Patents

Literature

52results about How to "Reduce measurement efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

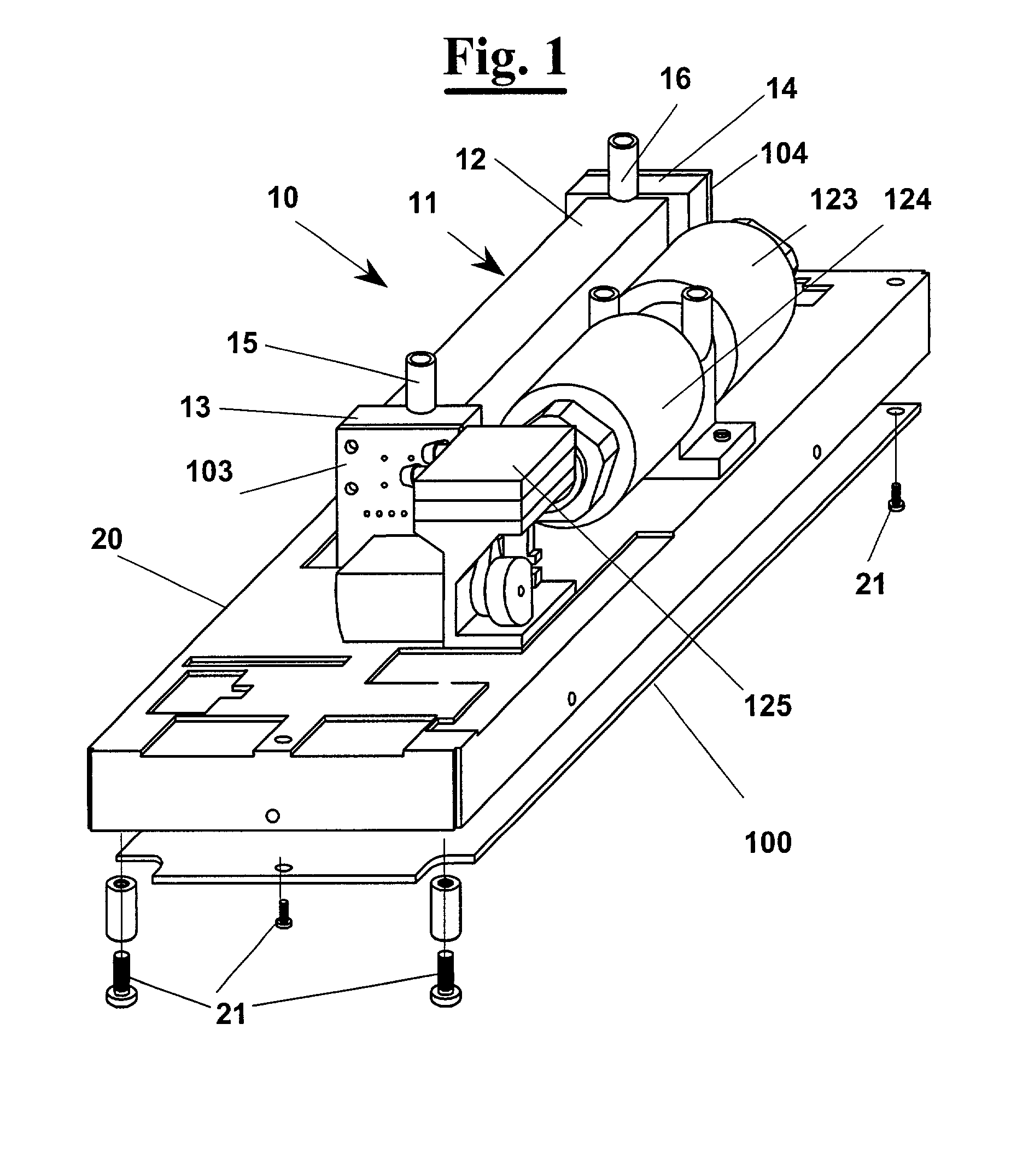

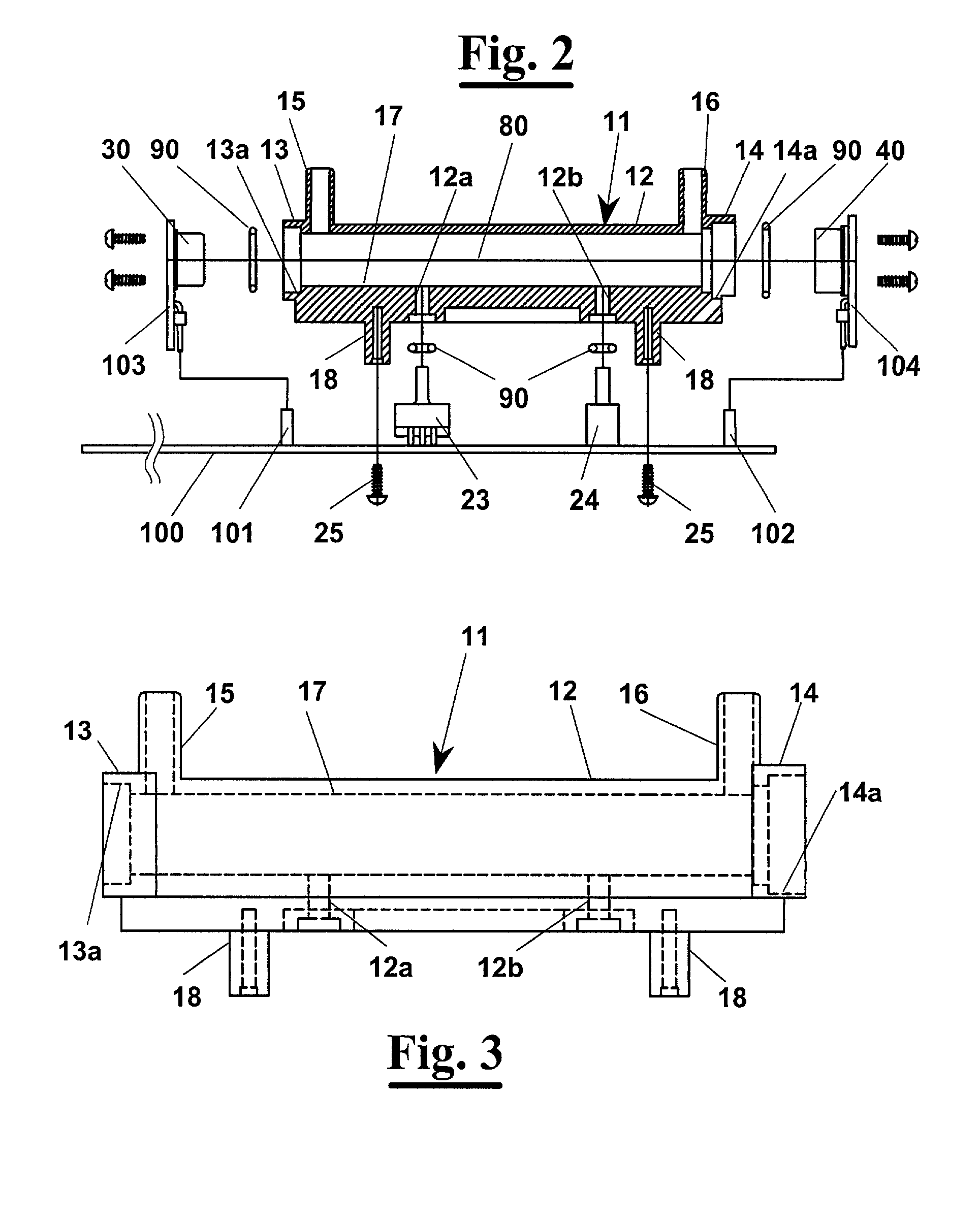

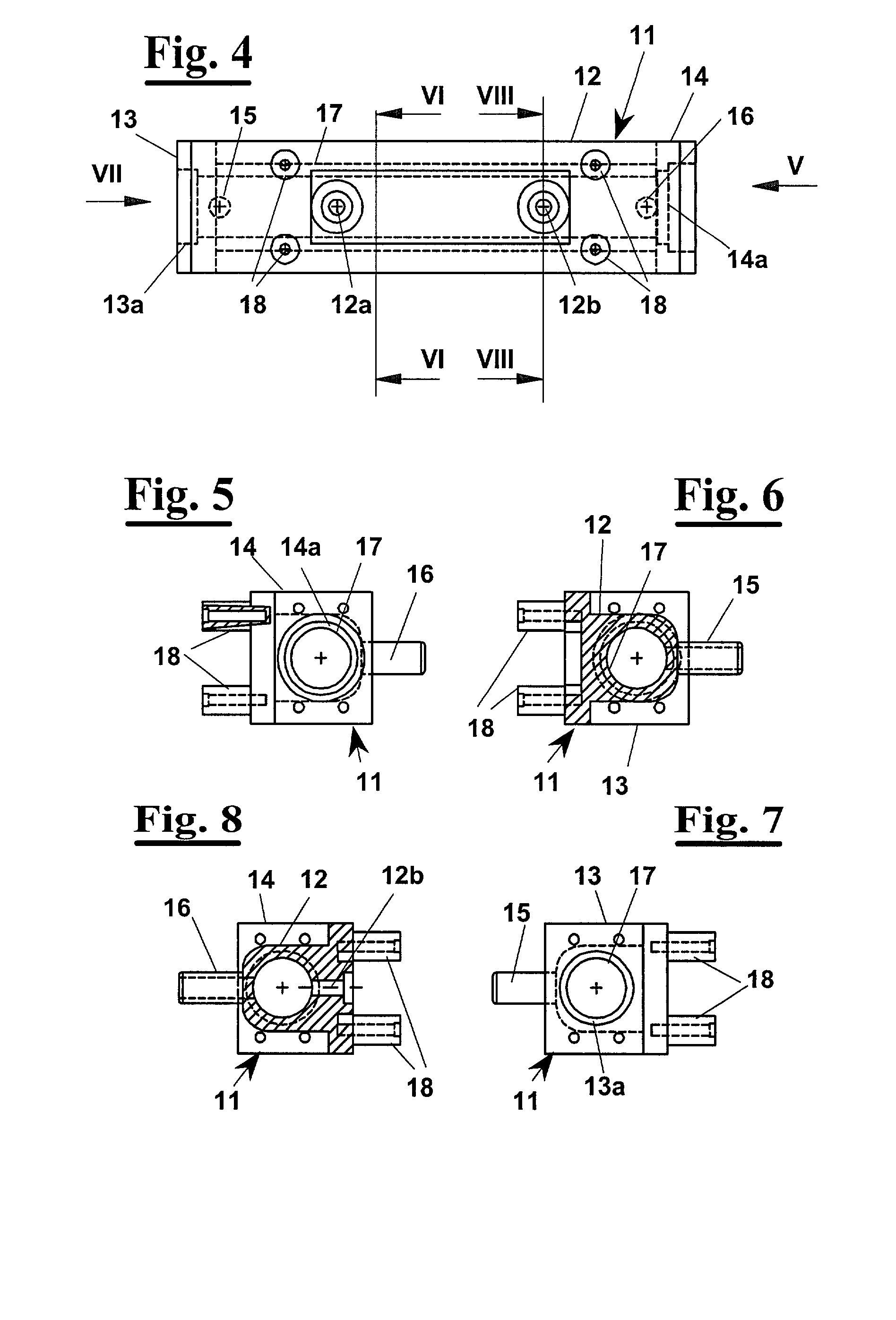

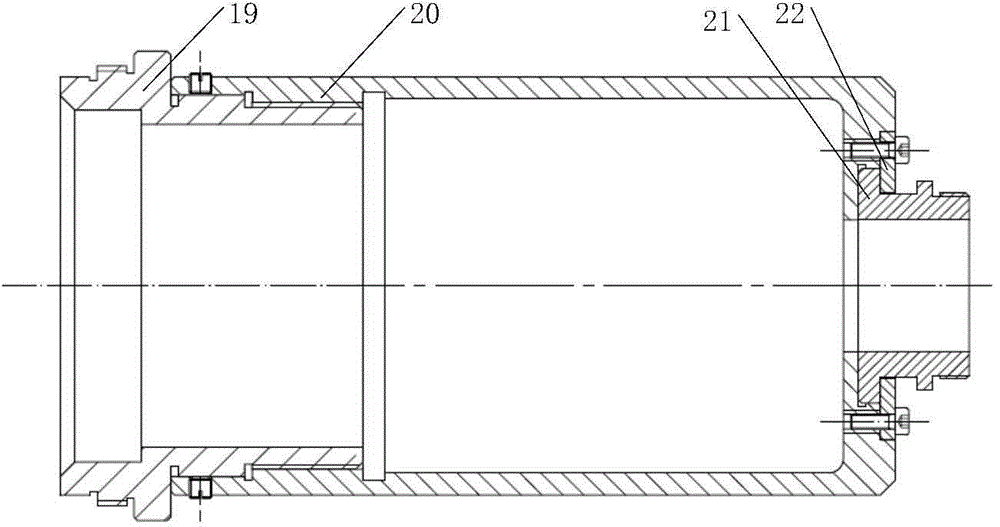

Non-dispersive infrared cell for gas analysis

InactiveUS20010048079A1Complex structureReduce measurement efficiencyRadiation pyrometryTransmissivity measurementsGas analyserPrinted circuit board

A method non-dispersive infrared (NDIR) gas analysis, which can be carried out by a gas analyser comprising a cell (10) containing of gas, a sender (30) of IR waves and at least a receiver (40) of such waves. The transmission of IR waves and / or the reception of IR waves after the passage of the gas occur directly in the cell (10) same wherein the gas is fed. The analyser has a body (11) defining the cell (10), a sender (30) of IR waves and at least a receiver (40) of such waves, that are located opposite to each other with respect to the cell (10). The IR sender (30) and the receiver (40) are both arranged in the cell (10) at its end (13,14). The body (11) has inlet (15) and outlet (16) channels for the gas and a cavity (17), which can be metal coated inside and that defines the optical path (80) for the IR waves. The body (11) is directly mounted on a printed circuit board (100) that has the electronic control unit for transmission of the IR waves and for analysis of the signals coming from the receiver (40).

Owner:BRUNAMOTI MASSIMO +2

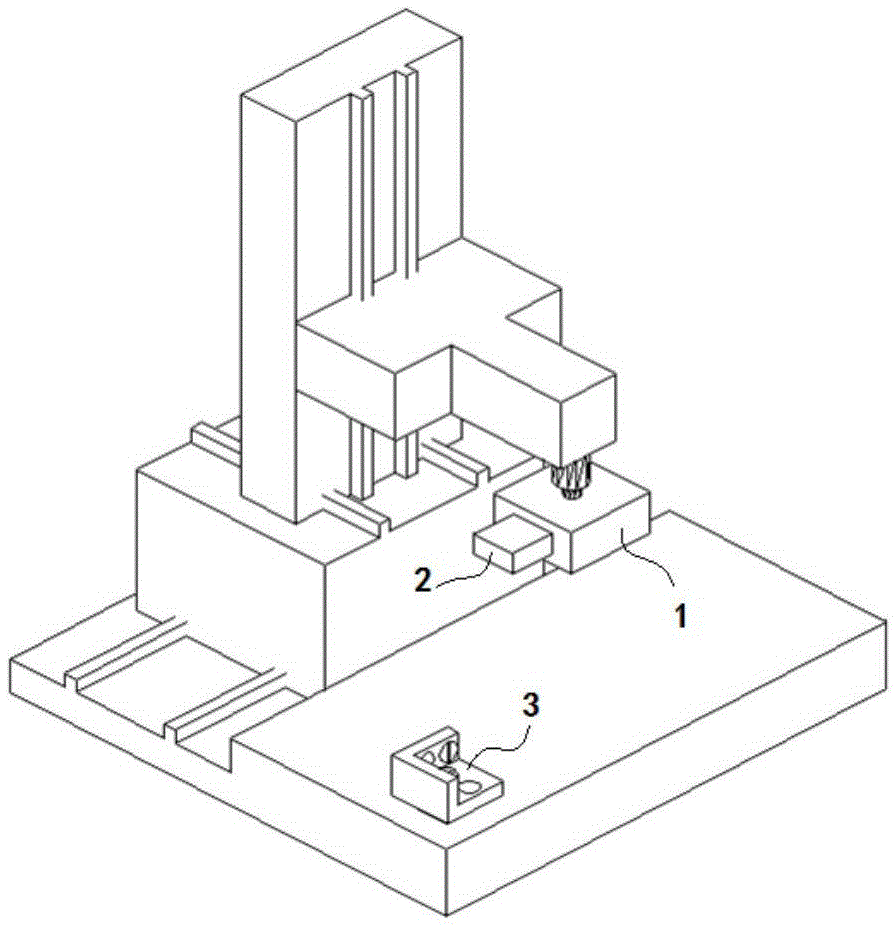

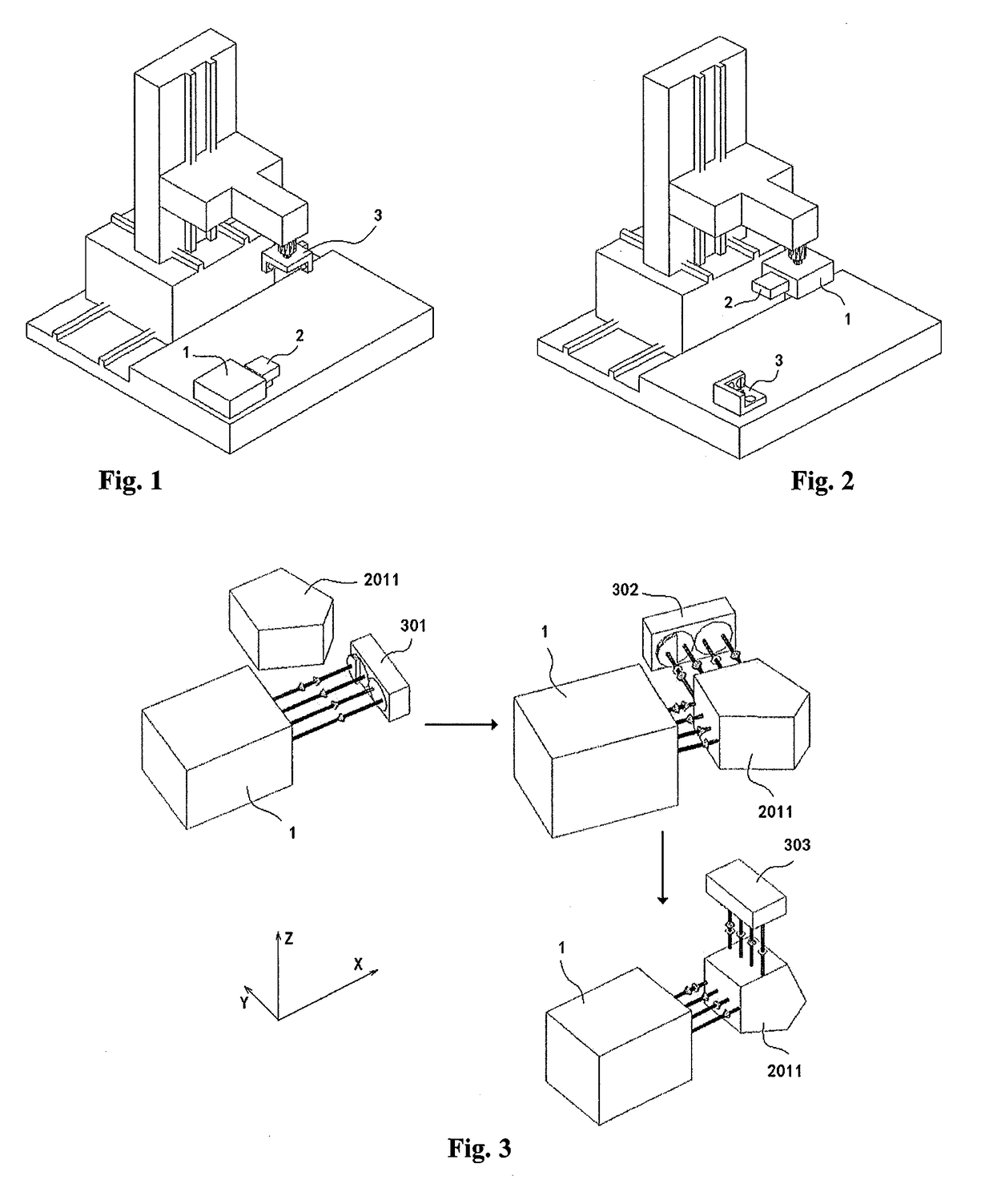

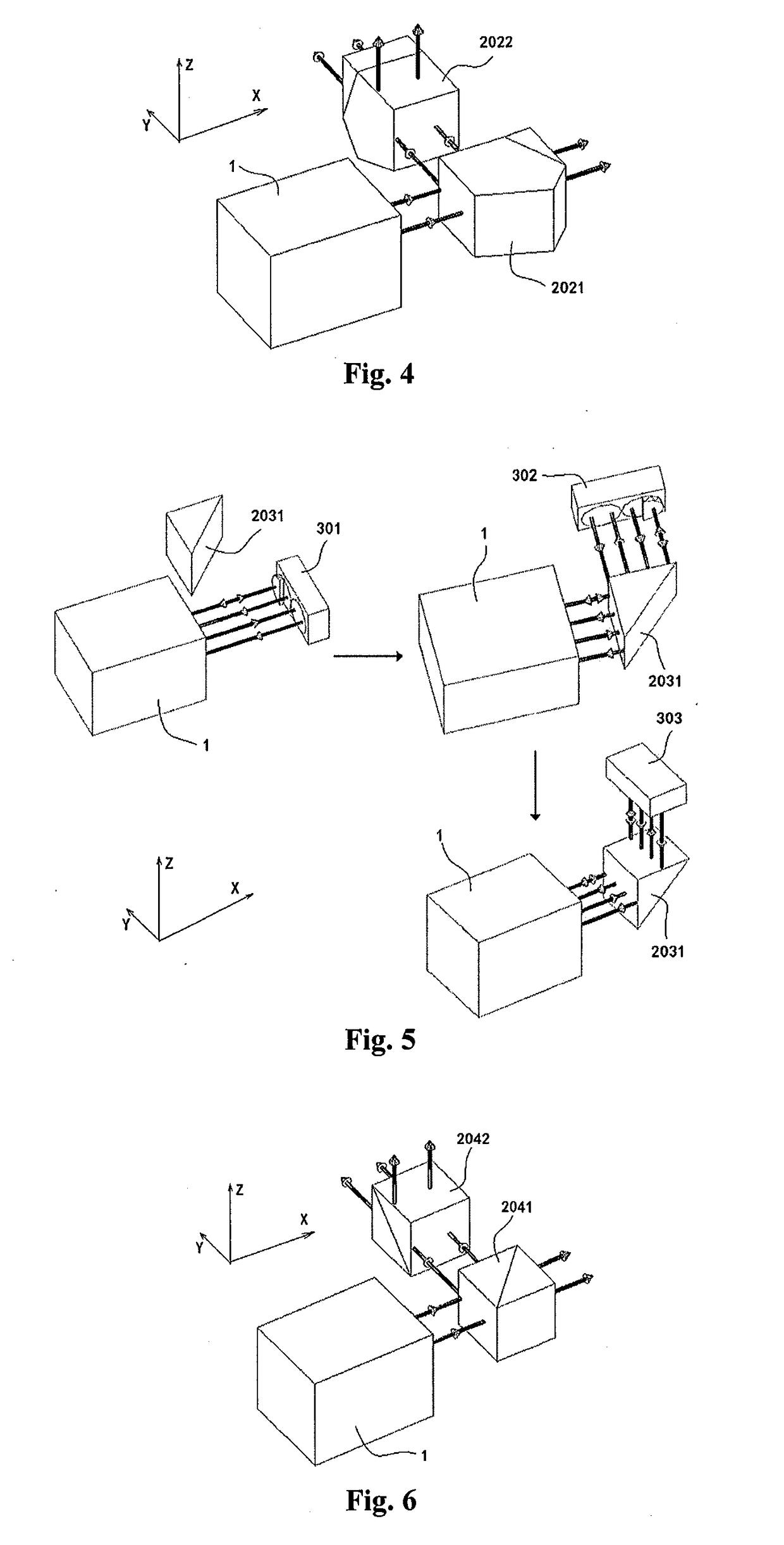

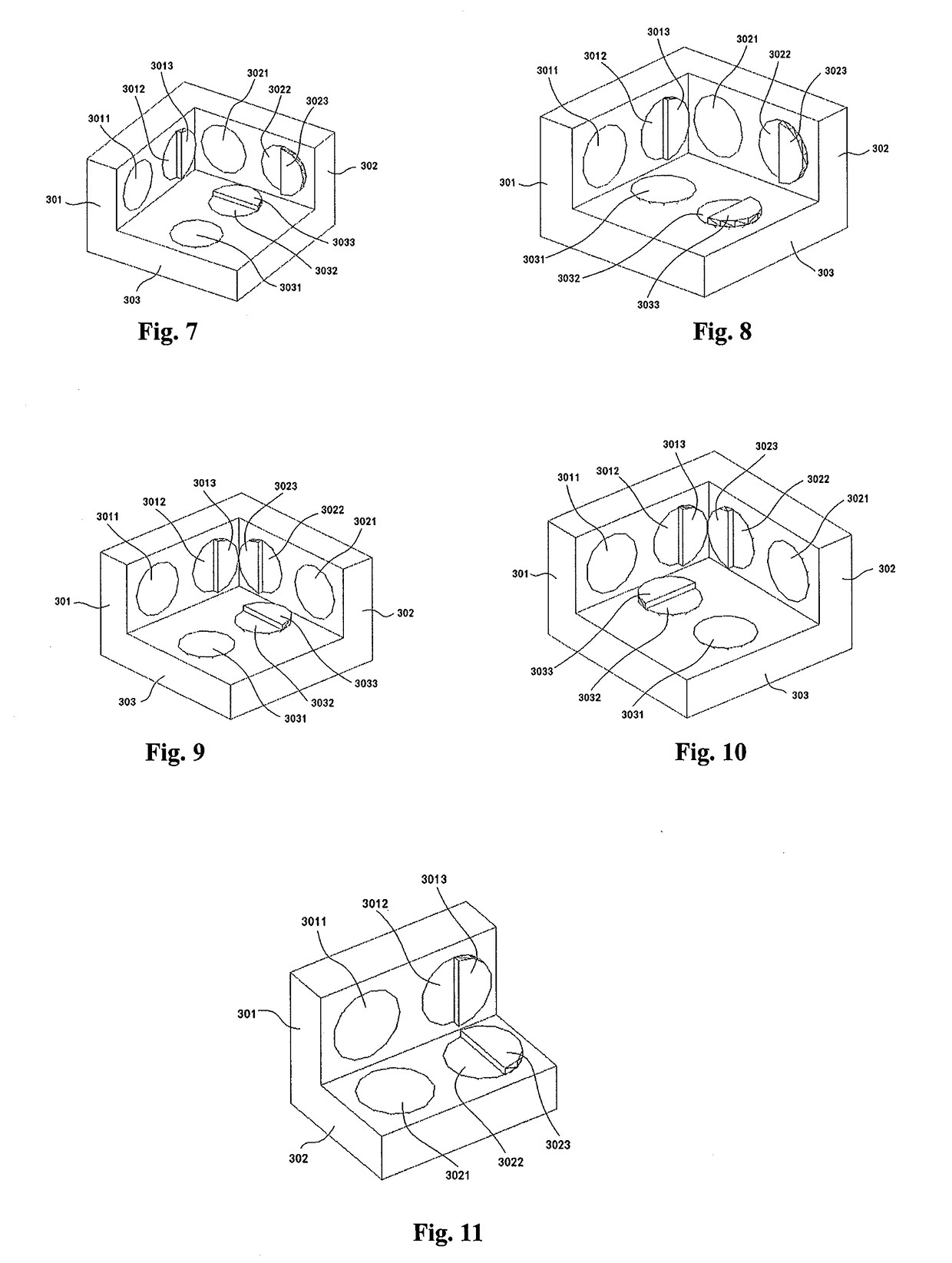

Laser measurement system and method capable of detecting 21 geometric errors

ActiveCN105492860AHighly integratedImprove detection efficiencyAngle measurementInterferometersLight beamEngineering

Owner:BEIJING JIAOTONG UNIV

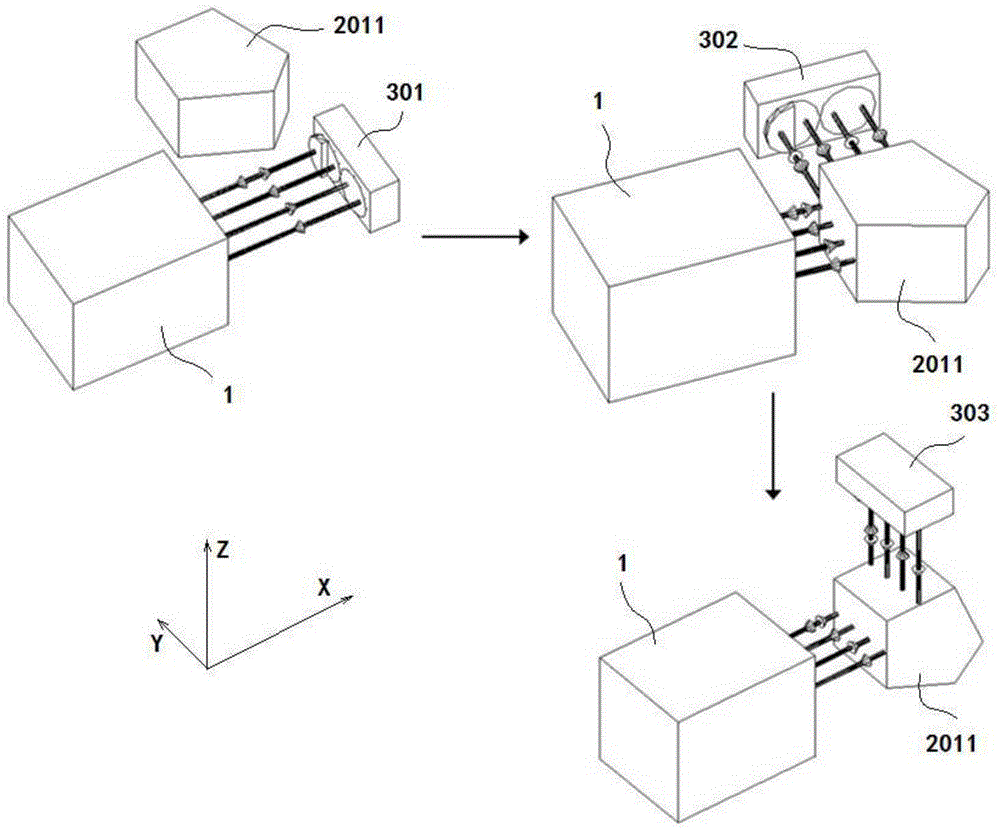

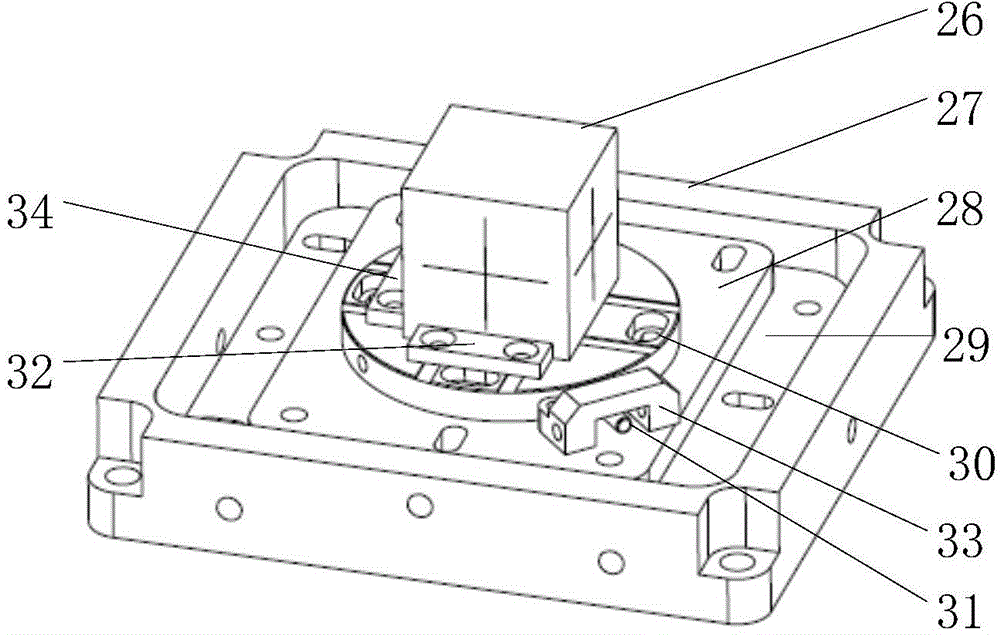

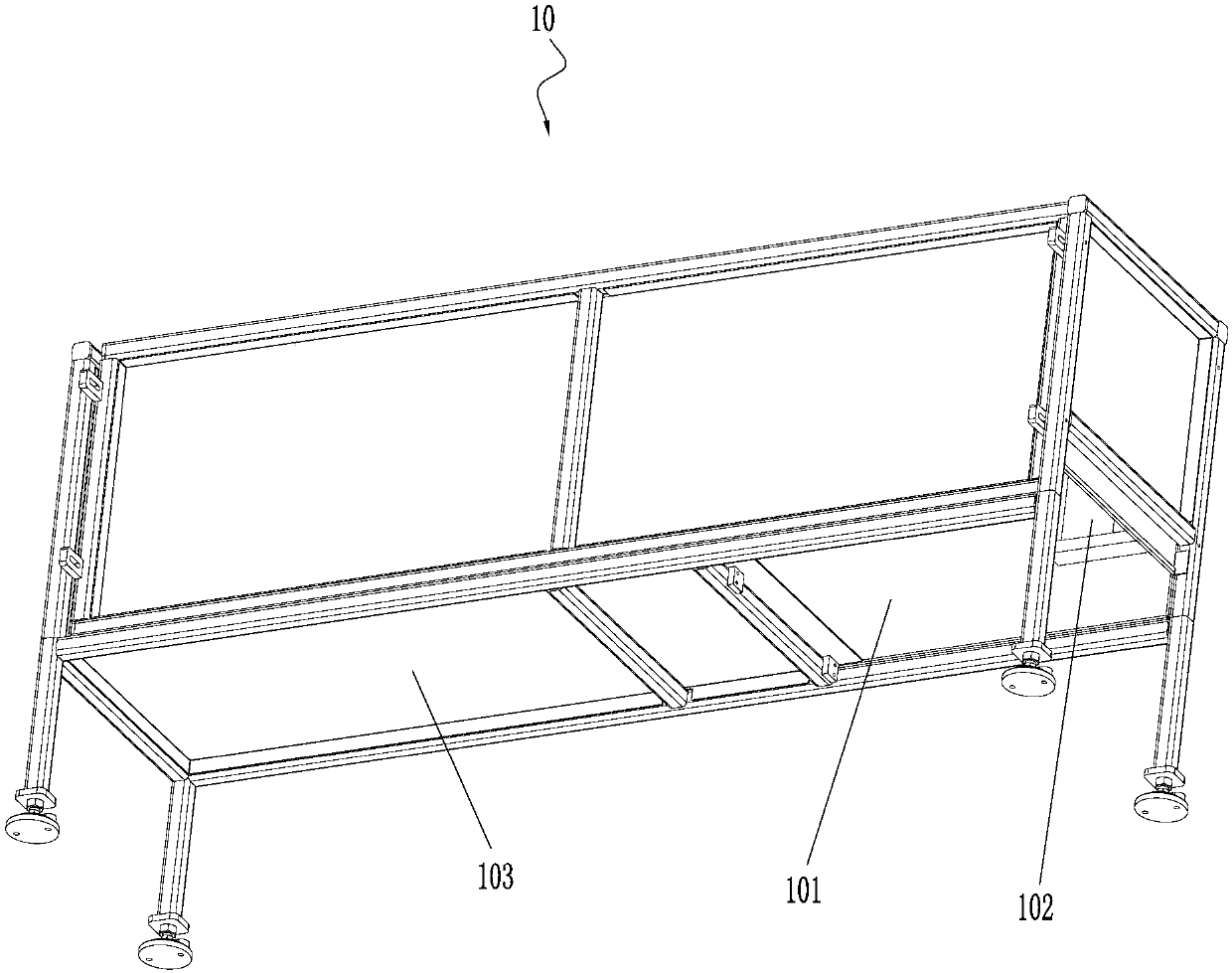

Device for calibrating geometric quantity of static calibration table of wind tunnel balance

ActiveCN104568374AHigh measurement accuracyImprove measurement efficiencyAerodynamic testingGratingEngineering

The invention discloses a device for calibrating geometric quantity of a static calibration table of a wind tunnel balance, belongs to the field of geometric quantity, and is suitable for calibrating geometric parameters of a return mechanism of the static calibration table of the wind tunnel balance, a measurement system and a loading mechanism. According to the device, a loading coordinate system is reproduced by cooperation of a micro-alignment telescope and a reference cubic mirror mounted on a loading head; the micro-alignment telescope is rotated at an angle of 180 degrees by a precise rotary table; a linear guide rail equipped with a double-grating scale is driven to drive the micro-alignment telescope to move and be aligned to a reference line of the loading mechanism, and the geometric parameters of the loading mechanism are measured by data of the double-grating scale, so that the problems of low precision and low efficiency of an existing mounting measurement method are solved; in addition, a lifting mechanism is driven through a spiral lifting machine to adjust the height of the device, so that the calibration needs of geometric parameters of static calibration stables of wind tunnel balances different in type can be met.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

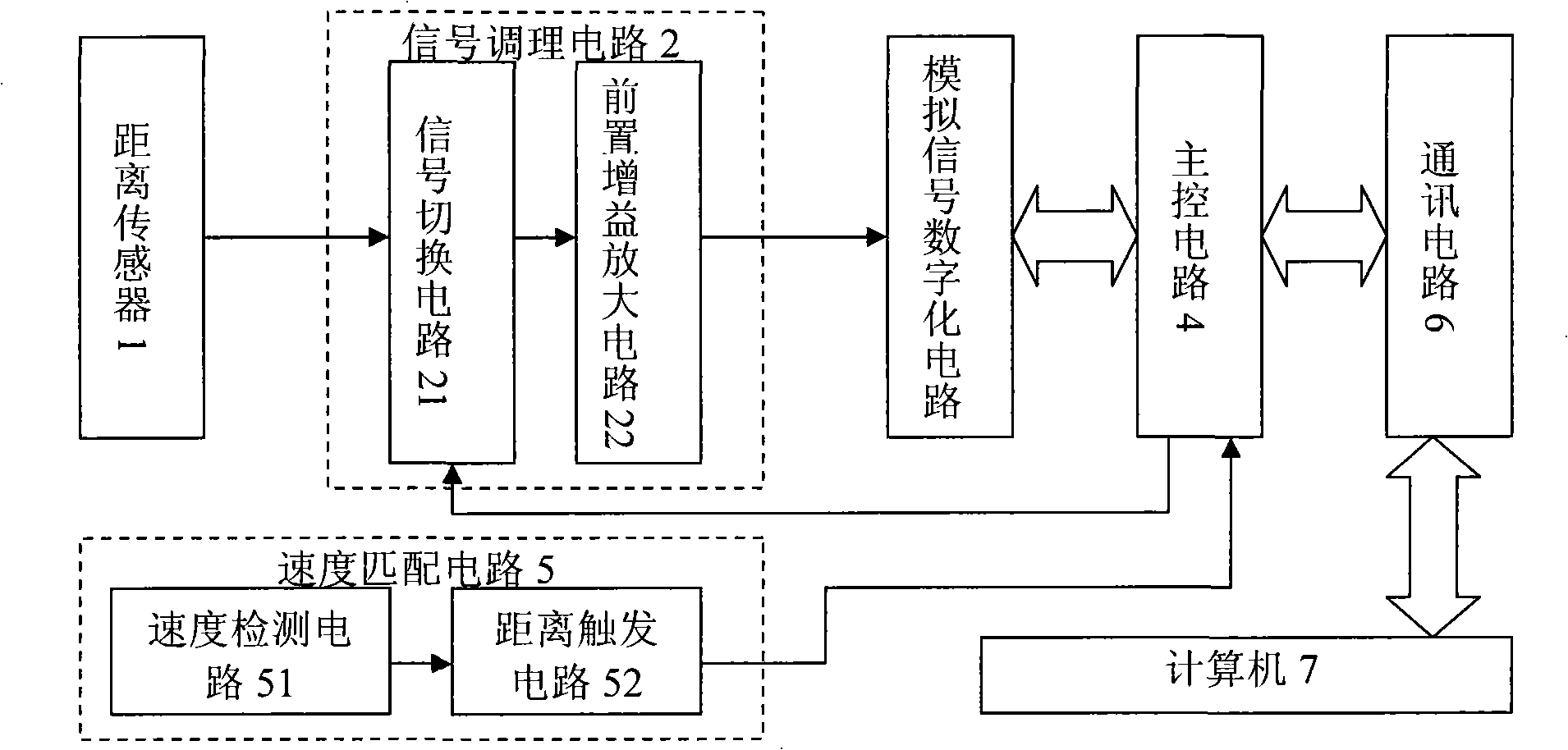

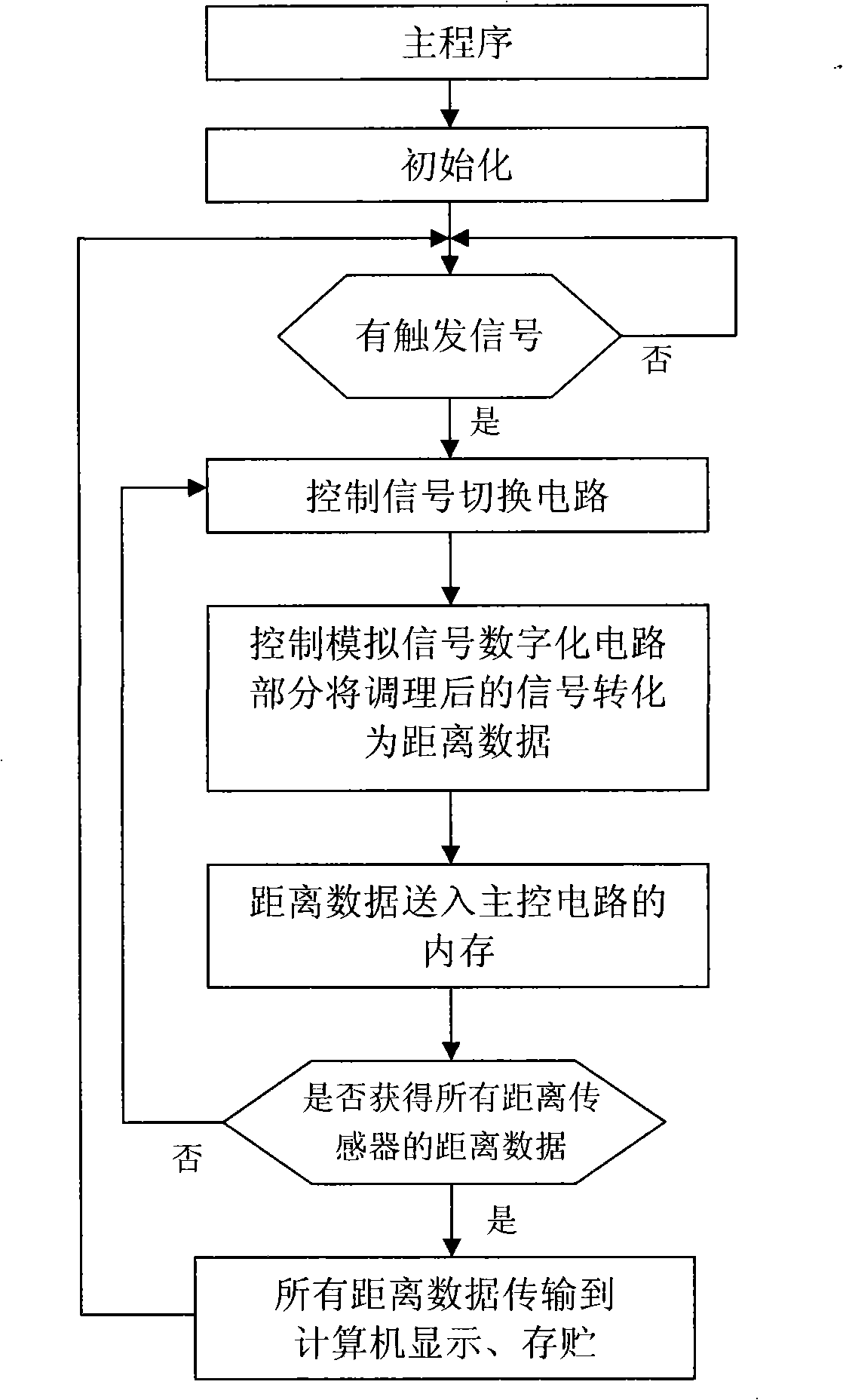

Rut testing instrument and testing method thereof

ActiveCN101302738AImprove detection speed and accuracySolve the detection speed is slowRoads maintainenceElectromagnetic wave reradiationDistance sensorsAnalog-to-digital converter

Owner:HARBIN INST OF TECH

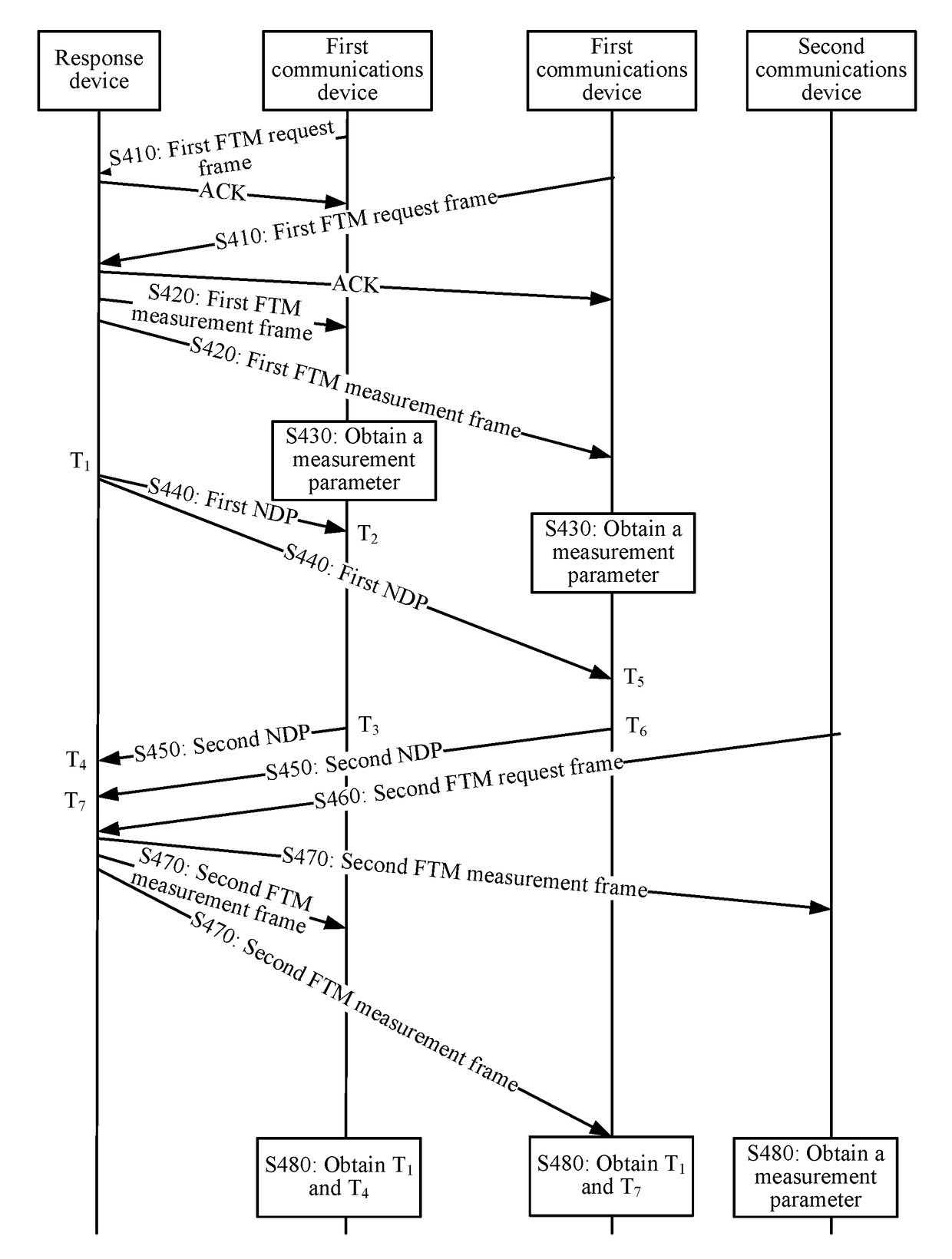

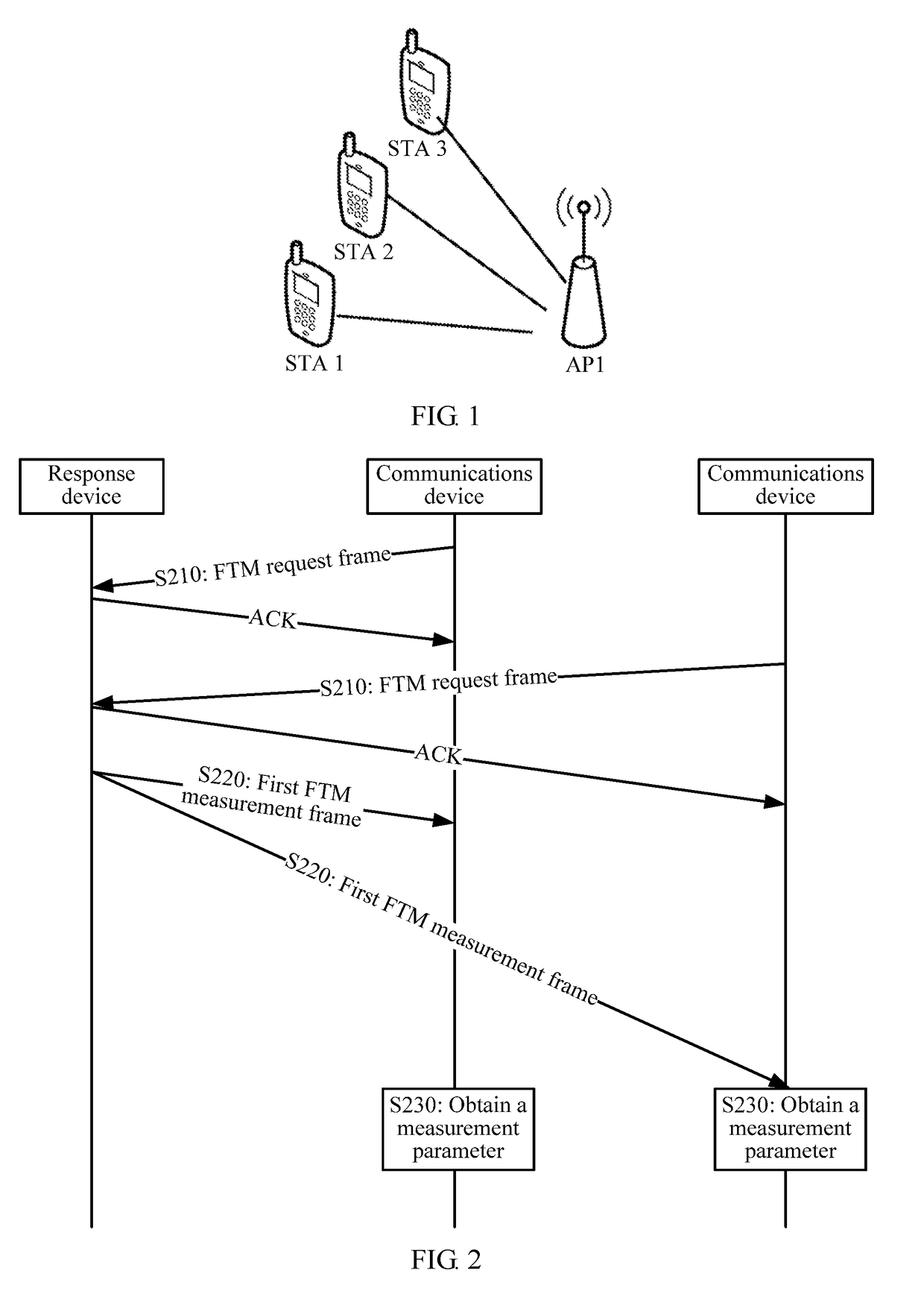

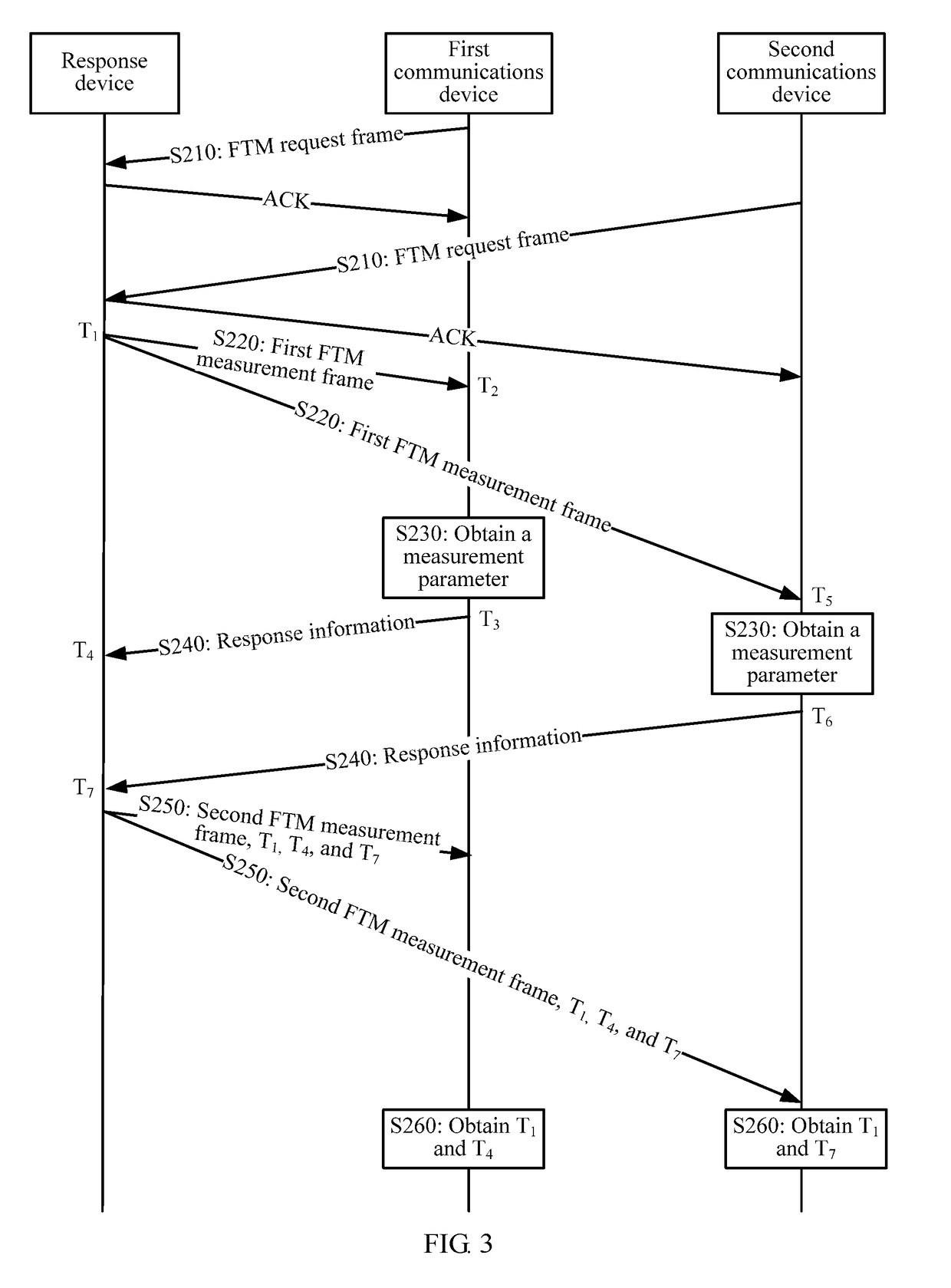

Fine timing measurement ftm method and communications device

ActiveUS20180310194A1Long measurement timeReduce measurement efficiencySynchronisation arrangementSynchronisation information channelsCommunication deviceReal-time computing

Owner:HUAWEI TECH CO LTD

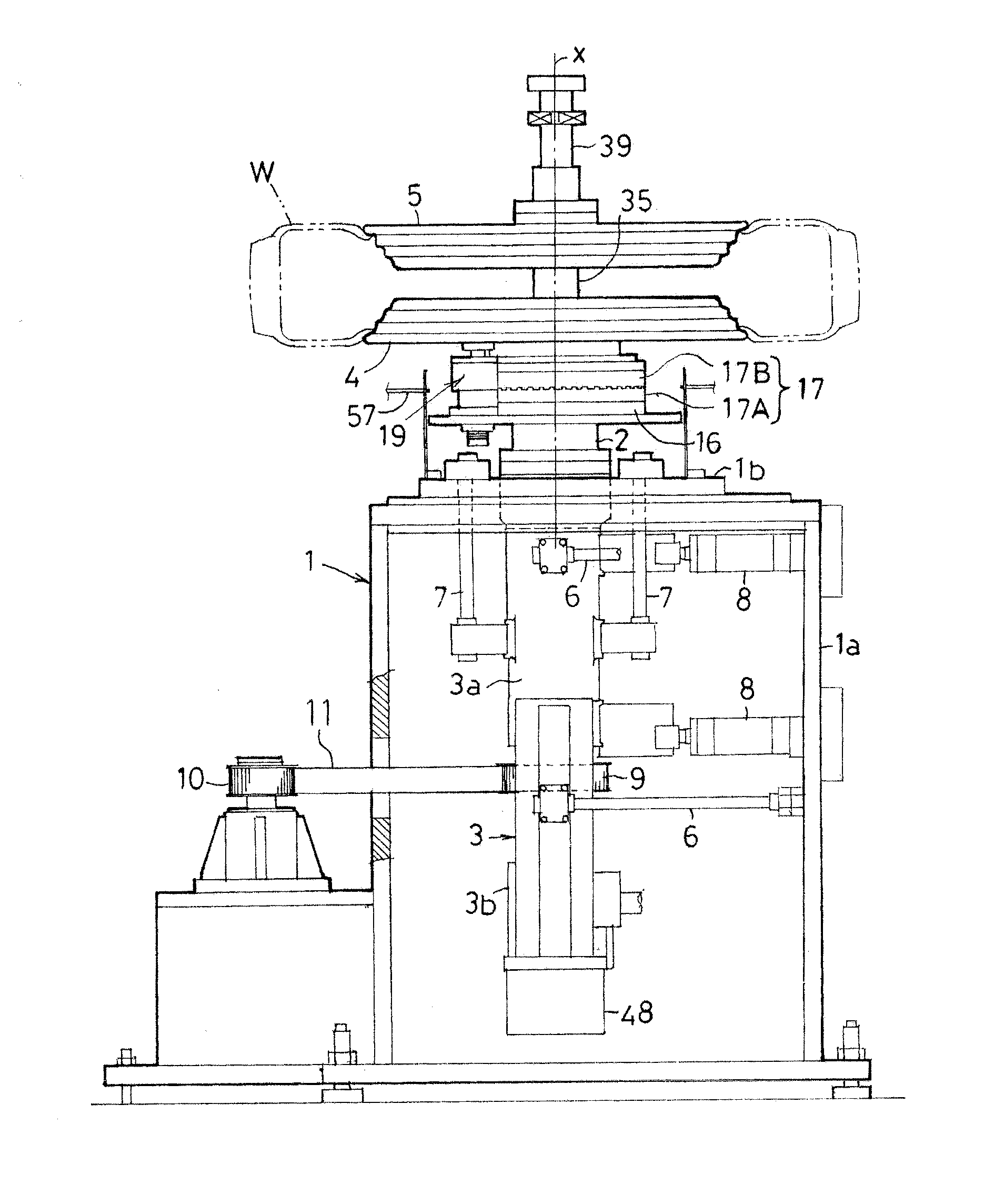

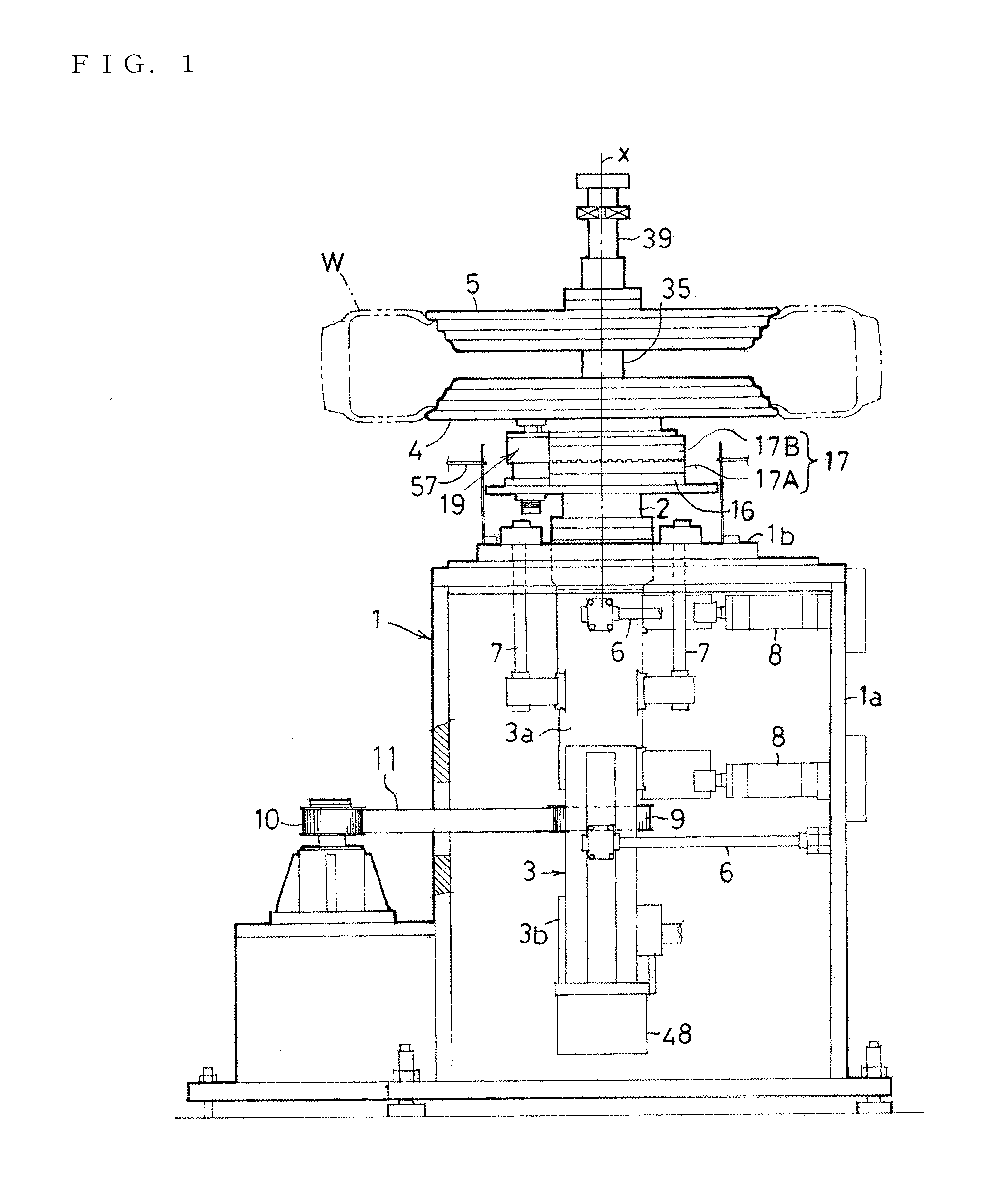

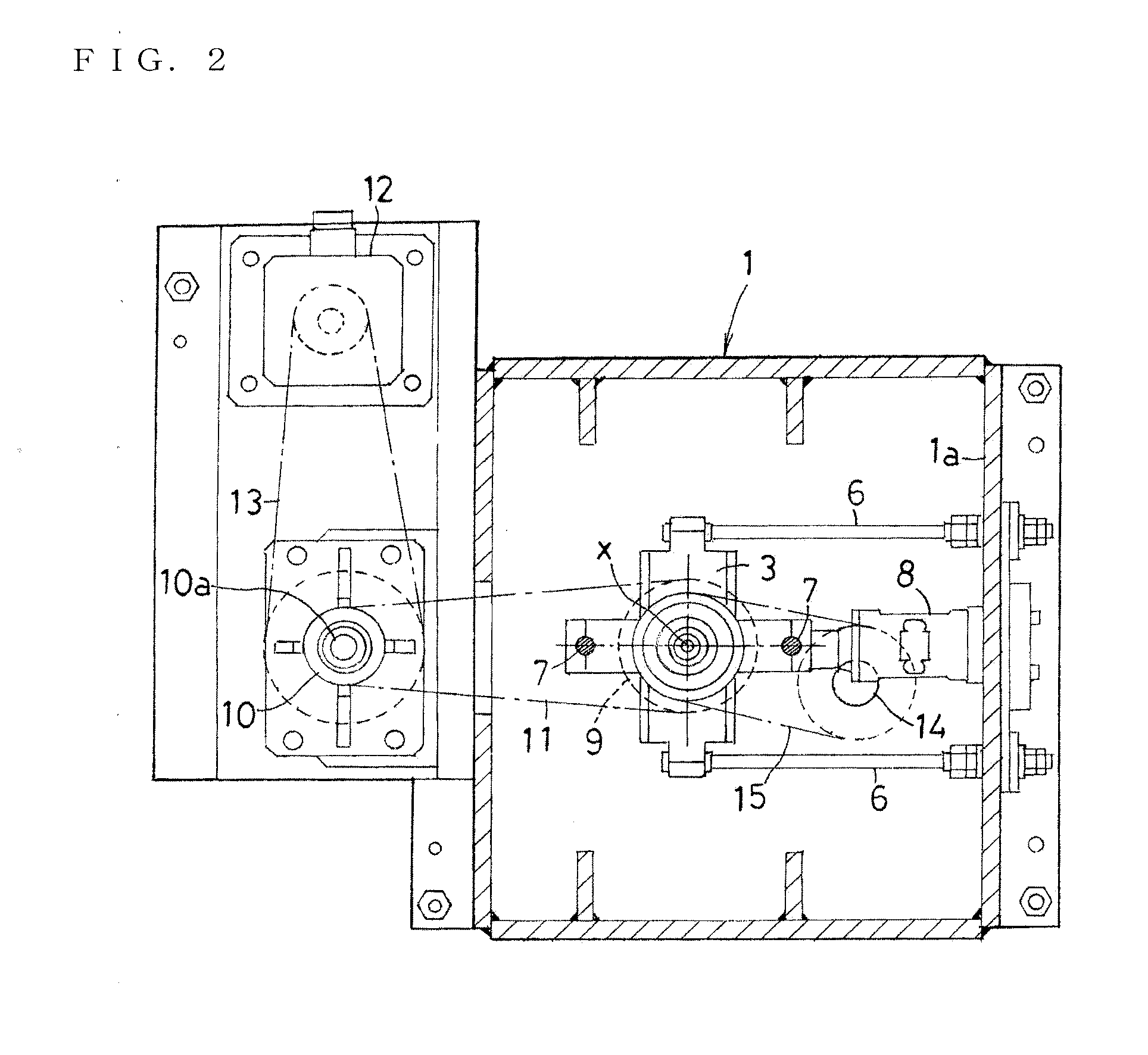

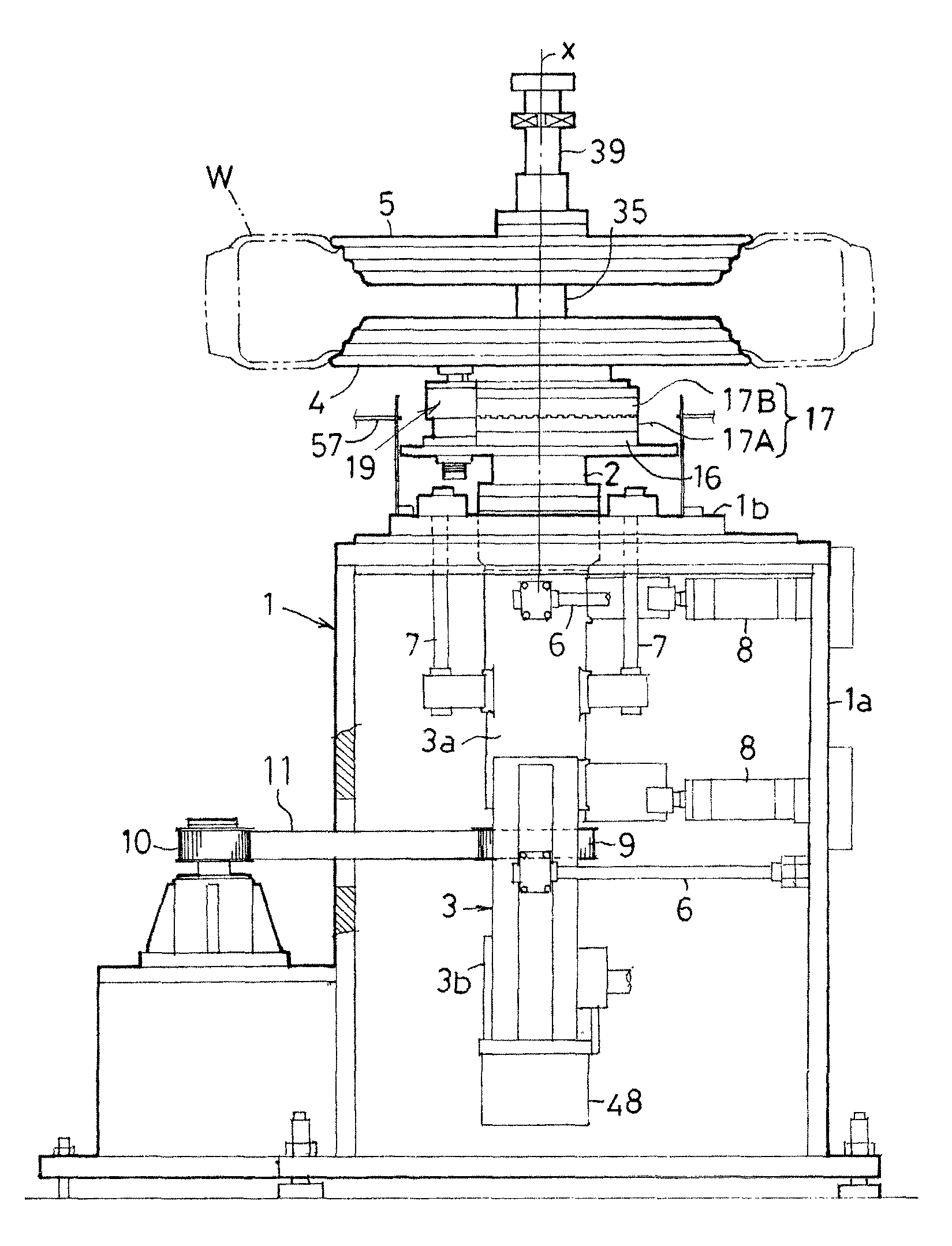

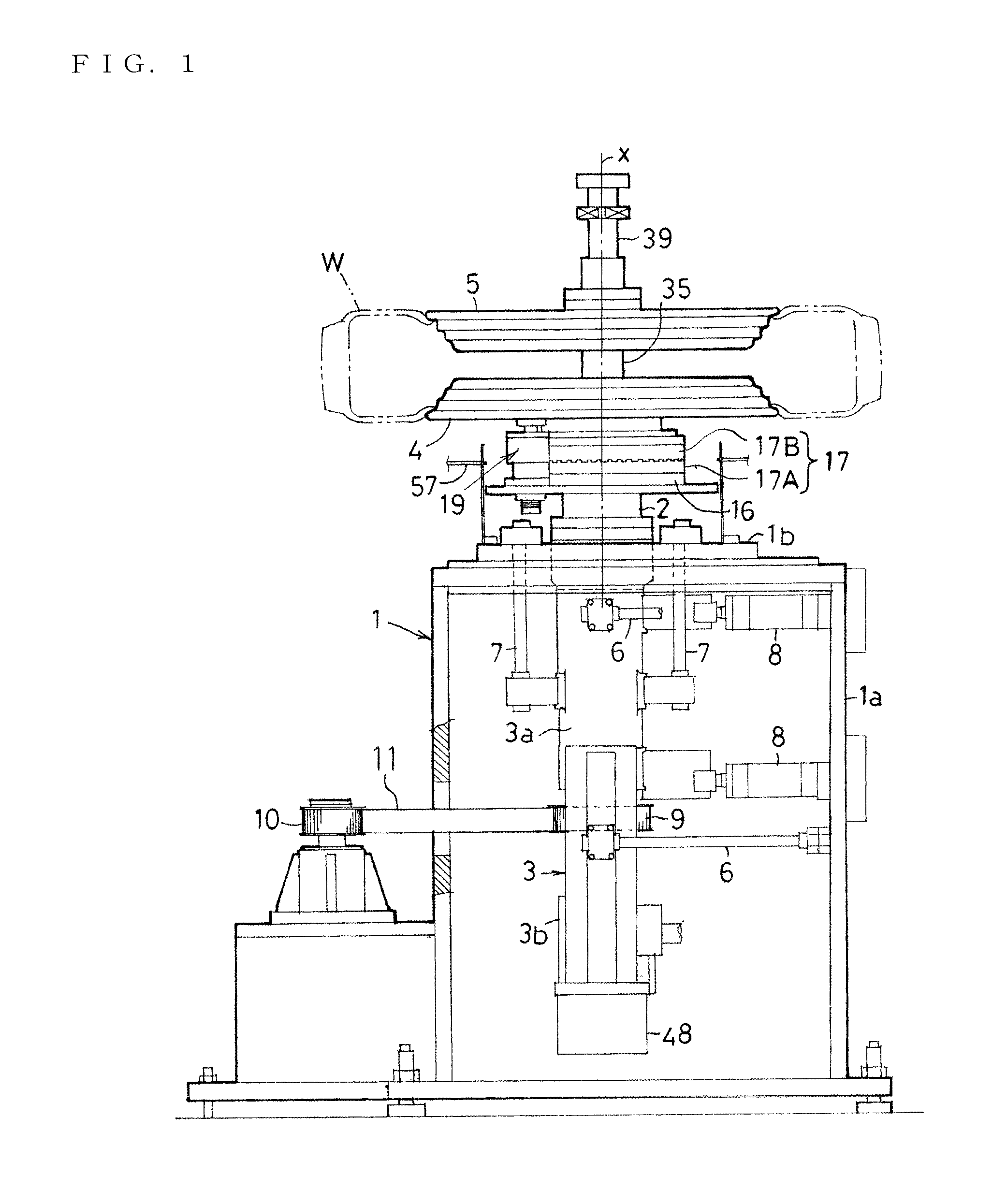

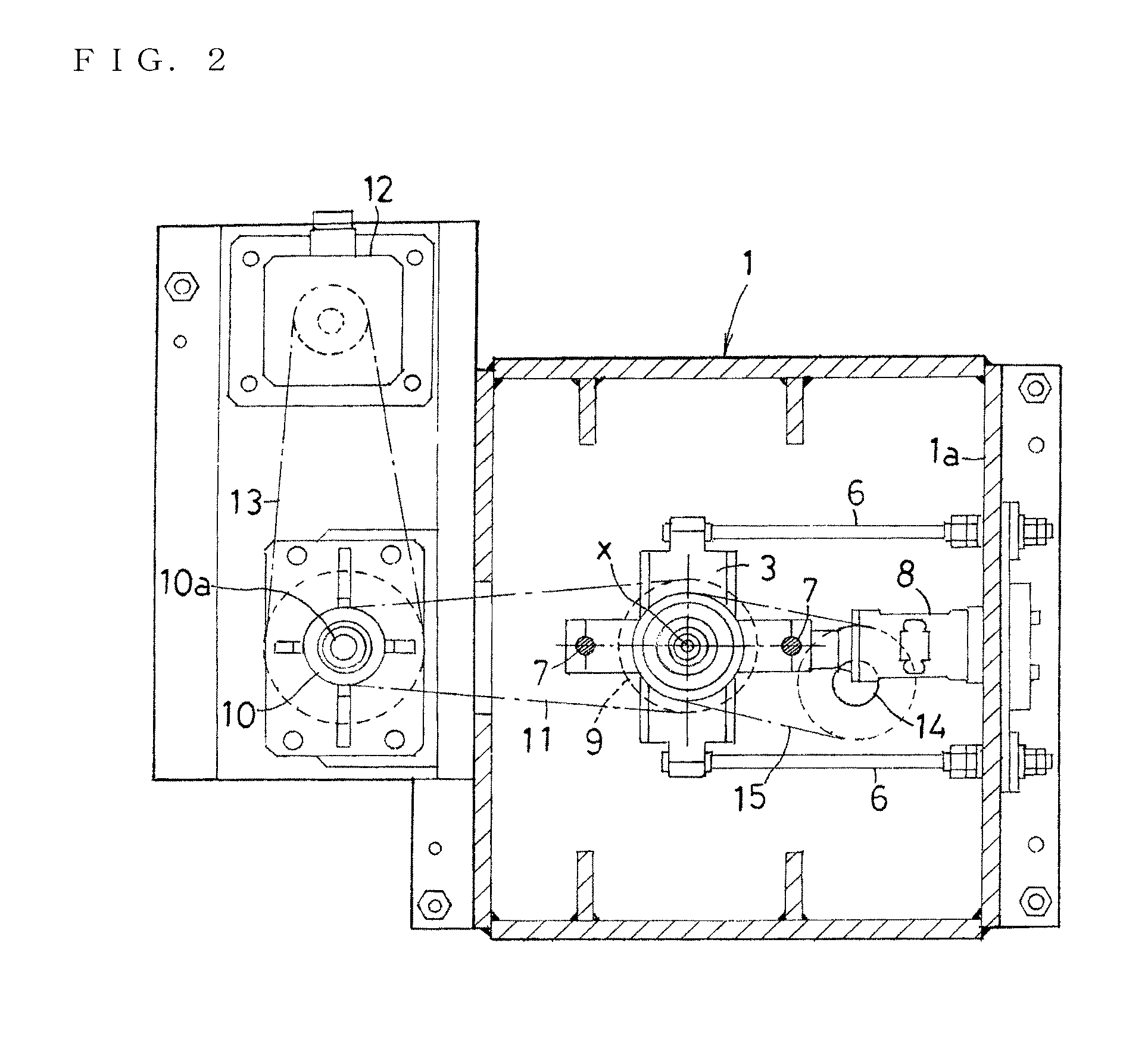

Rim replacing device in tire balance measuring device

ActiveUS20140191480A1Easily and promptly performInconvenience being requiredSleeve/socket jointsStatic/dynamic balance measurementTire balanceCoupling

A lower side coupling of a Hirth coupling is coaxially coupled and fixed to a spindle, an upper side coupling of the Hirth coupling is coaxially coupled and fixed to a lower rim, the upper side coupling of the lower rim is meshed with the lower side coupling of the spindle, and upward separation of the lower rim from the spindle is prevented by chuck mechanisms.

Owner:YAMATO SCALE CO LTD

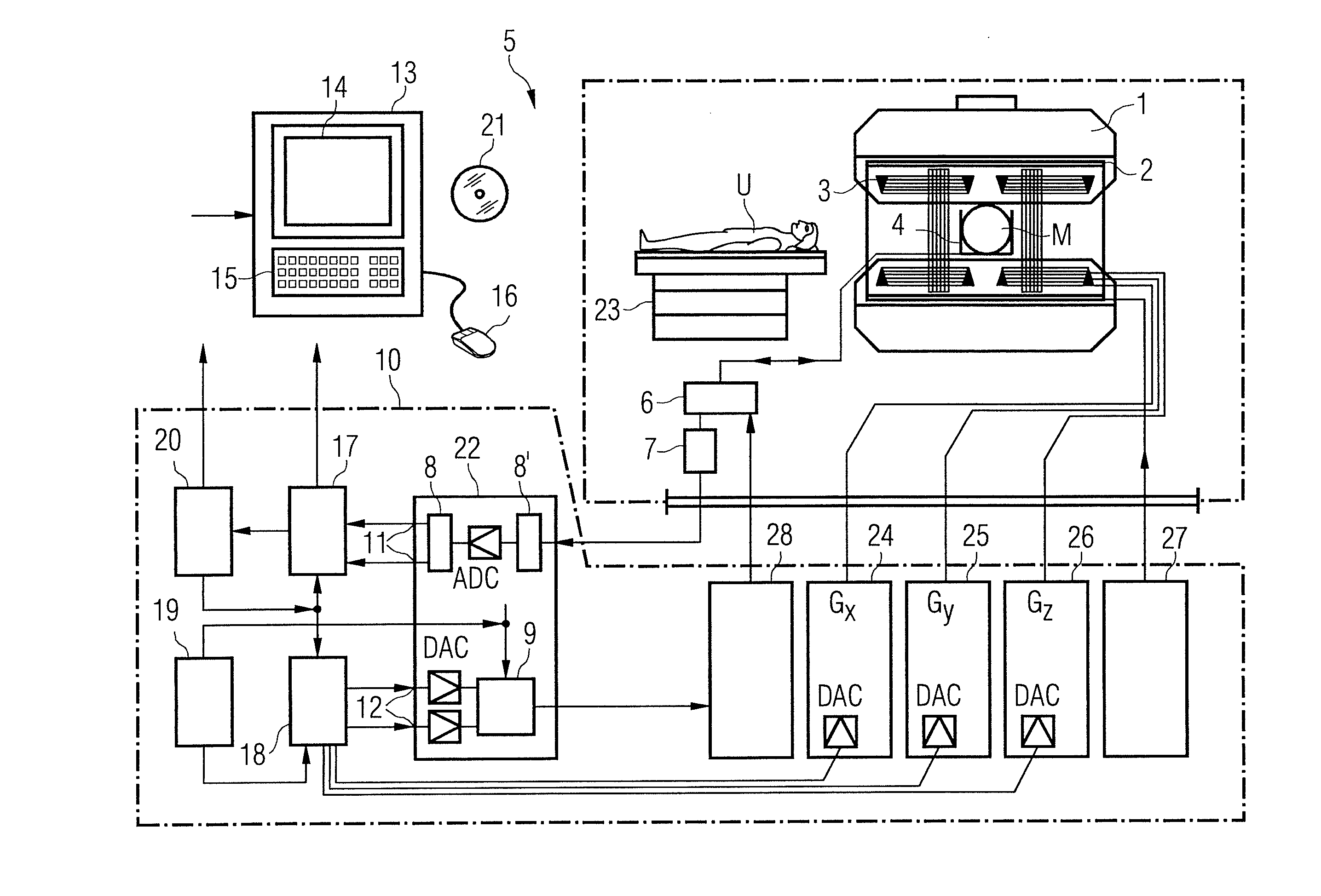

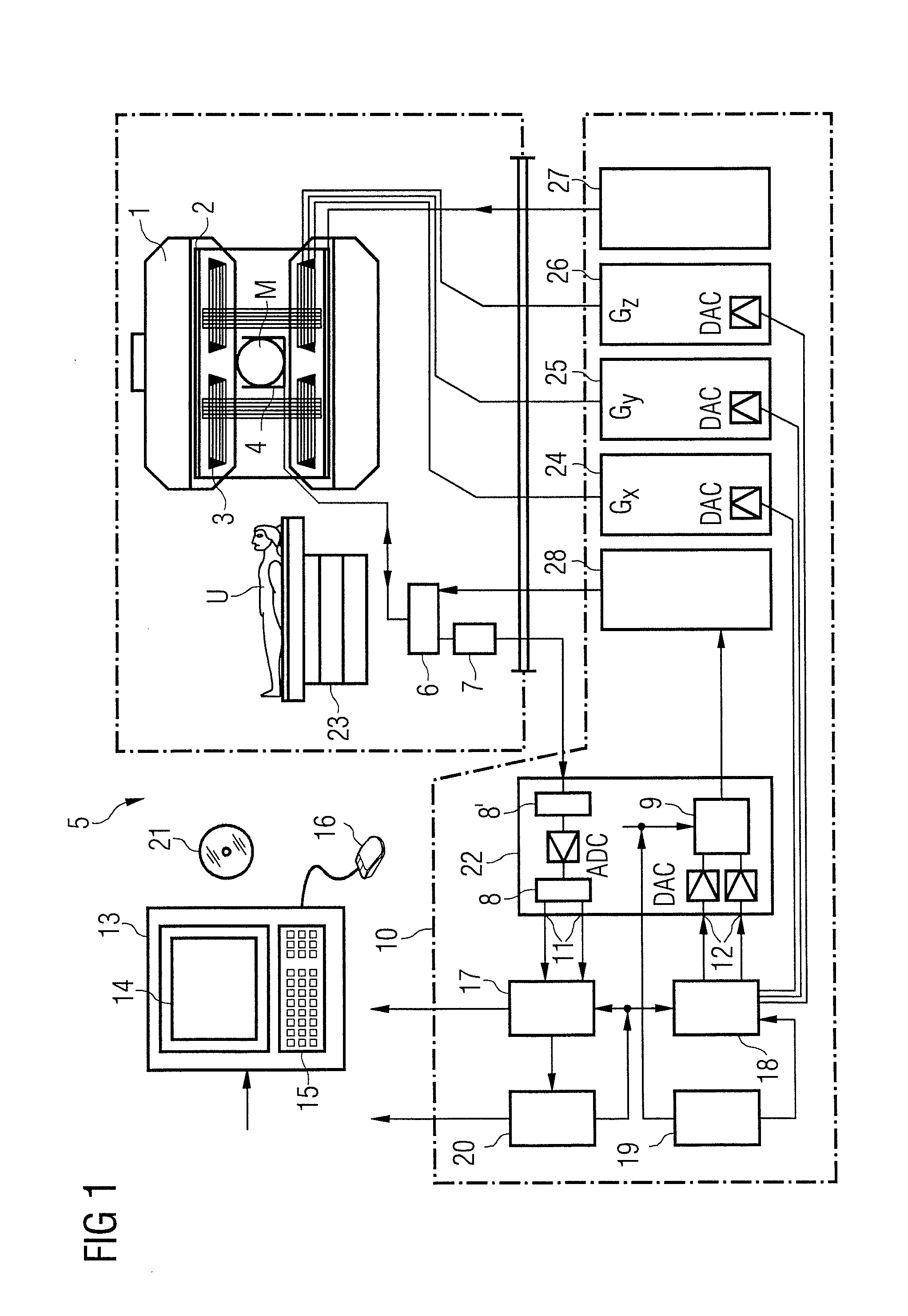

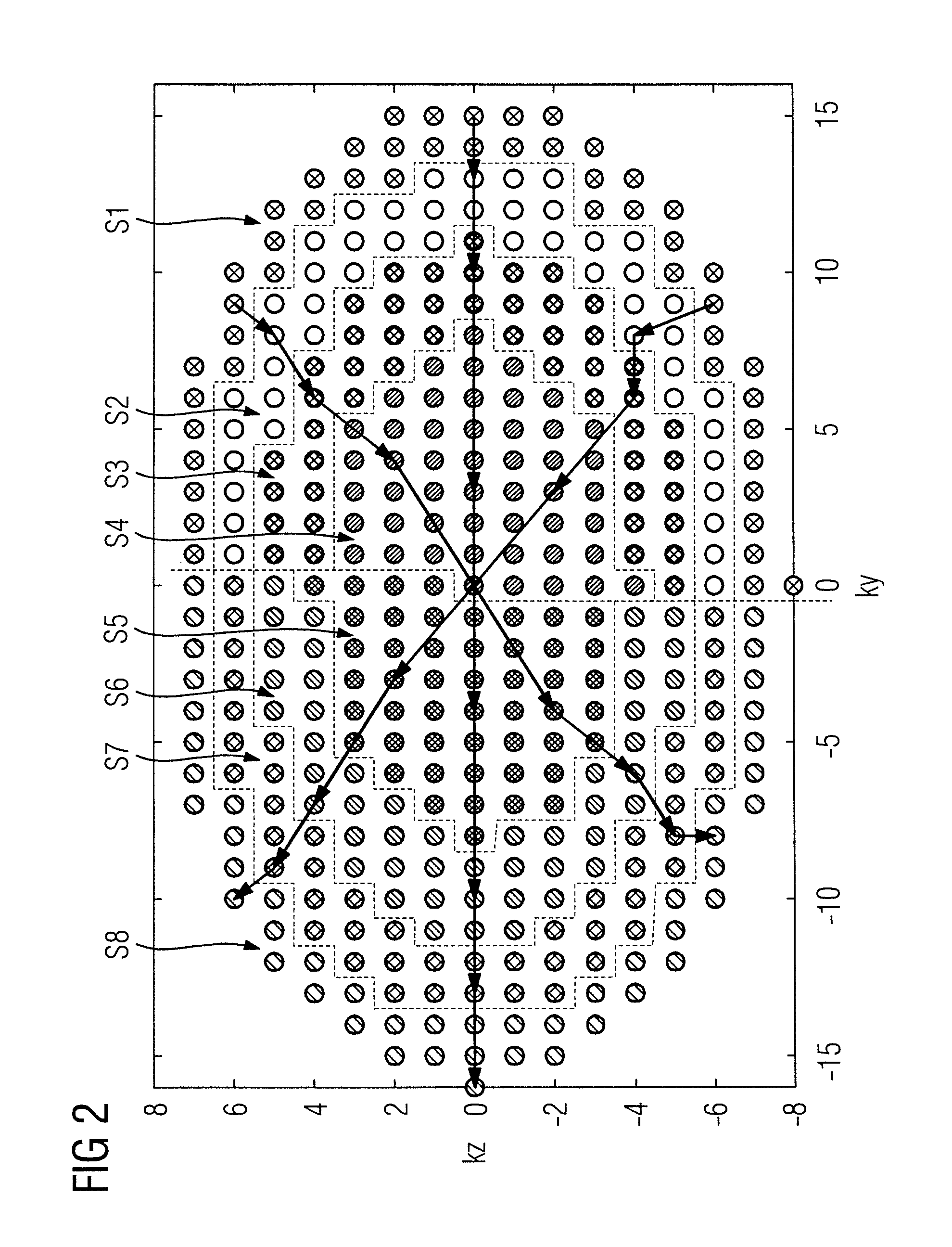

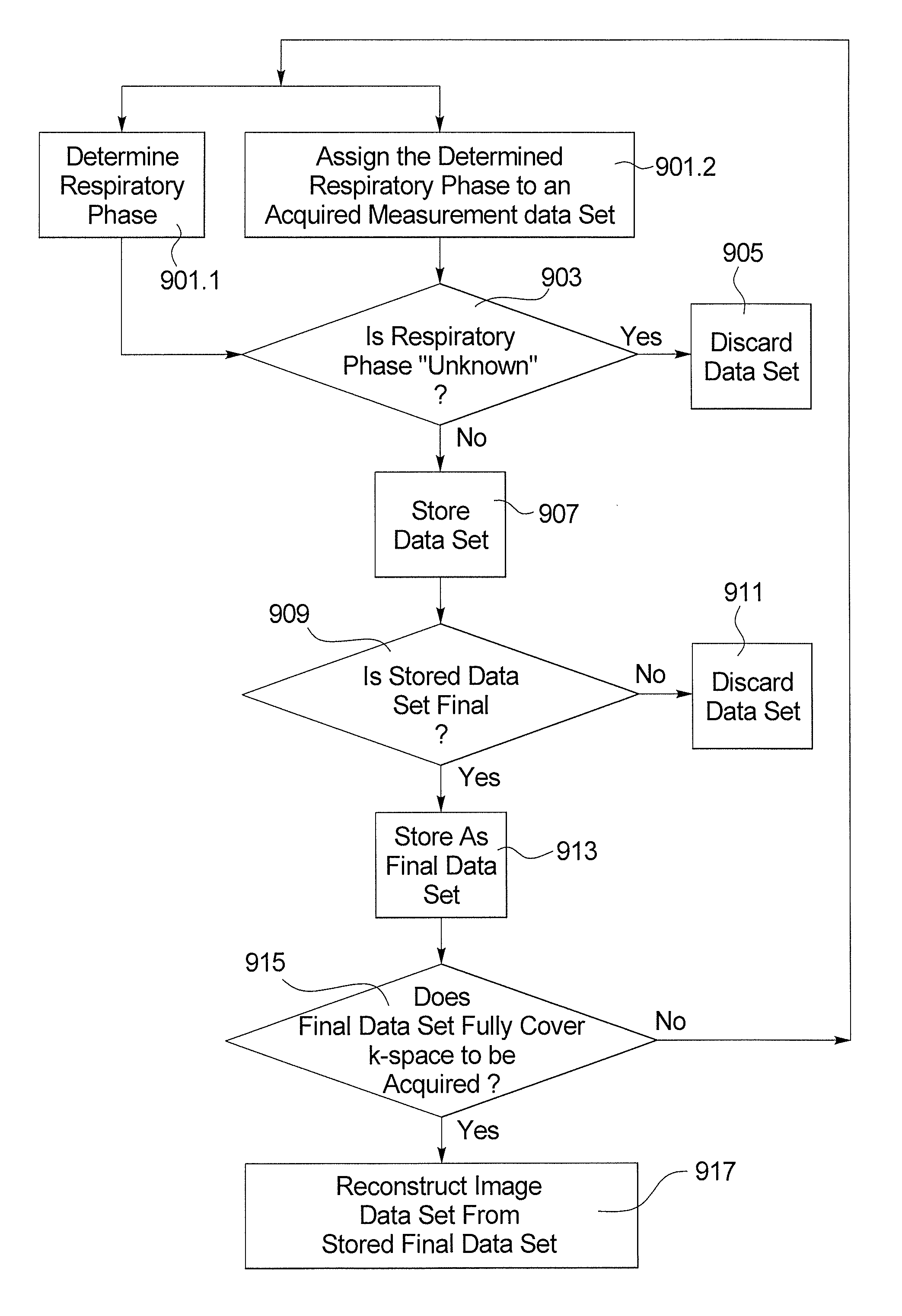

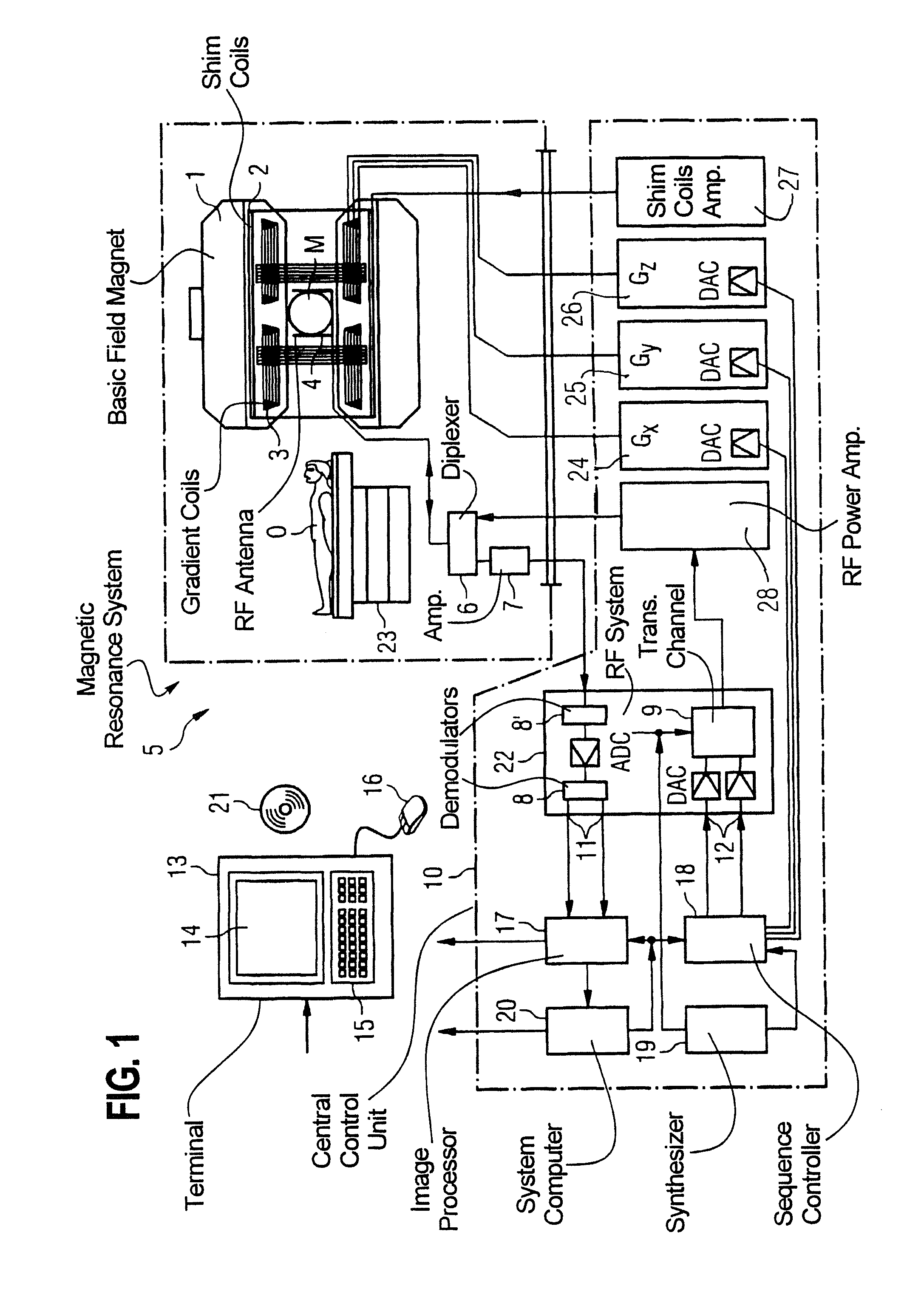

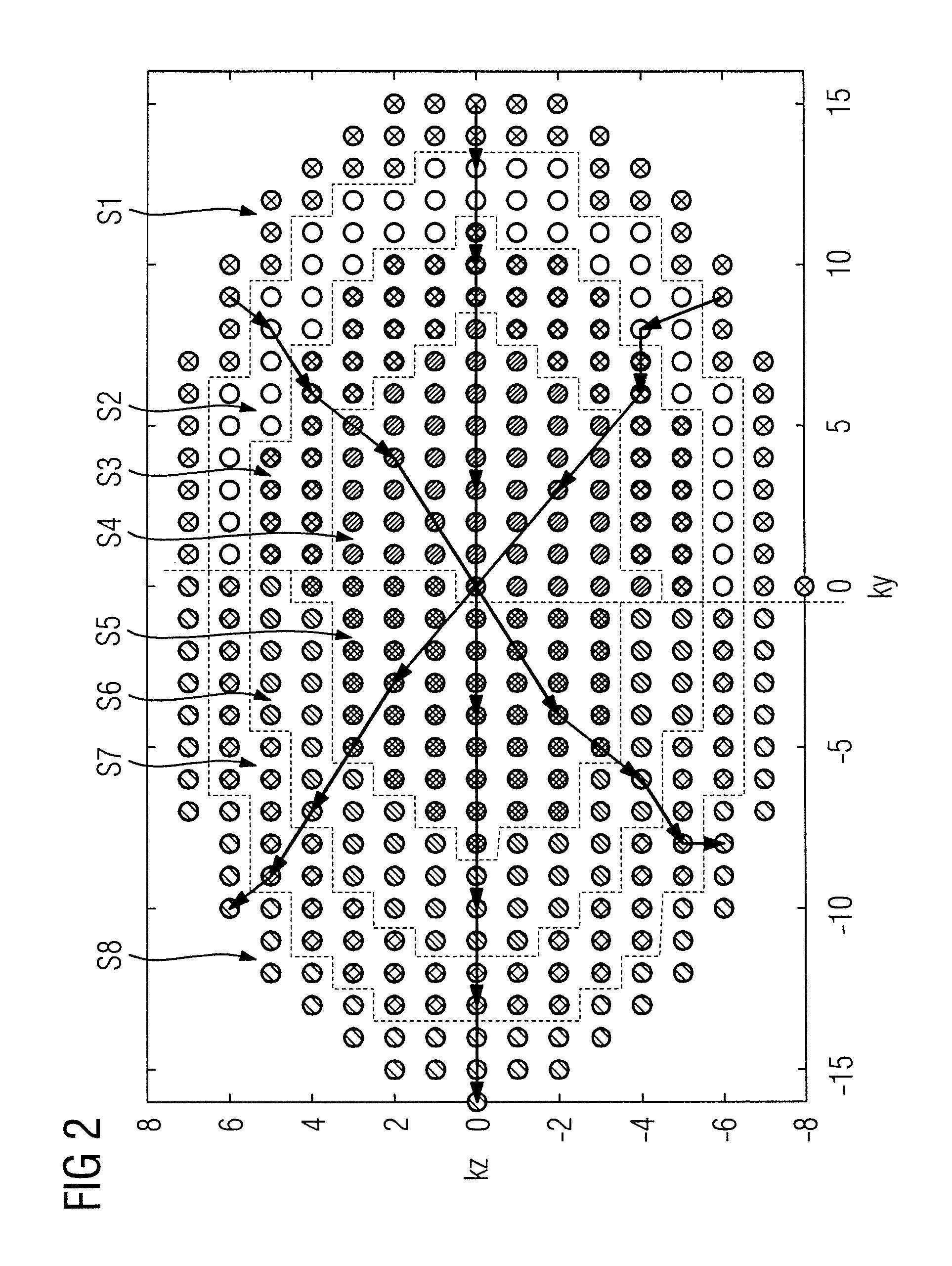

Magnetic resonance method and apparatus for obtaining a set of measured data relating to a breathing object of interest

ActiveUS20130281824A1Eliminate needReduce measurement efficiencyMagnetic measurementsRespiratory organ evaluationRespiratory phaseData set

In a method for acquisition of a measurement data set of a respirating examination subject by magnetic resonance technology, the measurement data set is acquired by numerous individual measurements, wherein, for each individual measurement, a respiratory position and a respiratory phase are determined, based on which it is decided whether the individual measurement is to be included in the final measurement data set from which an image data set is reconstructed.

Owner:SIEMENS HEALTHCARE GMBH

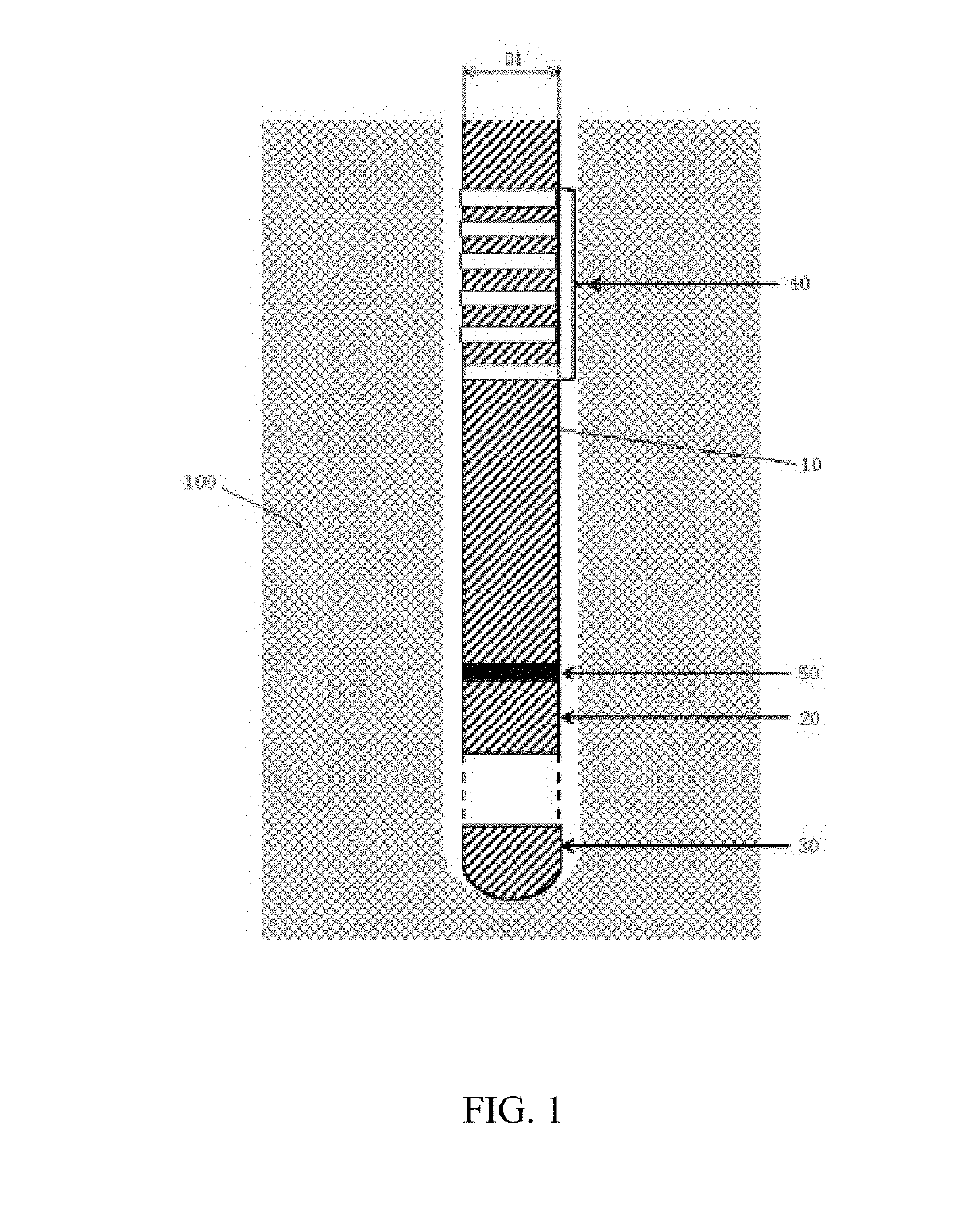

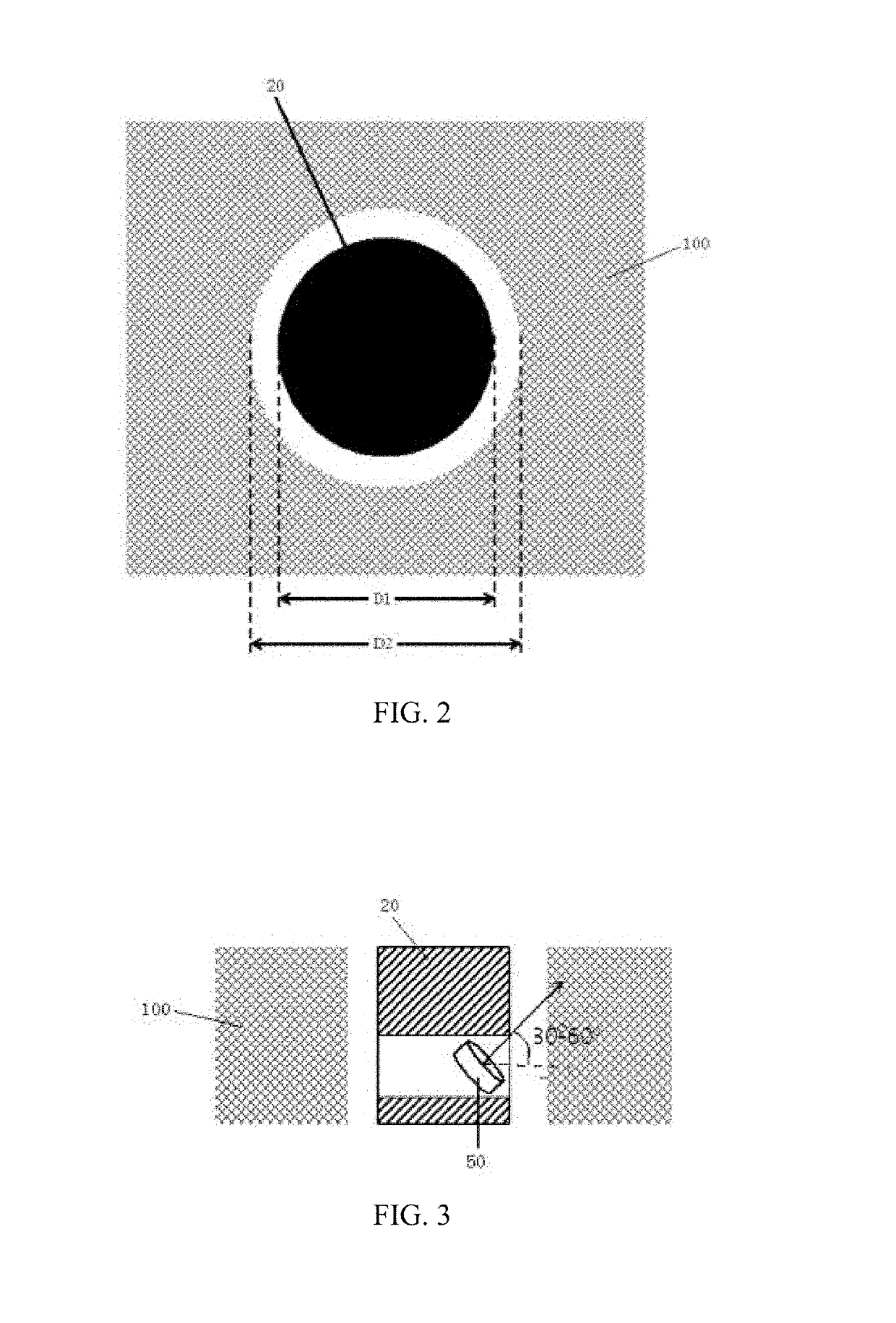

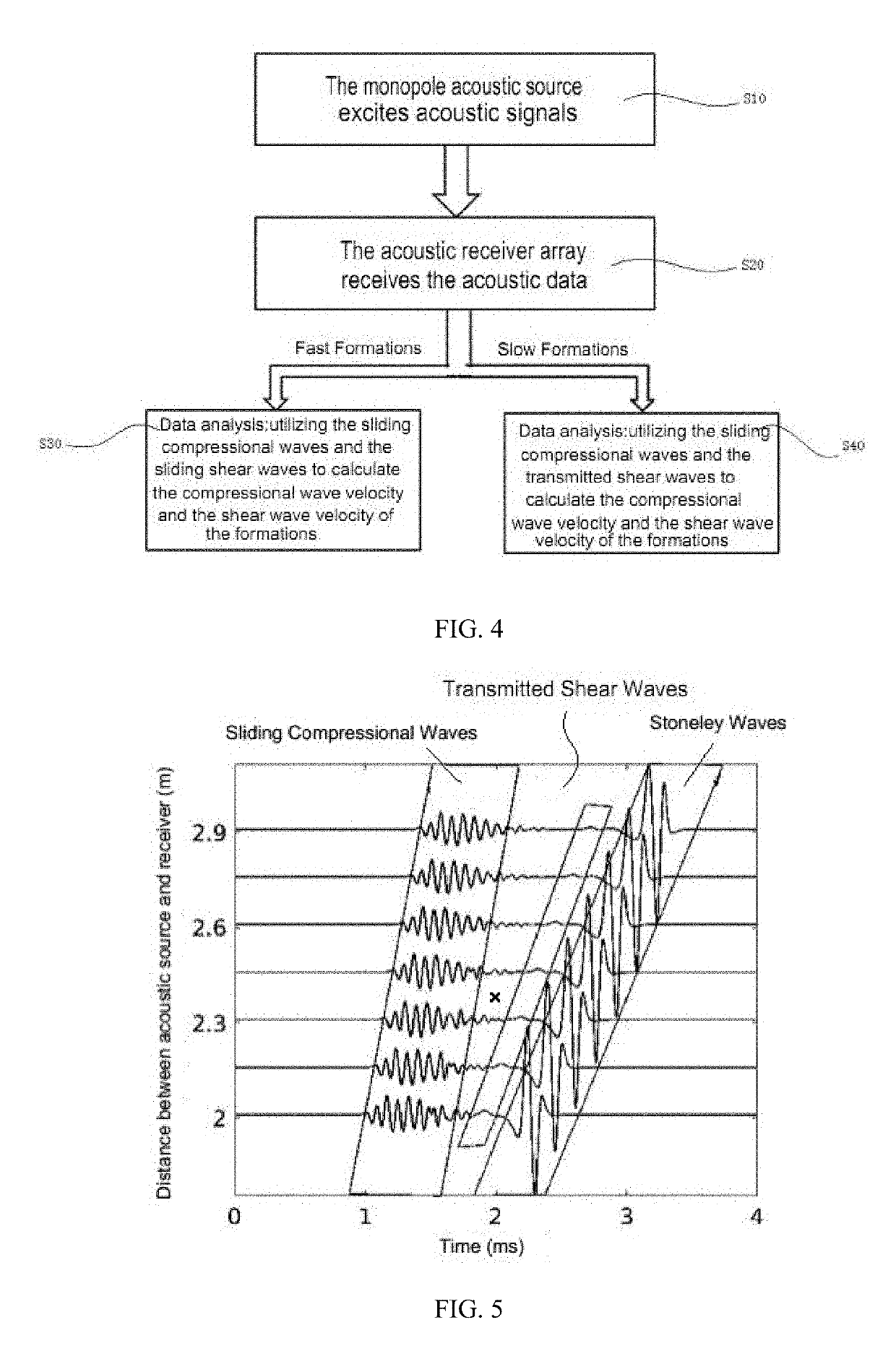

Monopole acoustic logging while drilling instrument used together with bottom hole assembly, method for measuring shear wave velocity of slow formations

ActiveUS20190257970A1Difficult to operateReduce measurement efficiencyConstructionsSeismic energy generationDrill bitLogging

A monopole acoustic logging while drilling instrument used together with a bottom hole assembly and a method for measuring a shear wave velocity of slow formations, wherein the bottom hole assembly includes a drill collar and a drill bit, wherein the monopole acoustic logging while drilling instrument is installed on the drill collar. The monopole acoustic logging while drilling instrument comprises: an acoustic receiver array installed on the drill collar; a monopole acoustic source arranged at the drill collar, wherein the monopole acoustic source is configured to emit acoustic waves with a frequency in a preset frequency range, and the ratio of the outer diameter D1 of the drill collar to the outer diameter D2 of the drill bit is d, and 0.75<d<1.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Magnetic resonance method and apparatus for obtaining a set of measured data relating to a breathing object of interest

ActiveUS9138162B2Reduce measurement efficiencyInterrupt stabilityMagnetic measurementsRespiratory organ evaluationRespiratory phaseData set

Owner:SIEMENS HEALTHCARE GMBH

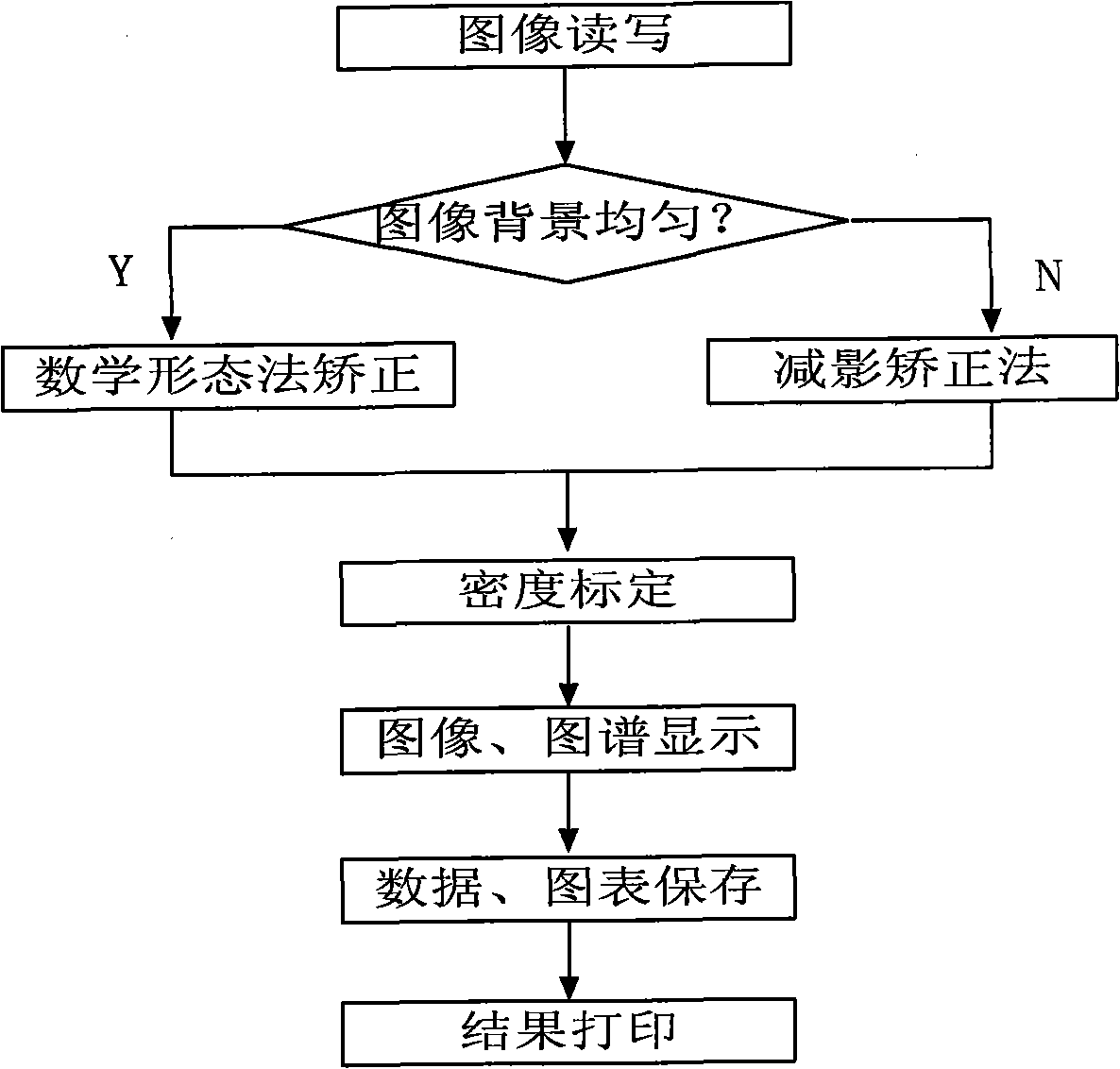

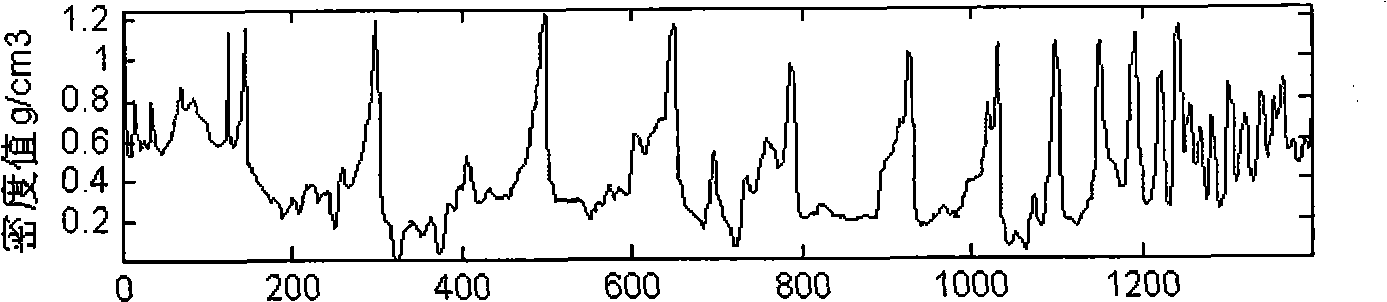

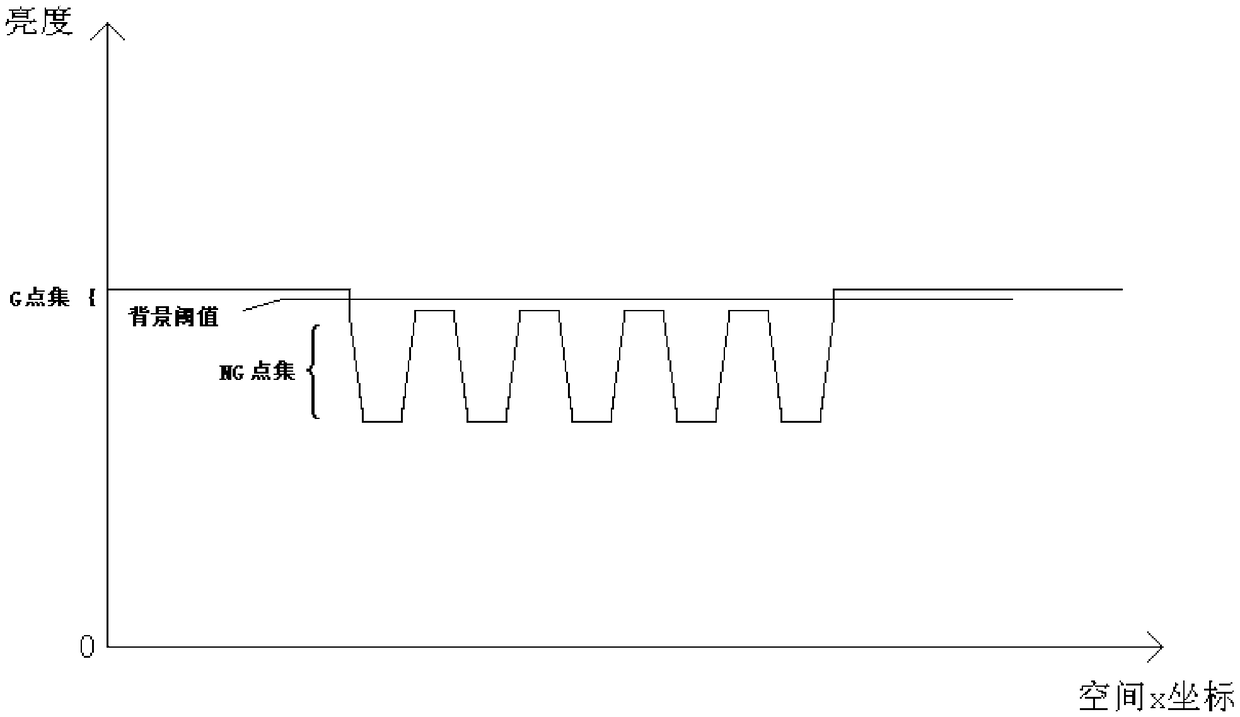

Method for analyzing micro-density image of tree annual ring

InactiveCN101354357ACancel noiseIncrease image brightnessImage enhancementMaterial analysis by optical meansX-rayMethod of images

The invention discloses a method for analyzing wood growth ring micro-density images, which belongs to the field of electronic information, in particular to a method for collecting and analyzing the wood growth ring micro-density images. Growth ring micro-density measuring methods include traditional weighing methods and X ray densimeter methods, etc. The traditional weighing methods are simple, but have low measuring efficiency and low precision. The X ray densimeter methods have high measuring precision but expensive price. The method for analyzing the wood growth ring micro-density images of the invention builds universal high-precision processing techniques and application platforms of the wood growth ring images, and adopts self-adaptive wave filtering, histogram equalizing technique, mathematical morphology and image difference methodology for processing the wood growth ring images so as to eliminate noise, increase image brightness and rectify background error. The method for analyzing the wood growth ring micro-density images can analyze X ray images, scanning images and digital camera images, etc., measure not only growth ring density but also growth ring width, and implement intuitive cross dating during measurement.

Owner:ANHUI AGRICULTURAL UNIVERSITY

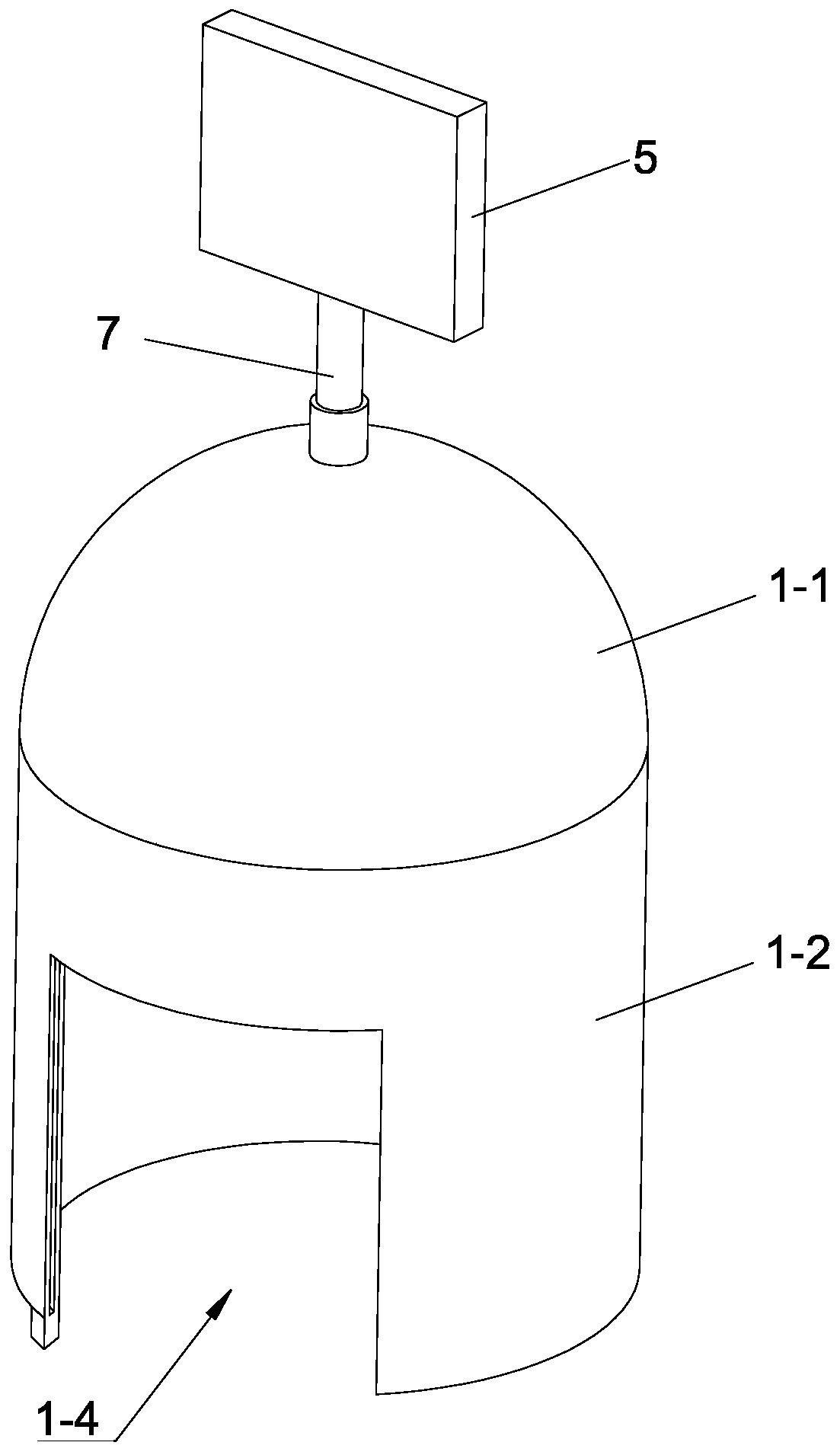

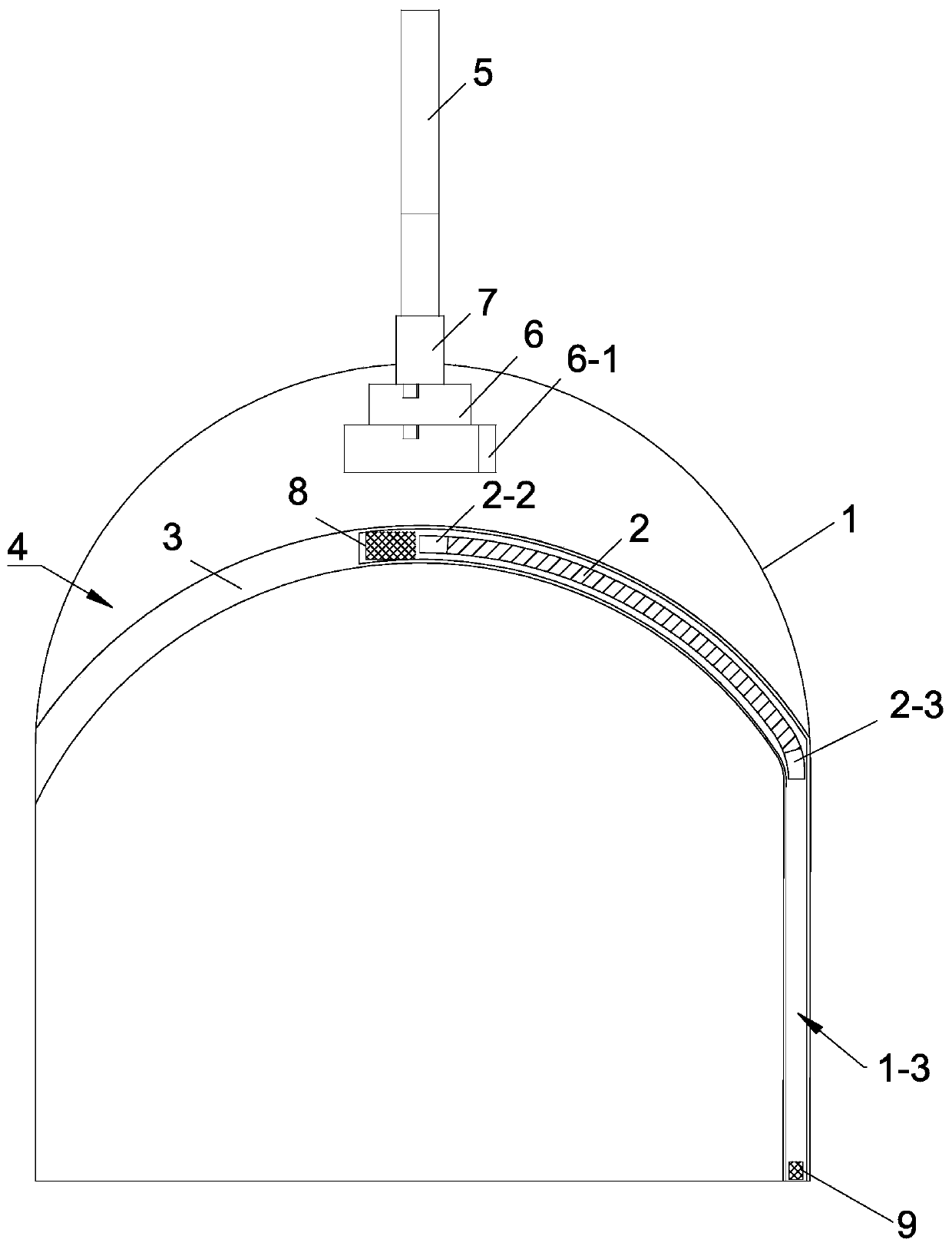

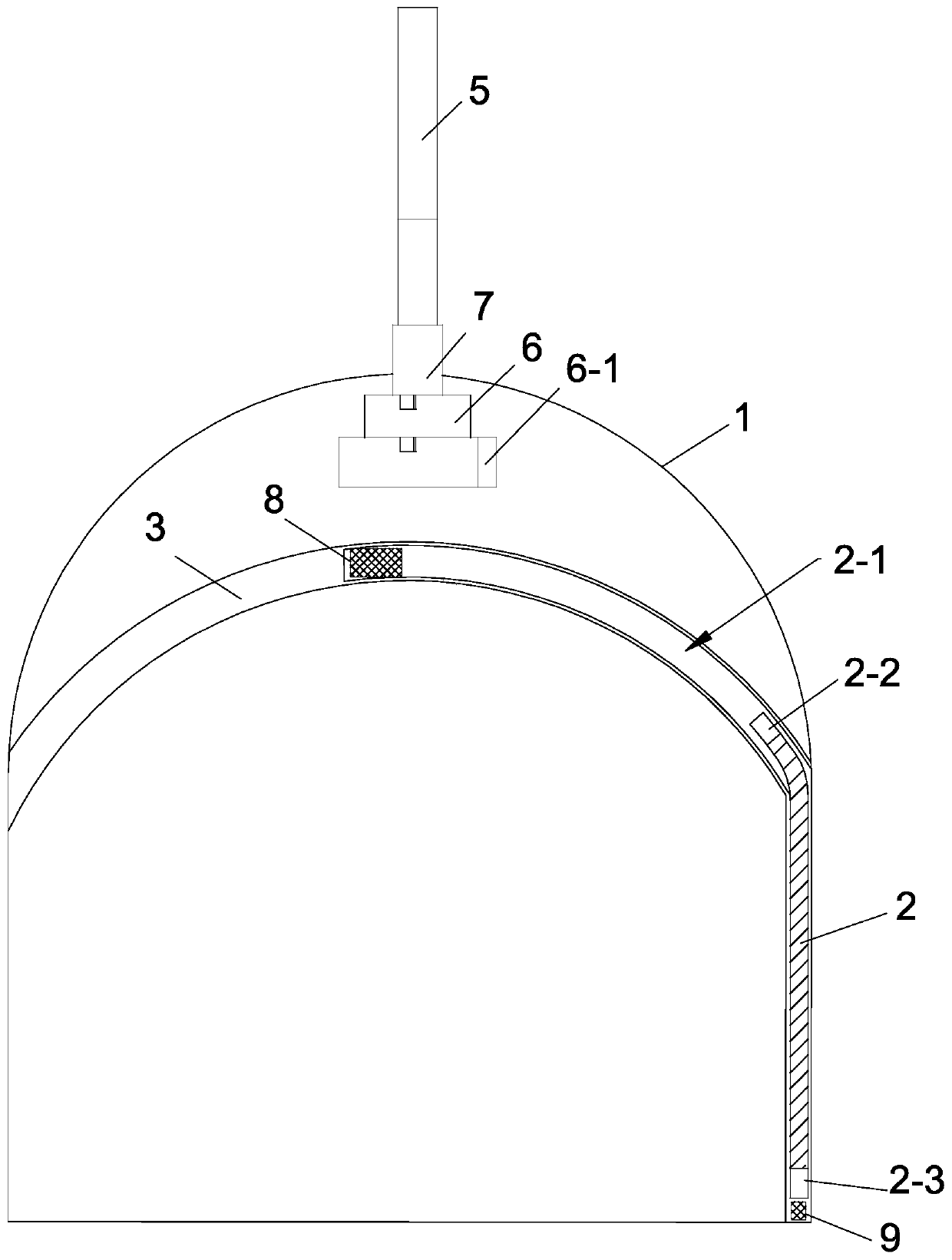

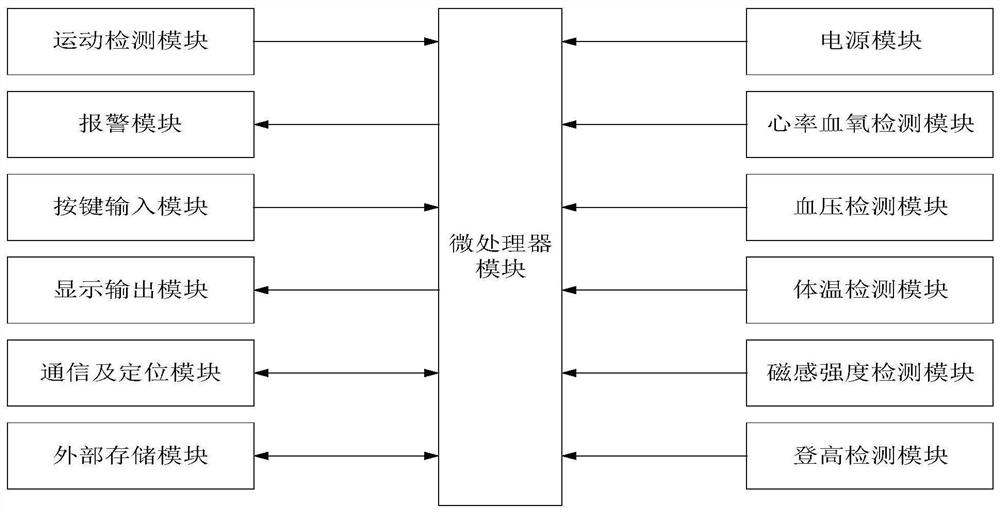

Antitoxin and anti-drift helmet suitable for operation of plant-protecting unmanned aerial vehicle and use method of antitoxin and anti-drift helmet

ActiveCN109832706AWith automatic protection functionImprove protectionHelmetsHelmet coversWireless transmissionControl system

The invention discloses an antitoxin and anti-drift helmet suitable for the operation of a plant-protecting unmanned aerial vehicle and a use method of the antitoxin and anti-drift helmet. The antitoxin and anti-drift helmet comprises a helmet body, a shielding screen arranged on the helmet body, a shielding screen driving mechanism for driving the shielding screen to be opened and closed, a fog drop detecting module used for detecting the concentration of fog drops near the helmet, and a control system, wherein the fog drop detecting module comprises a fog drop monitoring sensor and a first motor; and the control system comprises a safety monitoring processor, a wireless transmission module and a power supply, and the fog drop monitoring sensor, the shielding screen driving mechanism andthe first motor are connected with a signal input end of the safety monitoring processor. With the antitoxin and anti-drift helmet provided by the invention, when fog drops drift so as to cause invasion to a drone pilot, a protection role can be played on the drone pilot, the spraying operation of the plant-protecting unmanned aerial vehicle also can be controlled, so that a pollution source is cut off from the source, and the effects of reducing the waste of pesticides and reducing the environmental pollution are achieved.

Owner:SHANDONG UNIV OF TECH

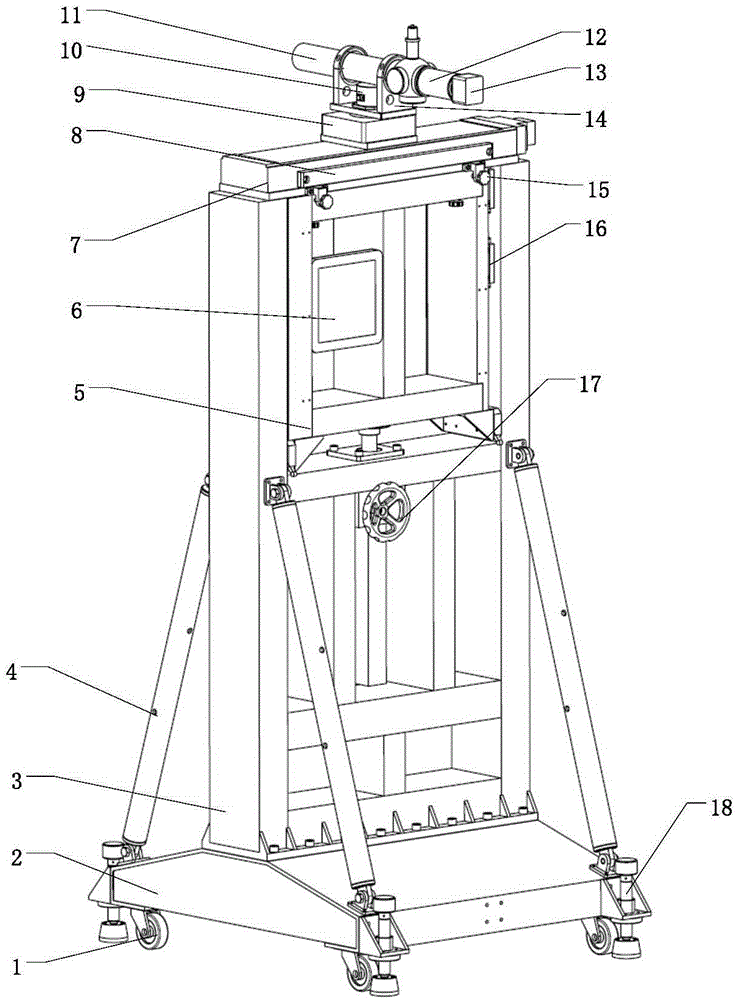

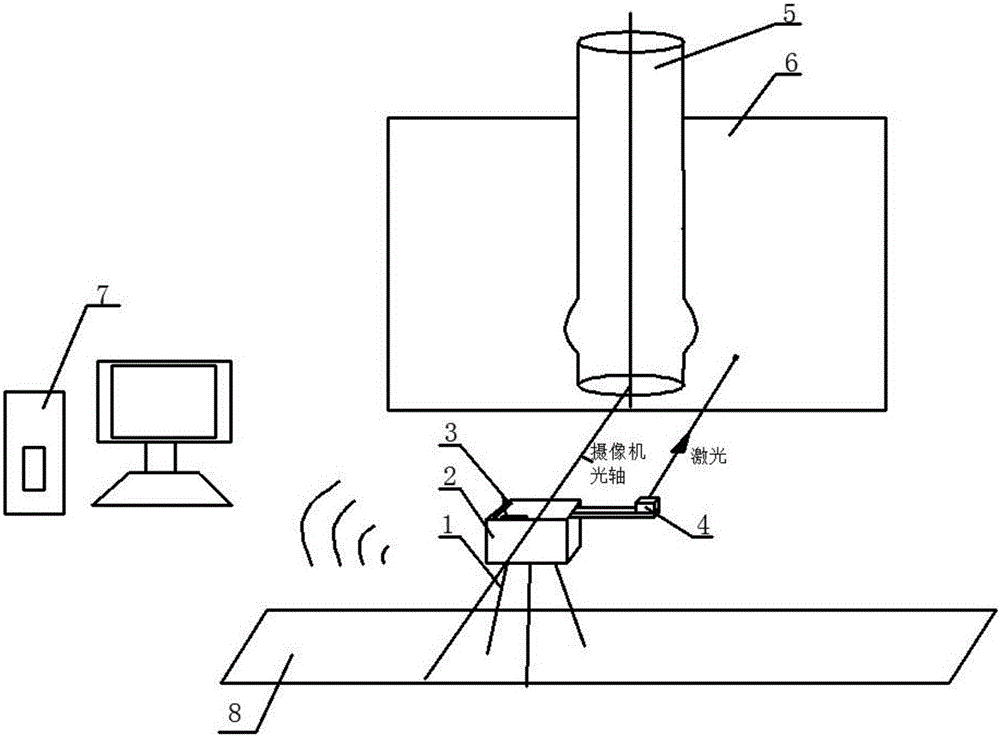

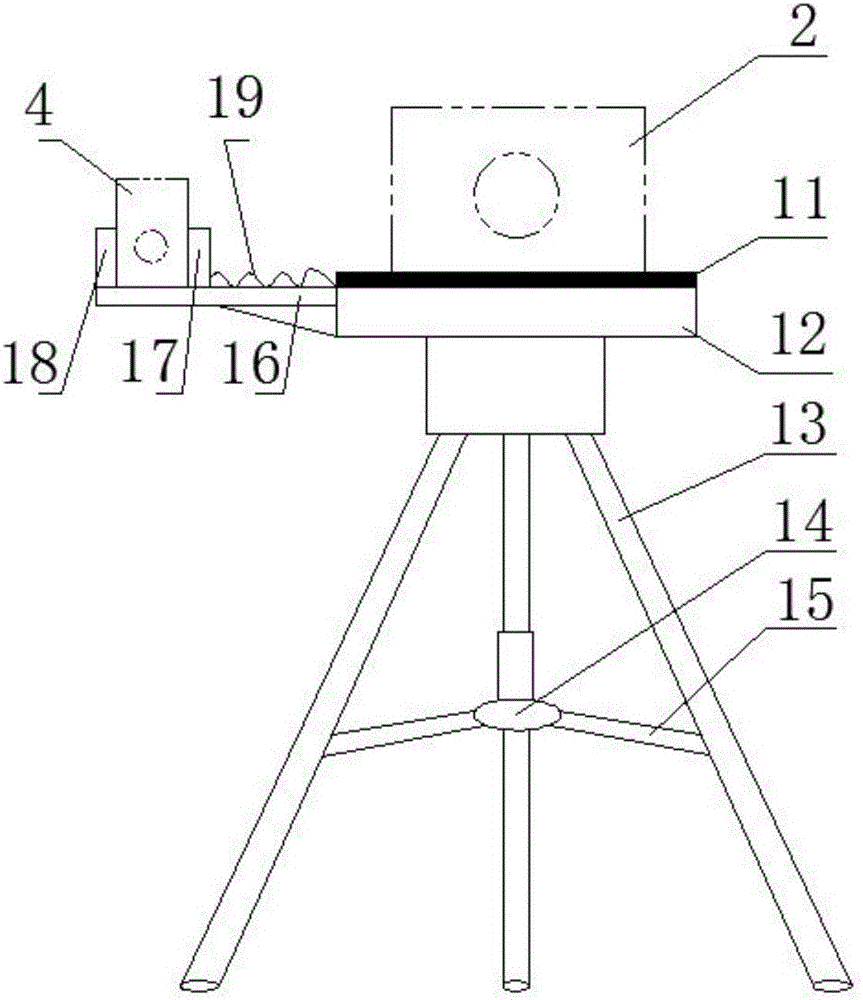

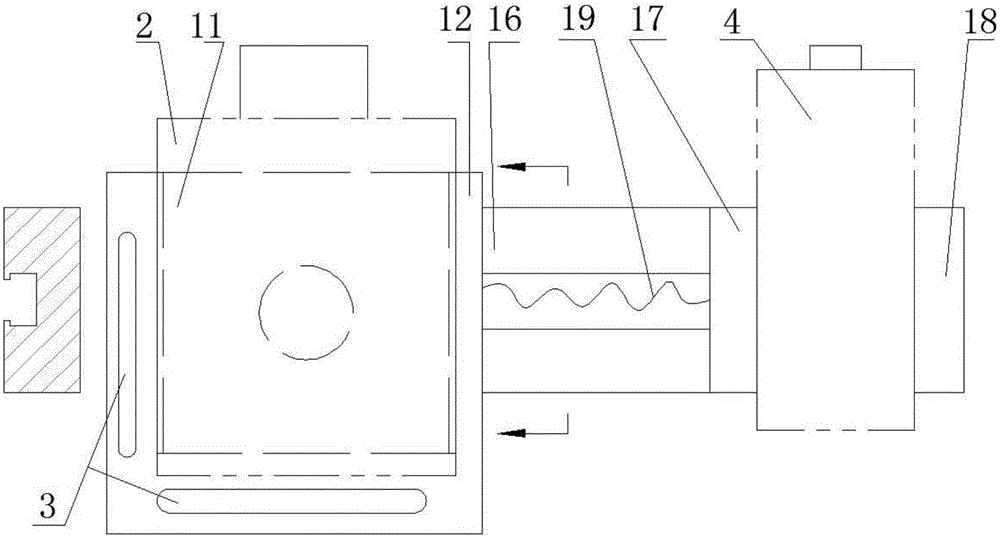

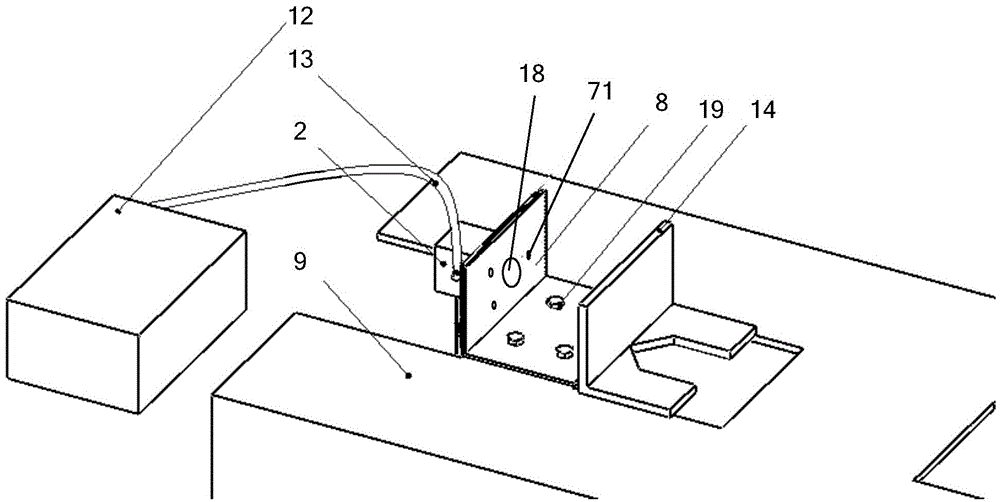

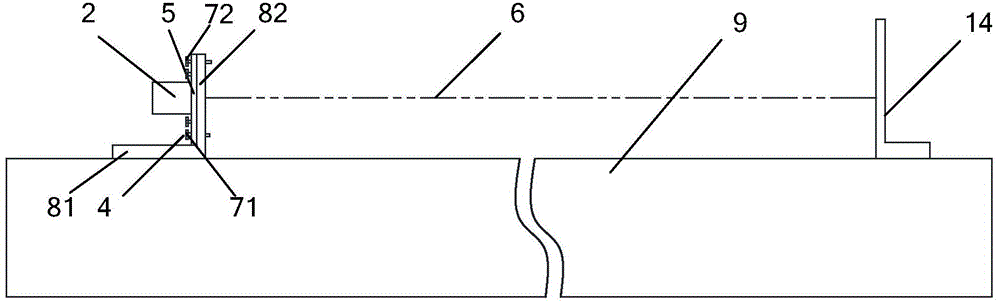

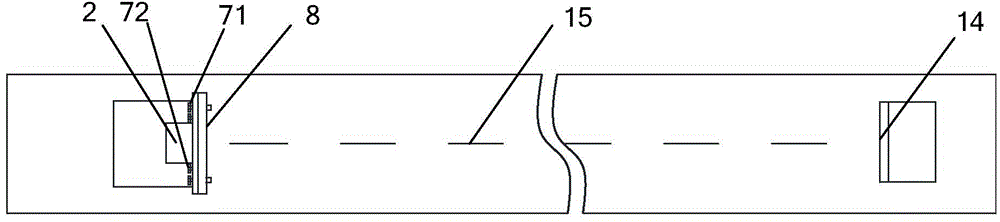

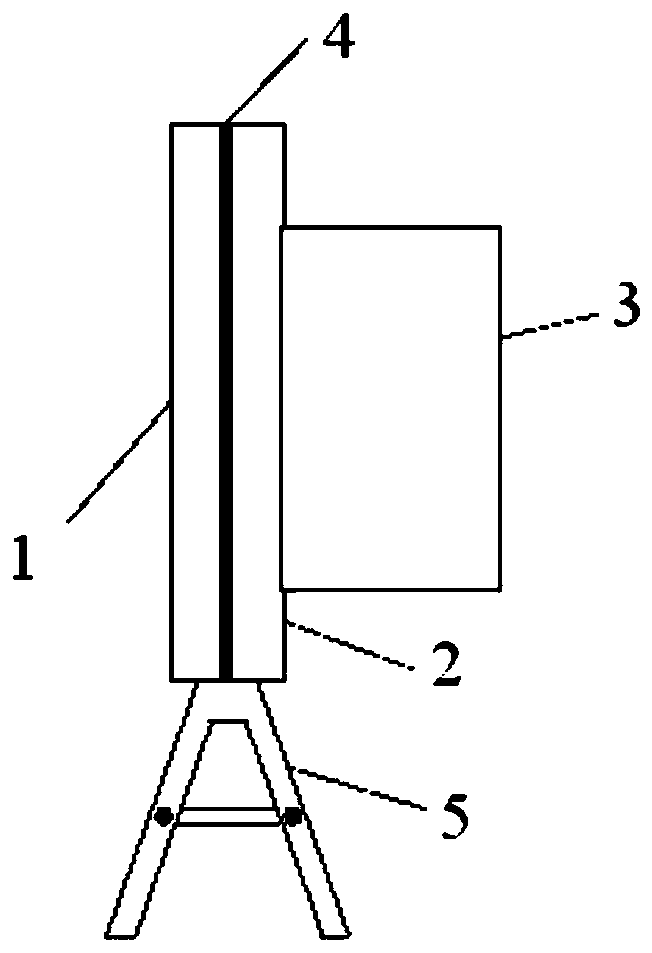

Cylinder special-shaped buckling detection device and recognition method

ActiveCN106289678AImprove mobilityIncrease flexibilityElasticity measurementMeasurement deviceMaximum diameter

The invention discloses a cylinder special-shaped buckling detection device and a recognition method. The device comprises a camera, a laser range finder, a level instrument and a tripod. Monocular vision and laser are combined for detecting the maximum diameter of the special-shaped buckling appearing after a concrete filled steel tubular column is detected to be subjected to low cyclic loading. Measurement requirements can be met, the maneuverability, the flexibility and the measurement accuracy of the measurement device can be improved, the phenomenon that the measurement efficiency and the measurement precision are reduced as the camera and the laser range finder mutually separated are used frequently in turn can be avoided; Hough transform based on secondary gray value processing is used, a circle tangent to points at two ends of the maximum diameter of the buckling is found and calculated, secondary gray value threshold processing is carried out, remaining noise points are reduced, and the accurate maximum buckling position at a sample and the maximum diameter of the special-shaped buckling can be acquired.

Owner:GUANGDONG UNIV OF TECH +1

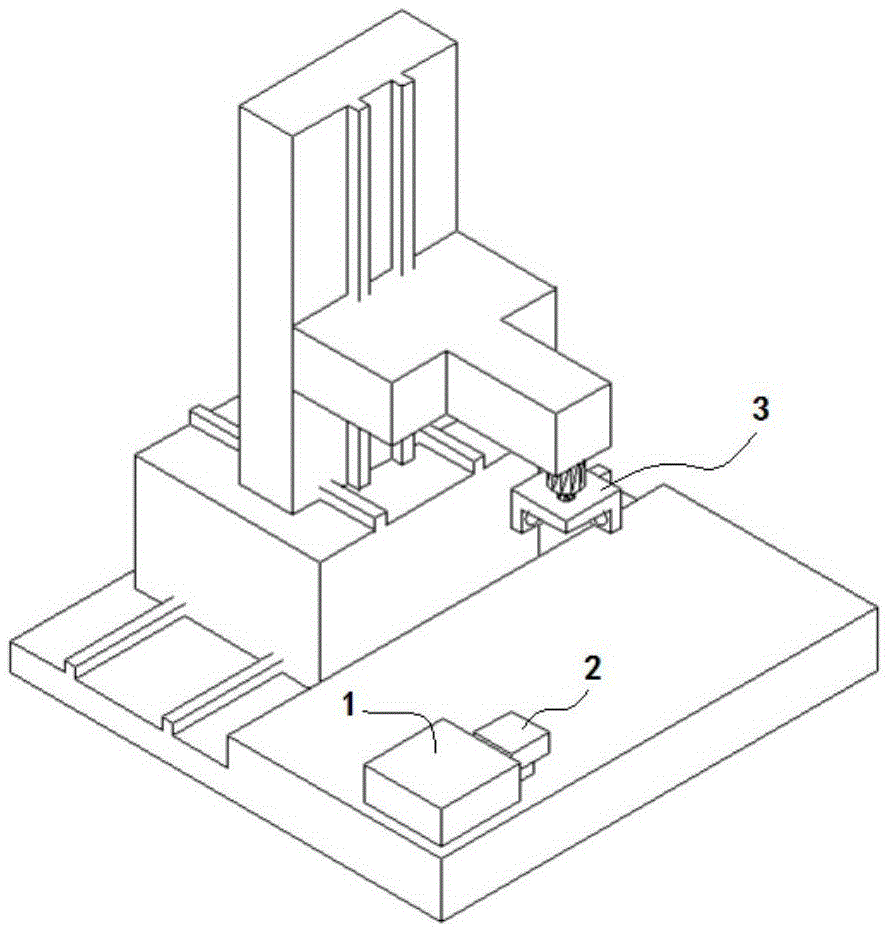

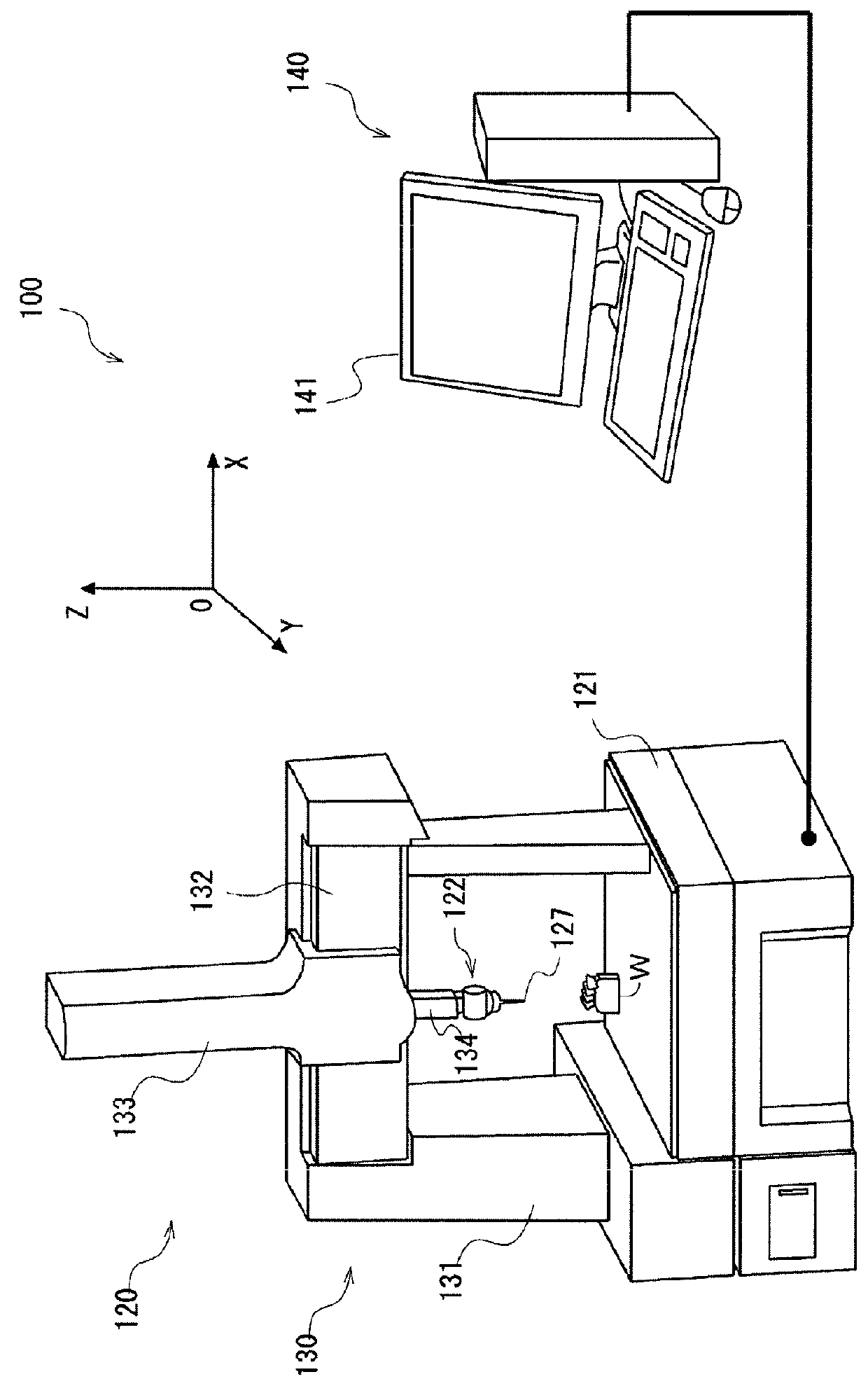

Laser measurement system and method for measuring 21 gmes

ActiveUS20170314916A1Improve measurement efficiencyLower potentialAngle measurementInterferometersLinear motionGeometric error

A laser measurement system for measuring up to 21 geometric errors, in which a six-degree-of-freedom geometric error simultaneous measurement unit and a beam-turning unit are mounted on either the clamping workpiece or the clamping tool, while an error-sensitive unit is mounted on the remaining one, the beam-turning unit has several switchable working postures and multi-component combinations in its installation state, it can split or turn the laser beam from the six-degree-of-freedom geometric error simultaneous measurement unit to the X, Y, and Z directions in a proper order, or the beam-turning unit can split or turn a beam from the error-sensitive unit to the six-degree-of-freedom geometric error simultaneous measurement unit. The present invention is of simple configuration and convenient operation. Up to 21 geometric errors of three mutual perpendicular linear motion guides are obtained by a single installation and step-by-step measurement.

Owner:BEIJING JIAOTONG UNIV

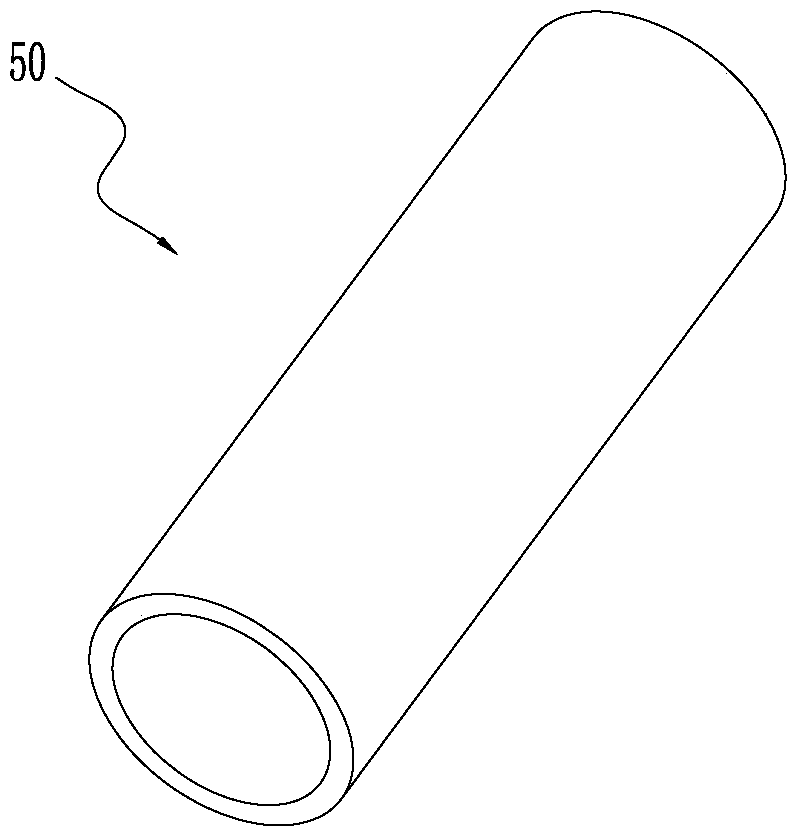

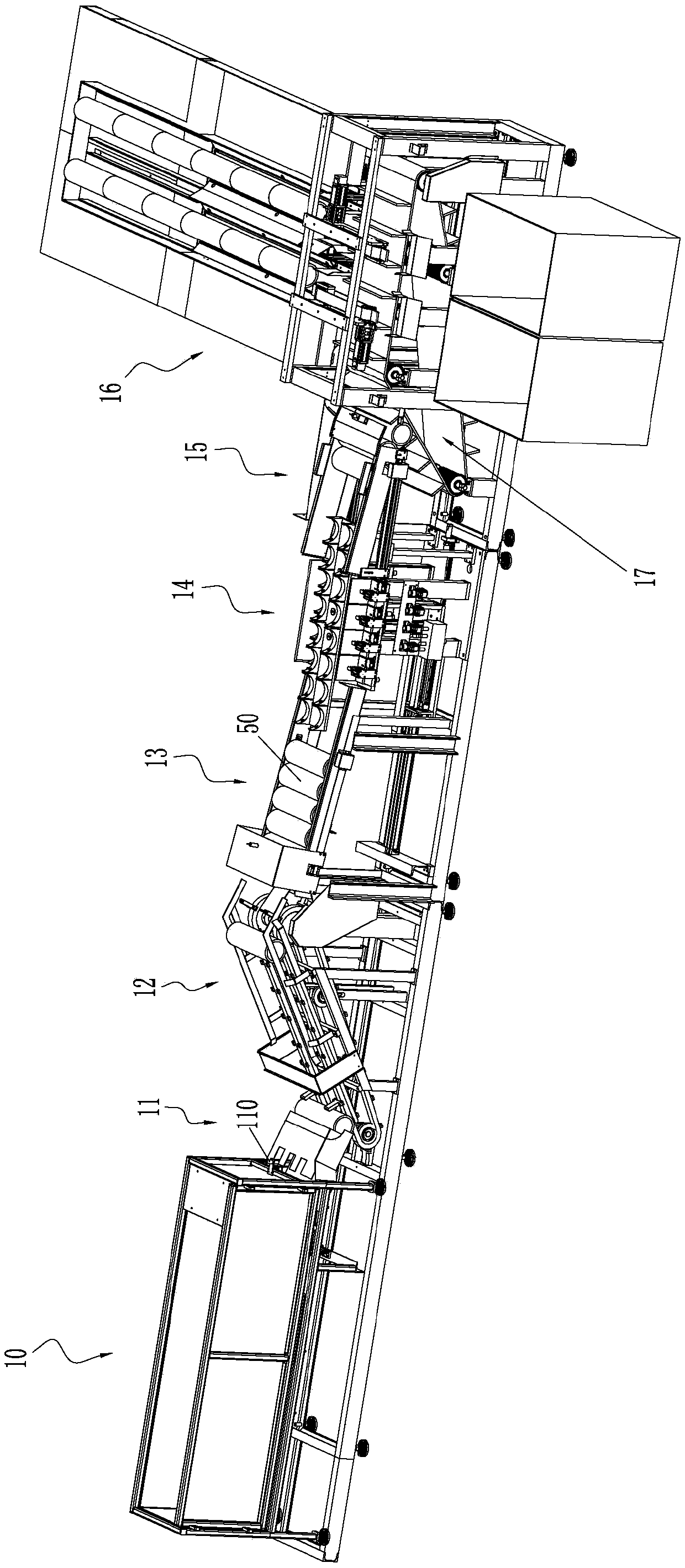

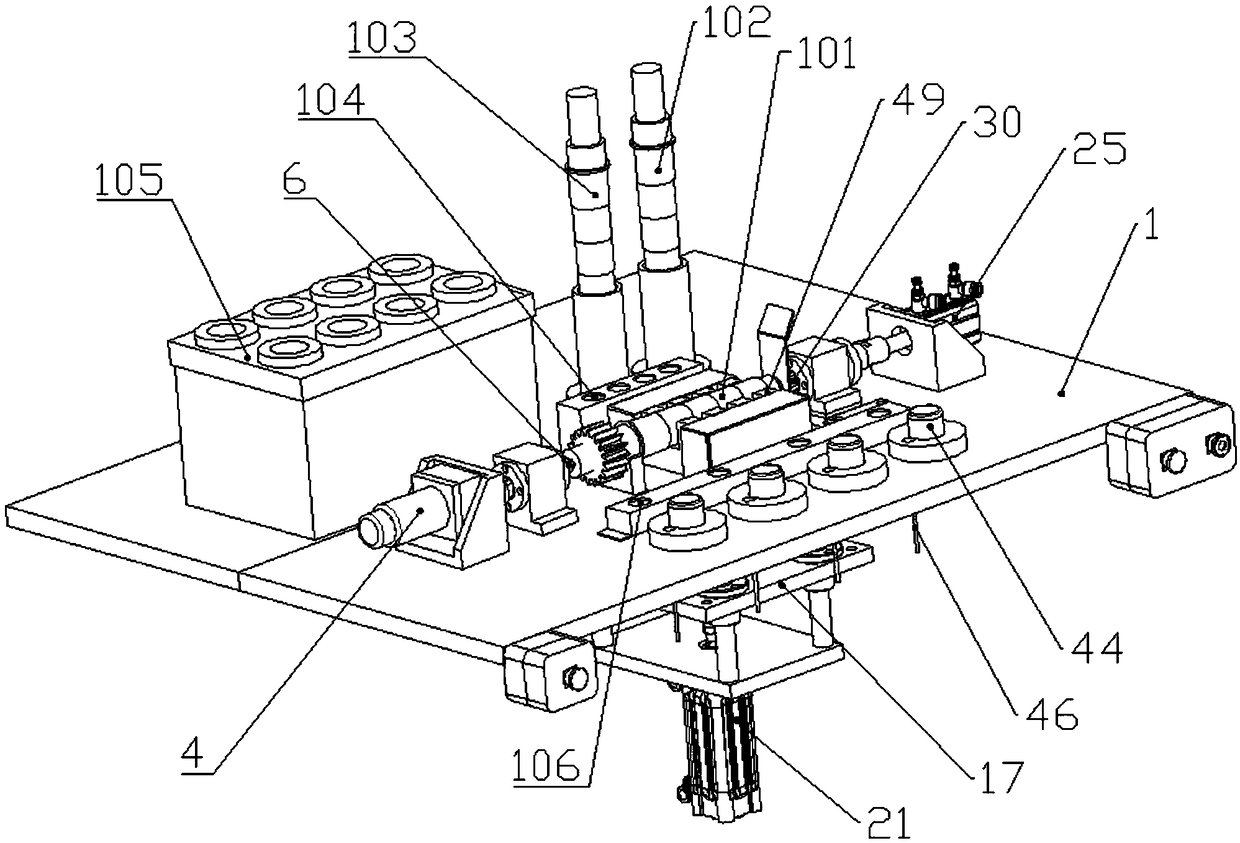

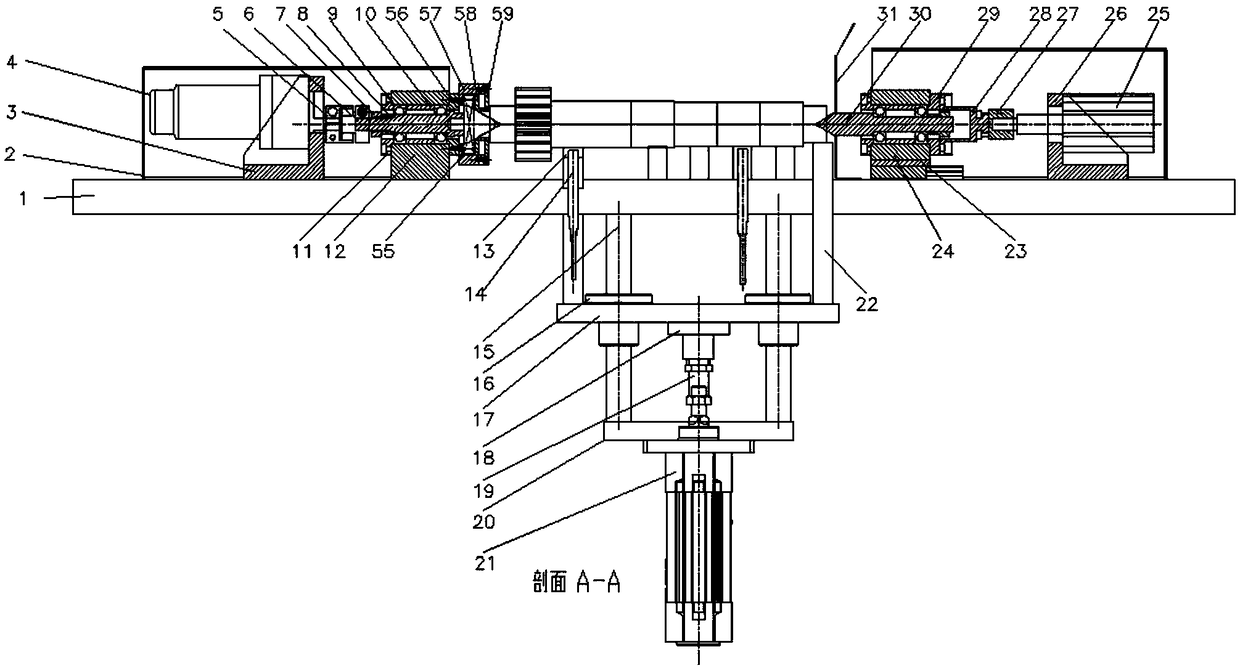

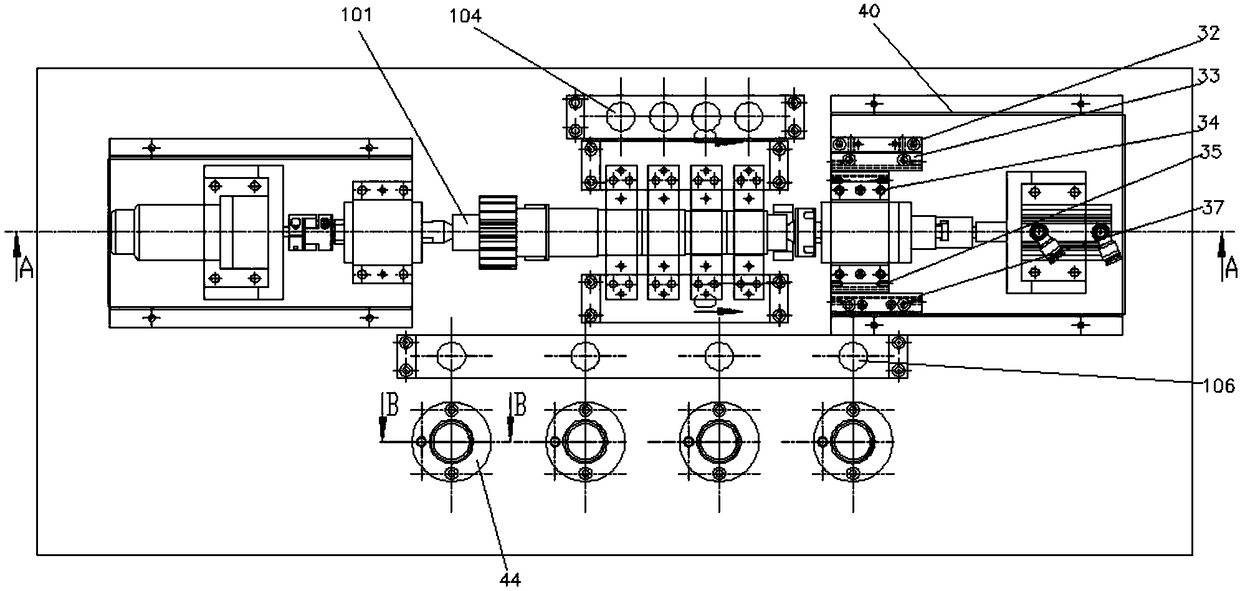

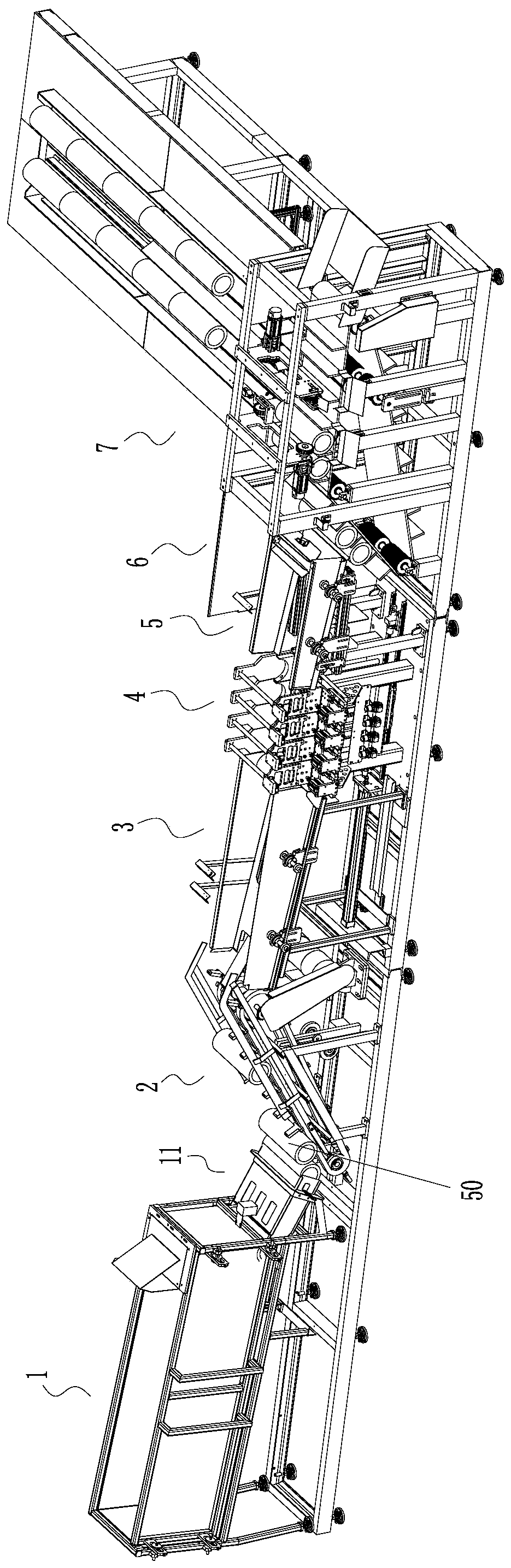

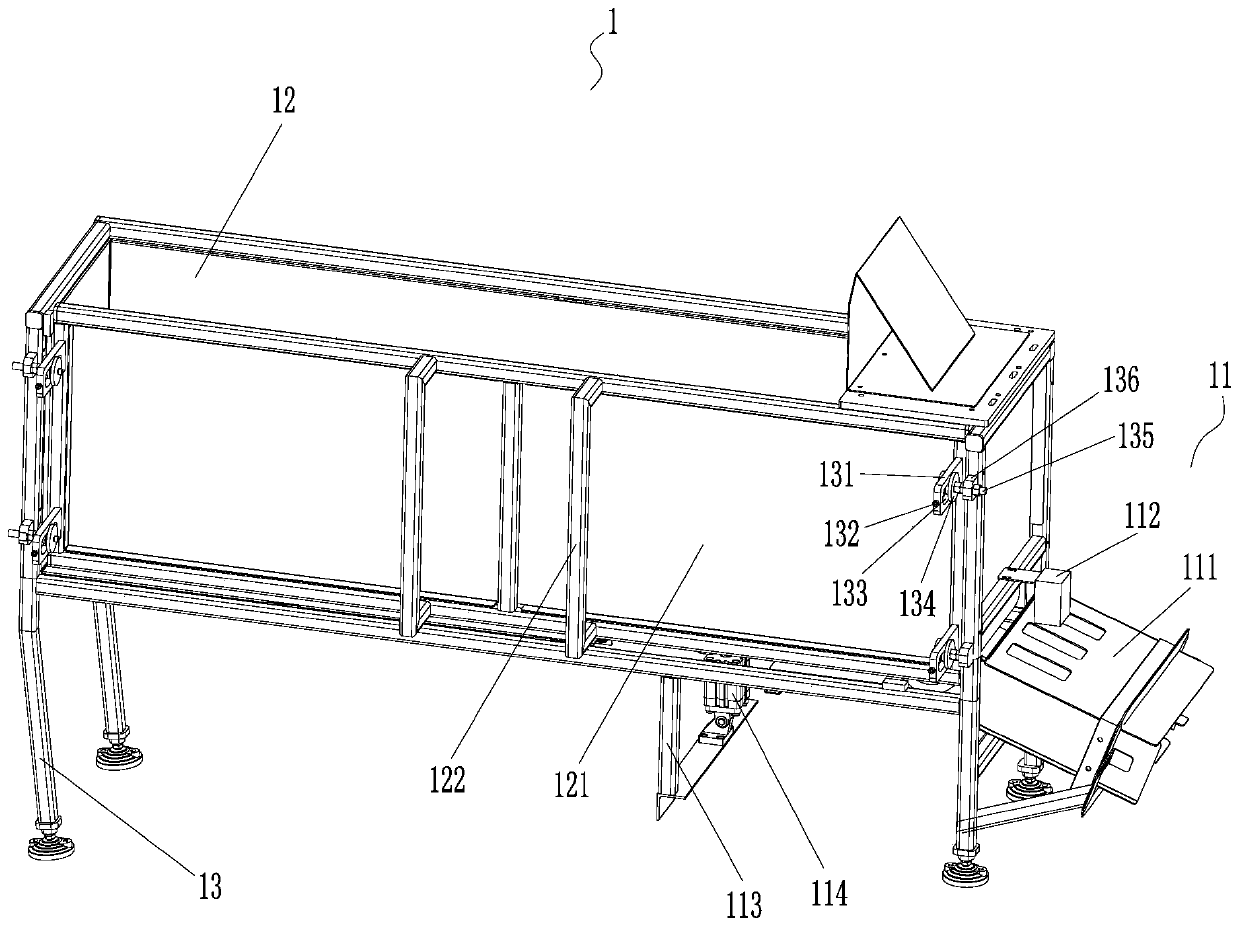

High-efficiency full-automatic paper tube measuring and sorting machine

ActiveCN109590228AHigh measurement accuracyIncrease productivitySortingPulp and paper industryEngineering

The invention relates to a high-efficiency full-automatic paper tube measuring and sorting machine. The high-efficiency full-automatic paper tube measuring and sorting machine comprises a material storage box, a continuous material feeding mechanism, a material collecting groove, a detecting mechanism, a material discharging groove, a continuous material receiving mechanism and a material stirringand sorting mechanism which are sequentially arranged from left to right, wherein the material storage box is used for storing to-be-detected paper tubes, a material discharging mechanism used for conveying the paper tubes to the continuous material feeding mechanism is arranged at the right end of the material storage box, the continuous material feeding mechanism is used for continuously conveying the paper tubes conveyed from the material discharging mechanism to the material collecting groove, the detecting mechanism is used for detecting the lengths of the paper tubes in the material collecting groove and conveying the detected paper tubes to the material discharging groove, the continuous material receiving mechanism is used for receiving the paper tubes conveyed from the material discharging groove, the material stirring and sorting mechanism is used for sorting the paper tubes conveyed from the continuous material receiving mechanism, the appropriate paper tubes are allocatedto a finished product area, and the non-appropriate paper tubes are allocated to a waste area. According to the high-efficiency full-automatic paper tube measuring and sorting machine, the lengths ofthe paper tubes can be automatically measured, then screening and classification are performed, so that the labor intensity of workers and the production cost are greatly reduced, and the measuring precision and the production efficiency of the paper tubes are improved.

Owner:嘉兴市日新自动化科技有限公司

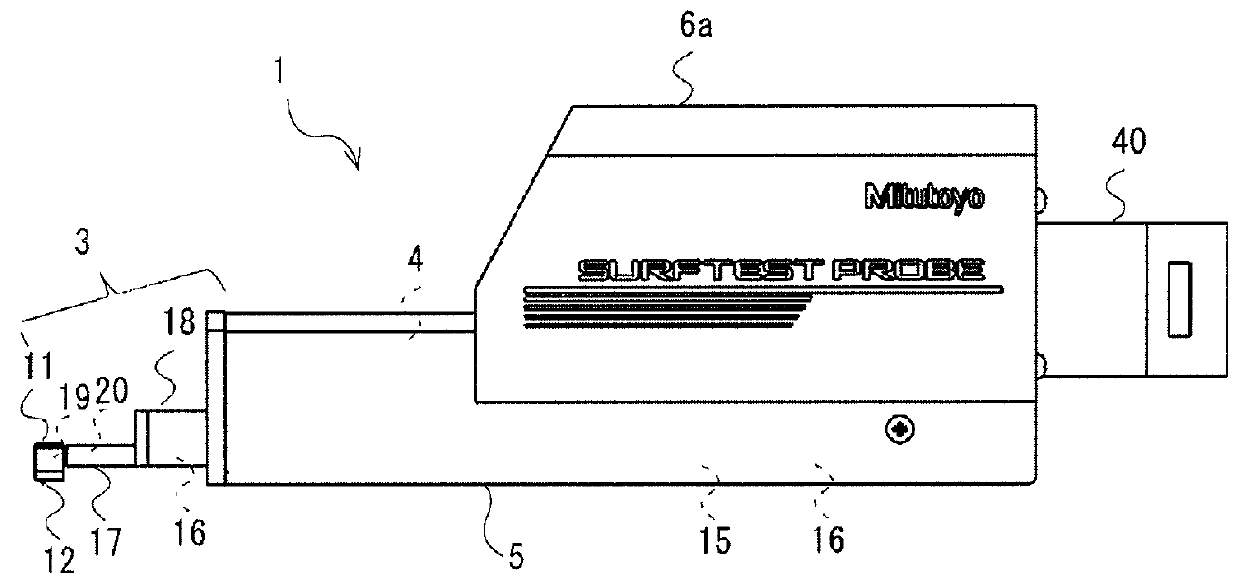

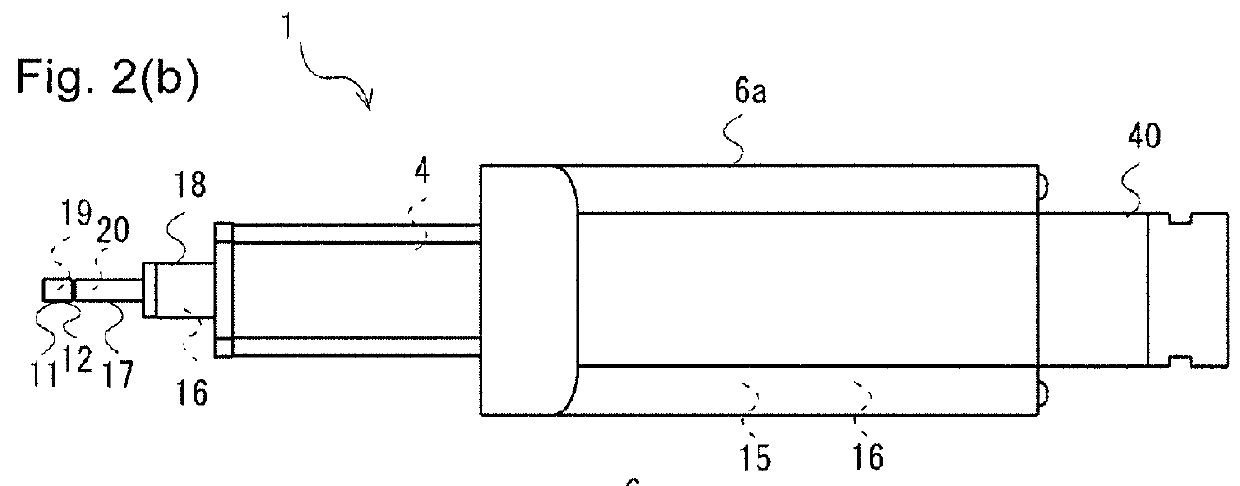

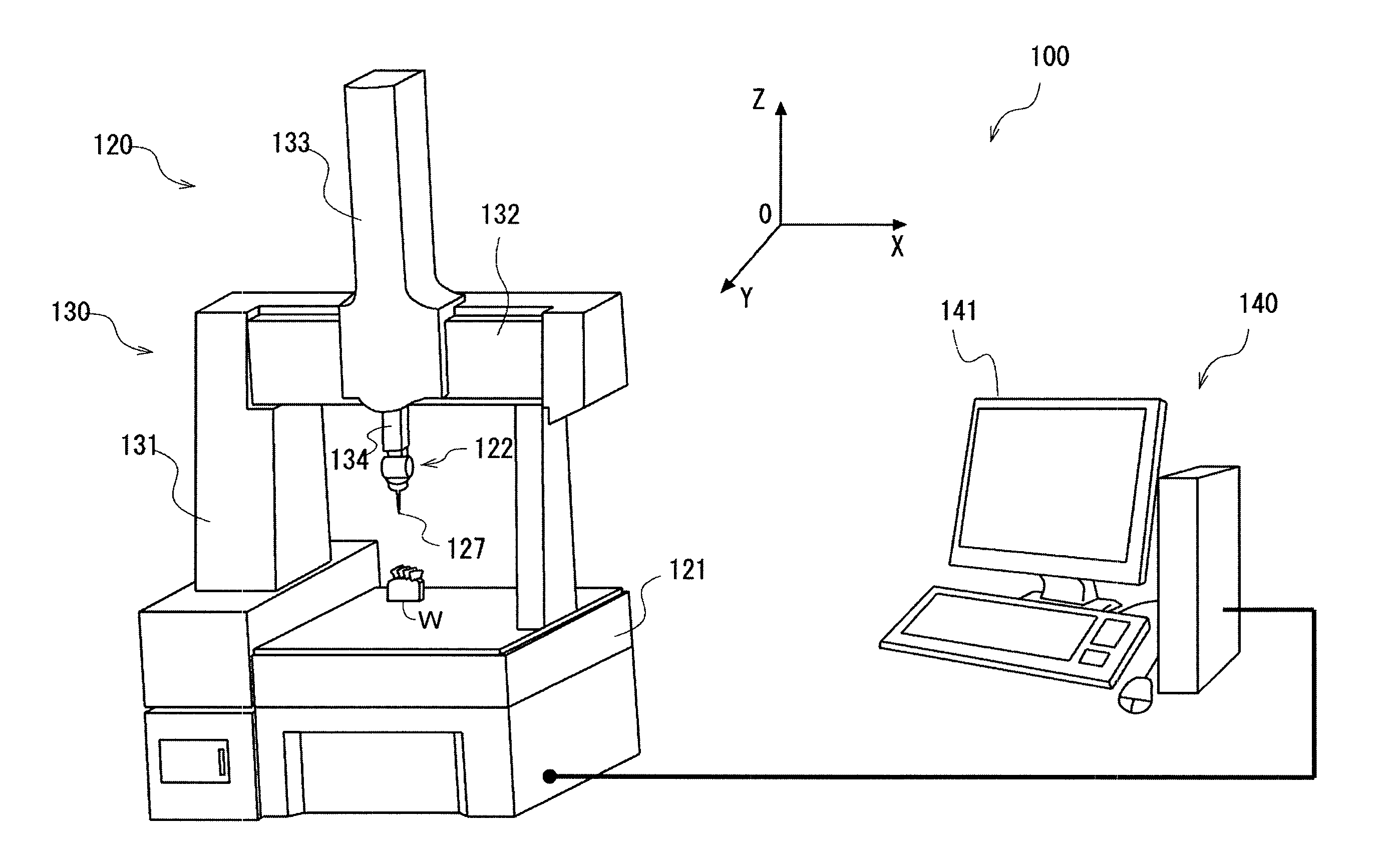

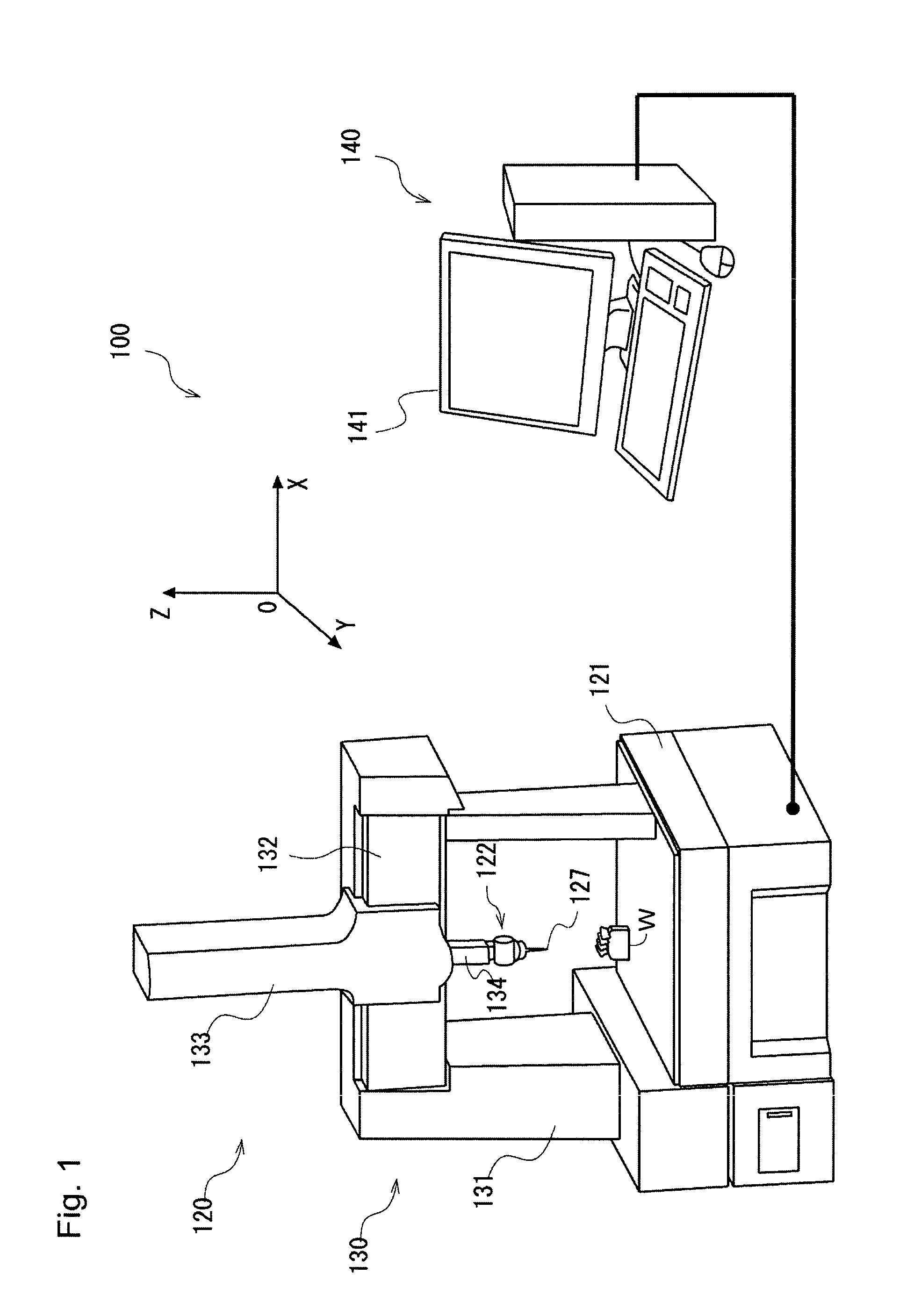

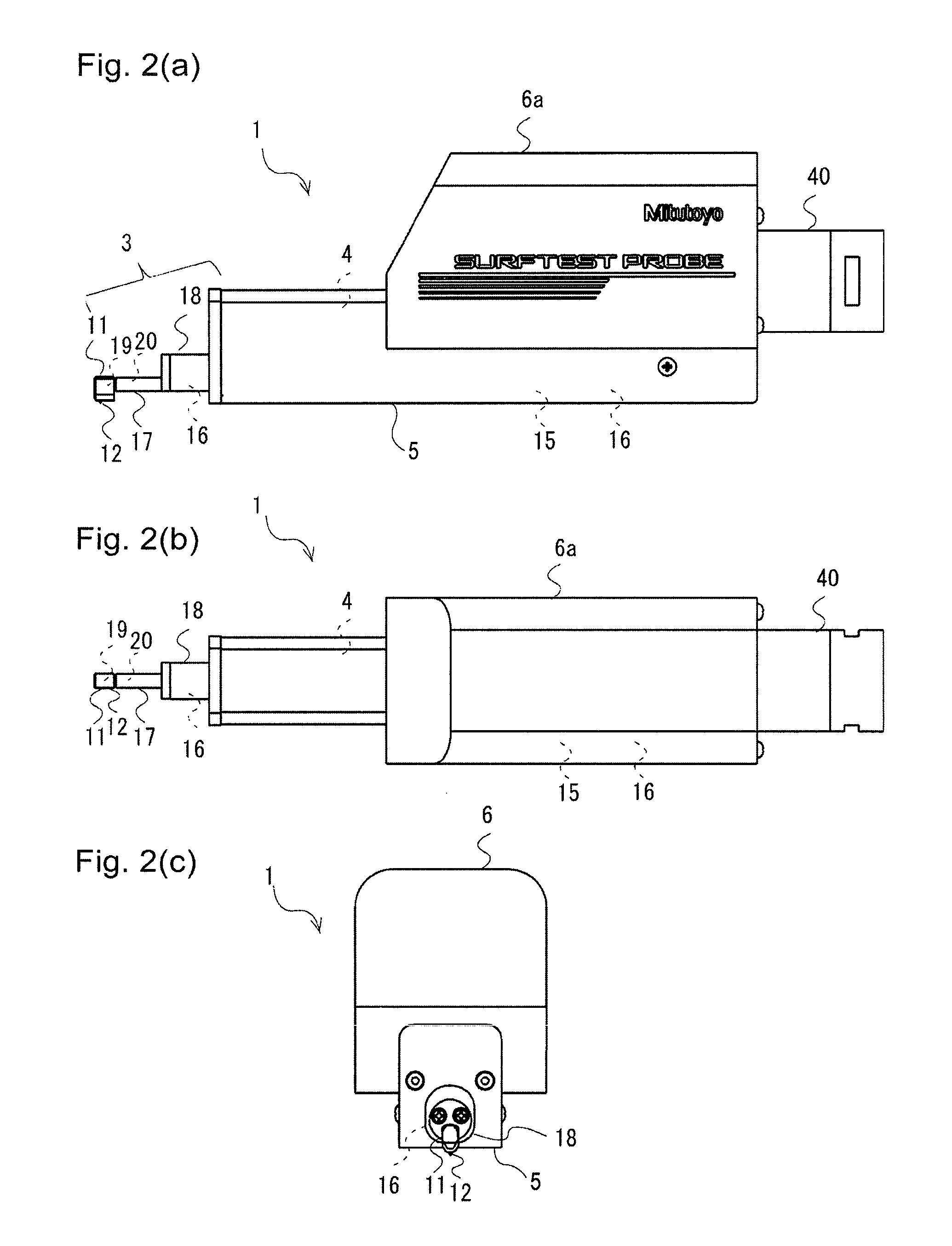

Surface roughness measuring unit and coordinate measuring apparatus

ActiveUS9250053B2Reduce measurement efficiencyMechanical diameter measurementsMechanical clearance measurementsSurface roughnessEngineering

A surface roughness measuring unit according to the present invention includes a contact pin unit having a contact pin and a displacement detector, the contact pin being provided so as to project and retract through a through-hole of a skid and scanning and moving along a surface of a work piece, the displacement detector detecting displacement of the contact pin in a direction perpendicular to the work piece surface; a driver moving the contact pin unit forward and backward along the surface of the work piece; and a joint coupling the contact pin unit and the driver to a measurement head holder of a coordinate measuring system. The surface roughness measuring unit further includes a contact detector that detects contact of the skid on the surface of the work piece.

Owner:MITUTOYO CORP

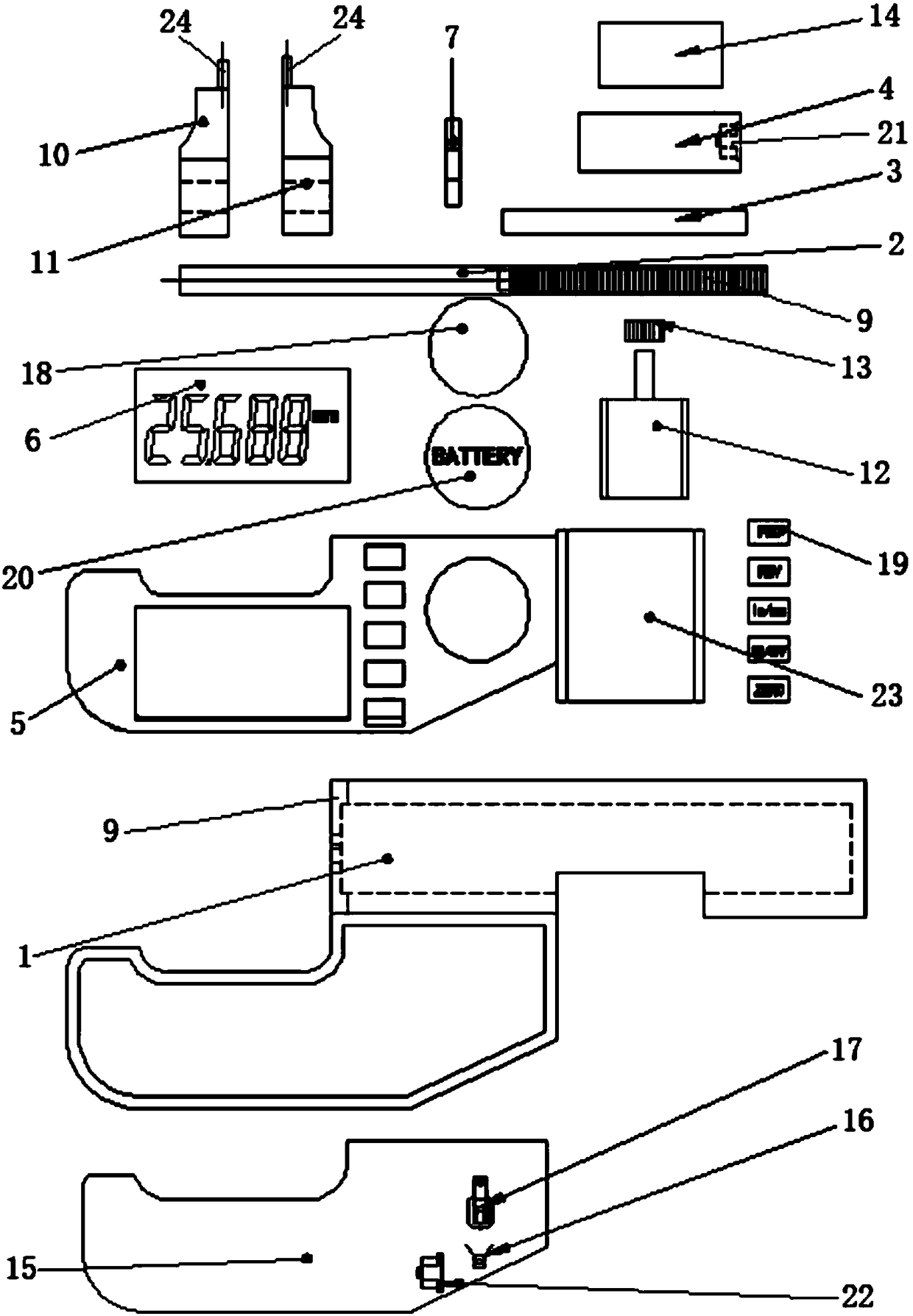

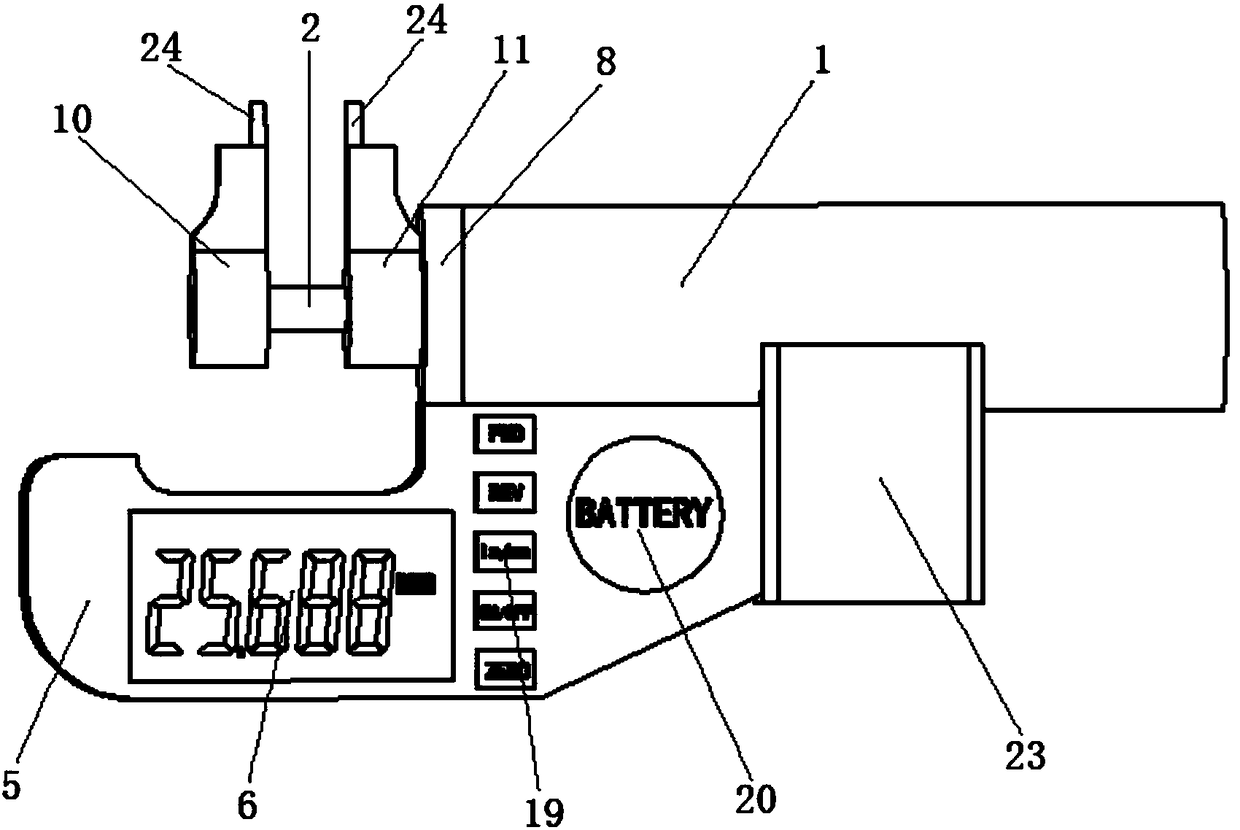

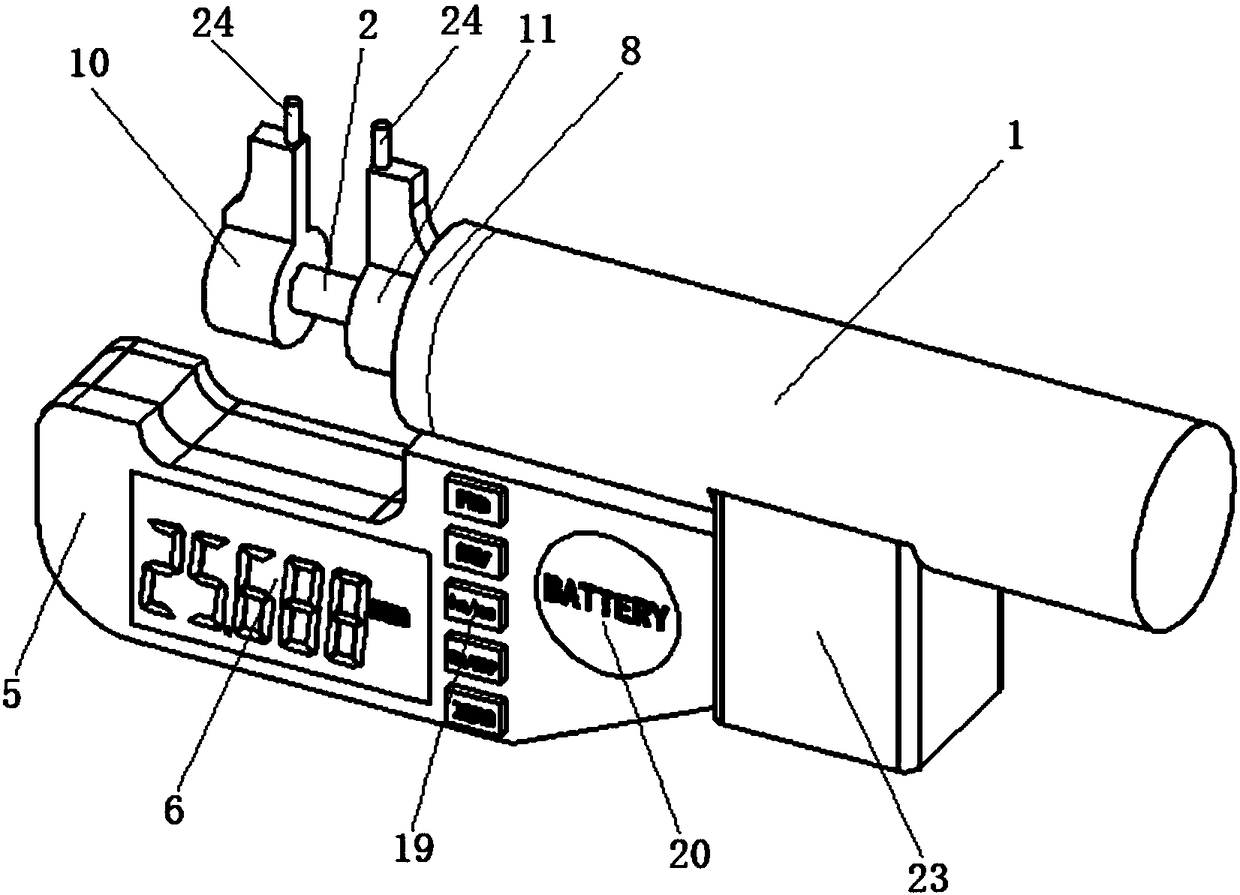

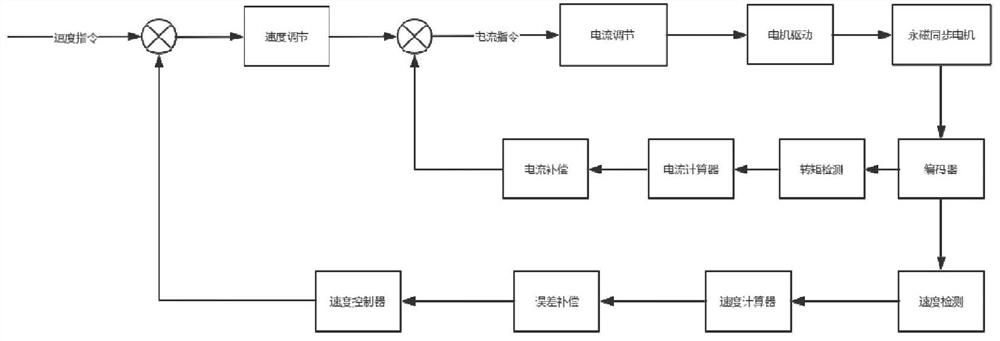

Electric quick-measurement digimatic micrometer

The invention discloses an electric quick-measurement digimatic micrometer, which comprises a micrometer body, a measurement rod, a fixed grid, a movable grid, a plastic shell and a display screen, wherein the display screen is arranged in the opening of the plastic shell; the upper part of the micrometer body is provided with a cylindrical cavity; a positioning sleeve with a center hole is arranged in the cavity of the micrometer body; the measurement end of the cavity of the micrometer body is provided with a guide sleeve with a center through hole; one side of the measurement rod is cylindrical, and the other side of the measurement rod is provided with a rack; the cylindrical end part of the measurement rod is provided with a movable measurement head; the outer side of the guide sleeveis fixedly connected with a fixed measurement head with a through hole; the micrometer is provided with a small electromotor, a transmission gear arranged on the rotation shaft of the small electromotor is meshed with the rack of the measurement rod; the measurement rod is provided with the fixed grid; the fixed grid and the movable grid are cooperated, the movable grid is arranged on a movable grid holder, and the movable grid holder is fixedly connected with the micrometer body; the measurement rod respectively forms clearance fit with the through hole of the fixed measurement head, the through hole of the guide sleeve and the through hole of the positioning sleeve.

Owner:DEQING LIANGFENG ELECTRONICS TECH CO LTD

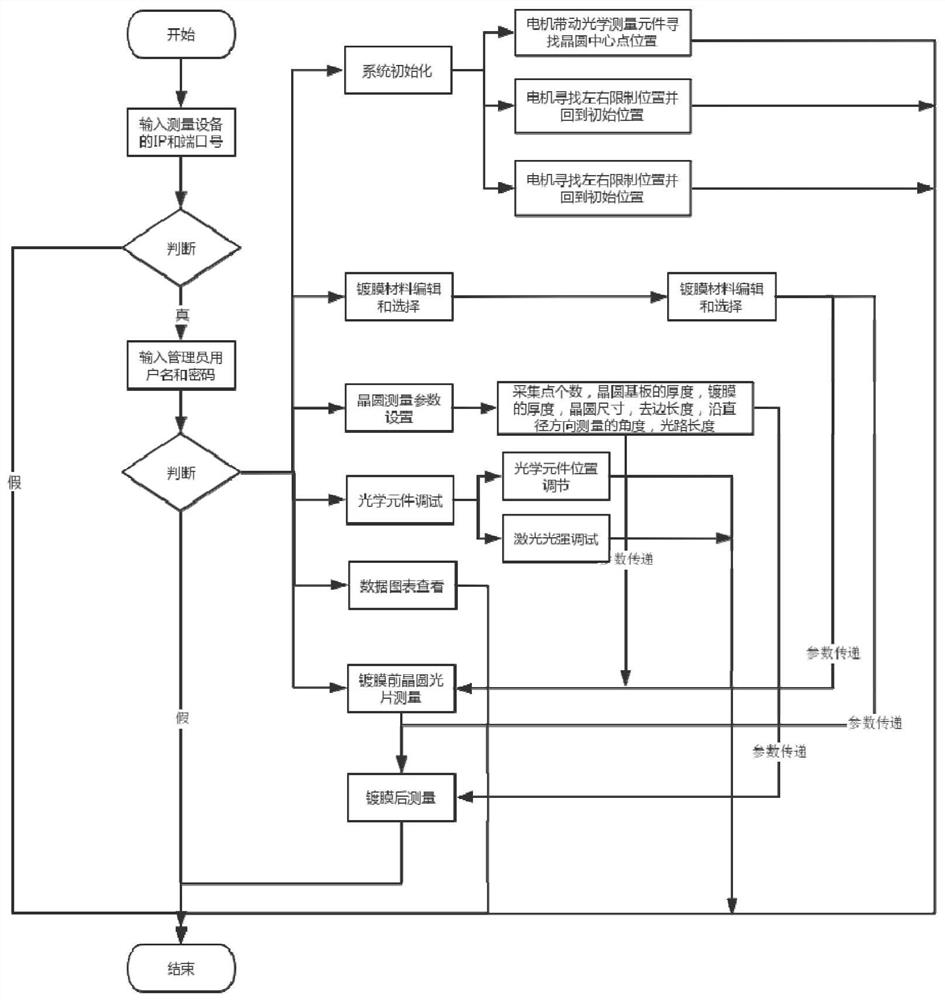

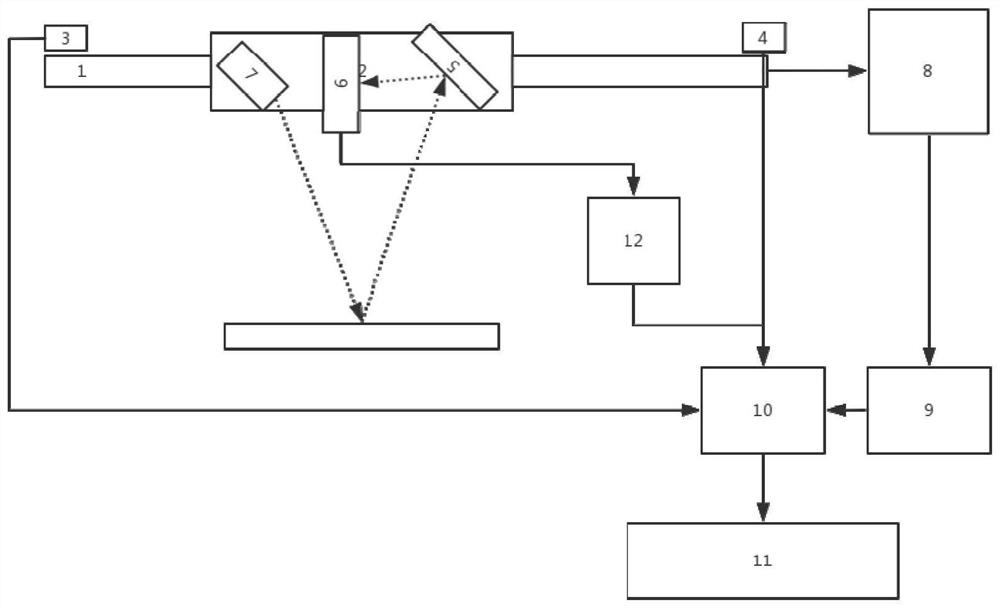

Laser detection system for visually measuring film stress

PendingCN113889423AIncreased testing requirementsImprove product qualitySemiconductor/solid-state device testing/measurementWaferEngineering

The invention discloses a laser detection system for visually measuring film stress, and belongs to the technical field of semiconductor manufacturing and detection. The system comprises a laser measurement module, the laser measurement module at least comprises a one-dimensional linear sensor, wherein the laser measurement module is configured to emit laser to the surface of a wafer and irradiate the laser reflected by the wafer to the one-dimensional linear sensor; an acquisition end configured to acquire current changes at the two ends of the light curtain on the one-dimensional linear sensor; a main control end, wherein the main control end is in wireless communication connection with the acquisition end, and the main control end is configured to calculate wafer film stress data according to current changes at the two ends of a light curtain on the one-dimensional linear sensor and generate a visual command according to the wafer film stress data, and send the visual data to a visual terminal which is in communication connection with the main control end for real-time display. Data visualization is adopted, different wafer sizes and different coating materials are manually selected for measurement through the visualization platform, and multiple purposes are achieved through one machine.

Owner:EAST CHINA NORMAL UNIV

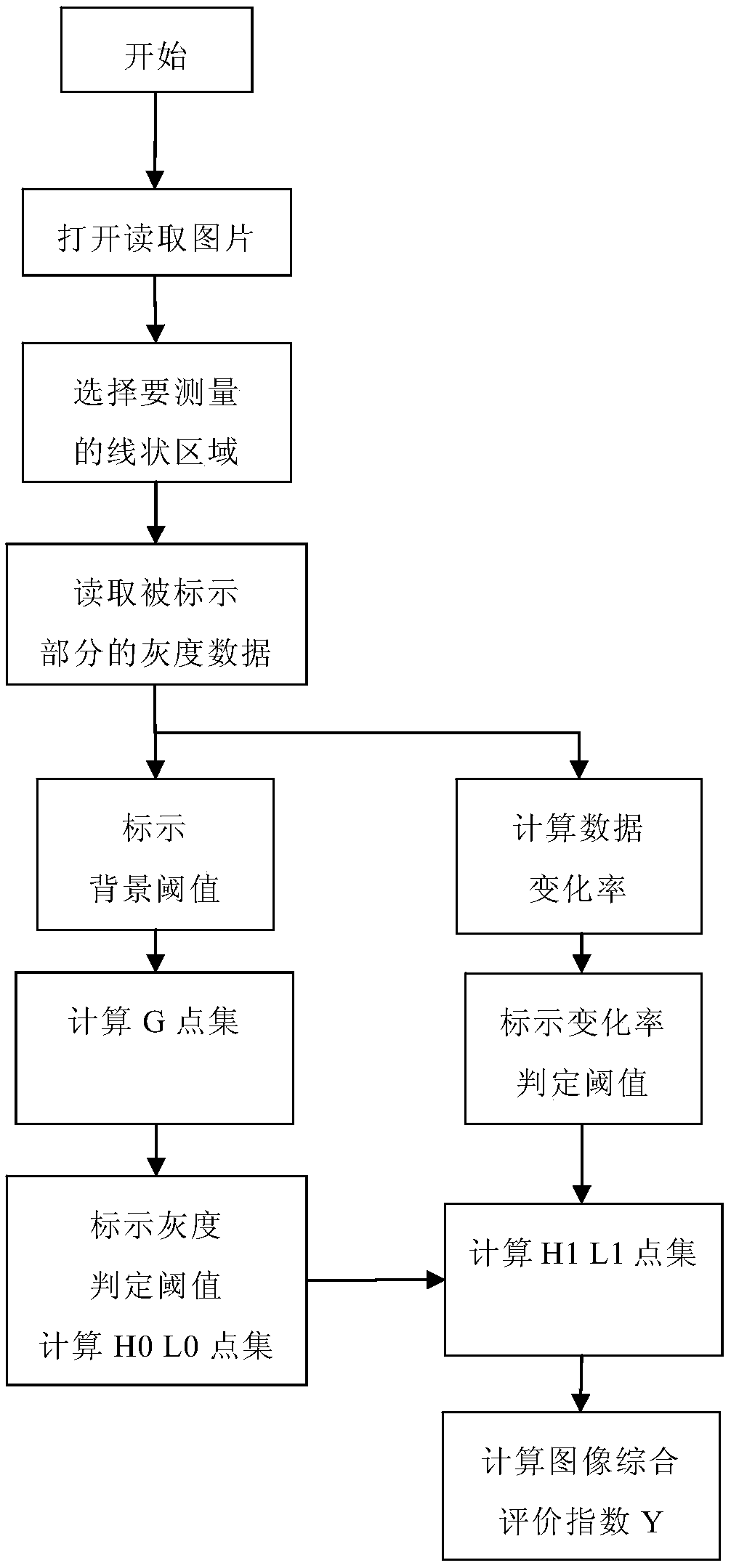

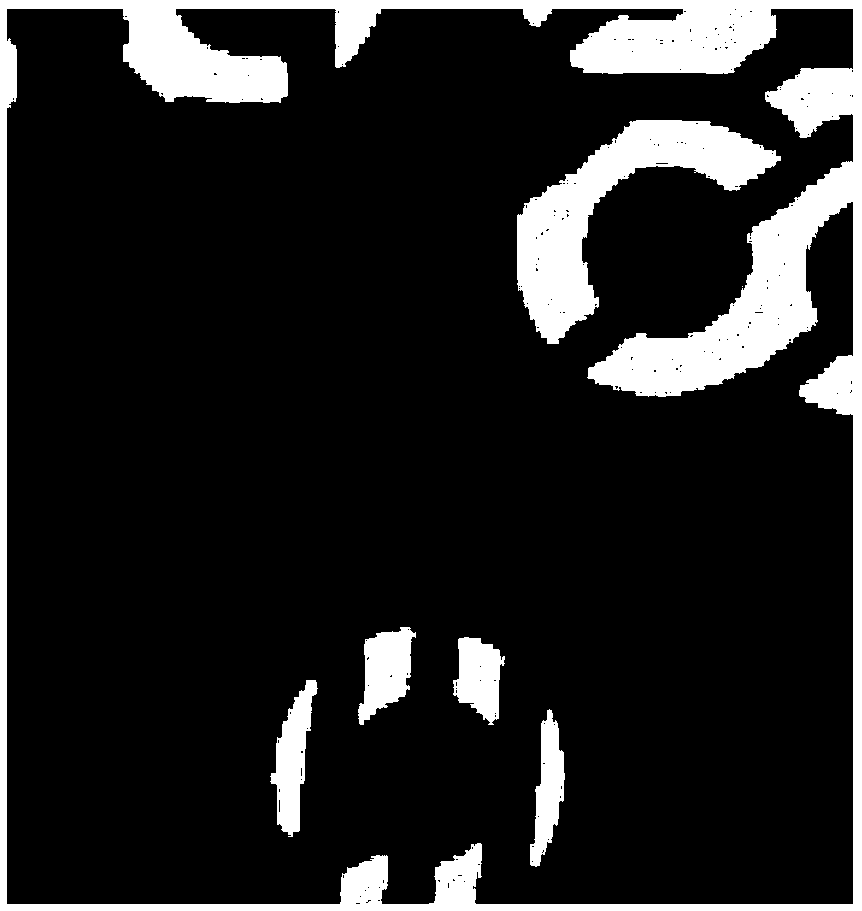

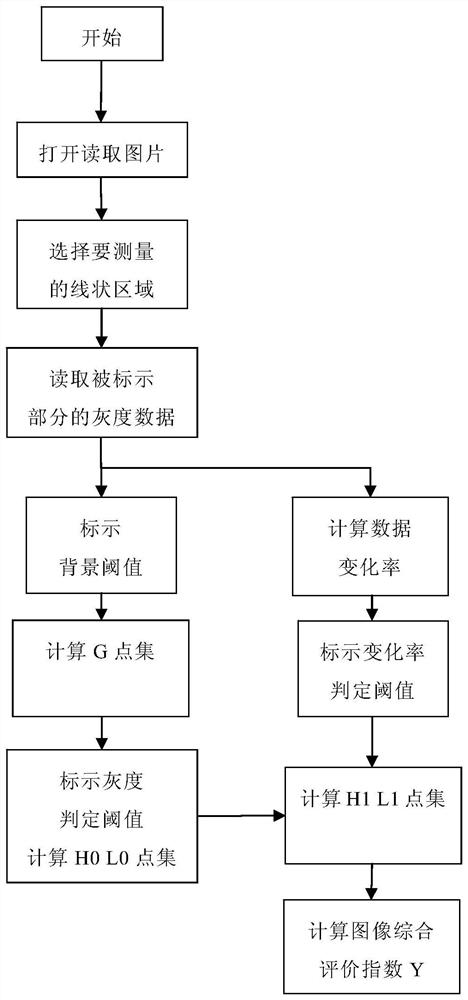

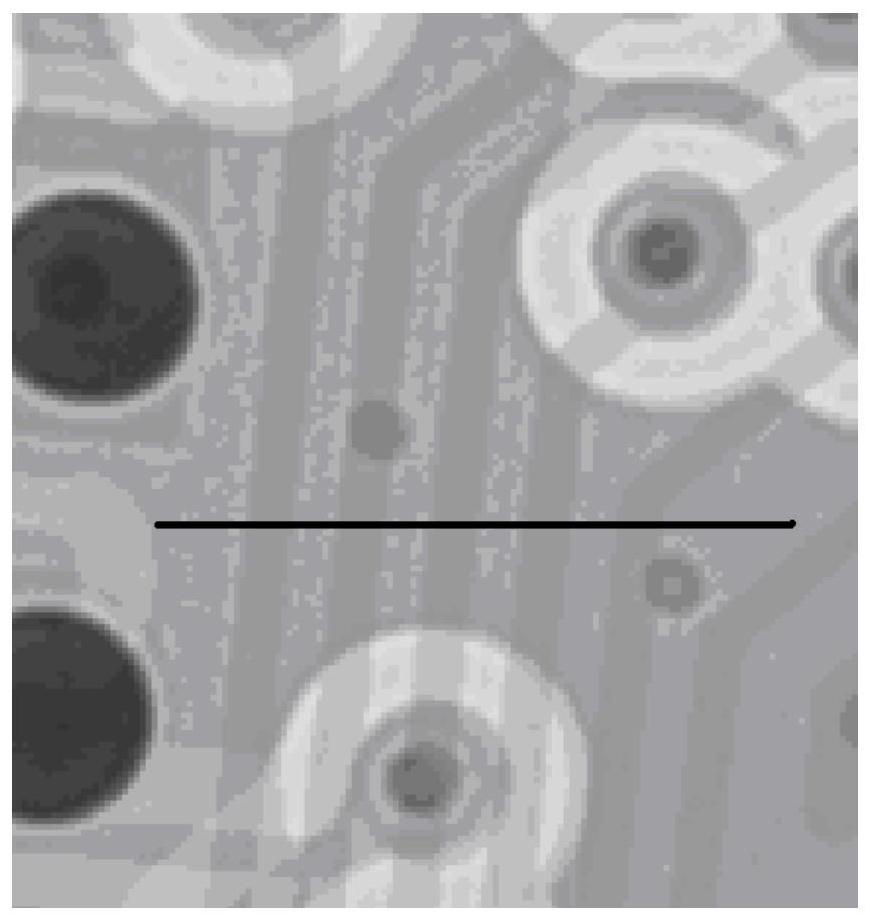

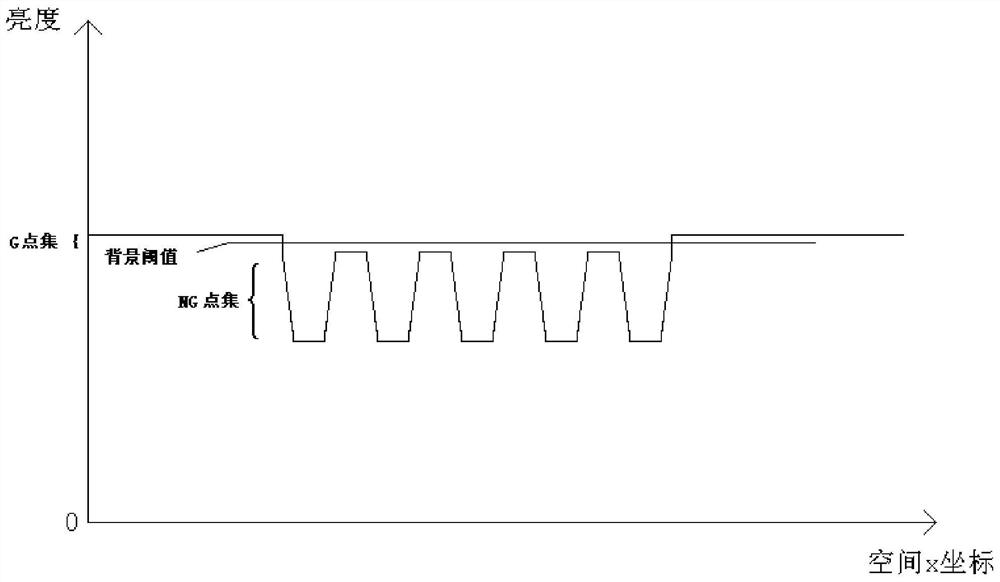

A method for determining the modulation degree of a ray digital image and an application thereof are disclosed

InactiveCN108986080AReduce measurement efficiencyHigh standardImage enhancementImage analysisPattern recognitionImaging quality

The invention relates to a method for determining the modulation degree of a ray digital image and an application thereof. Aiming at the problem that the subjective evaluation and objective evaluationof the X-ray digital images obtained by a micro-focus X-ray machine from PCB assemblies are inconsistent, the local image quality is accurately identified by calibrating the pixel edges of the recognized digital image and using the software transfer function algorithm. Based on this method, the application criteria of the image modulation degree Y and the image comprehensive evaluation index y are given. The experimental results show that the image comprehensive evaluation index and subjective evaluation result obtained by this method have high fitting degree, the problem of inconsistency between subjective judgment and objective judgment can be solved, and the drawbacks of artificial subjective judgment of image quality are effectively avoid.

Owner:BEIJING AEROSPACE GUANGHUA ELECTRONIC TECH CO LTD

Method for measuring germination biology threshold temperature of cucumber seed

InactiveCN101129111AHigh precisionSimple and fast operationGerminating apparatusThreshold temperatureCucumber seed

The invention discloses a testing method of biological starting point temperature of cucumber seed germination, which comprises the following steps: (1) sampling the seed; (2) seeding the dried seed directly; (3) changing daily seed temperature to germinate slowly; (4) testing and correcting the germination; (5) calculating the daily even temperature and respective germination time of the seed under specific germination level; (6) calculating the theoretical value of biological starting point temperature. The invention has precision result and convenient operation, which reduces the working quantity.

Owner:HUNAN AGRICULTURAL UNIV

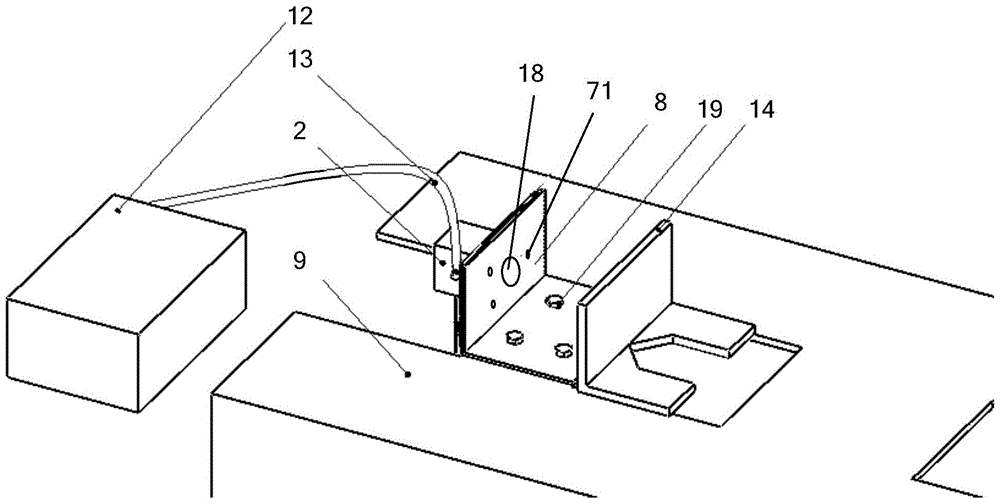

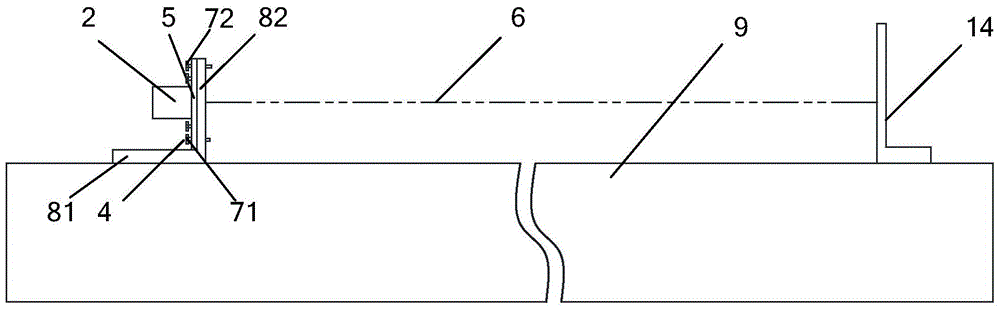

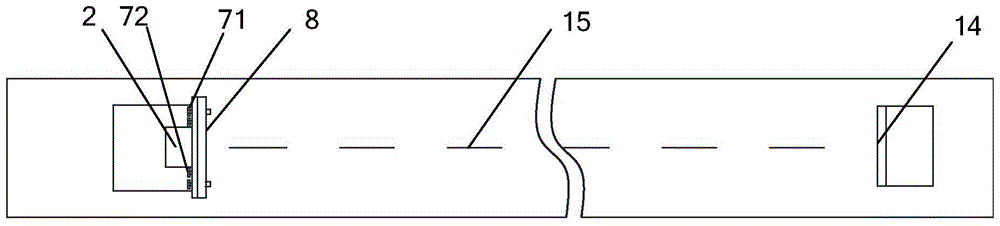

Installation structure and installation method for perpendicularity sensor on overlong square tubular column

ActiveCN104457717AReduce measurement efficiencyOvercome installation and positioning problemsSurveying instrumentsIncline measurementLaser transmitterEngineering

The invention discloses an installation structure and an installation method for a perpendicularity sensor on an overlong square tubular column. The installation structure comprises a laser inclinometer internally provided with a perpendicularity sensor and a laser emitter, a regulating plate, a right-angled bending plate, a light target, a coarse tuning bolt component and a fine tuning bolt component, wherein the laser of the laser emitter is parallel to a measuring baseline of the perpendicularity sensor; through holes for emitting laser are correspondingly formed in a laser inclinometer connecting plate and the regulating plate; the position of the regulating plate is regulated by virtue of the coarse tuning bolt component and the fine tuning bolt component, so that the position of the laser on the light target is unchanged when the light target is arranged on different installation baselines, and the laser emitted after the laser inclinometer is installed and fixed is parallel to the axis of the square tube column. The installation structure can be used for solving the installation and positioning problem of the perpendicularity sensor on the square tube column in an automatic test method of the perpendicularity sensor, realizing the convenient and accurate detection of the square tube column, and realizing the real-time detection of the perpendicularity of the overlong square tube column.

Owner:SHANGHAI CONSTRUCTION GROUP

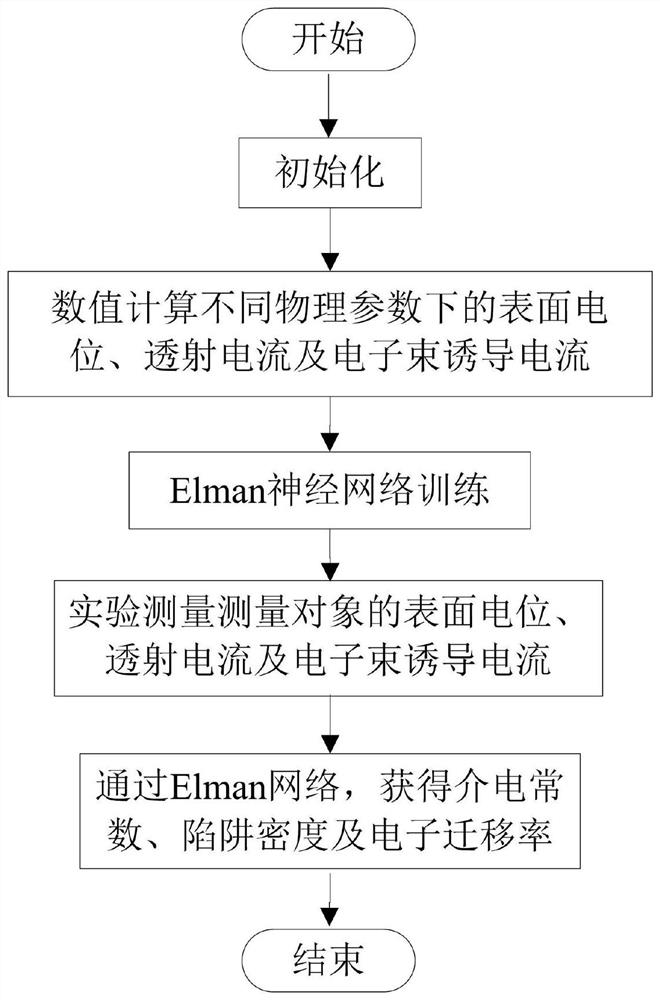

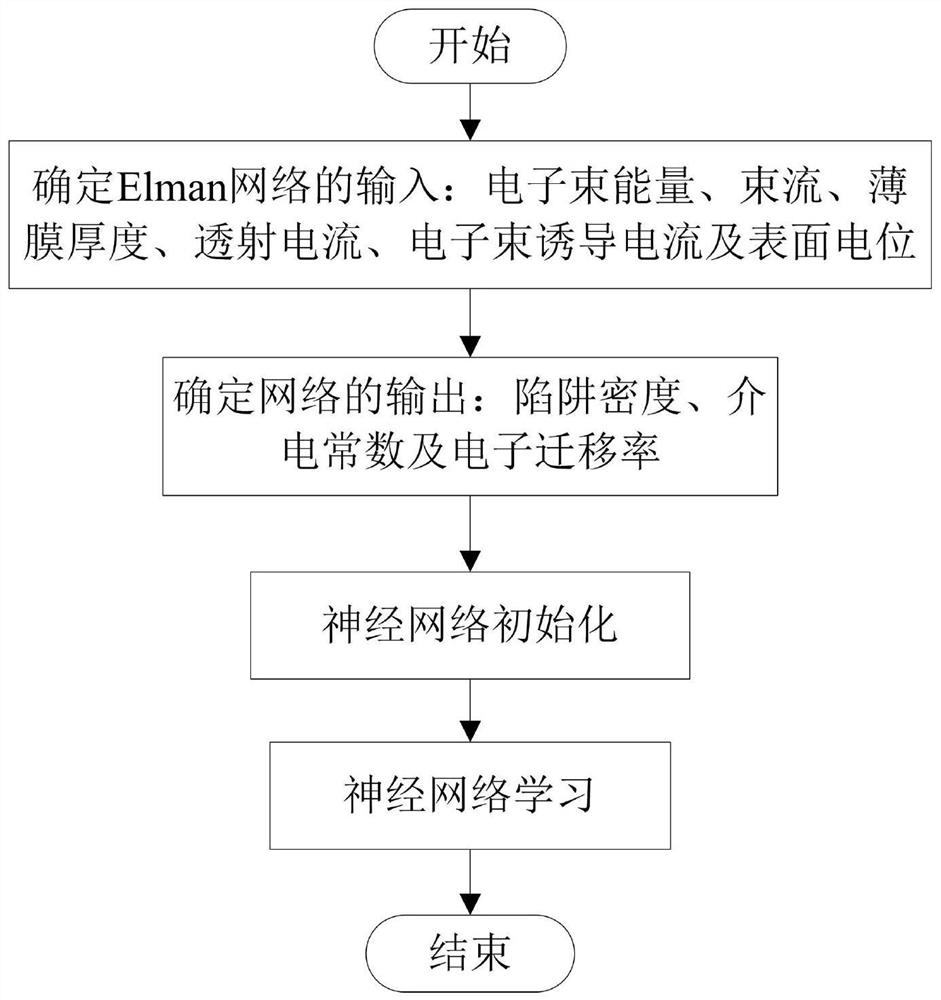

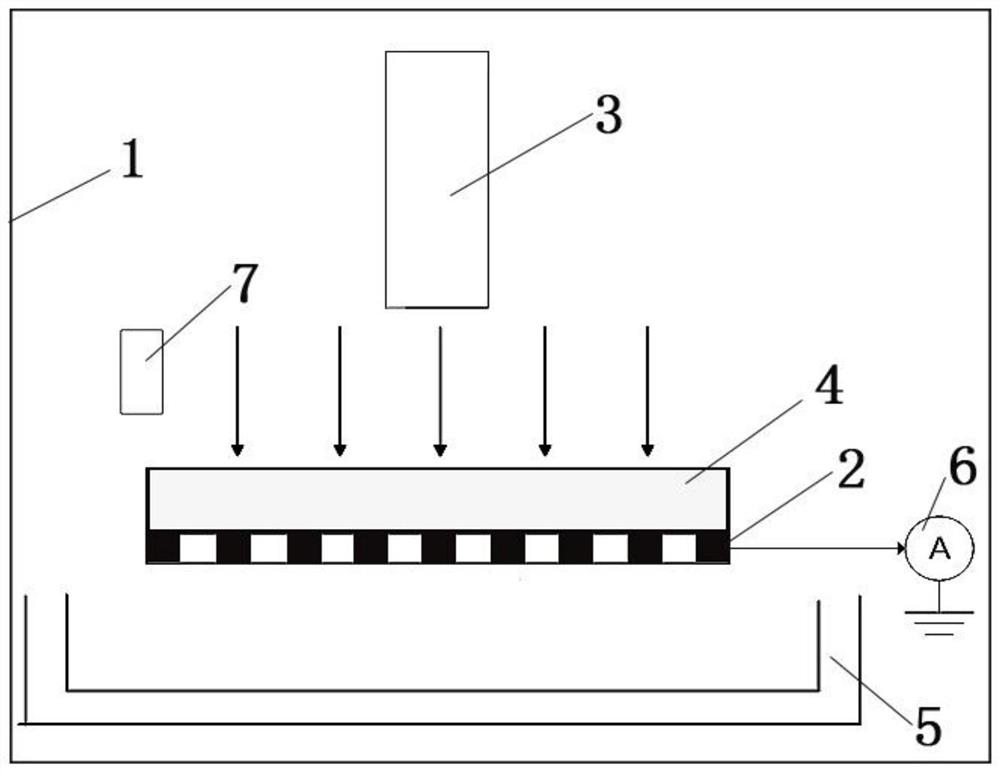

Method for simultaneously measuring multiple physical parameters of dielectric film

PendingCN112964937AGuaranteed reliabilityReduce measurement efficiencyDielectric property measurementsDesign optimisation/simulationDielectricParticle physics

The invention relates to a method for simultaneously measuring multiple physical parameters of a dielectric film. Physical parameters, such as defect density, dielectric constant and electron mobility, of a film are indirectly measured according to transmission current, electron beam induced current and surface potential under electron beam irradiation. According to the basic idea, the corresponding transmission current, electron beam induction current and surface potential are obtained through numerical calculation according to a given dielectric film, given electron beam irradiation conditions, trap density, electron mobility and dielectric constant; a non-linear relationship between the multiple physical parameters and the transmission current, the electron beam induced current and the surface potential is established based on an Elman artificial neural network; and finally, the transmission current, the electron beam induced current and the surface potential of a to-be-measured object are measured in an experiment, and finally multiple physical parameters are obtained through the Elman network. The method has the advantages of being reliable in measurement, high in measurement speed and low in measurement cost.

Owner:江苏腾锐电子有限公司

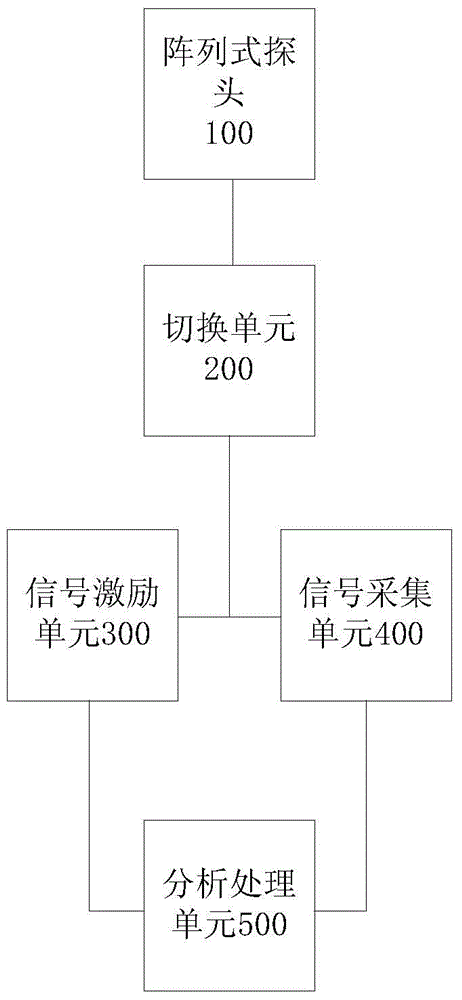

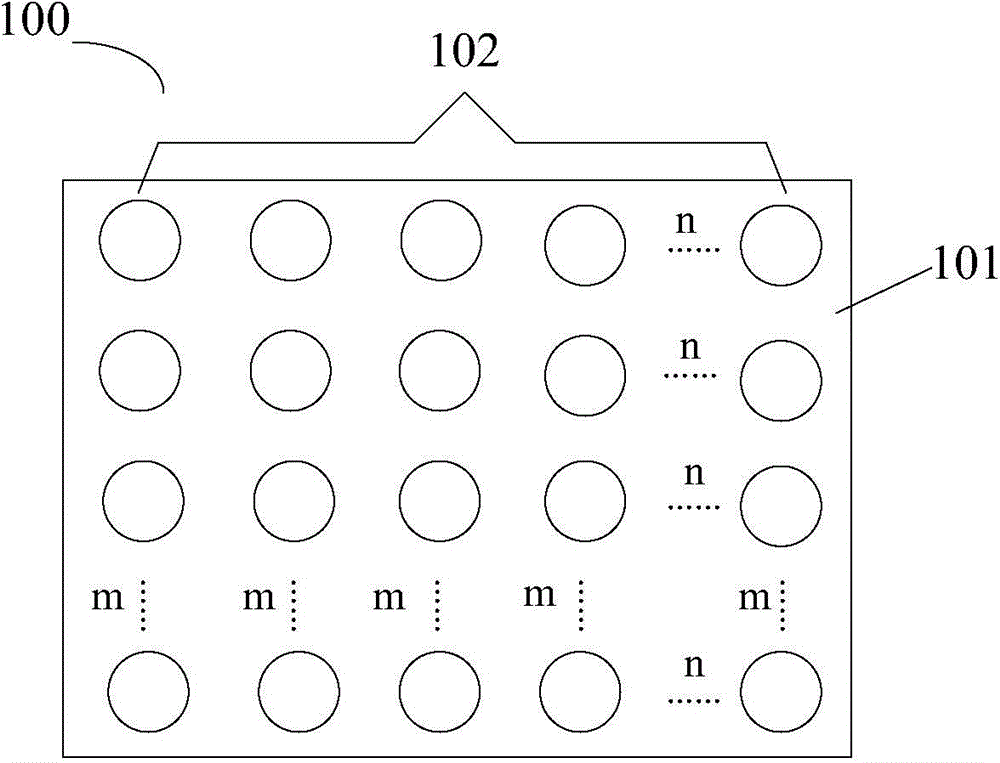

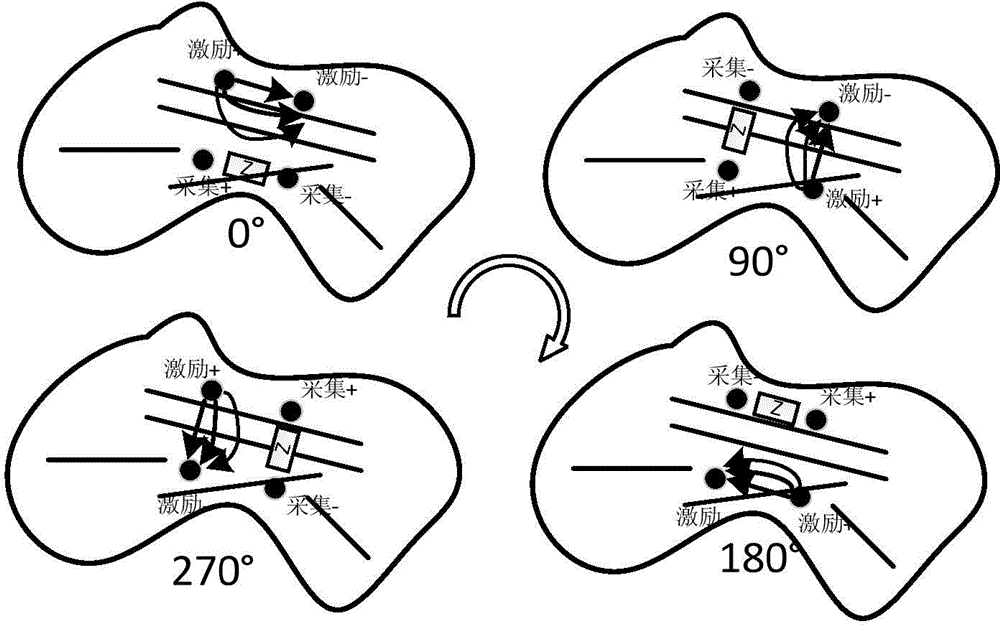

Quick measuring device and quick measuring method on basis of bio-impedance technologies

InactiveCN105286863AImprove measurement accuracyGuaranteed SensitivityDiagnostic recording/measuringSensorsFast measurementMeasurement device

The invention particularly discloses a quick measuring device and a quick measuring method on the basis of bio-impedance technologies. The quick measuring device comprises an array probe, a switching unit, a signal excitation unit, a signal acquisition unit and an analysis and processing unit. An electrode array of the array probe is connected with the signal excitation unit and the signal acquisition unit by the switching unit, the array probe comprises a substrate and the electrode array, the electrode array is embedded in the substrate, N*M micro-electrodes are arranged in an array manner to form the electrode array, and a plurality of detection regions for measuring bio-impedance in a unit of two or four micro-electrodes are formed by the electrode array. The quick measuring device and the quick measuring method have the advantages that the detection regions are increased, the repeated point selection frequencies are reduced, different depths and surfaces of to-be-measure biological tissues can be measured, accordingly, the to-be-measured biological tissues can be omni-directionally measured without dead spaces, and missing detection can be thoroughly prevented.

Owner:SEALAND TECH CHENGDU

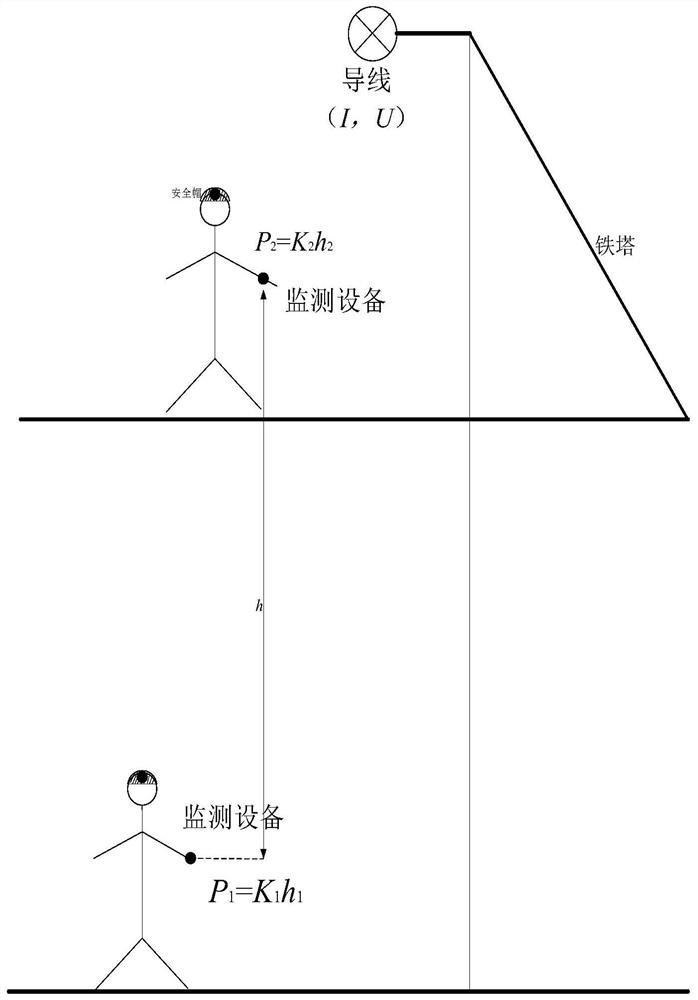

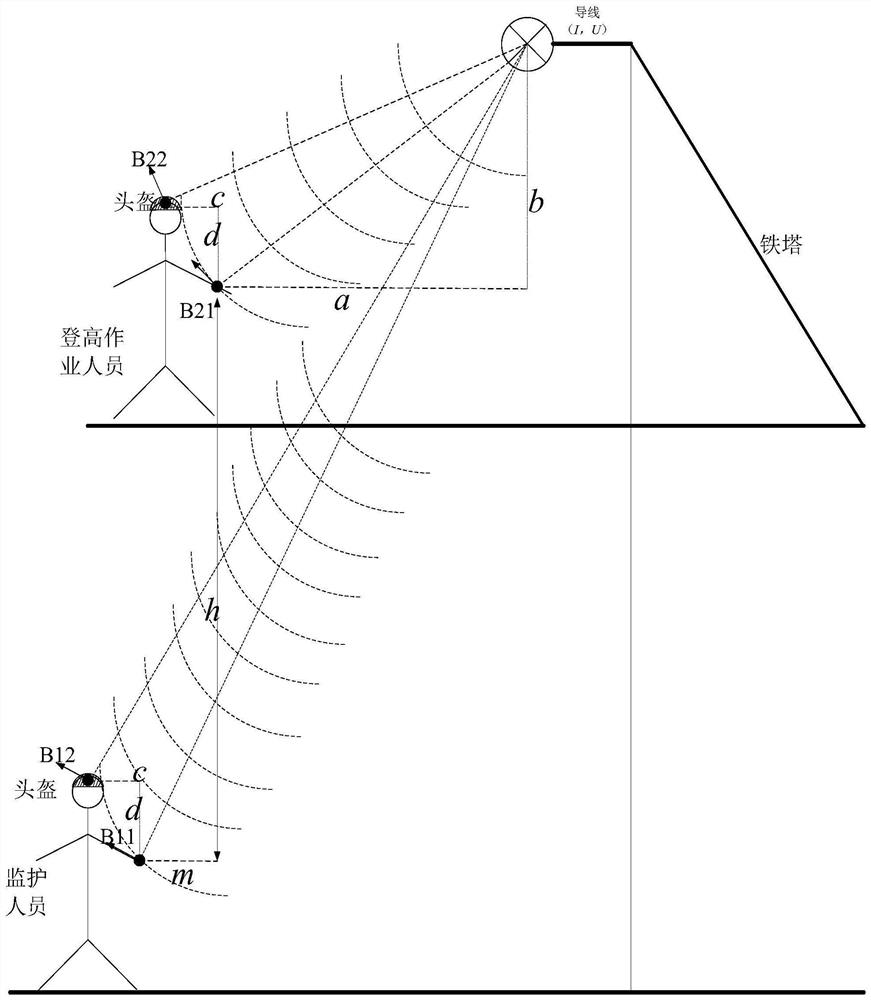

Operation safety real-time monitoring method and system

PendingCN113805115AImprove securityEliminate the effects ofProgramme controlComputer controlLaser rangingSimulation

The invention belongs to the technical field of operation safety monitoring, and particularly relates to an operation safety real-time monitoring method and system. The height difference between a climbing worker and a guardian is calculated according to the relation between the air pressure and the height. As a relative value is adopted for calculation, the influence of the atmospheric pressure on the measurement result is eliminated, and the measurement and calculation precision is improved. According to the invention, no matter how a climbing worker moves, the height difference between the climbing worker and a guardian can be calculated in a self-adaptive manner, and the situation that the measurement efficiency is reduced due to the fact that a laser ranging module is constantly adjusted to follow the movement is avoided. Meanwhile, a guardian can receive related information in time when monitoring that a climbing worker climb without permission, and the safety of operation is improved. Whether the distance between a climbing worker and a power transmission conductor is safe or not is judged according to the relation between the magnetic induction intensity and the distance from the power transmission conductor, measurement of the safe distance is converted into measurement of the magnetic field intensity, and the measurement is more visual.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

Surface roughness measuring unit and coordinate measuring apparatus

ActiveUS20140109422A1Reduce measurement efficiencyUsing electrical meansNanotechnologyMeasurement deviceSurface roughness

A surface roughness measuring unit according to the present invention includes a contact pin unit having a contact pin and a displacement detector, the contact pin being provided so as to project and retract through a through-hole of a skid and scanning and moving along a surface of a work piece, the displacement detector detecting displacement of the contact pin in a direction perpendicular to the work piece surface; a driver moving the contact pin unit forward and backward along the surface of the work piece; and a joint coupling the contact pin unit and the driver to a measurement head holder of a coordinate measuring system. The surface roughness measuring unit further includes a contact detector that detects contact of the skid on the surface of the work piece.

Owner:MITUTOYO CORP

Comprehensive test tool for outer diameter of stepped shaft and inner hole of gear

InactiveCN108627132AHigh positioning accuracyImprove detection efficiencyMeasurement devicesEngineeringMechanical engineering

The invention discloses a comprehensive test tool for detecting the outer diameter of a stepped shaft and the inner hole of a gear, which belongs to the technical field of automobile part assembly size inspection. The comprehensive test tool comprises a positioning assembly used for stepped shaft positioning, a feeding assembly used for feeding the stepped shaft, an outer diameter measuring assembly used for measuring the outer diameter of the stepped shaft, and an inner hole measuring assembly used for detecting the inner hole of the gear. The positioning assembly, the feeding assembly, the outer diameter measuring assembly and the inner diameter measuring assembly are all installed on a bottom plate. The invention is advantageous in that the structure is simple, positioning is accurate,operation is convenient, and the measuring efficiency of the outer diameter of the stepped shaft and the inner hole of the gear is high.

Owner:JIANGNAN UNIV

Automatic feeding structure for measuring paper tubes with different diameters

PendingCN111299192AHigh measurement accuracyIncrease productivitySortingMechanical engineeringIndustrial engineering

The invention discloses an automatic feeding structure for measuring paper tubes with different diameters. The automatic feeding structure comprises an automatic feeding box, a continuous conveying mechanism, a material collecting groove, a different-diameter-paper-tube measuring mechanism, a material discharging groove, a continuous material receiving mechanism and an automatic material stirringand conveying mechanism which are sequentially arranged from left to right. The automatic feeding box is used for storing the paper tubes to be detected, and a discharging mechanism used for conveyingthe paper tubes to the continuous conveying mechanism is arranged at the right end of the automatic feeding box; the continuous conveying mechanism is used for continuously conveying the paper tubesconveyed by the discharging mechanism to the material collecting groove; the different-diameter-paper-tube measuring mechanism is used for detecting the lengths of the paper tubes in the material collecting groove and conveying the paper tubes to the material discharging groove; the continuous material receiving mechanism is used for receiving the paper tubes conveyed by the material discharging groove; and the automatic material stirring and conveying mechanism is used for sorting the paper tubes conveyed by the continuous material receiving mechanism. According to the structure, the assembly-line automatic measurement of the paper tubes with different diameters is realized, the labor intensity of workers and the production cost are greatly reduced, and the measurement precision and the production efficiency of the paper tubes are effectively improved.

Owner:嘉兴市日新自动化科技有限公司

Rim replacing device in tire balance measuring device

ActiveUS9464964B2Reduce measurement efficiencyGuaranteed to workSleeve/socket jointsStatic/dynamic balance measurementTire balanceCoupling

A lower side coupling of a Hirth coupling is coaxially coupled and fixed to a spindle, an upper side coupling of the Hirth coupling is coaxially coupled and fixed to a lower rim, the upper side coupling of the lower rim is meshed with the lower side coupling of the spindle, and upward separation of the lower rim from the spindle is prevented by chuck mechanisms.

Owner:YAMATO SCALE CO LTD

A method for determining the modulation degree of a ray digital image and its application

InactiveCN108986080BReduce measurement efficiencyHigh standardImage enhancementImage analysisImaging qualityRadiology

The invention relates to a method and application for determining the modulation degree of a digital ray image. Aiming at the problem of inconsistency between the subjective evaluation and the objective evaluation of the ray digital image obtained by detecting the printed board assembly with a micro-focus ray machine, the pixel edge of the recognized digital image is calibrated. , through the software transfer function algorithm, accurately identify the local image quality, and based on this method, the application criteria of image modulation degree Y and image comprehensive evaluation index y are given. The experimental results show that the image comprehensive evaluation index obtained by this method has a high degree of fitting with the subjective evaluation results, which can solve the problem of inconsistency between subjective judgment and objective judgment, and effectively avoid the disadvantages of manual subjective judgment of image quality.

Owner:BEIJING AEROSPACE GUANGHUA ELECTRONIC TECH CO LTD

Plant leaf fixing device for single integrating sphere measurement system

InactiveCN111307729AHigh precisionReduce measurement efficiencyScattering properties measurementsTransmissivity measurementsAgricultural engineeringLeaf blade

The invention discloses a plant leaf fixing device for a single integrating sphere measurement system. The plant leaf fixing device comprises a first clamping piece, a second clamping piece and a clamping piece, the first clamping piece and the second clamping piece match each other and are used for clamping and fixing a plant leaf to be detected; and the clamping piece matches a reflectivity andtransmissivity measuring port of the single integrating sphere and is used for detachably fixing the plant leaf fixing device on the reflectivity and transmissivity measuring port of the single integrating sphere. When the plant leaf fixing device matches a single integrating sphere measuring system to measure the reflectivity and transmissivity of a plant leaf; when the plant leaf is transferredfrom the reflectivity measurement port to the transmittance measurement port, the plant leaf to be detected does not need to be taken down from the fixing device, and the fixing device with the plantleaf to be measured is directly transferred, so that mismatching of measurement points due to human factors is avoided, and the acquisition precision of spectral data of the plant leaf can be improved.

Owner:ZHEJIANG UNIV

Installation Structure and Method of Verticality Sensor on Super Rectangular Pipe String

ActiveCN104457717BReduce measurement efficiencyOvercome installation and positioning problemsSurveying instrumentsIncline measurementLaser transmitterEngineering

The invention discloses an installation structure and an installation method for a perpendicularity sensor on an overlong square tubular column. The installation structure comprises a laser inclinometer internally provided with a perpendicularity sensor and a laser emitter, a regulating plate, a right-angled bending plate, a light target, a coarse tuning bolt component and a fine tuning bolt component, wherein the laser of the laser emitter is parallel to a measuring baseline of the perpendicularity sensor; through holes for emitting laser are correspondingly formed in a laser inclinometer connecting plate and the regulating plate; the position of the regulating plate is regulated by virtue of the coarse tuning bolt component and the fine tuning bolt component, so that the position of the laser on the light target is unchanged when the light target is arranged on different installation baselines, and the laser emitted after the laser inclinometer is installed and fixed is parallel to the axis of the square tube column. The installation structure can be used for solving the installation and positioning problem of the perpendicularity sensor on the square tube column in an automatic test method of the perpendicularity sensor, realizing the convenient and accurate detection of the square tube column, and realizing the real-time detection of the perpendicularity of the overlong square tube column.

Owner:SHANGHAI CONSTRUCTION GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com