Pressure-regulating and mold-filling high-pressure solidification casting device and casting method

A technology of pressure regulation and high pressure, which is applied in the field of solidification of alloy liquid under the action of high pressure of the hammer head, and in the field of pressure regulation and filling high-pressure solidification casting devices, which can solve the problem of affecting the internal quality and mechanical properties of castings, and the easy formation of entrained gas and oxidized slag , easy to precipitate and form pinholes, etc., to avoid shrinkage porosity, avoid the formation of oxidized slag, and reduce the effect of contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment is the conveying process of molten aluminum for preparing automobile wheel hubs by extrusion casting, and the casting material is ZL114A aluminum alloy.

[0030] The specific process is as follows:

[0031] 1) The highest point of the feed port on the barrel is located 20mm below the bottom of the mold cavity, the vertical height of the feed port is 40mm, the length of the hammer used is 60mm, which is 20mm longer than the feed port, and the initial position of the hammer head is set to be the lowest of the feed port point, the hammer head’s final rising height is 10mm below the bottom of the mold cavity, and the final stop height of the aluminum liquid level is set by calculation to be 20mm below the highest point of the mold cavity;

[0032] 2) After the ZL114A aluminum alloy is refined and transformed in the smelting furnace 3, the mold 1 is closed, the air in the cavity of the mold 1 is extracted, and compressed air is introduced into the smelting fu...

Embodiment 2

[0036] This embodiment is a process of conveying molten aluminum for preparing an automobile control arm by squeeze casting, and the casting material is ZL101A aluminum alloy.

[0037] The specific process is as follows:

[0038] 1) The highest point of the feeding port on the barrel is located 15mm below the bottom of the mold cavity, the vertical height of the feeding port is 20mm, the length of the hammer head used is 40mm, which is 20mm longer than the feeding port, and the initial position of the hammer head is set as the lowest point of the feeding port point, the hammer head’s final rising height is 5mm below the bottom of the mold cavity, and the final stop height of the liquid aluminum level is set by calculation to be 40mm below the highest point of the mold cavity;

[0039]2) After the ZL101A aluminum alloy is refined and transformed in the melting furnace 3, the mold 1 is closed, the air in the cavity of the mold 1 is extracted, and compressed air is introduced int...

Embodiment 3

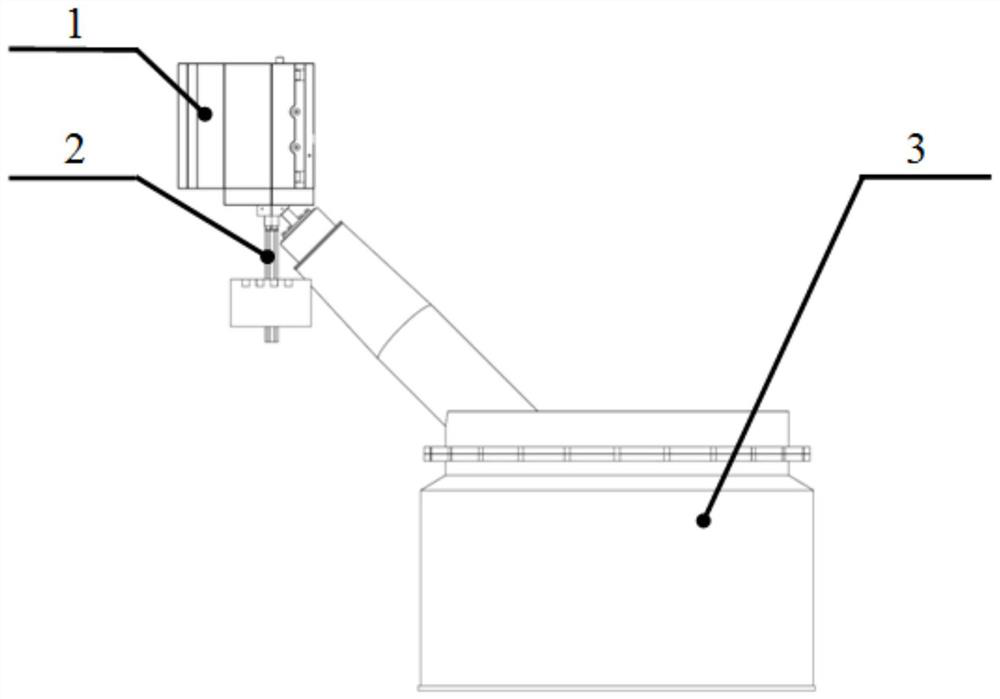

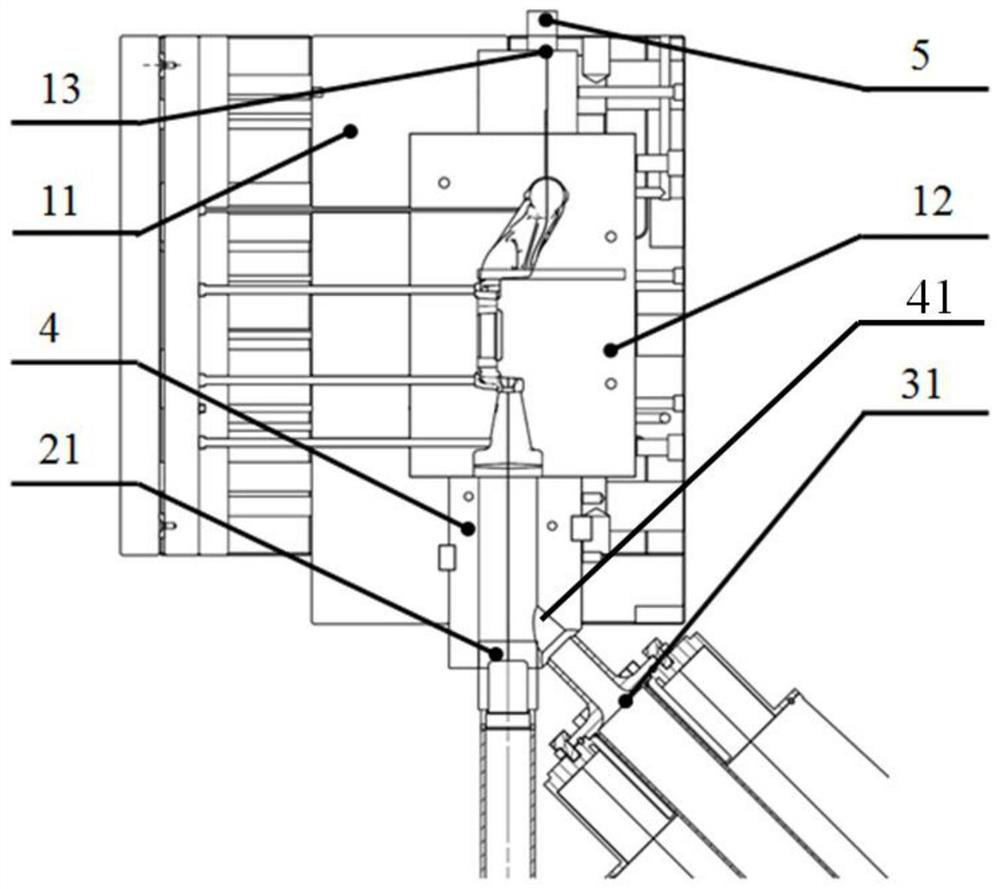

[0043] A pressure-adjusting and filling-type high-pressure solidification casting device, said device comprising a melting furnace 3, a shot rod 2, a riser pipe 31, a hammer head 21, a barrel 4, a mold 1, a vacuum pipe 5 and a vacuum shut-off valve 13;

[0044] Wherein, the barrel 4 is located below the mold 1, the hammer head 21 is installed above the injection rod 2, and is pushed by the plunger 2 to move up and down in the barrel 4; the melting furnace 3 is placed under the side of the mold 1, and the furnace body Good sealing, one end of the liquid riser 31 goes deep into the crucible in the furnace, and the other end is connected to the barrel 4; the mold 1 is composed of a movable mold 11 and a fixed mold 12, and the upper part of the fixed mold 12 has a hole and is connected to a vacuum stop valve 13. The vacuum tube 5 is connected with vacuum equipment to vacuum the cavity of the mold 1 . The barrel 4 is provided with a lateral feed port 41, and the highest point of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com