Laser measurement system and method capable of detecting 21 geometric errors

一种激光测量系统、几何误差的技术,应用在测量装置、测量角度、测绘与导航等方向,能够解决无法测量三直线运动轴滚转角误差、系统安装调节困难、系统结构复杂等问题,达到结构简单、抗干扰能力强、系统集成度高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

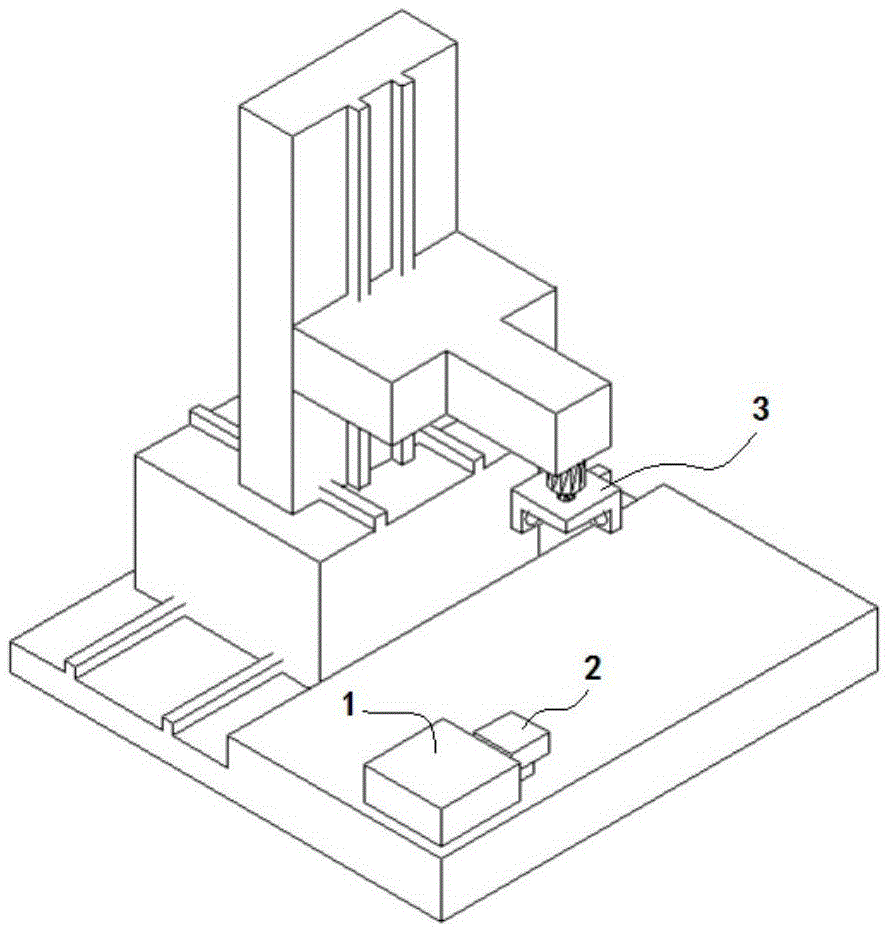

[0043] Such as figure 1 As shown, a 21-item geometric error laser measurement system according to the present invention is mainly composed of a laser six-degree-of-freedom error simultaneous measurement unit 1, a laser light steering unit 2, and a geometric error sensitive unit 3. The geometric error sensitive Unit 3 is fixed on the clamping tool part of the measured CNC machine tool, machining center or three-coordinate measuring machine. On the clamping workpiece part of the center or three-coordinate measuring machine.

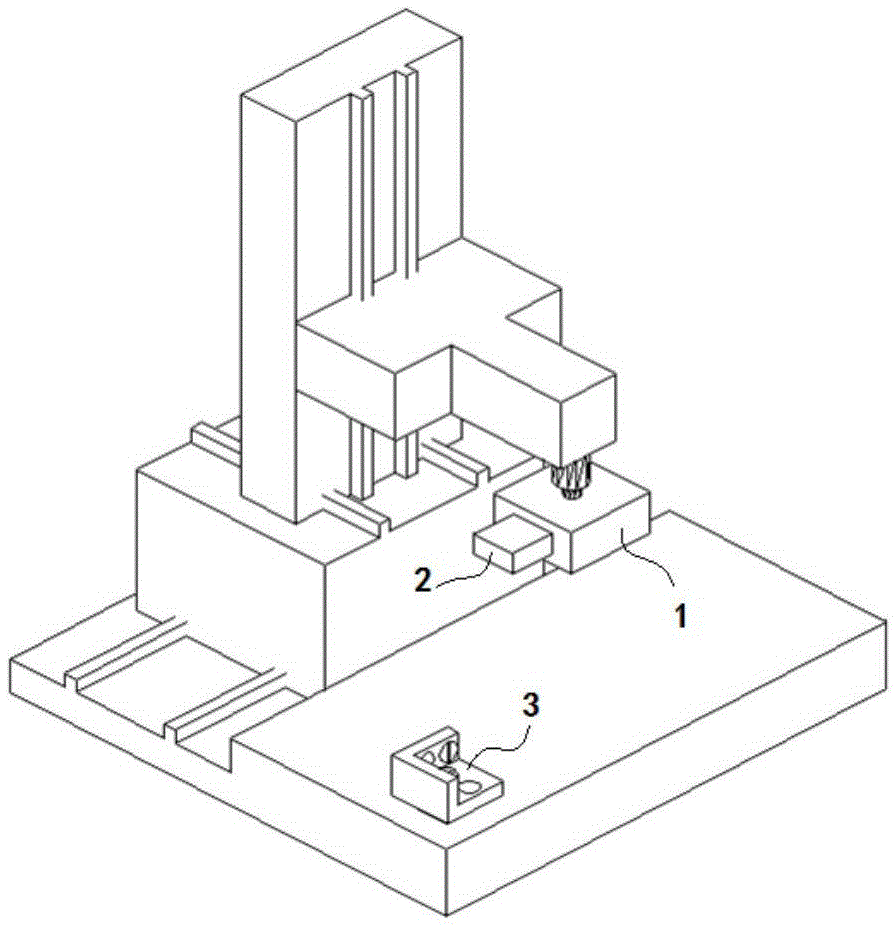

[0044] Such as figure 2 As shown, the geometric error sensitive unit 3 can also be fixed on the clamping workpiece part of the measured CNC machine tool, machining center or three-coordinate measuring machine, and the laser six-degree-of-freedom error measurement unit 1 and the laser light The steering unit 2 can also be integrally fixed on the clamping tool part of the measured numerical control machine tool, machining center or three-coordinate measuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com