Vacuum sucking cast process of preparing magnesium base composite material

A composite material and vacuum suction casting technology, applied in the field of casting, can solve the problems of low density, unable to form, difficult to form aluminum alloy, etc., and achieve the effect of simple process, low price and cost, and easy oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

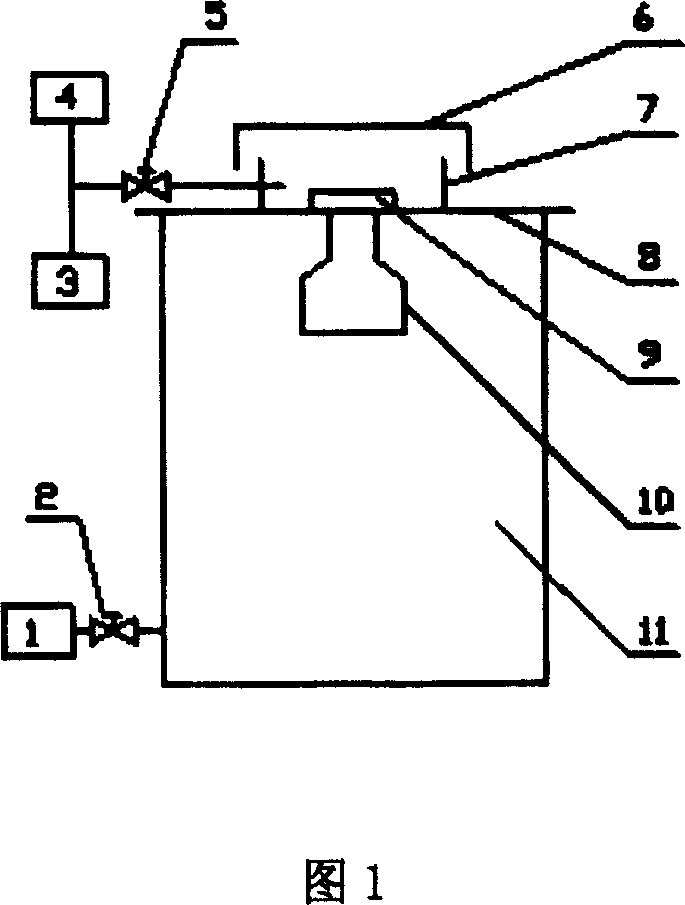

Embodiment 1

[0018] The formwork 10 is fixed on the partition plate 8 with the formwork fixing sleeve 9, and the preheating temperature of the formwork 10 is 200°C. Pass SO at the gate of the formwork 10 2 and CO 2 Mixed gas for protection, the flow rate of the protective gas is 3L / min, open the stop valve 2, vacuumize the sealed cavity to -0.05Mpa, keep the vacuum dynamic balance for 2min, and put TiB with a mass percentage of 5% 2p After the / ZM5 composite material is poured into the cavity of the mold shell, it is immediately evacuated to a vacuum degree of -0.1Mpa, and the vacuum is maintained for 1min to achieve 5wt.%TiB 2p / ZM5 Vacuum suction casting of thin-walled parts of composite materials, no air holes on the castings.

Embodiment 2

[0020] The formwork 10 is fixed on the partition plate 8 with the formwork fixing sleeve 9, and the preheating temperature of the formwork 10 is 400°C. Pass SF at the gate of the formwork 10 6 and CO 2 Mixed gas for protection, the flow rate of the protective gas is 30L / min, open the stop valve 2, vacuumize the sealed cavity to -0.08Mpa, keep the vacuum dynamic balance for 15min, and put TiC with a mass percentage of 5% p After the / ZM5 composite material is poured into the cavity of the mold shell, it is immediately evacuated to a vacuum degree of -0.05Mpa, and the vacuum is maintained for 3 minutes to achieve 5wt.%TiC p / ZM5 Vacuum suction pouring of thin-walled complex parts of composite materials, no air holes on the castings.

Embodiment 3

[0022] The formwork 10 is fixed on the partition plate 8 with the formwork fixing sleeve 9, and the preheating temperature of the formwork 10 is 250°C. Pass SF at the gate of the formwork 10 6 and Ar 2 Mixed gas for protection, the flow rate of the protective gas is 50L / min, open the stop valve 2, vacuumize the sealed cavity to -0.1Mpa, keep the vacuum dynamic balance for 8min, and put the mass percentage of 5% (TiB 2 +TiC) hybrid reinforced ZM5-based composite material poured into the cavity of the mold shell, immediately evacuated to a vacuum degree of -0.7Mpa, and kept the vacuum for 5min to achieve 5wt.% (TiB 2 +TiC) / ZM5 composite thin-walled complex parts vacuum casting, no pores on the casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com