Gas analyzing apparatus with built-in calibration gas cell

An analysis device and gas chamber technology, applied in the field of gas analysis devices, can solve the problems of theoretical consistency, limited optical adjustment, etc., and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

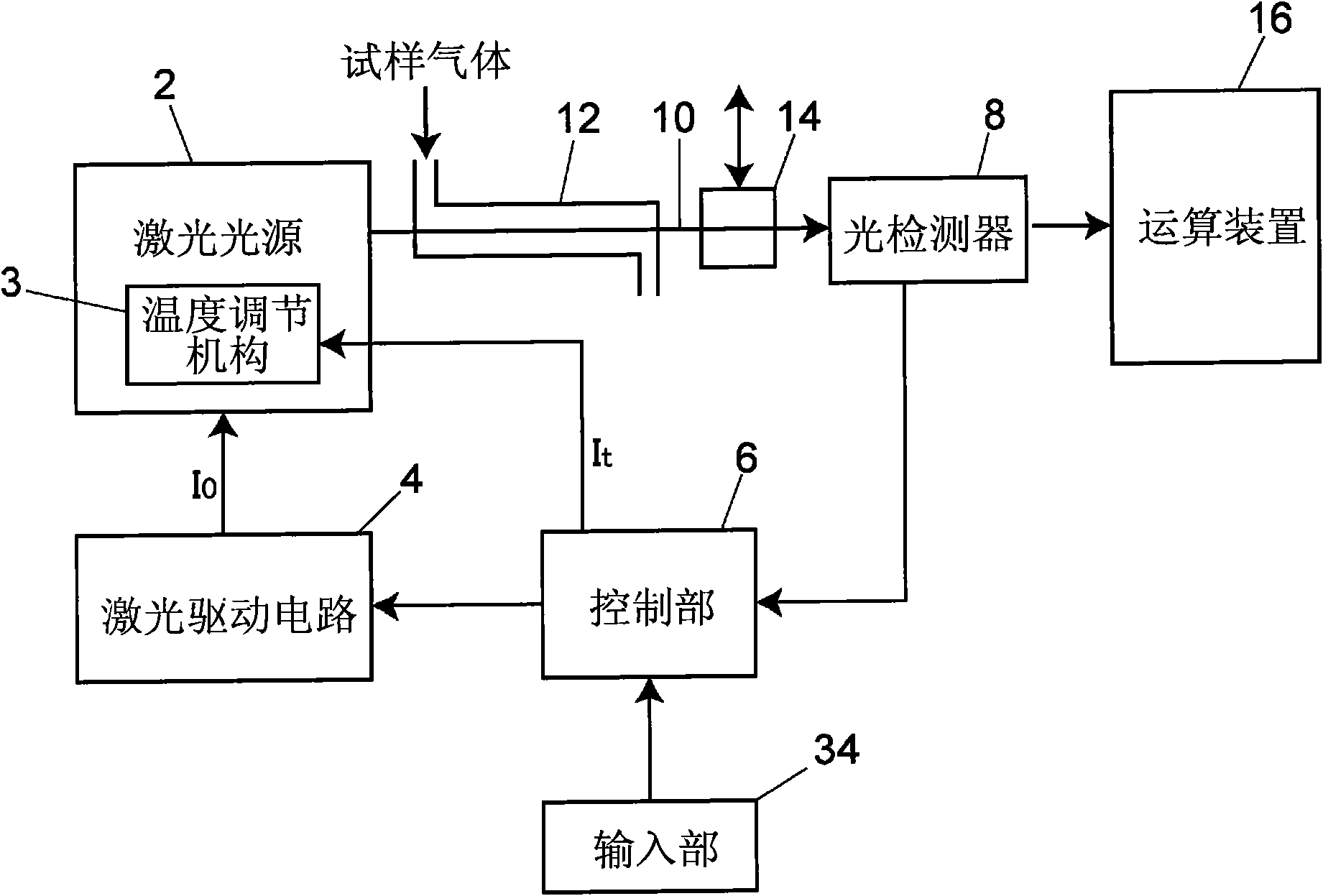

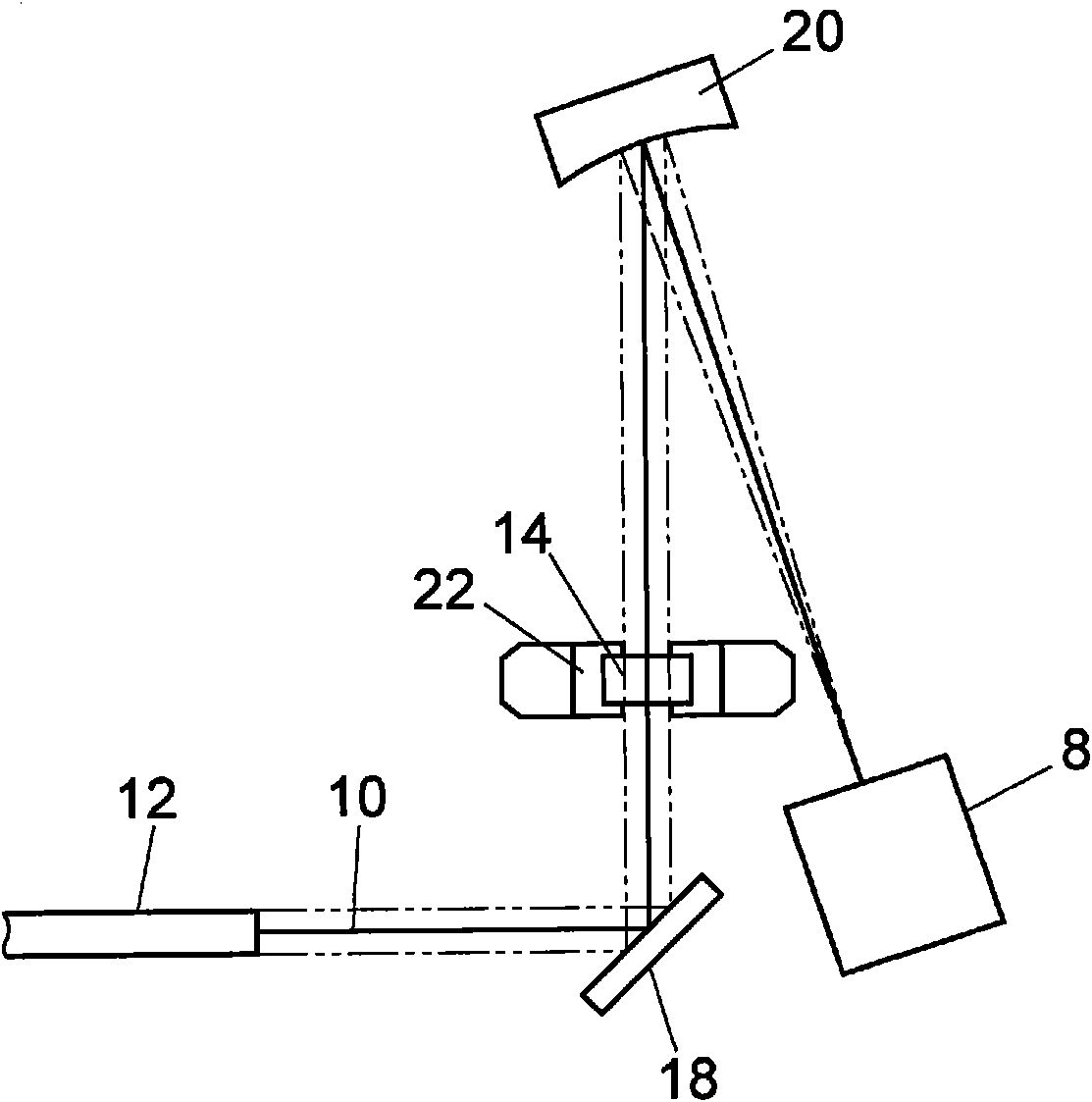

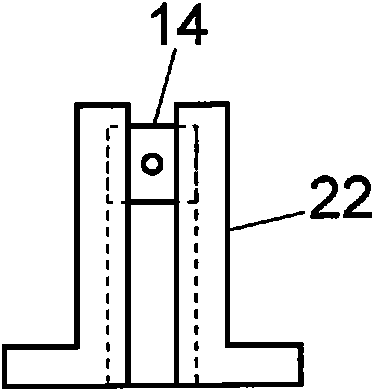

[0044] figure 1 An analysis device according to one embodiment is schematically shown. In the present embodiment, the laser light source 2 that generates laser light as measurement light having a specific wavelength absorbed by a measurement object component in the sample gas is a DFB laser diode capable of changing wavelength. The type of laser light source capable of changing the wavelength is not particularly limited. In order to adjust the temperature of the laser body of the laser light source 2, the laser light source 2 incorporates a temperature adjustment mechanism 3 composed of a Peltier element.

[0045] The laser light source drive control device for controlling the drive of the laser light source 2 includes a laser drive circuit 4 and a control unit 6 composed of an arithmetic processing circuit or a dedicated computer or a general-purpose personal computer. The laser driving circuit 4 provides a fixed reference current Io as a driving current for driving the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com