Powder supply device for supplying powder to container of food processing machine

一种供给装置、食品加工的技术,应用在材料的装置领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

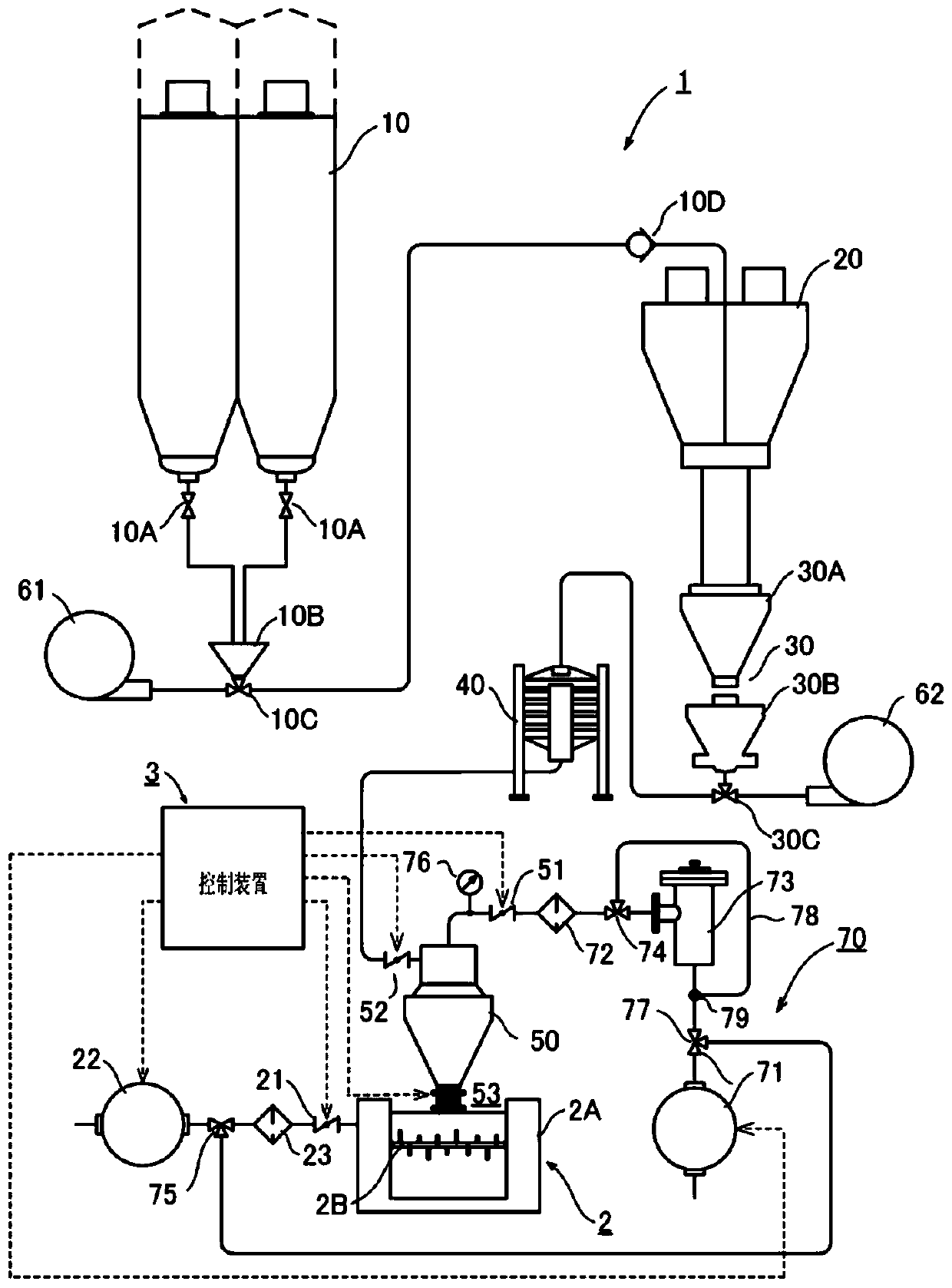

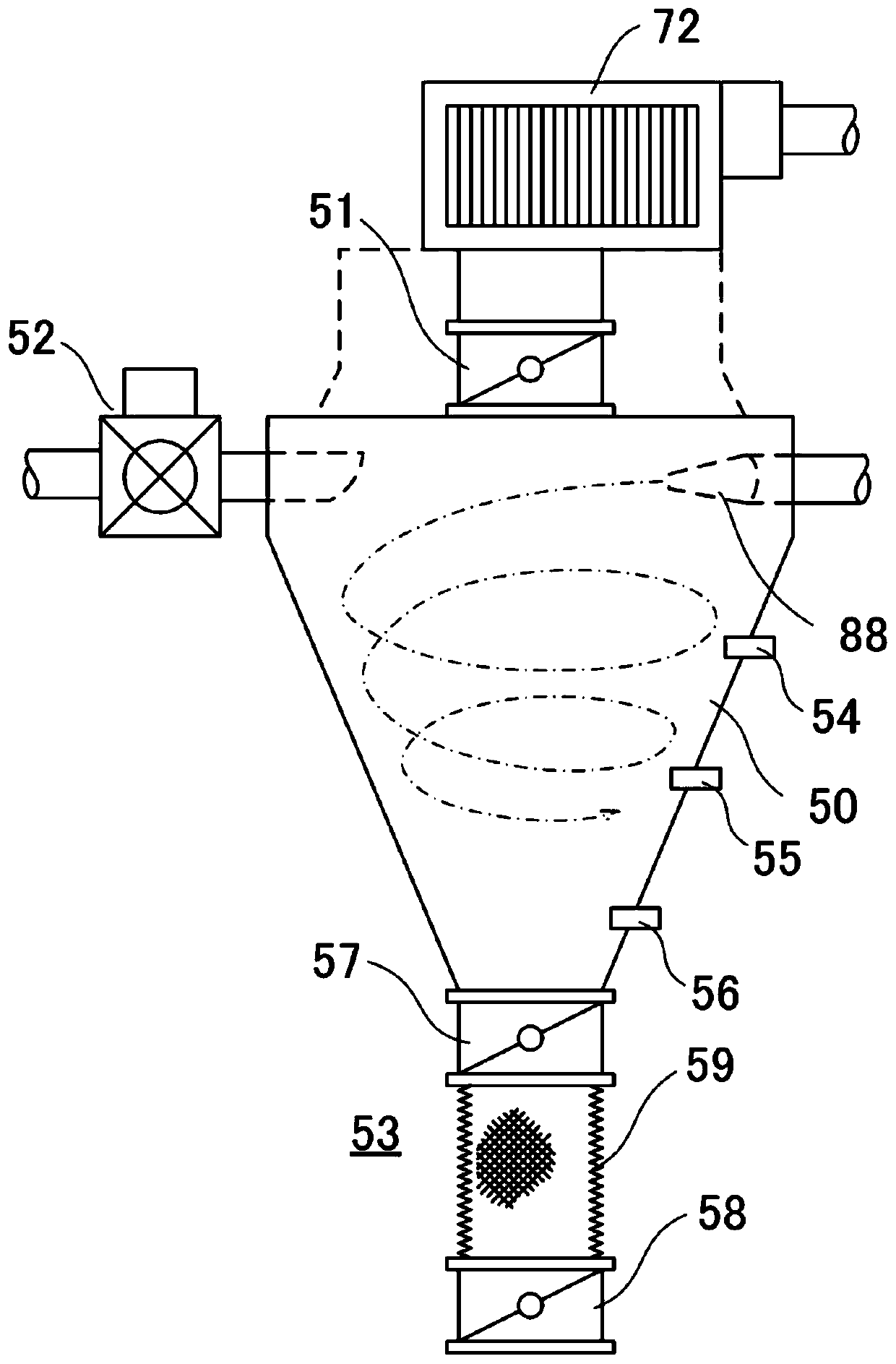

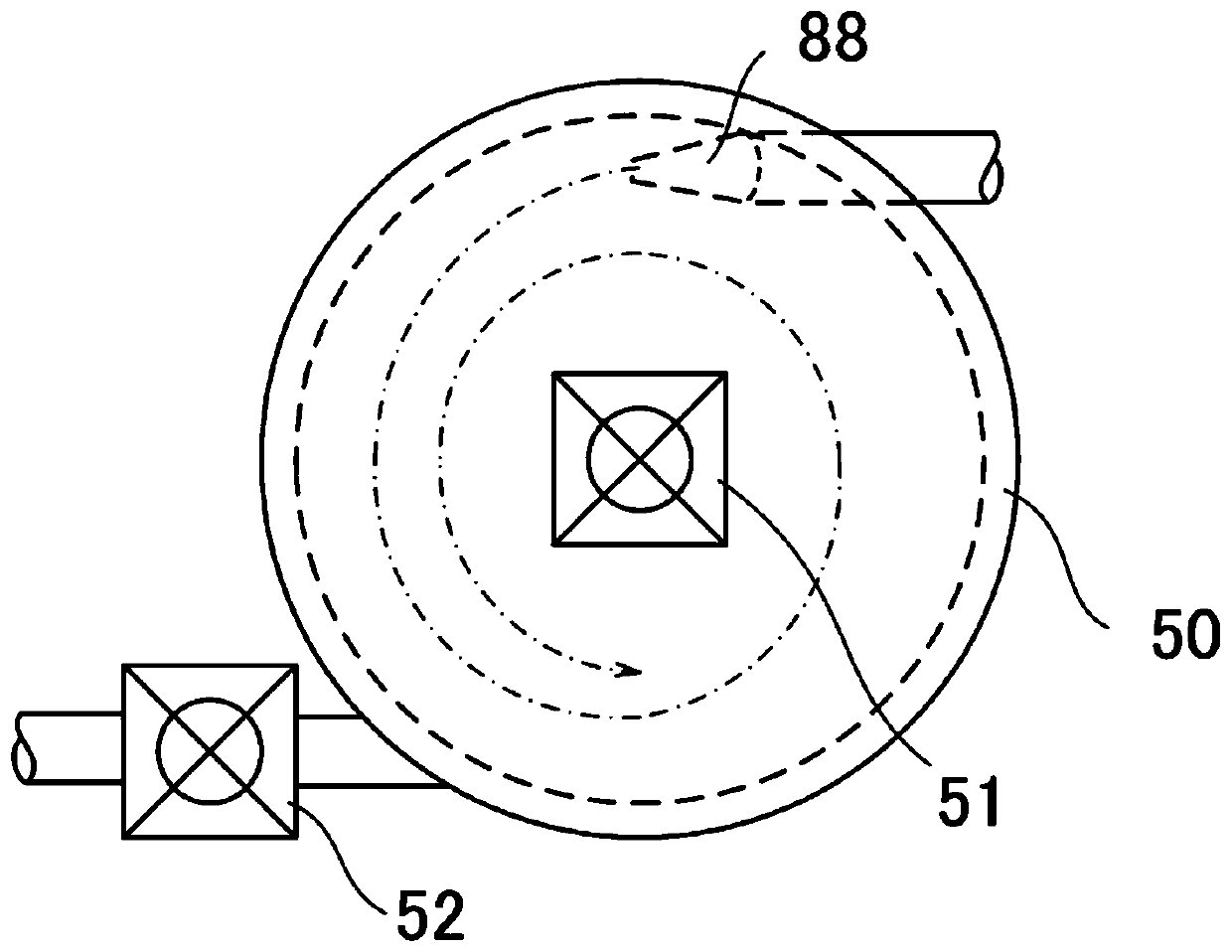

[0028]Embodiments of the present invention will be described in detail with reference to the drawings. Materials suitable for use in the present invention are mealy bodies comprising cereals or legumes. Flour can also be barley flour, cornstarch, oat flour, rye flour, rice flour, potato flour, buckwheat flour flour), wheat grain, barley grain, corngrain, oats, rye grain, rice grain, buckwheat grain and soybean . Such as figure 1 As shown, the food manufacturing factory 1 includes one or more outdoor silos 10 and a vacuum mixer 2 as an example of a food processing machine. As other food processing machines for making dough for snacks, bread or noodles, it may also be an atmospheric mixer that kneads powder by adding water, or a screw that rotates in a barrel and extrudes the dough into a specific shape. The shape of the extruder (extruder), as a food processing machine, can also be considered as a mixer and a pulverizer. A powder or grain supply device for supplying wheat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com