Optical absorption gas analyser

a gas analyser and optical absorption technology, applied in the field of optical absorption gas analysers, can solve the problems of low cost design, inability to provide any kind of compensation for instrument drift, and inability to provide a separate, sealed gas reference cell containing inert gas, etc., and achieve the effect of economising battery power and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

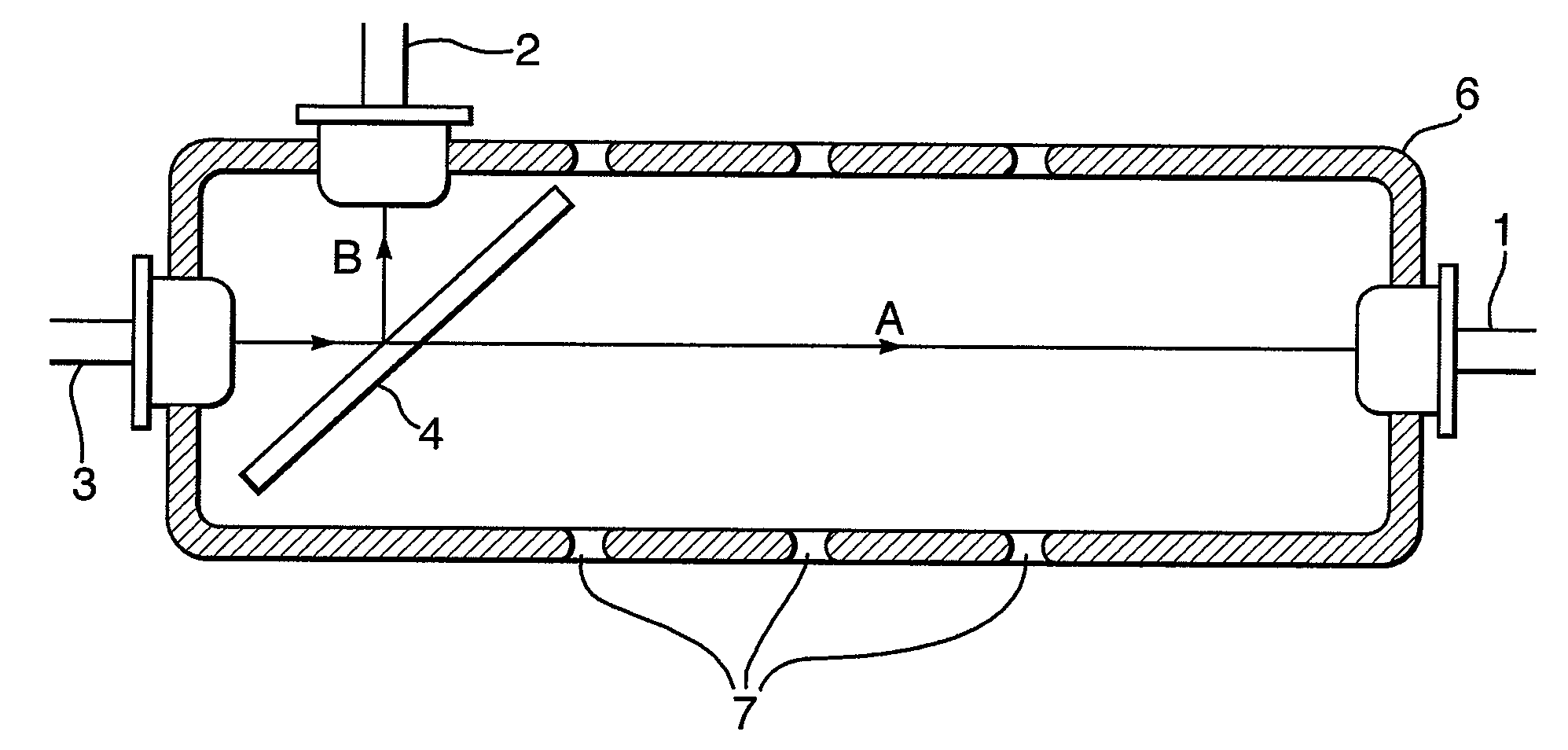

[0053]The first embodiment, shown in FIG. 1, implements a simple, linear design. An elongate chamber 6 is provided for containing a gas sample in use. In this example, the chamber 6 has a number of apertures 7 for gas ingress, which enables fluid communication between the interior of the chamber 6 and the surrounding atmosphere. A radiation source 3, in this case an InGaAs, PbS, or PbSe-based LED, is arranged at one end of the chamber 6 and is opposed by a first radiation detector 1, such as a photovoltaic detector, at the far end of the chamber 6. Radiation emitted by source 3 passes through the chamber 6 on a first optical path A to reach the first detector 1.

[0054]A light guiding assembly comprising a partially-reflective element in the form of semi-silvered mirror 4 is disposed between the radiation source 3 and the first detector 1 so as to intercept the radiation emitted by the source 3. Part of the radiation passes through the semi-silvered mirror 4 to continue on the first o...

second embodiment

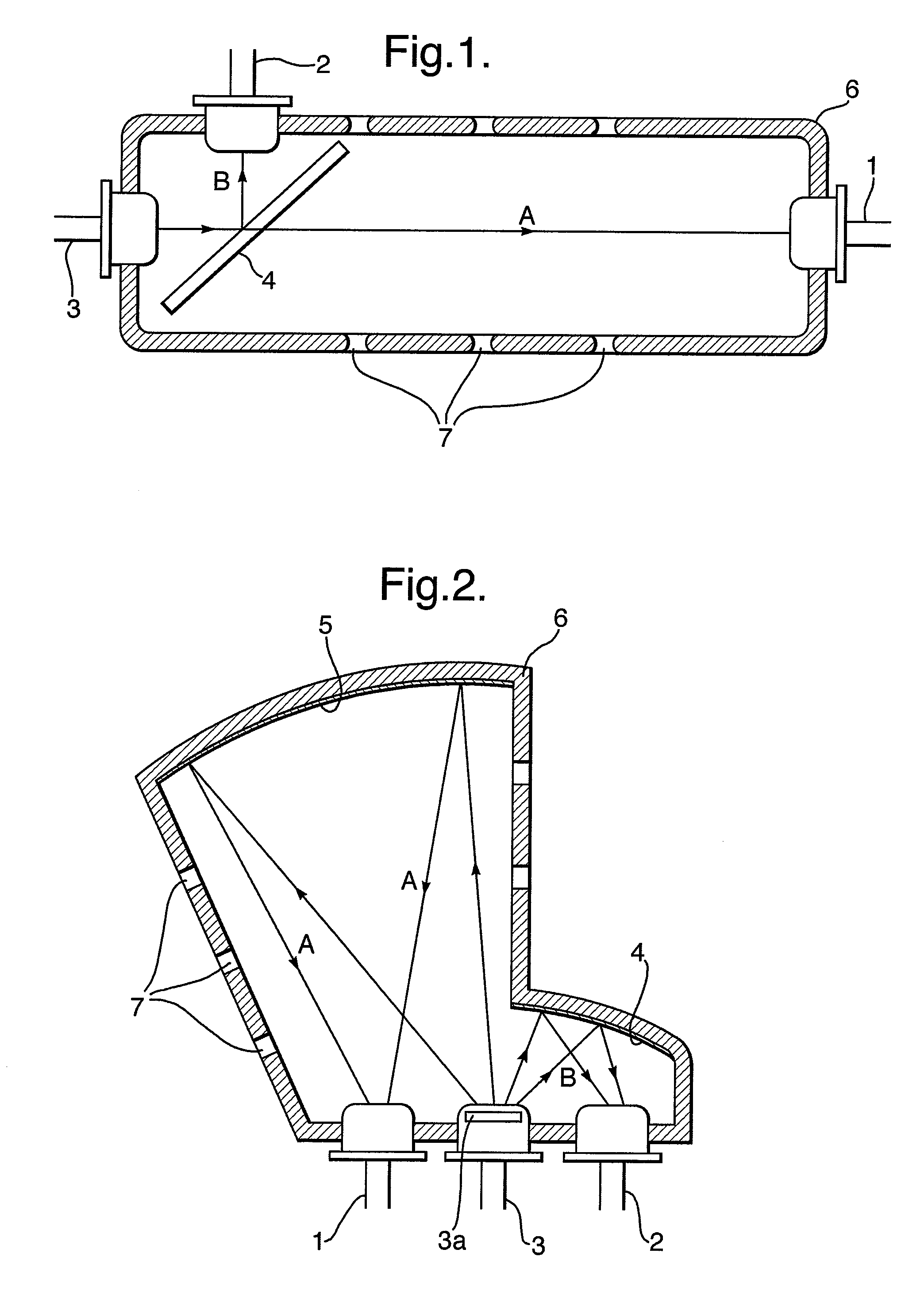

[0066]A second embodiment, shown in FIG. 2 (components equivalent to those in FIG. 1 retain the same reference numerals), is much improved in this sense, because photodetectors 1 and 2 are disposed close to one another, and on the same surface of the chamber 6.

[0067]This compact, temperature-stable design uses a light guiding assembly in the form of reflective mirrors 4 and 5. The chamber 6 is shaped so as to support a first mirror 4 close to the radiation source 3. The mirror intercepts only a portion of the radiation emitted by the source 3 and reflects it towards a photodetector 2 along a short optical path B. Radiation not intercepted by the first mirror 4 crosses a wide portion of the chamber 6 where it is reflected by a second mirror 5 towards another detector 1 along a longer optical path A. The long optical path A constitutes the sensing channel, and the short optical path B represents the reference channel.

[0068]The mirror elements 4 and 5 may comprise mirrors affixed to th...

third embodiment

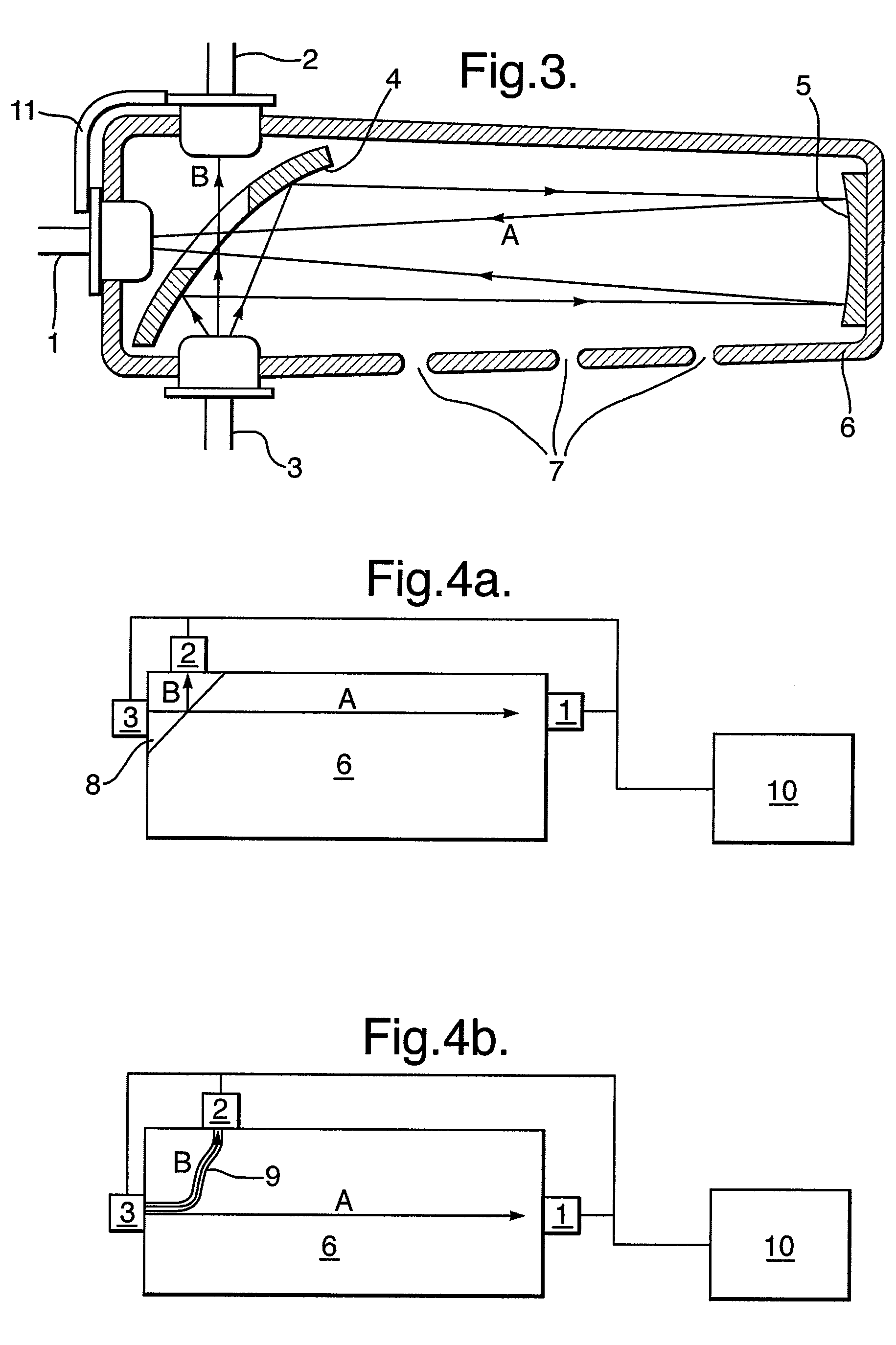

[0072]A third embodiment shown in FIG. 3, improves the temperature accuracy still further by the use of a thermal conductor 11 connecting the first and second detectors 1 and 2. In this way the photodetectors will have good thermal contact, leading them to remain in thermal equilibrium and maintain the same temperature as each other with a good accuracy.

[0073]The third embodiment makes use of a light guiding assembly comprising a partially reflective mirror 4 arranged adjacent the radiation source 3. As in the case of the second embodiment, the radiation source 3 may include a filter (not shown), such as a narrow bandwidth interference filter, adjusted to pass a radiation waveband corresponding to (at least including) an absorption line of the target gas. The reflected portion of the radiation is directed towards a mirror 5 arranged at the far end of the elongate chamber 6. The radiation is reflected back towards a first detector 1, passing through a transparent window in the partia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com