Measuring unit and gas analyzer

A technology of measurement unit and analysis device, which is applied to the construction details of measurement devices and gas analyzers, and analysis materials, etc., which can solve the problem of inability to obtain stable signals and measurement of light. internal issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

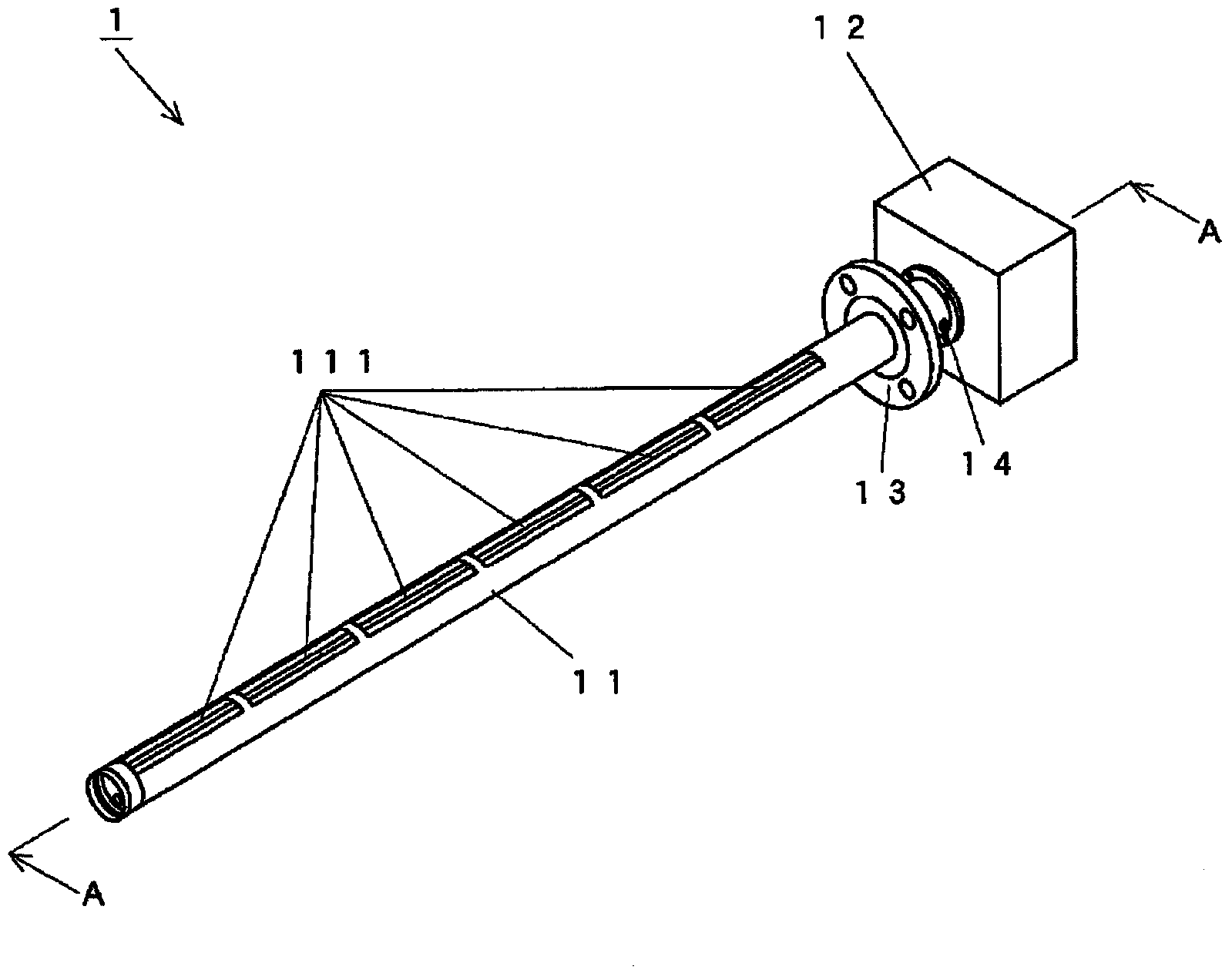

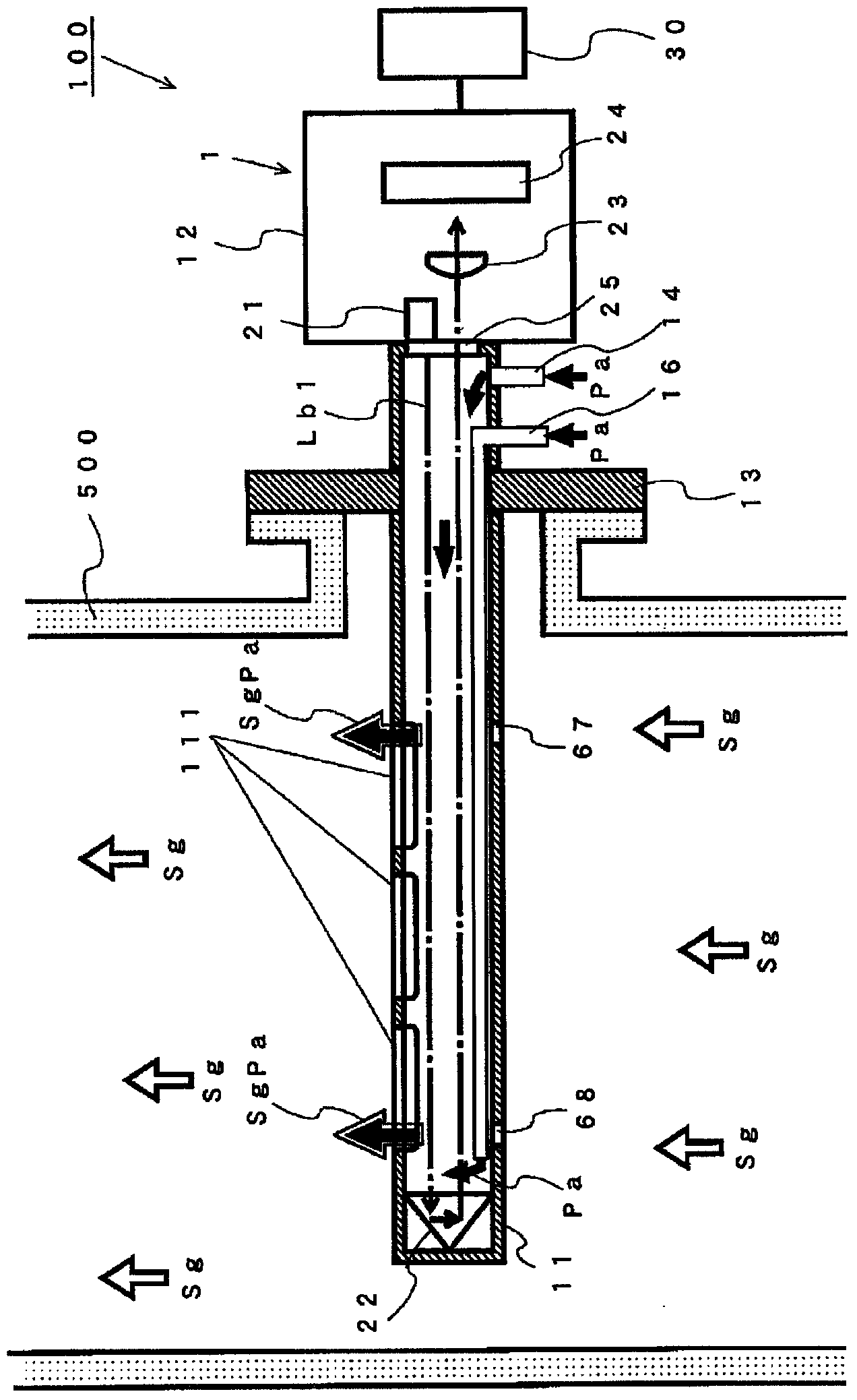

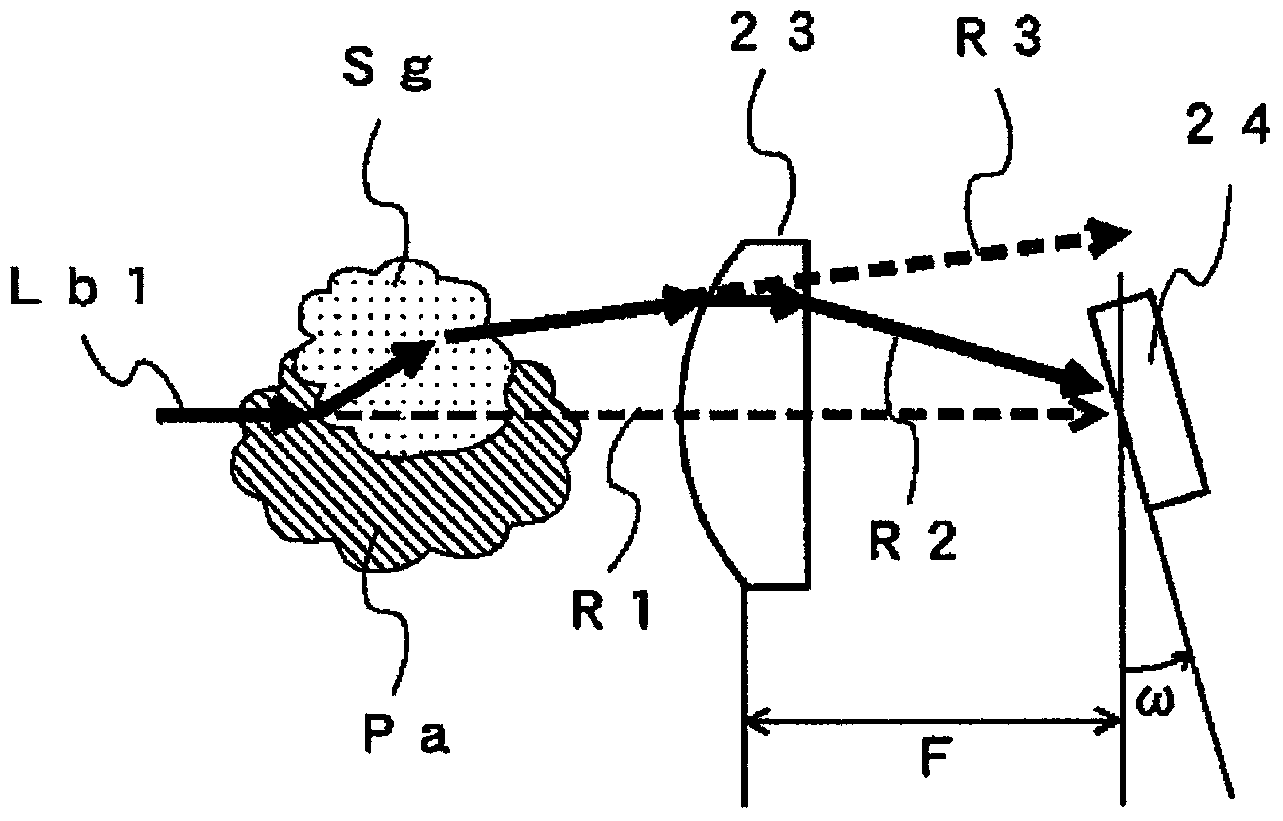

[0057] Next, the measurement unit 1 and the gas analysis device 100 using the measurement unit 1 will be described. The gas analysis device 100 is a so-called probe type gas analysis device, and the measurement unit 1 is a so-called probe unit. First, refer to figure 1 and figure 2 , the structure of the measurement unit 1 will be described. figure 1 It is an external configuration diagram of the measurement unit 1 of the first embodiment. also, figure 2 It is a sectional view showing the internal structure of the measurement unit 1 of the first embodiment. in addition, figure 2 is included figure 1 A diagram of the section A-A of the measuring cell 1 is shown. Such as figure 1 As shown, the measurement unit 1 includes a probe tube 11 , an optical unit 12 and a flange 13 .

[0058] The probe tube 11 is a cylindrical member, and is provided with an introduction hole 111 through which the sample gas Sg is introduced into the interior by diffusion. The material o...

no. 2 approach )

[0083] In the first embodiment described above, an example in which the present invention is applied to a probe-type measuring unit has been described, but the present invention may also be applied to an aperture-type measuring unit. Next, the measurement unit 2 of the second embodiment and the gas analysis device 200 using the measurement unit 2 will be described. In addition, the same reference numerals are assigned to the same structures as those of the above-mentioned first embodiment, and detailed description thereof will be omitted.

[0084] Figure 8 It is a sectional view showing the internal structure of the measurement unit 2 of the second embodiment. Such as Figure 8 As shown, the measuring unit 2 is composed of an oscillator unit 32 and a detector unit 33 formed as a single body. The oscillator unit 32 is installed on one side of the chimney 500 through which the sample gas Sg flows, and the detector unit 33 is installed on the other side of the chimney 500 so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com