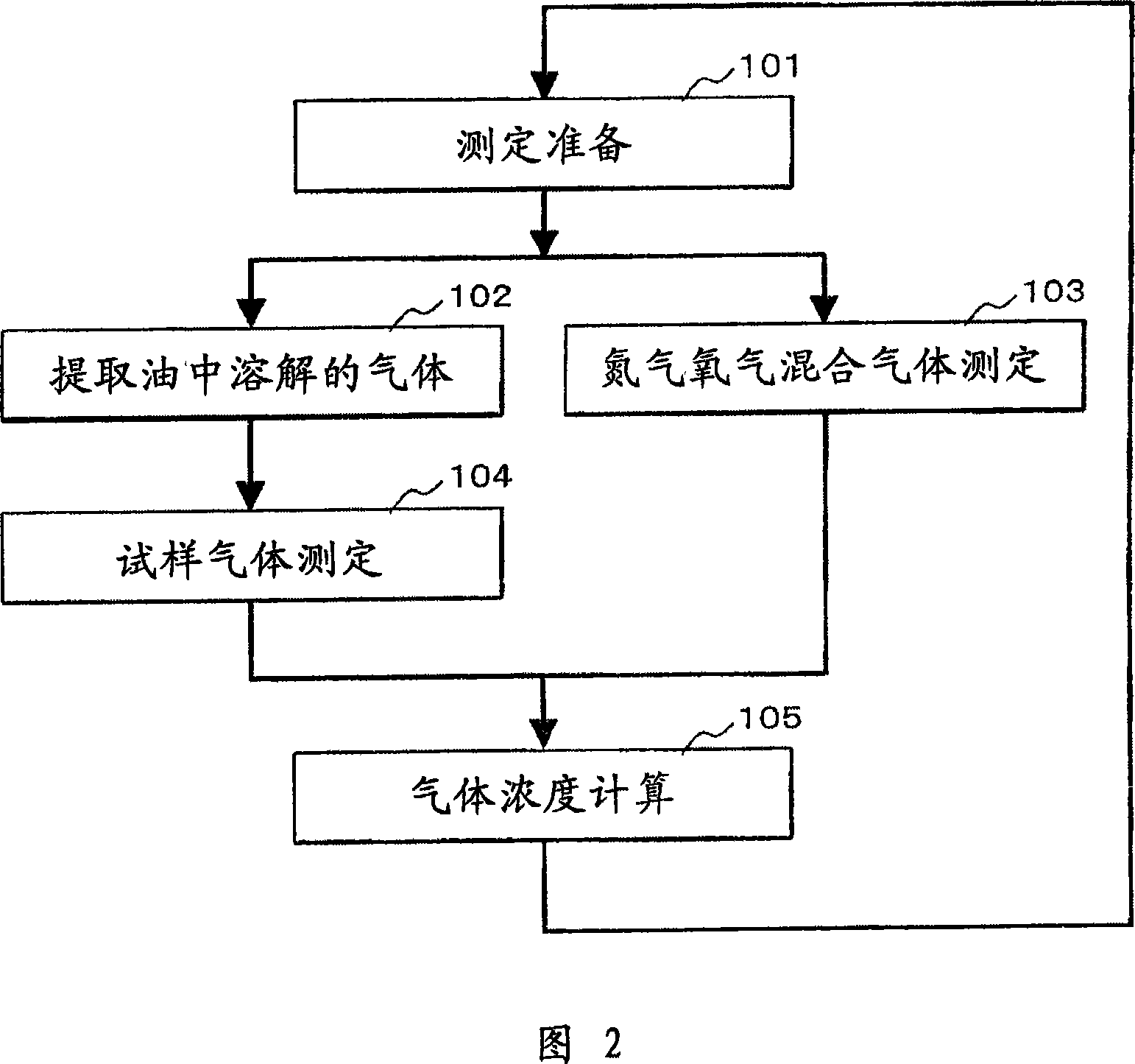

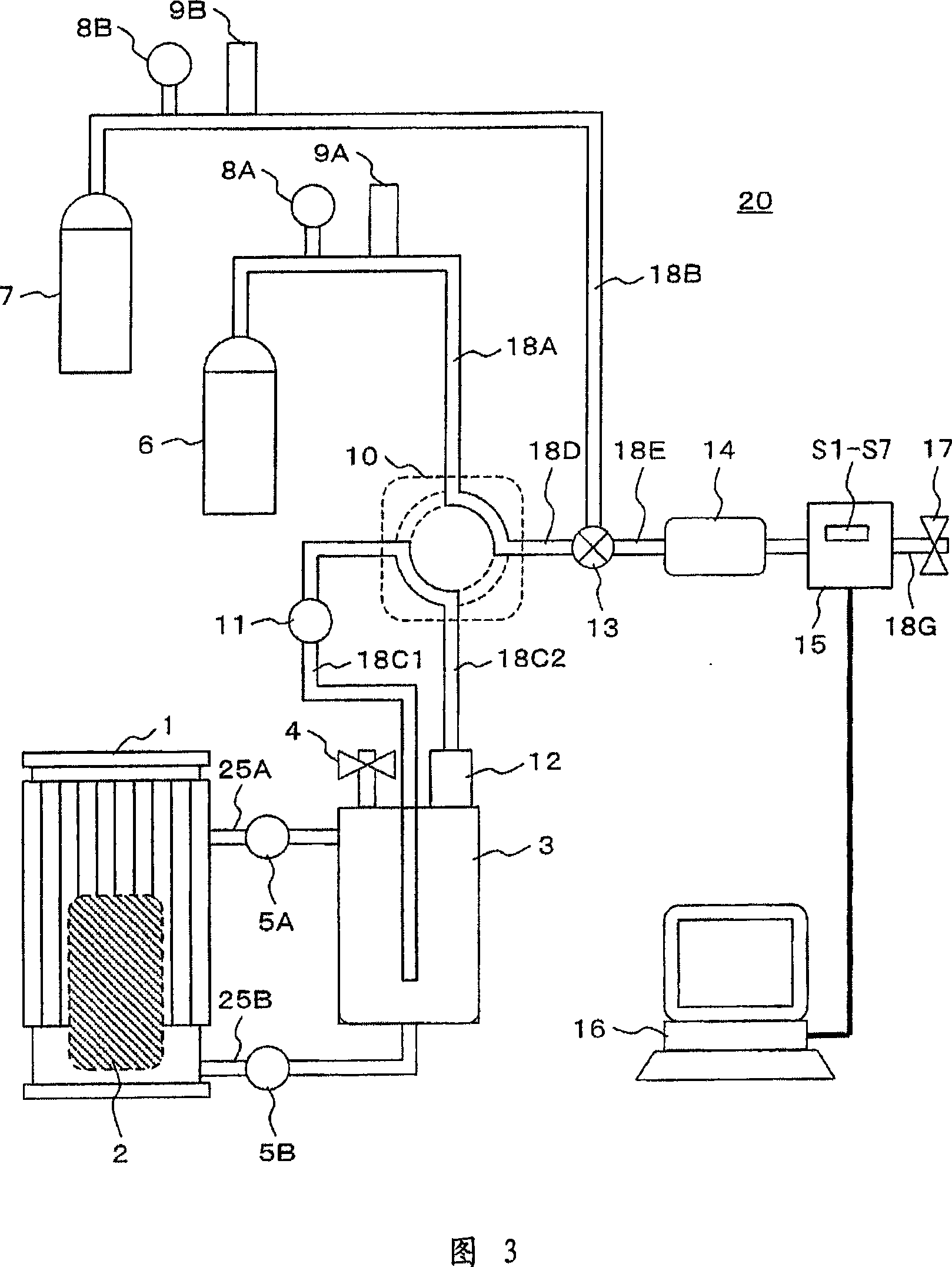

Device for analysis gas in insulating oil and method for analysis gas in insulating oil

The invention provides a device for analysis gas which can utilize the semiconductor sensor to detect various gas strengths with high reproducibility. The device for analysis gas comprises: a gas extractor that takes out the oil from the device; a gas test section of many semiconductor sensors that detects the various gas strengths of many gas compositions gathered from the oil; a model gas supply system for supplying the various gas strengths of many gas compositions gathered from the oil by the gas extractor to the gas test section; a standard gas supply system for supplying the standard gas using the detection value of the semiconductor sensor as the standard to the gas test section; a switch supplying mechanism for switching the model gas supply system and the standard gas supply system and supplying the device for analysis gas; and an arithmetic device for calculating the gas strengths of many gas compositions dissolved in the oil based on various detection values of the model gas and the standard gas detected by many semiconductor sensors of the gas test section.

Owner:FUJI ELECTRIC CO LTD

Gas analyser

ActiveUS20140291526A1Radiation pyrometryColor/spectral properties measurementsProcess windowGas analyser

A gas analyser for the absorption-spectroscopic in-situ determination of at least one chemical and / or physical parameter of a gaseous measurement medium, wherein the gas analyser includes a first housing; at least one laser as a radiation source, which laser is arranged in the first housing; at least one first process window for coupling the radiation emitted by the laser into a measurement medium; and at least one detector by which, following interaction with the measurement medium, the radiation is detected. The first process window can be configured as an afocal meniscus lens having a convex surface and a concave surface.

Owner:METTLER TOLEDO GMBH

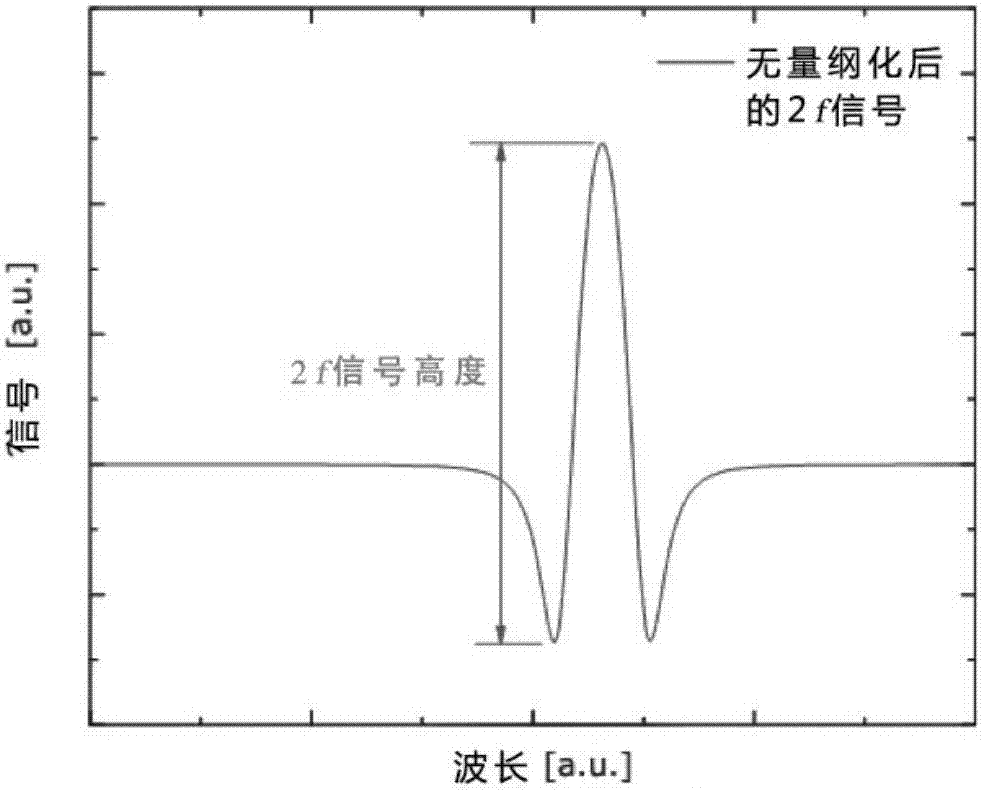

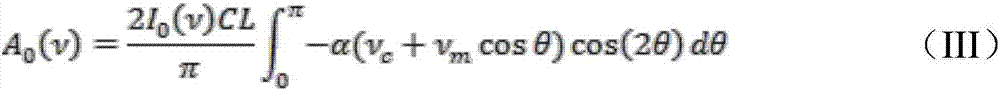

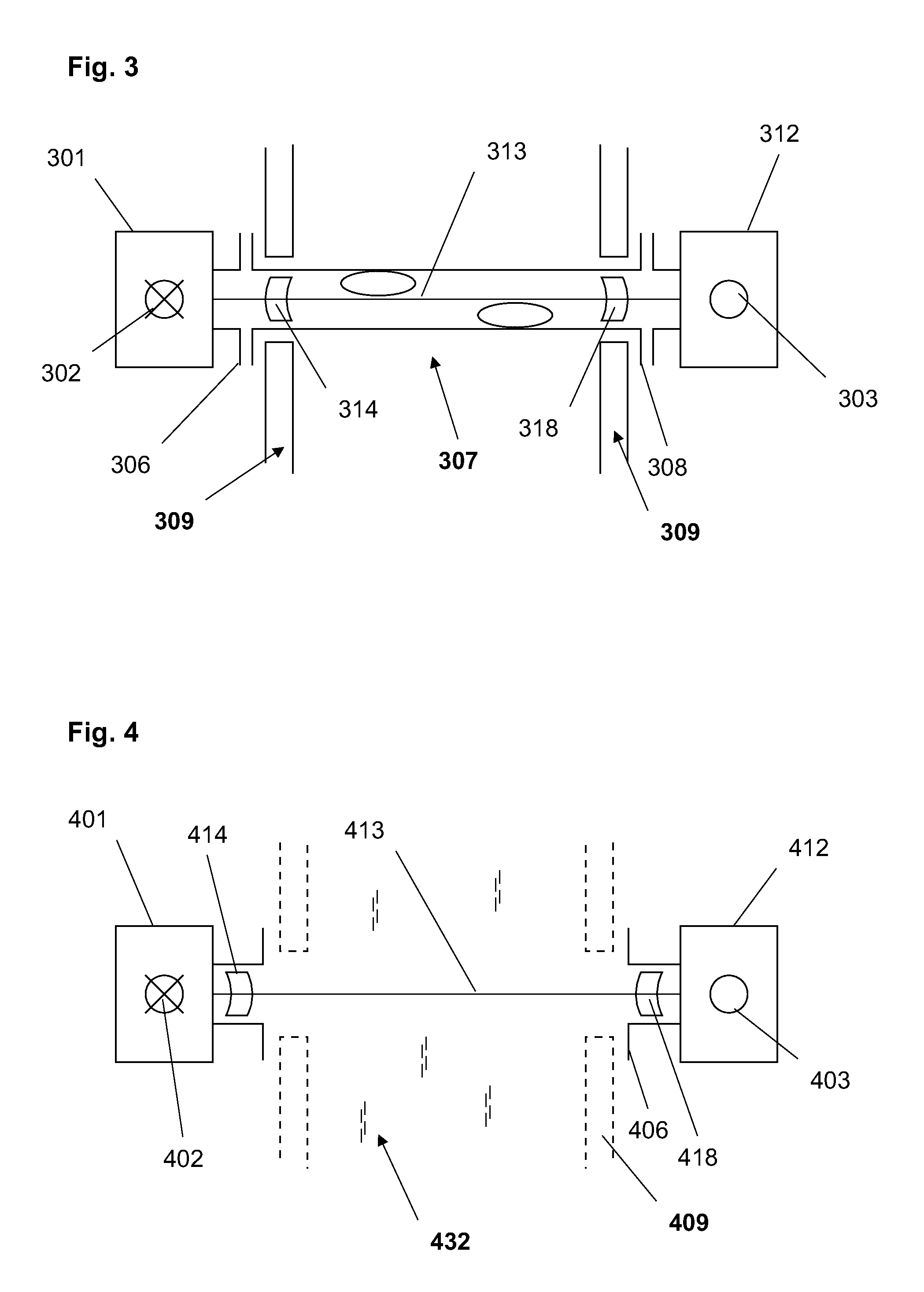

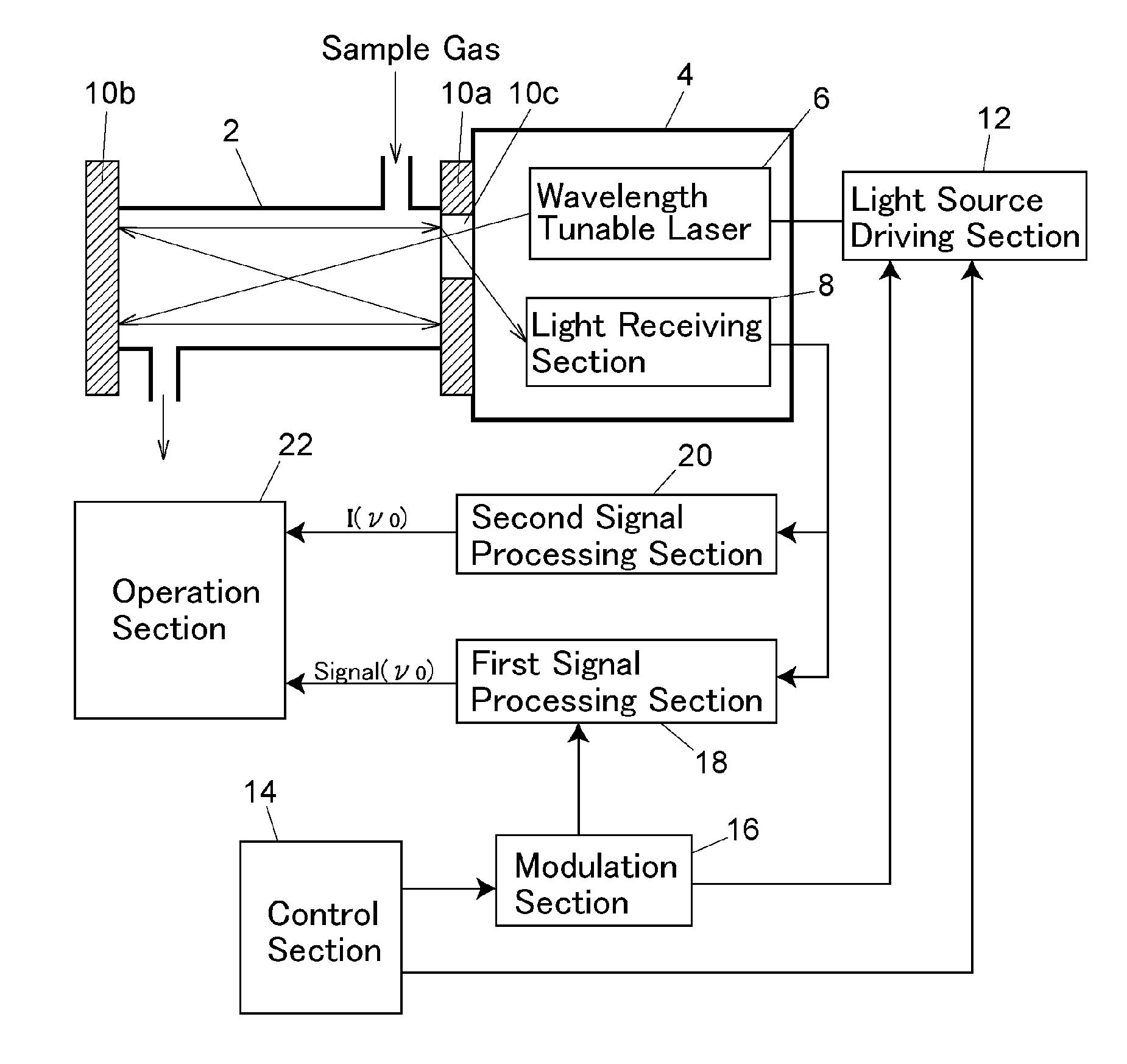

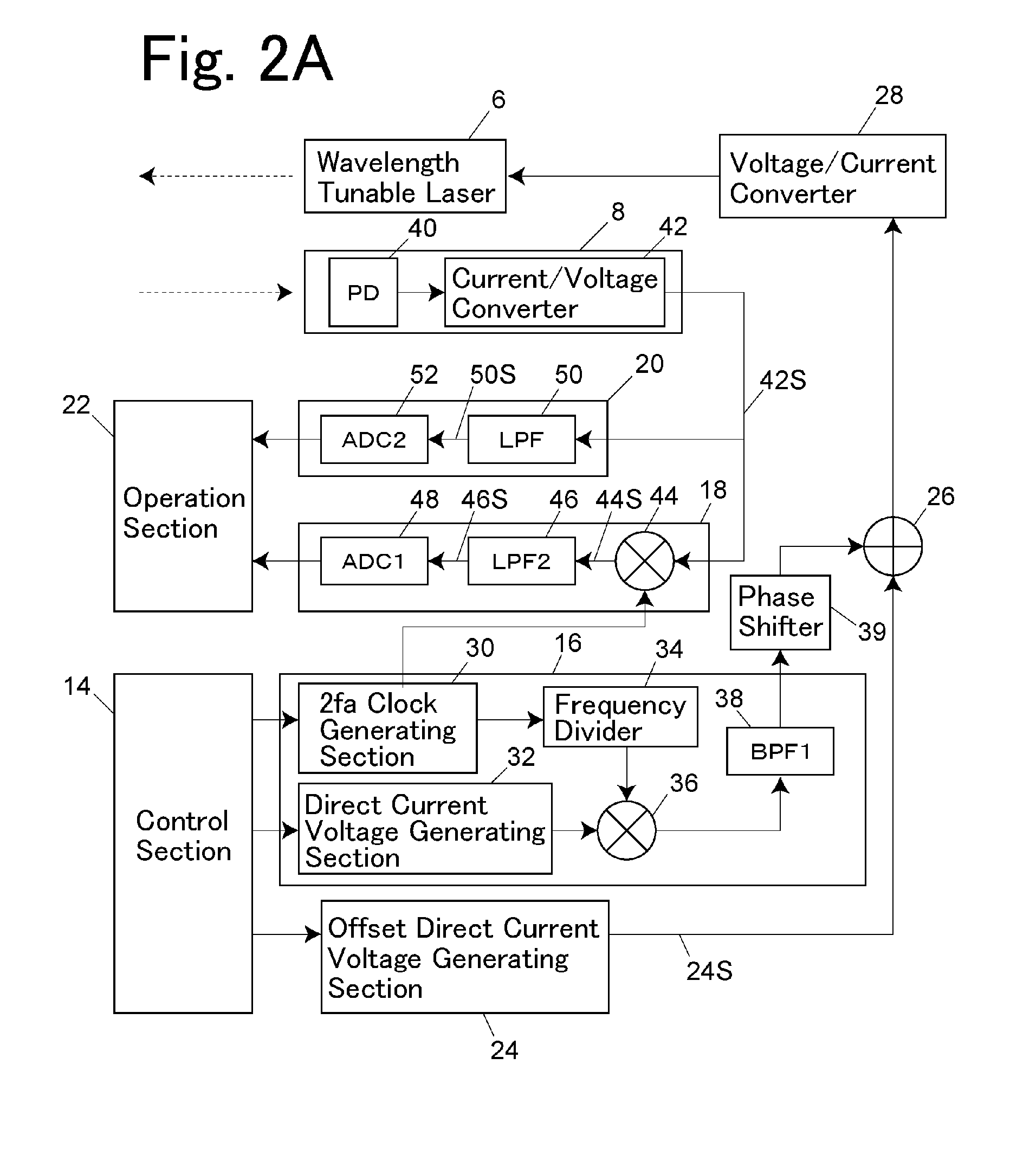

Gas analyzer

ActiveUS20140125967A1High sensitivityReduce sensitivityRadiation pyrometryPhotometryLaser lightVIT signals

A gas analyzer includes: a first signal processing section for synchronously detecting a light detection signal at a frequency being an integral multiple of a modulation frequency fa of a laser light, to detect a harmonic signal intensity Signal(ν) by a harmonic synchronous detection method; a second signal processing section for capturing a light detection signal and cutting off a frequency component not smaller than the frequency fa to detect a light intensity signal I(ν) at a specific light frequency absorbed by a component to be measured in a sample gas; and an operation section. The operation section includes a first operation means for calculating a density c of the component from the harmonic signal intensity Signal(ν) and a reference light intensity signal I0(ν) and a second operation means for calculating the density c from the light intensity signal I(ν) and the reference light intensity signal I0(ν).

Owner:SHIMADZU CORP

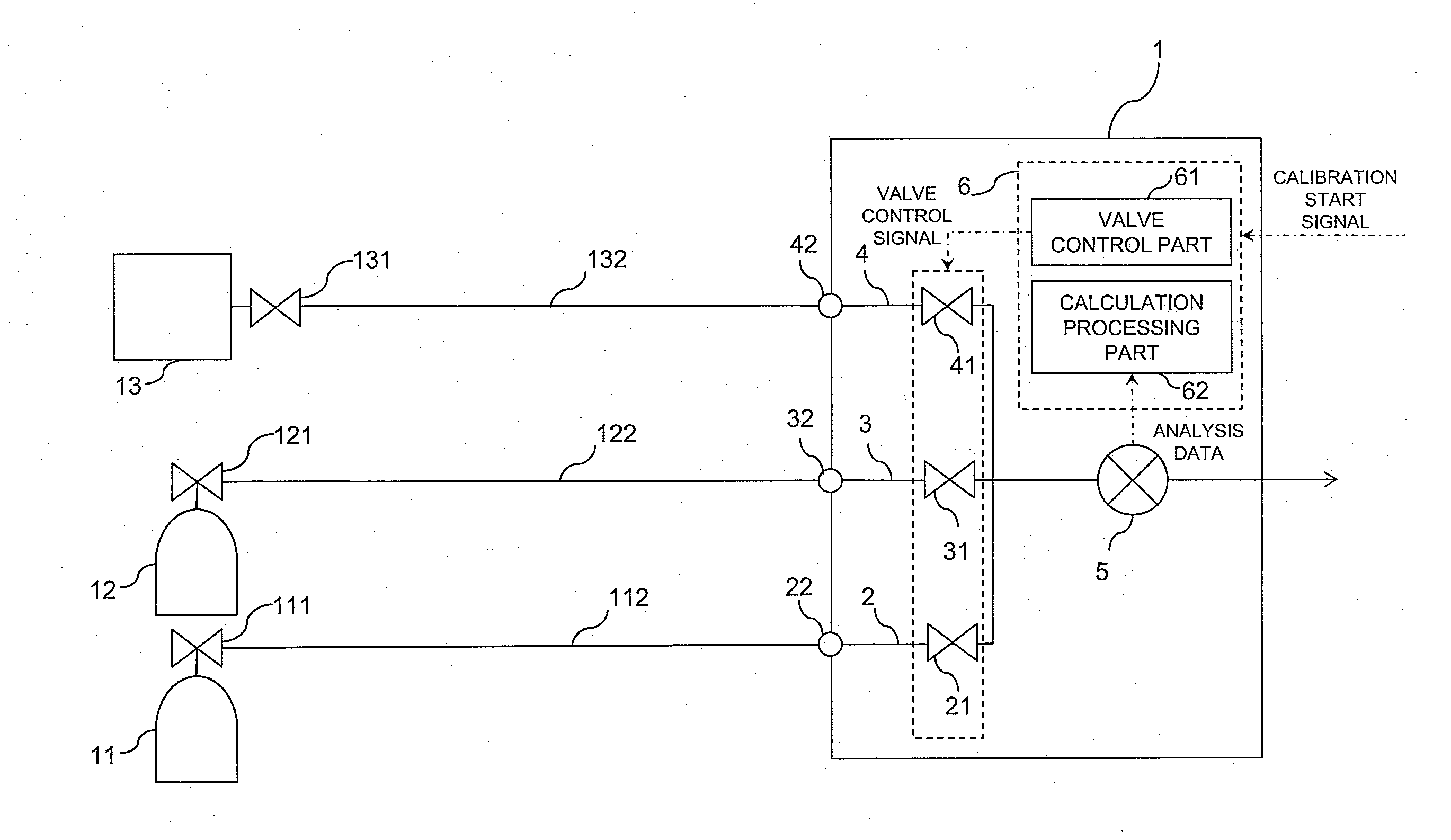

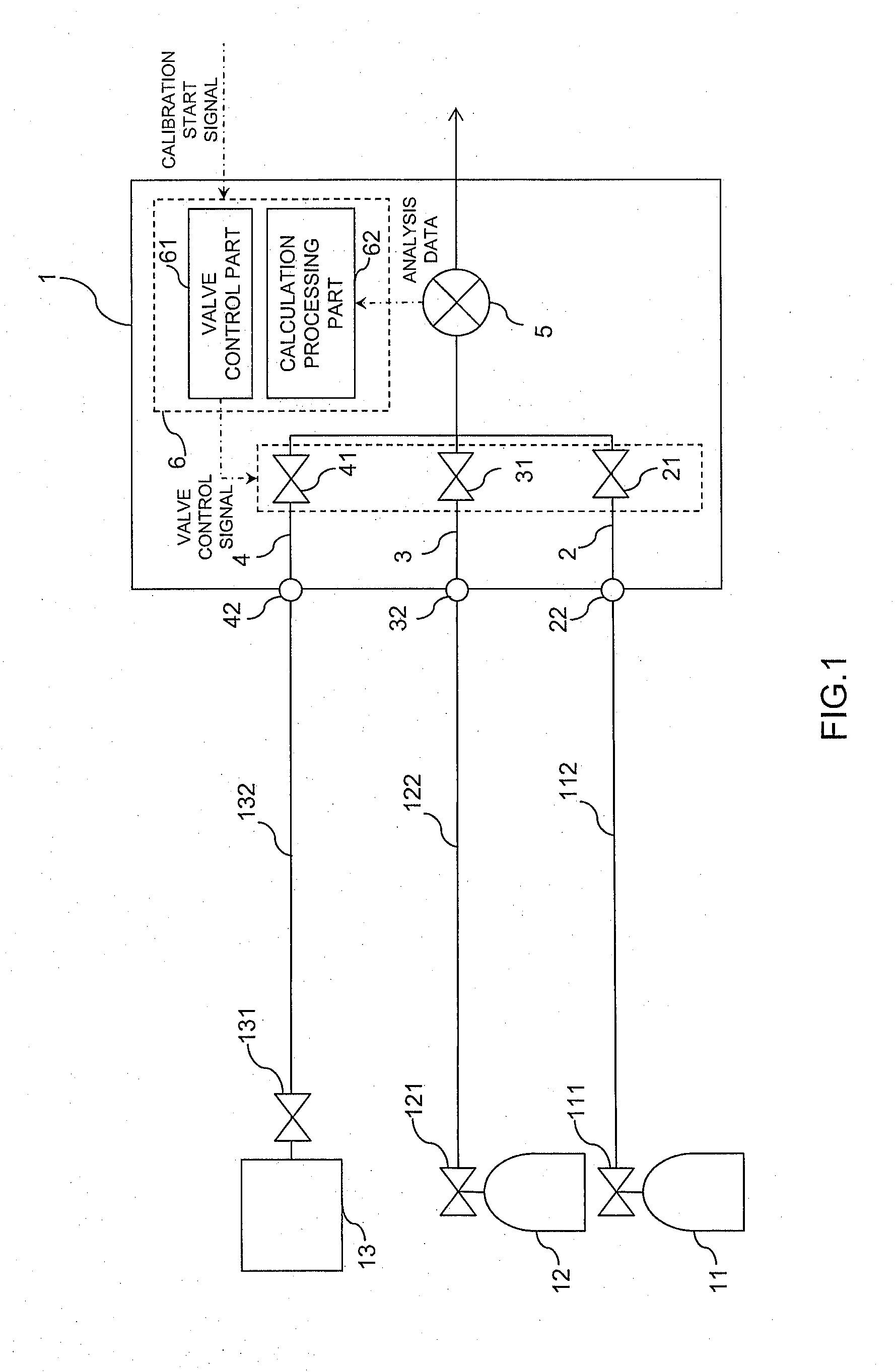

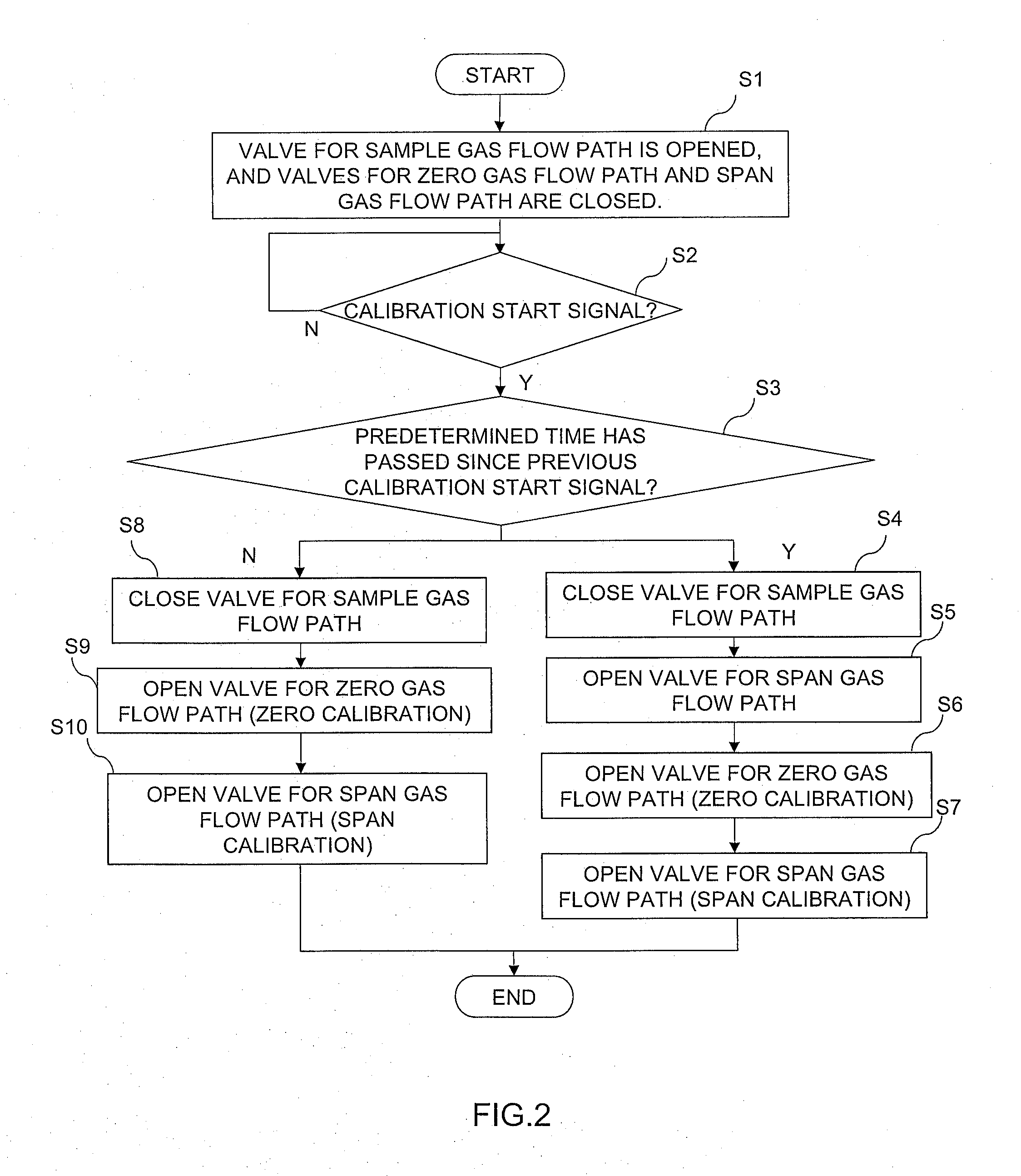

Gas analyzing system

ActiveUS20120260715A1Accurate CalibrationAnalytical results are reliableMaterial analysis by electric/magnetic meansAnalysis by thermal excitationLine tubingProcess engineering

A gas analyzing system that can perform calibration without being influenced by the deterioration of span gas in a span gas supply line. An open-close device control part that receives a calibration start signal issuing an instruction to start zero calibration and span calibration, and controls an open-close device for a span gas flow path. An open-close device for a zero gas flow path, wherein if the open-close device control part receives a new calibration start signal after a predetermined time has passed since previous calibration was performed, before the span calibration is started, for a predetermined time, the open-close device control part controls the open-close device for the span gas flow path so as to open the open-close device for the span gas flow path, and thereby purges span gas that remains in the span gas flow path.

Owner:HORIBA LTD

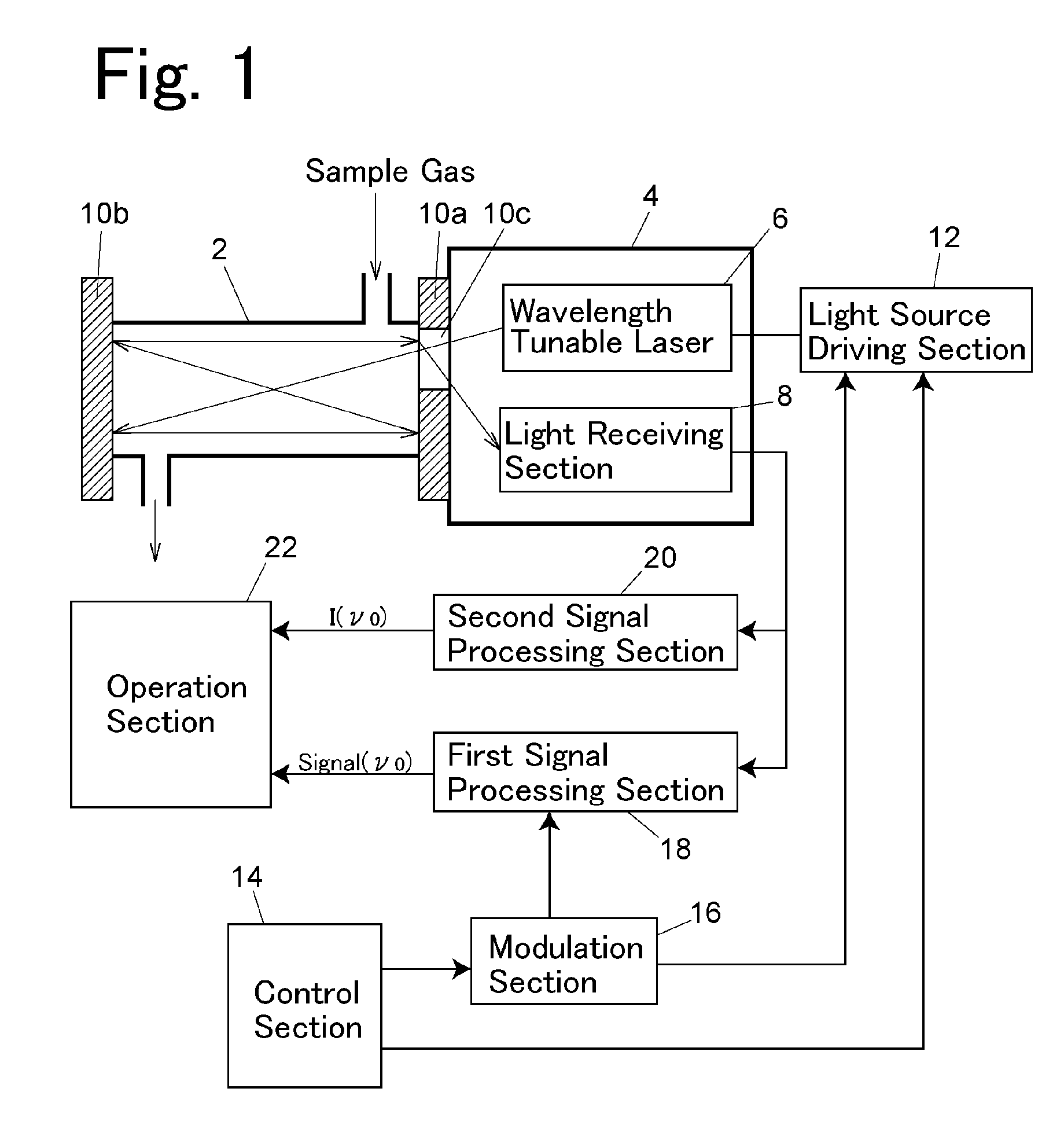

Measuring unit and gas analyzer

InactiveCN103547910AEfficient receptionIrradiation stableTransmissivity measurementsGas analyser construction detailsTemperature differenceGas analyser

A measuring unit (1), which is used in an analyzer for analyzing the concentrations of predetermined components in a sample gas, is provided with: an irradiation part (21) that irradiates measuring light inside the sample gas; a light-receiving part (24) that receives the measuring light on a light-receiving surface; a purge air inlet (14) that introduces purge air in the vicinity of the irradiation part (21) and / or the light-receiving part (24); and a condenser lens (23) which is positioned on the optical path of the measuring light from the irradiation part (21) to the light-receiving part (24), and which focuses the measuring light, the propagation path of which changes due to a thermal lens effect produced by temperature differences between the gas the purge air, on the light-receiving surface of the light-receiving part.

Owner:HORIBA LTD

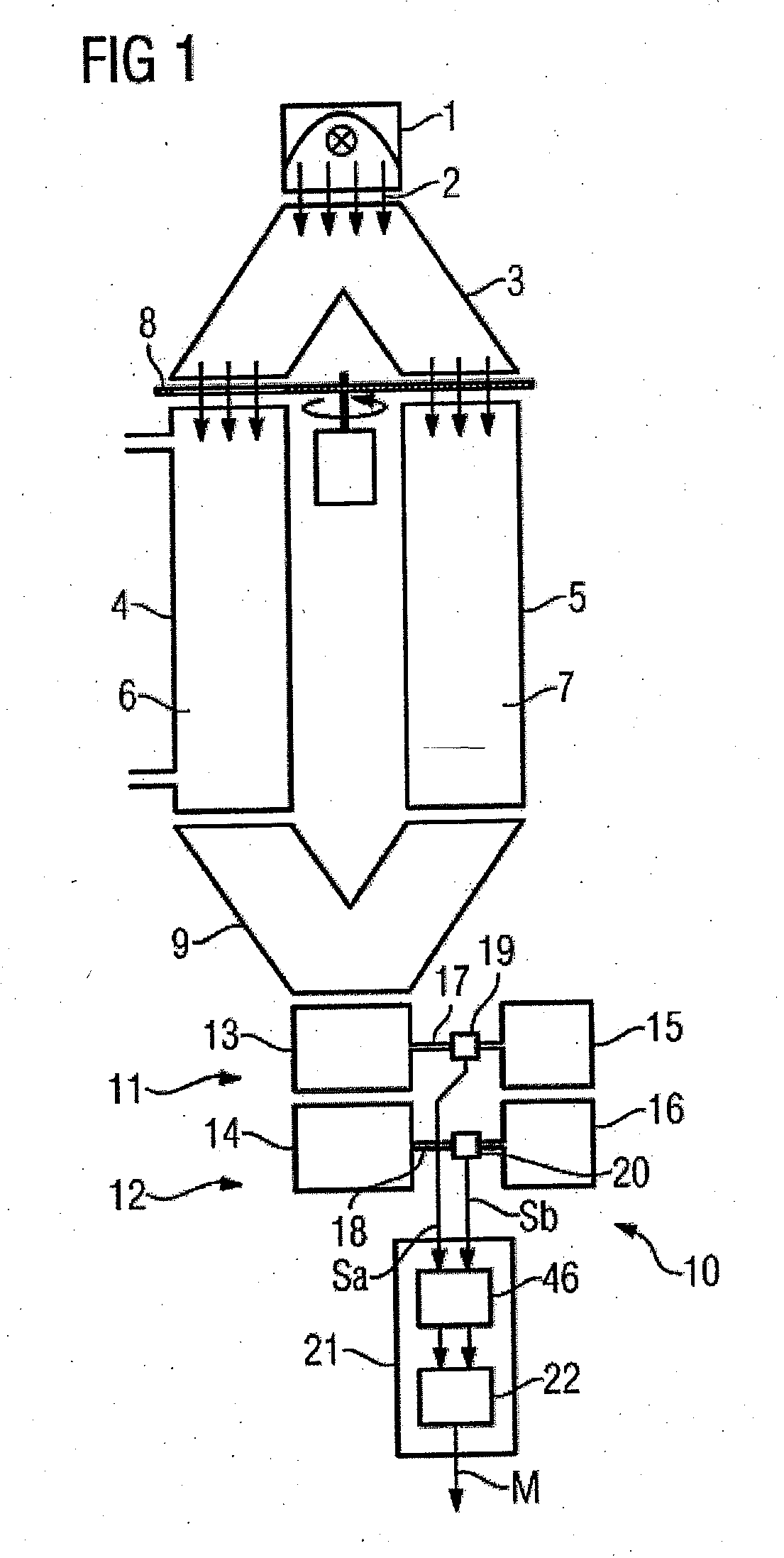

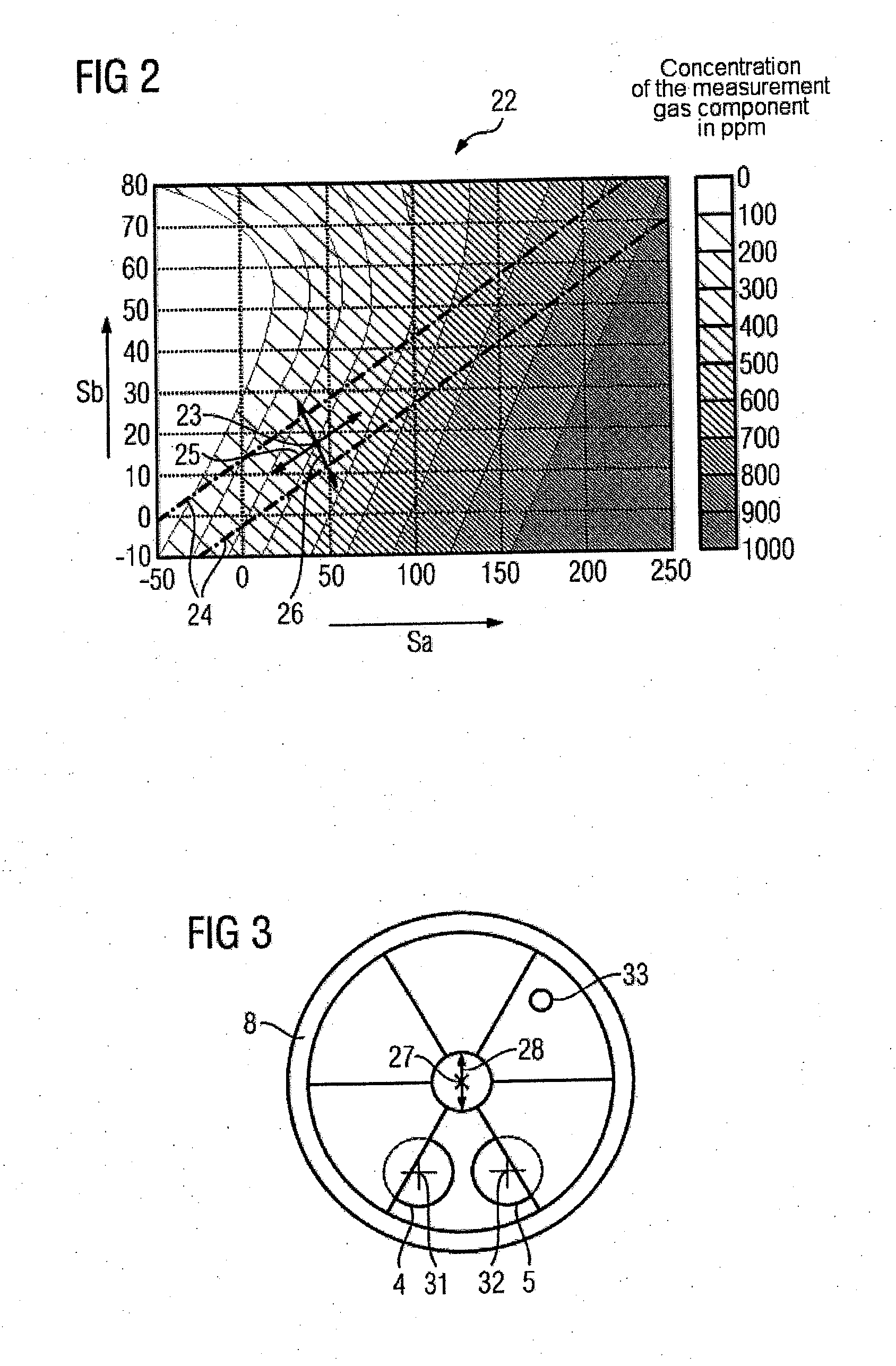

NDIR-two Beam Gas Analyser And Method For Determining The Concentration Of A Measuring Gas Component in a Gas Mixture by means of Said type of Gas Analyser

InactiveUS20120091346A1Compensation is simpleMaterial analysis by optical meansPyrometry using electric radation detectorsPhase imbalanceGas composition

The invention relates to a NDIR two beam gas analyser in which infrared radiation is guided by modulation in an alternating manner through a measuring chamber and a reference chamber and is subsequently detected, a measurement signal being produced due to the analysis which determines the concentration of a measurement gas component present in the measurement chamber. The detection and compensation of error effects, in particular modifications on the infrared radiation source or detector arrangement, is simplified as a phase imbalance is produced in the switching of the radiation between the chambers, and the measurement signal is detected in a phase-sensitive manner for modulating the radiation, a measurement signal vector (SF) comprising amplitude information and phase information (ΦF) is obtained such that during calibration of the gas analyser for different known concentrations (K1, K2, K3, K4, K5) of the measurement gas components, measurement signal vectors (S1, S2, S3, S4, S5) having different amplitudes and phases are determined, vectors define a characteristic line (43), and when an unknown concentration of the gas component is measured, the unknown concentration of the measurement gas component is determined from the intersection point (45) of an obtained measurement signal vector (SF) or the extension thereof with the characteristic line (43).

Owner:SIEMENS AG

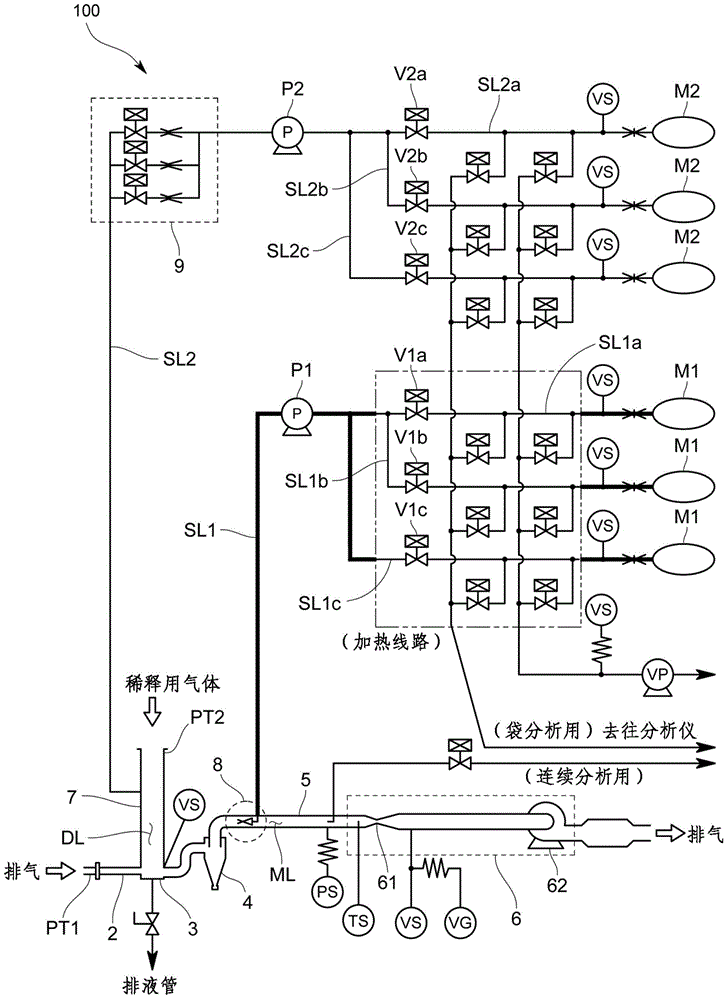

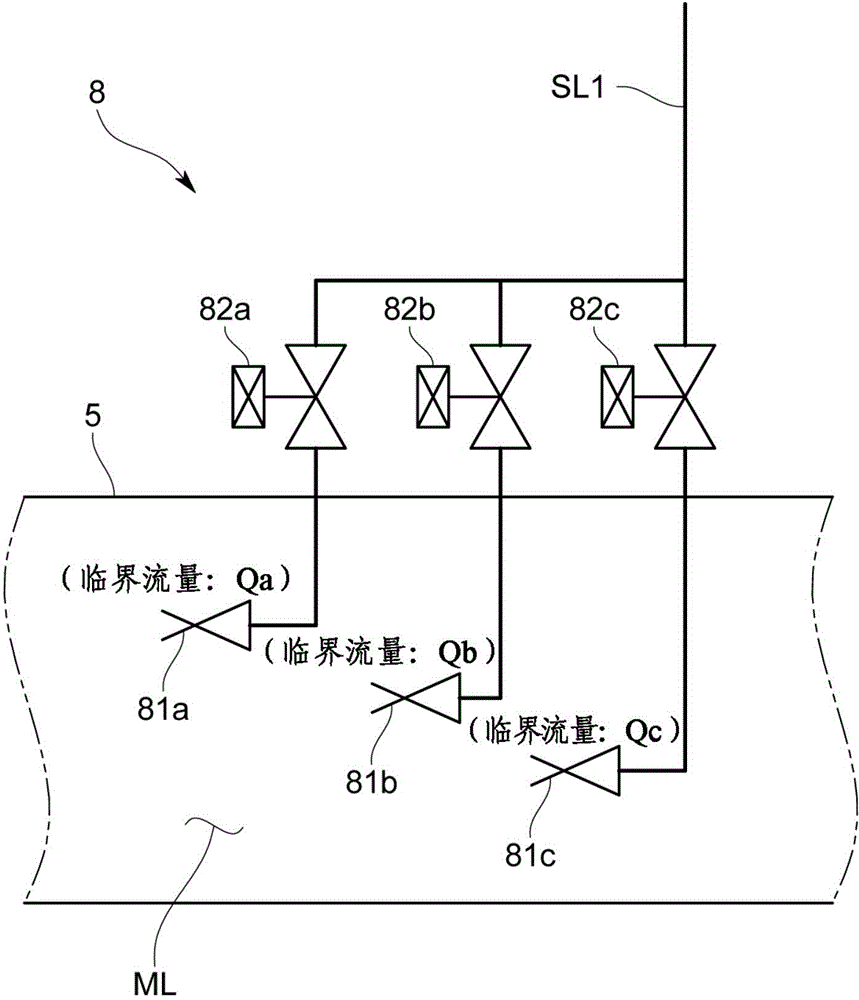

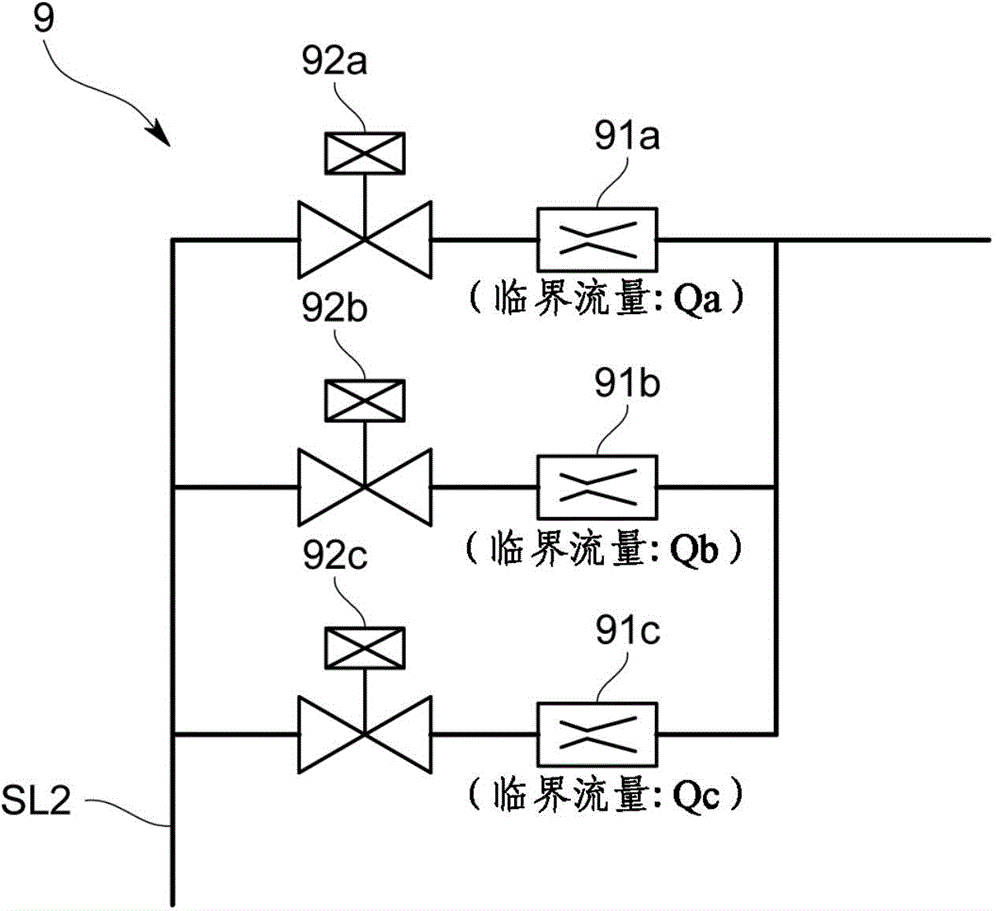

Exhaust gas sampling apparatus

ActiveCN104034561AReduce sizeDilutionhigh-precisionWithdrawing sample devicesPreparing sample for investigationProduct gasProcess engineering

The present invention is one that, in the case where a sampling part is configured to include a plurality of venturis, with suppressing an increase in size of an apparatus and an increase in cost, accurately obtains a diluent gas flow rate in accordance with a diluted exhaust gas flow rate obtained on the basis of a combination among the plurality of venturis, in which the sampling part (8) collecting part of diluted exhaust gas is configured to parallel connect the plurality of venturis that control the flow rate of the diluted exhaust gas, and a flow rate control part (9) provided in a diluent gas sampling flow path (SL2) is configured to parallel connect a plurality of venturis that control the flow rate of diluent gas to be introduced into a diluent gas analyzing device.

Owner:HORIBA LTD

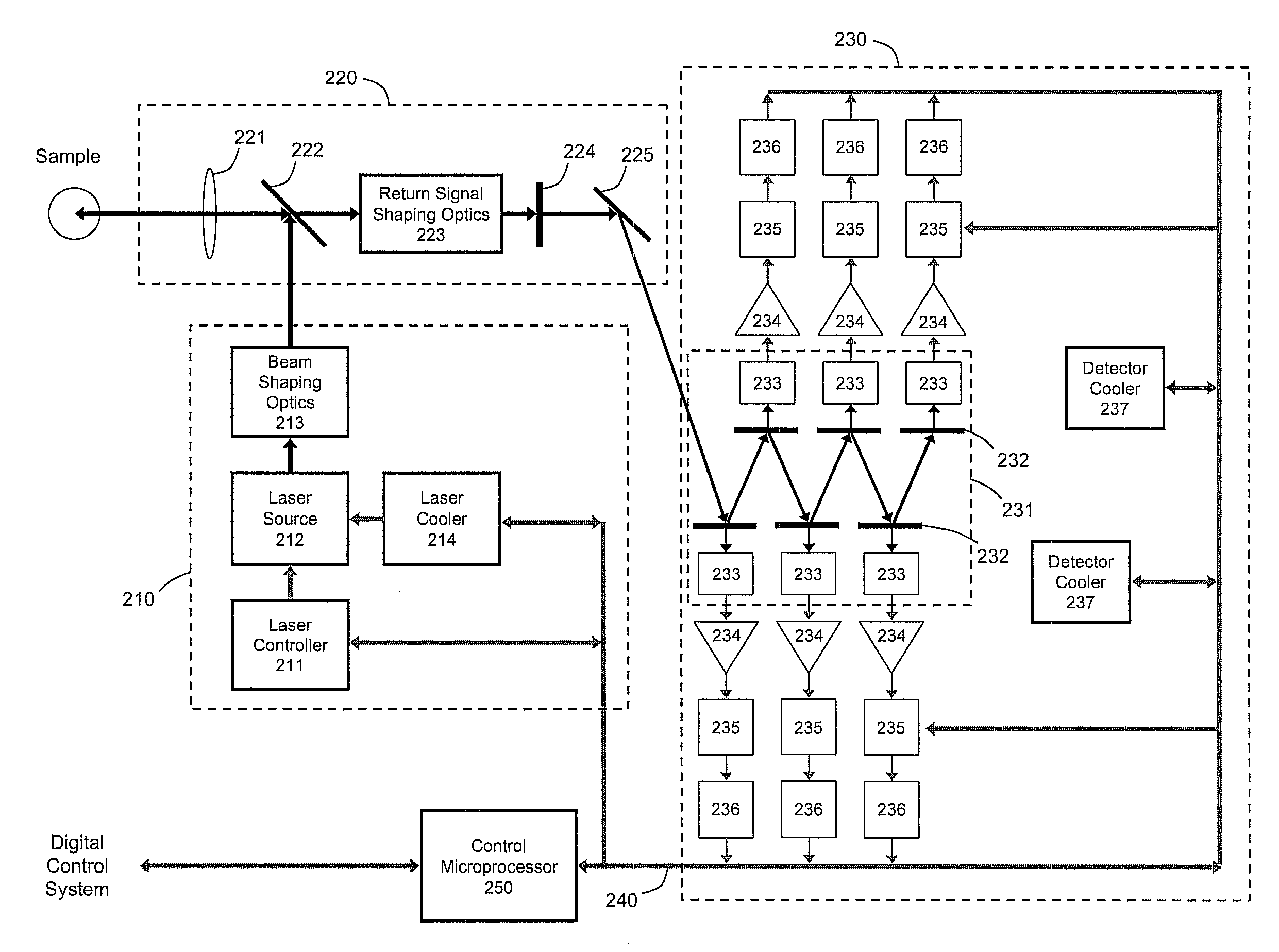

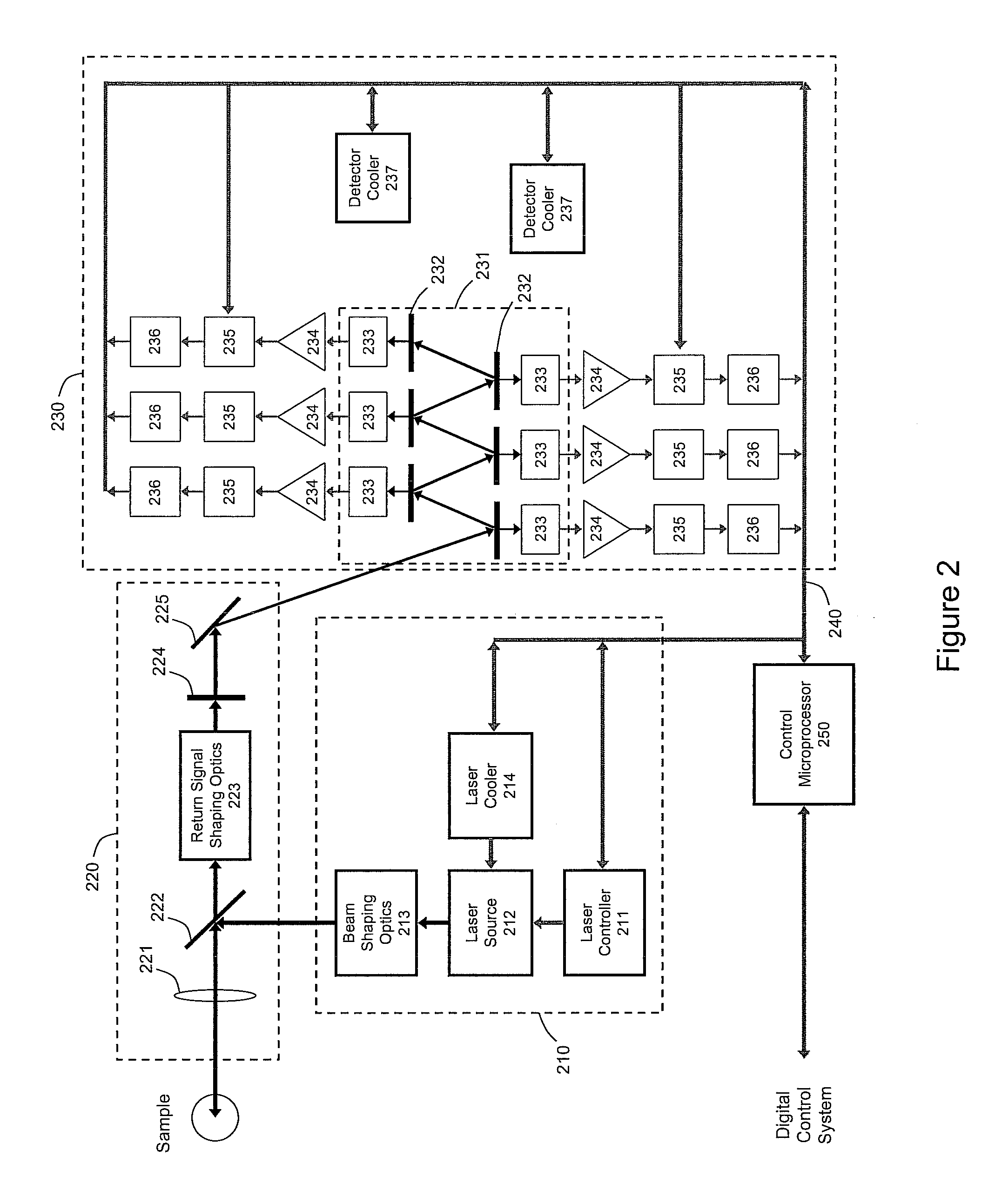

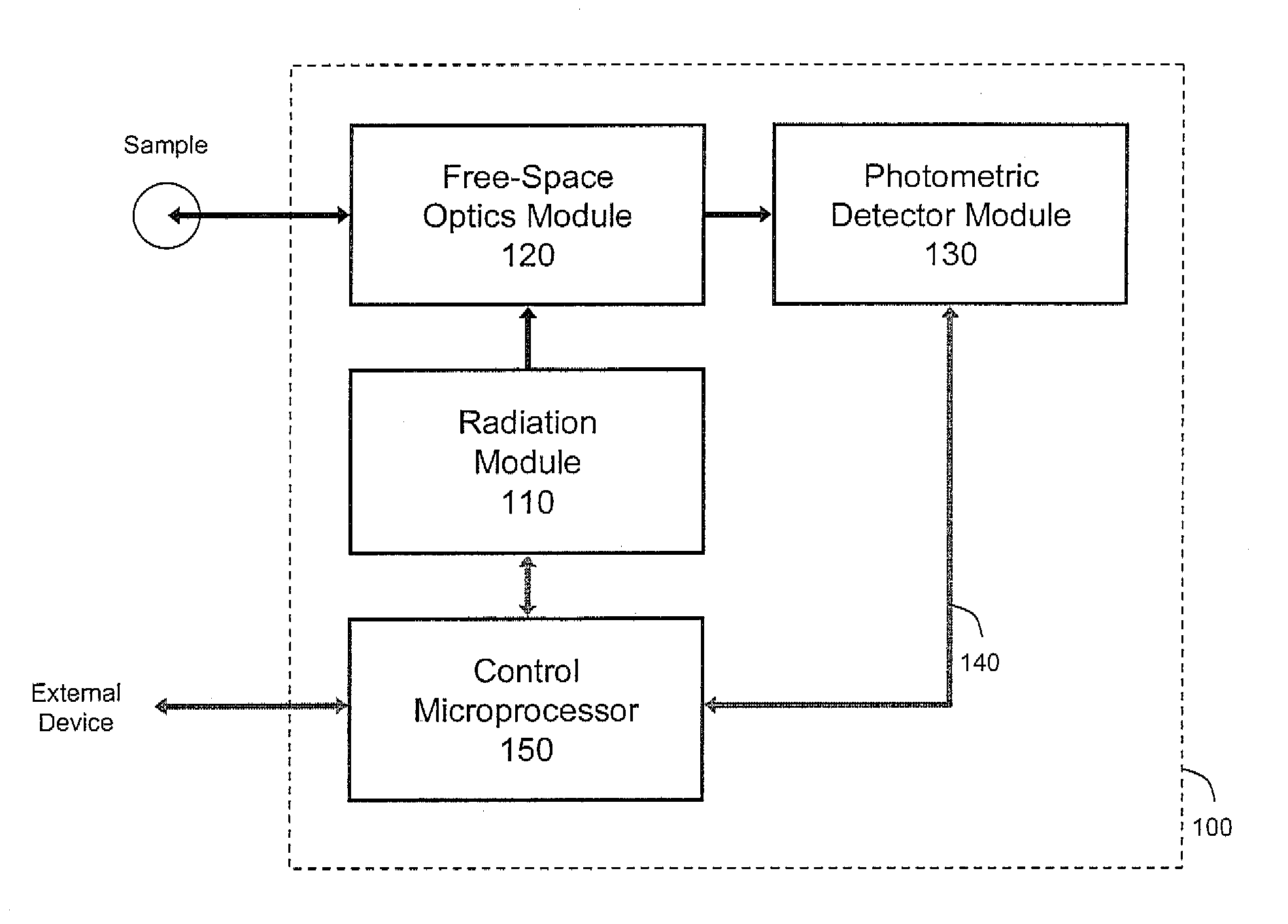

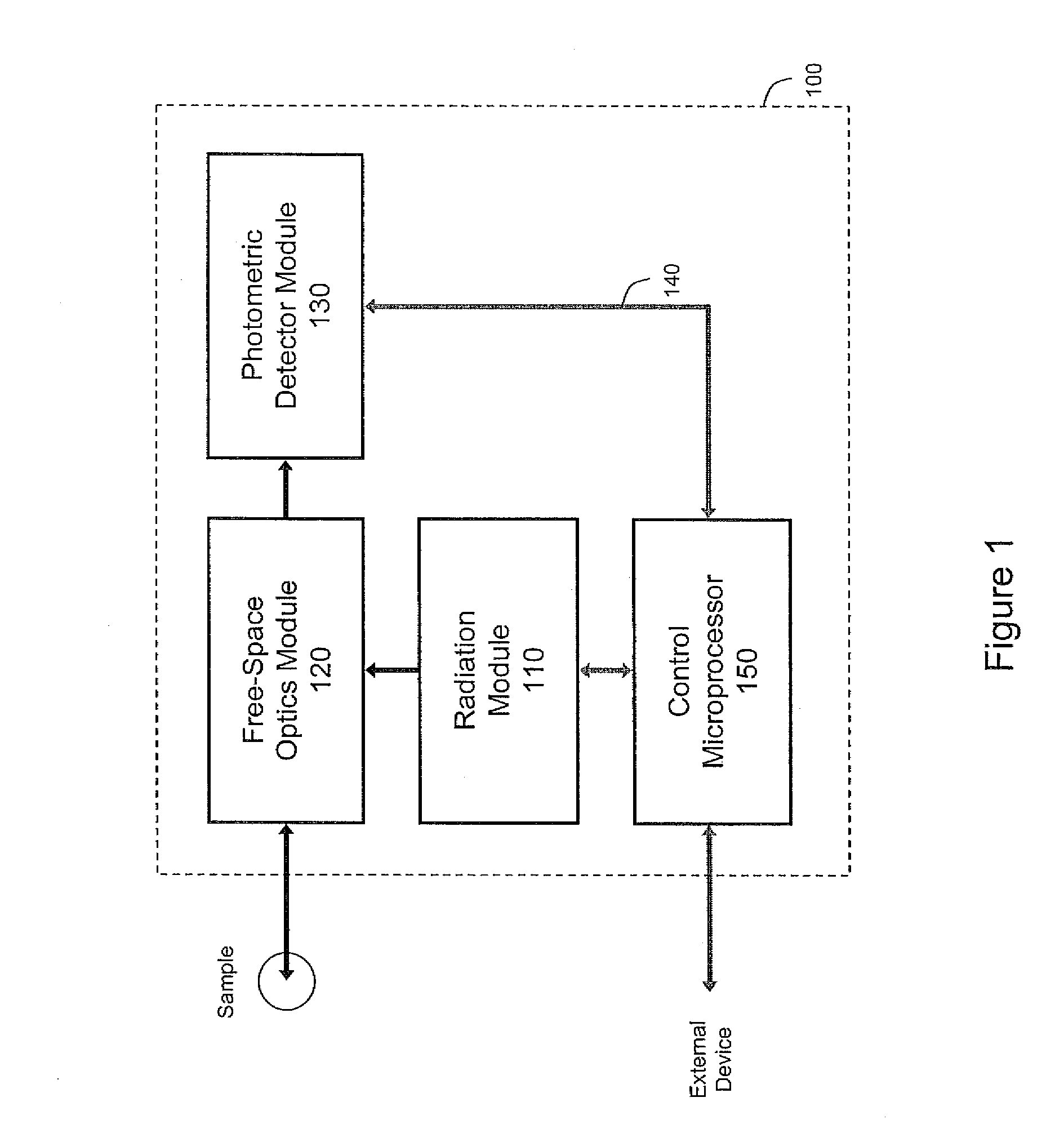

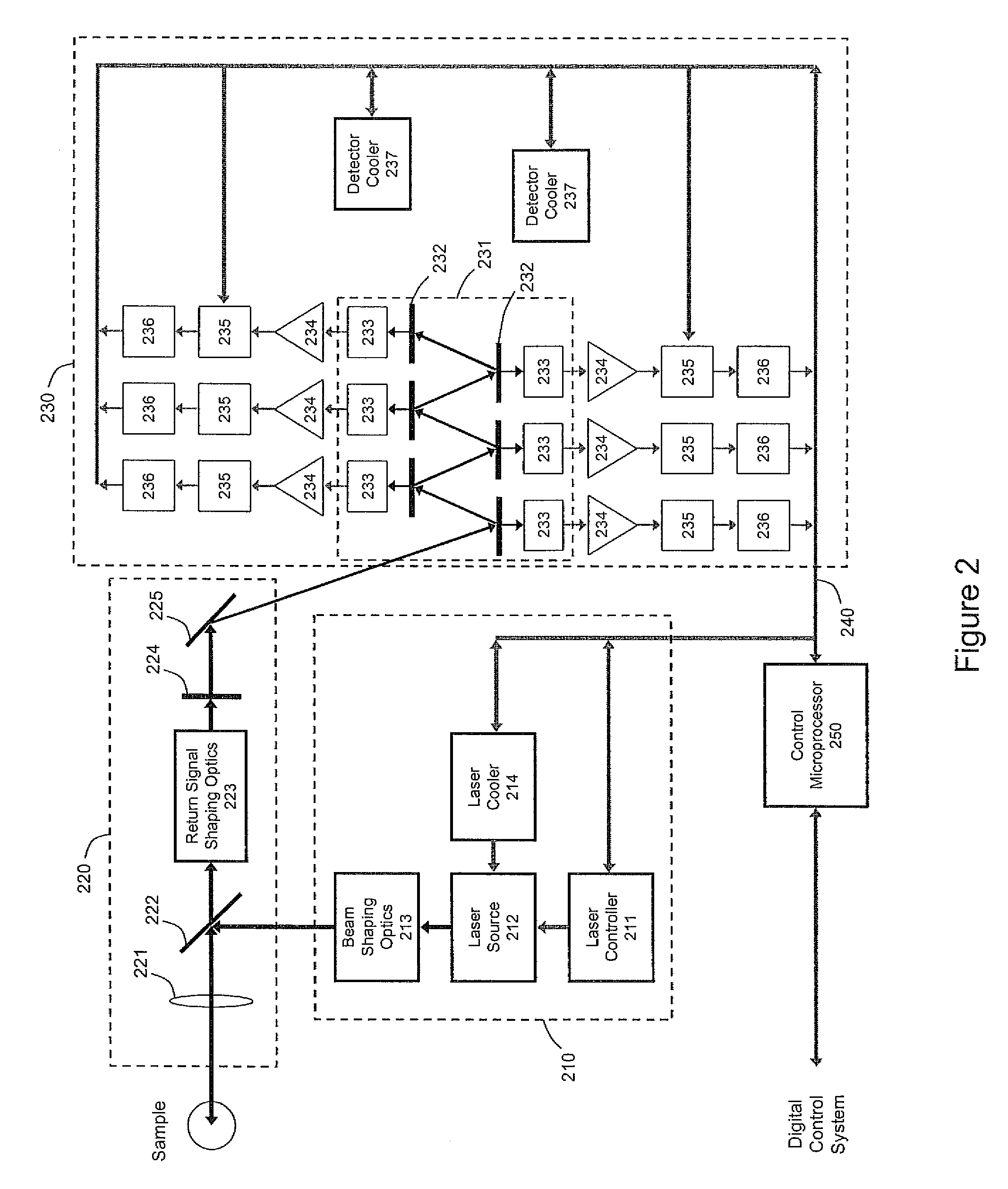

Chemical analyzer for industrial process control

ActiveUS8077309B2Improve signal-to-noise ratioLow costRadiation pyrometrySpectrum investigationNon destructiveSolid mass

An optical apparatus for measurement of industrial chemical processes. The analyzer uses Raman scattering and performs measurement of chemical concentrations in continuous or batch processes. The analyzer operates at a standoff distance from the analyte (or analytes) and can measure concentrations through an optical port, facilitating continuous, non-destructive, and non-invasive analysis without extracting the analyte or analytes from the process. The analyzer can measure one or several solid, liquid, or gaseous analytes, or a mixture thereof.

Owner:CAMBRIUS

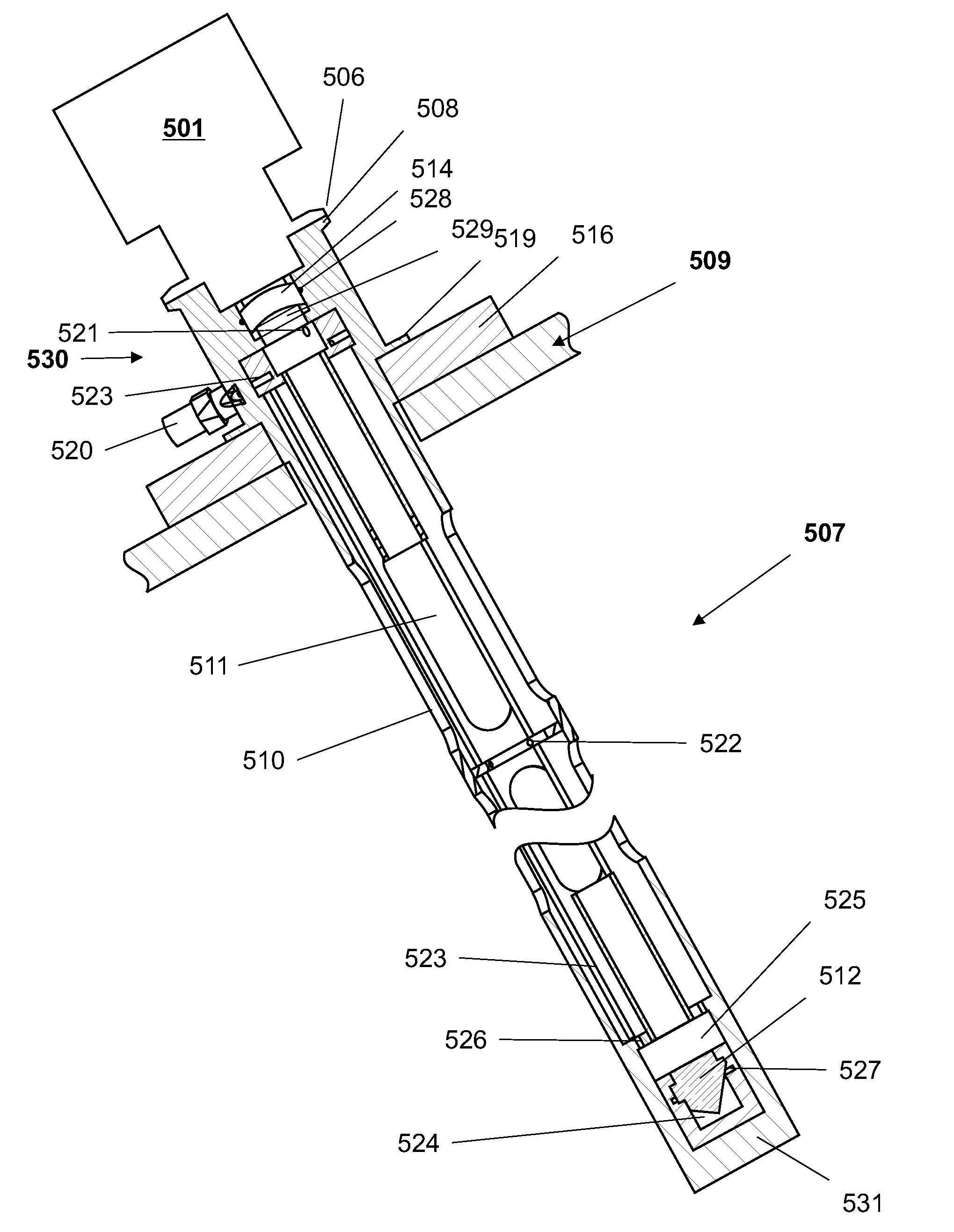

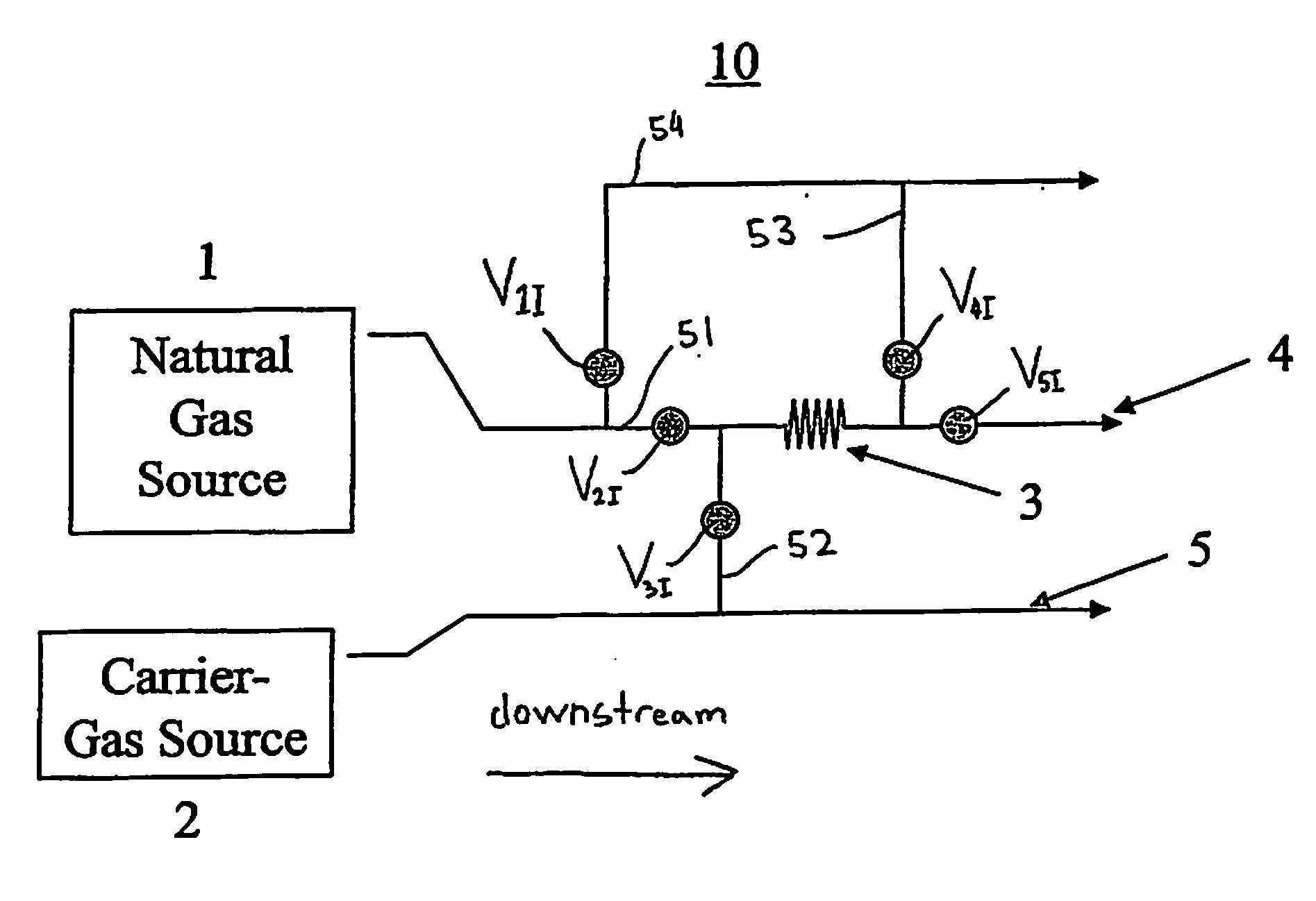

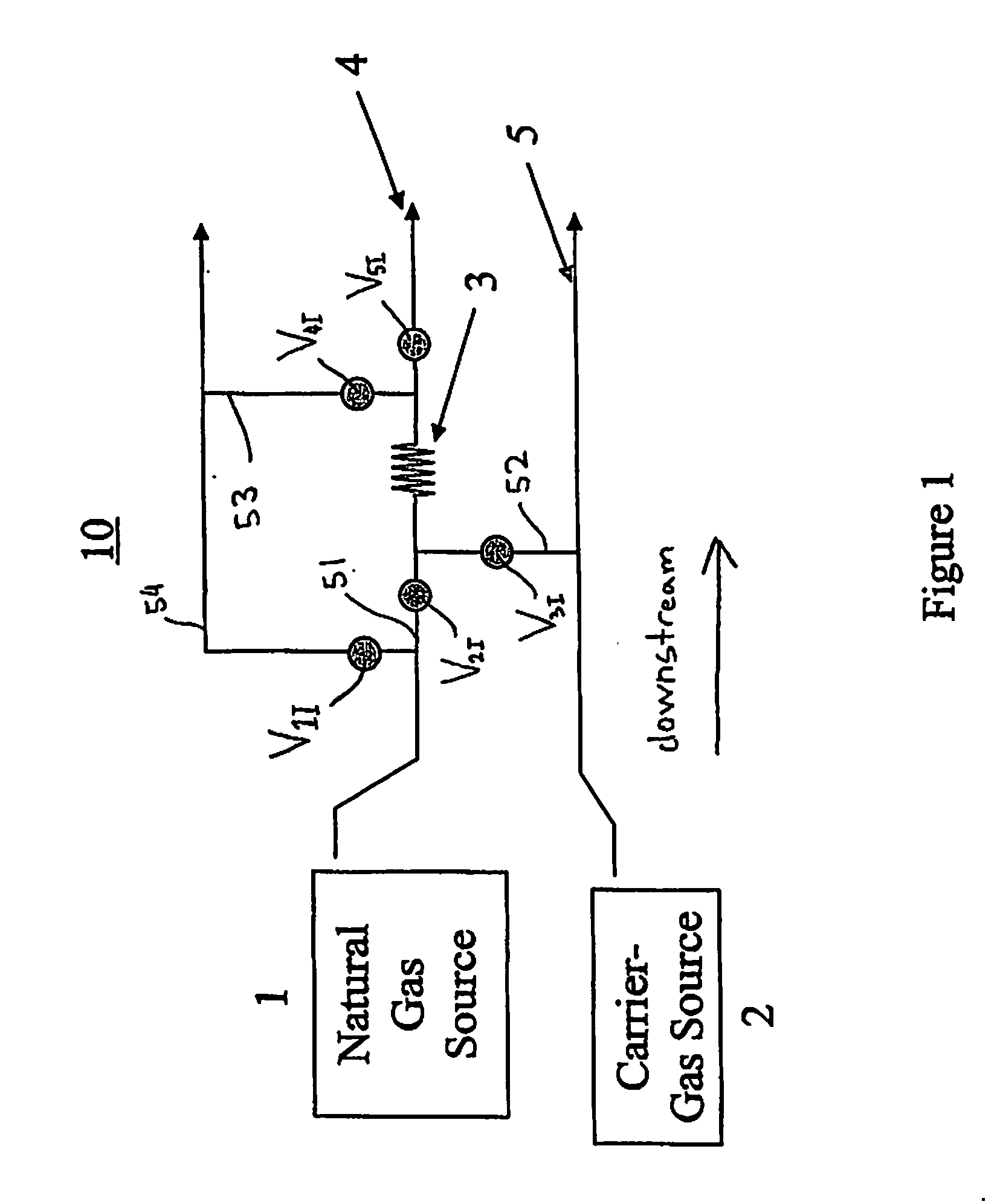

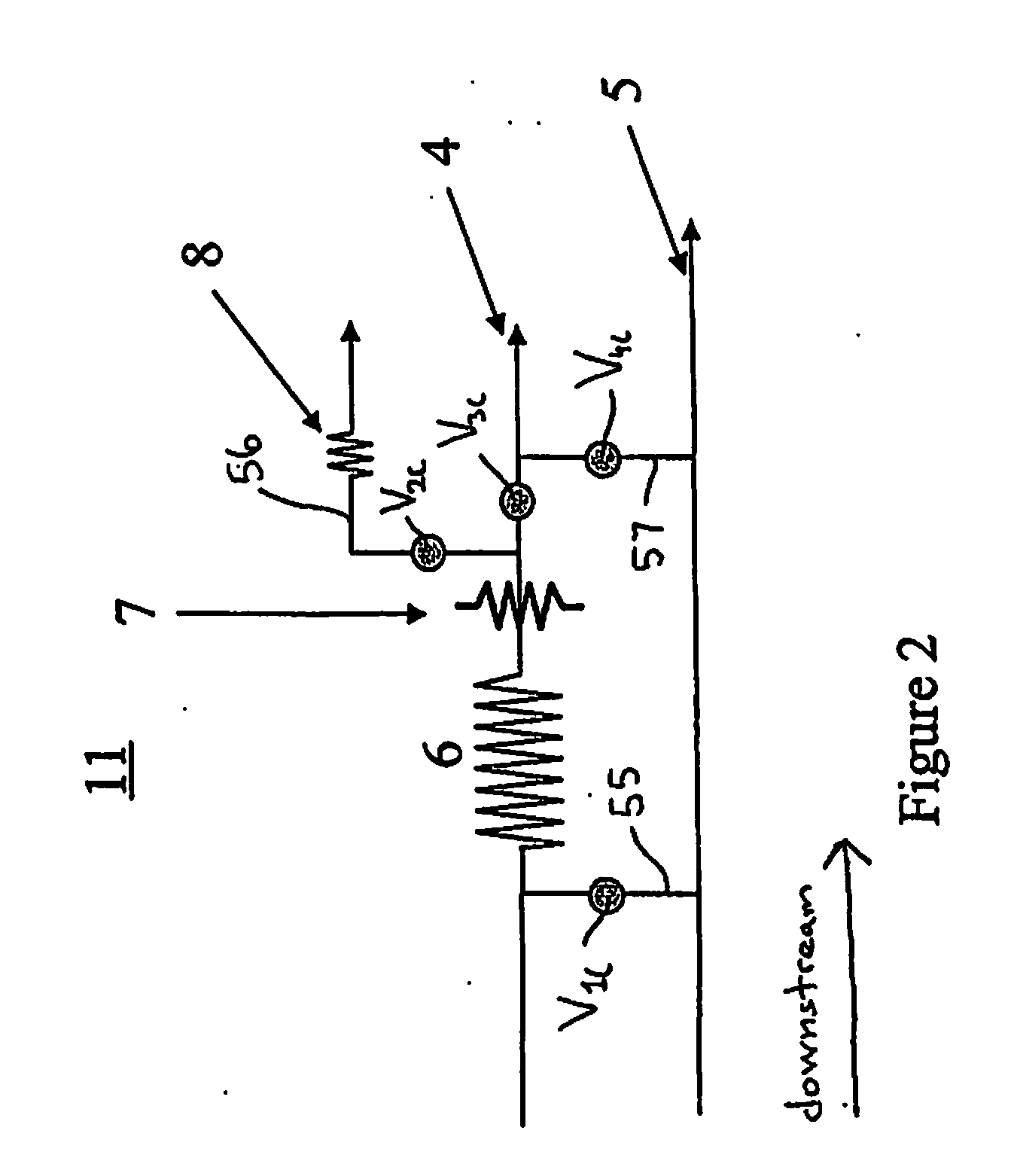

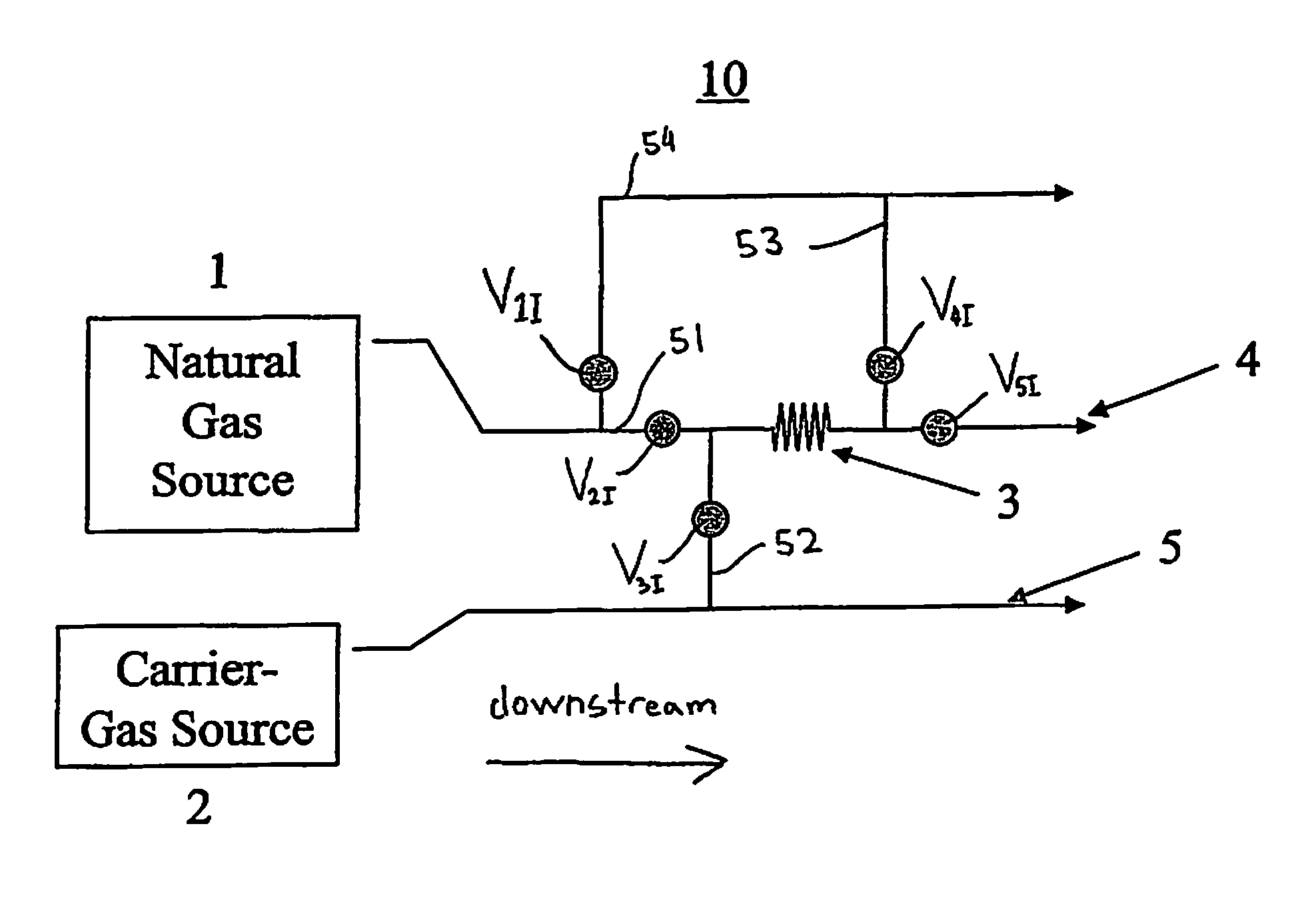

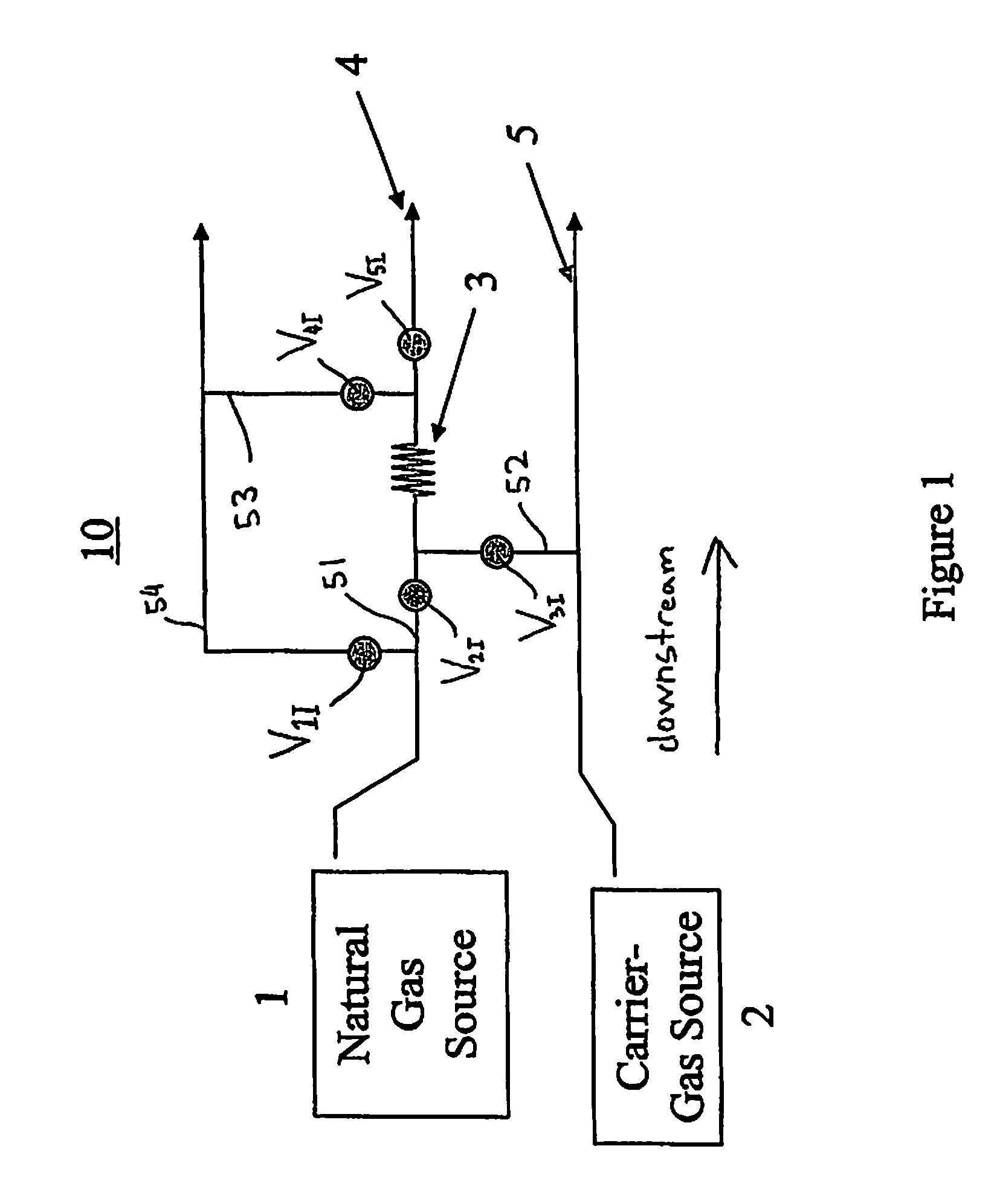

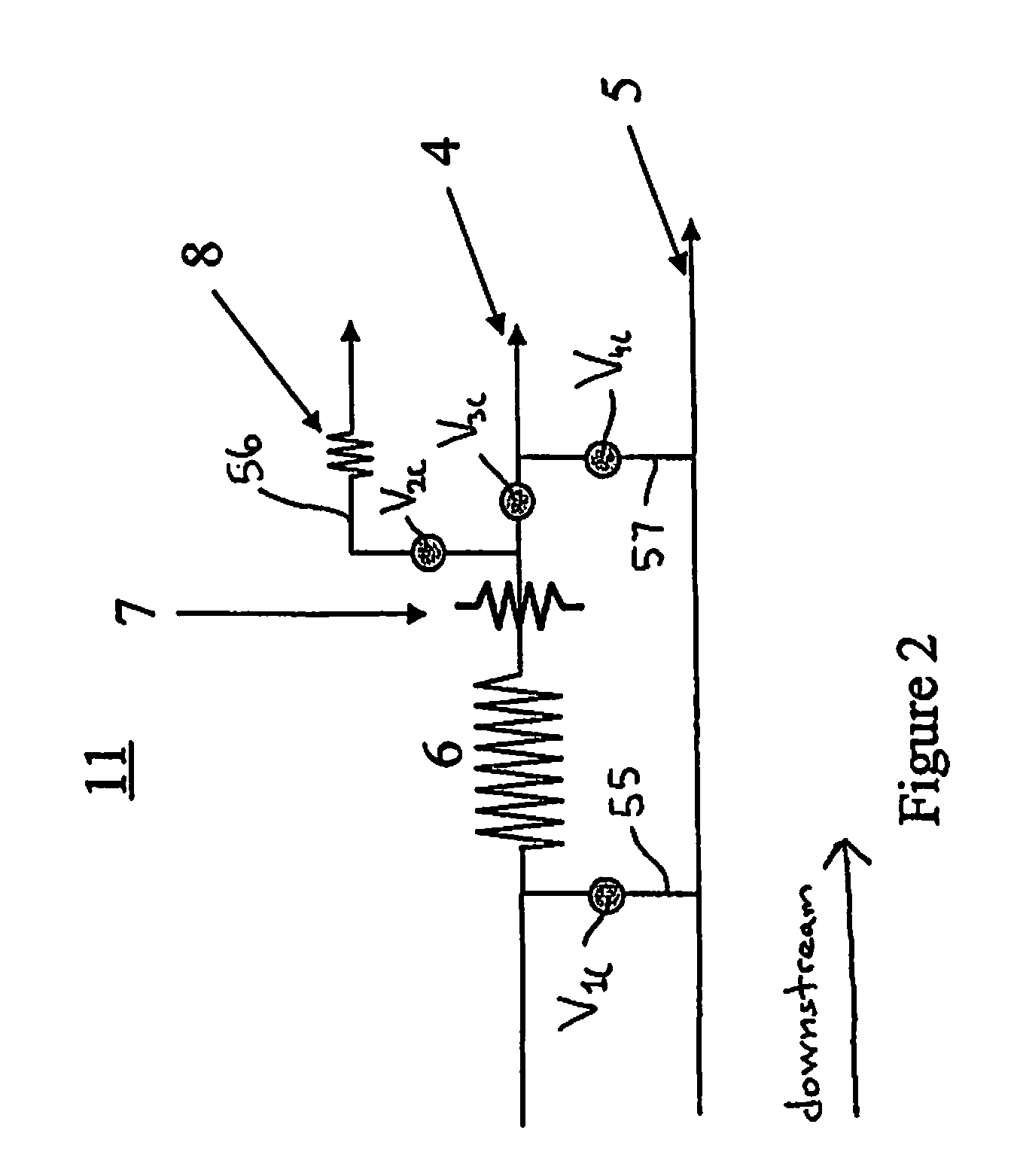

Natural gas analyzer on a micro-chip

A miniaturized gas analyzer formed onto a micro-chip and a method of separating components from a composite gas using the miniaturized gas analyzer are disclosed. The gas analyzer includes an injector block and two column blocks arranged in series along an analytical path. The injector block receives the composite gas and a carrier gas to create a gas sample. The gas sample is then injected into the column blocks to separate the components of the composite gas. Further, a valve used within the miniaturized gas analyzer is disclosed, in which the valve is formed onto the micro-chip and includes a flexible membrane and a rigid substrate.

Owner:SCHLUMBERGER TECH CORP

Natural gas analyzer on a micro-chip

A miniaturized gas analyzer formed onto a micro-chip and a method of separating components from a composite gas using the miniaturized gas analyzer are disclosed. The gas analyzer includes an injector block and two column blocks arranged in series along an analytical path. The injector block receives the composite gas and a carrier gas to create a gas sample. The gas sample is then injected into the column blocks to separate the components of the composite gas. Further, a valve used within the miniaturized gas analyzer is disclosed, in which the valve is formed onto the micro-chip and includes a flexible membrane and a rigid substrate.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com