Gas chromatography for measuring gas content and characteristic gas in insulating oil completed at one time of sample injection

A gas chromatography and characteristic gas technology, which is applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of increased workload, minimum detection concentration of temperature rise, high requirements for vacuum instruments and difficult to popularize, etc., and achieves small workload and simple operation. , the effect of reducing the analysis error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

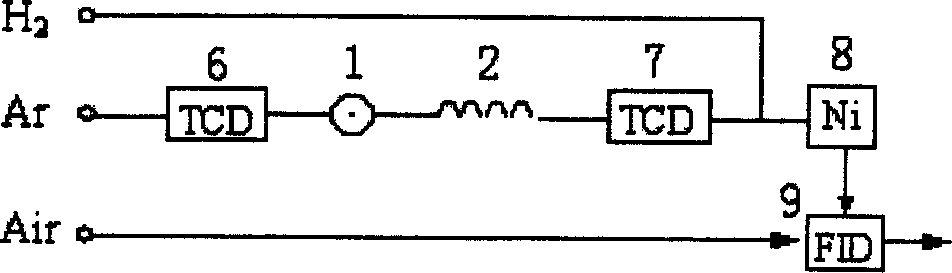

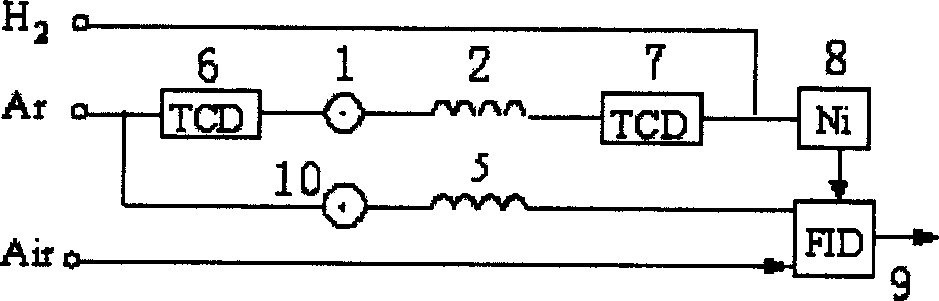

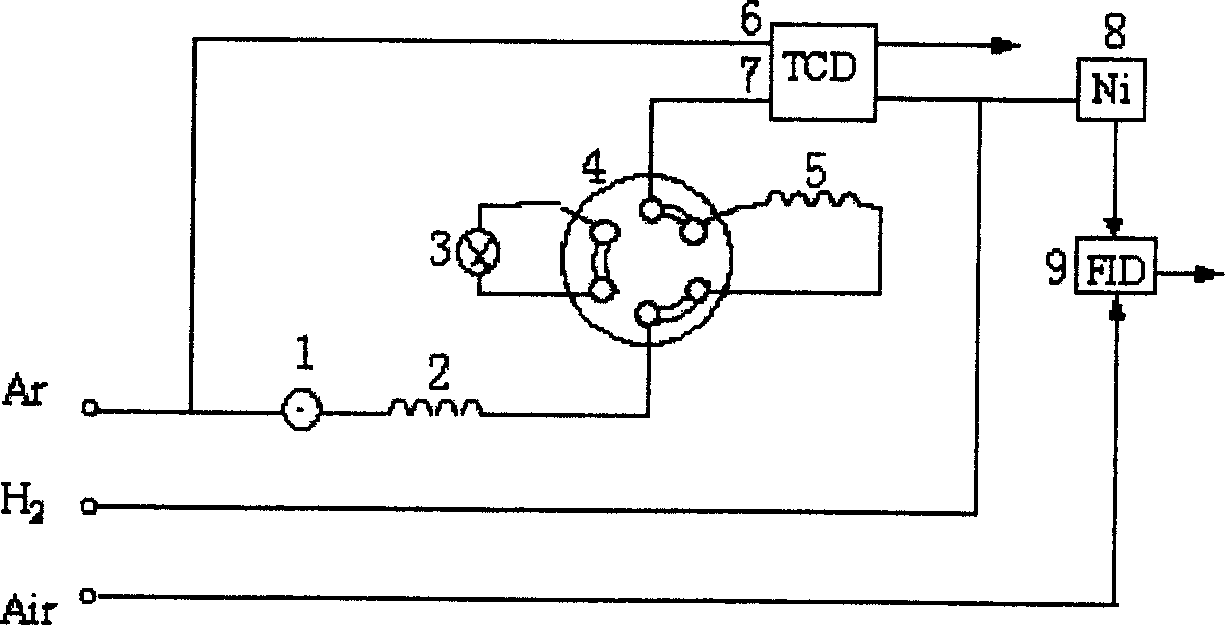

[0055] The first chromatographic column 2 is a stainless steel packed column, the column length is 365.76cm, the column inner diameter is 2.1mm, and the filler is 80-100 mesh polymer Porapak N; the second chromatographic column 5 is a stainless steel packed column, and the column length is 182.88cm , the inner diameter of the column is 2.1mm, and the filler is 60-80 mesh molecular sieve 5A;

[0056] Adjust the flow rate of argon (carrier gas) to 20ml / m, the flow rate of hydrogen to 45ml / m, and the flow rate of air to 450ml / m;

[0057] Thermal conductivity detector 7: bridge current 80mA, 100°C;

[0058] Hydrogen flame ionization detector 9: 380°C;

[0059] Oven temperature: 70°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com