Vacuum stop valve for mold

A shut-off valve and vacuum technology, applied in the direction of valve lift, valve details, valve devices, etc., can solve the problems of circuit breaker pins not being reset normally, frequent shutdowns, exhaust groove blockage, etc., to achieve automatic reset, high safety and reliability, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following specific examples are only explanations of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications without creative contribution to the present embodiment as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

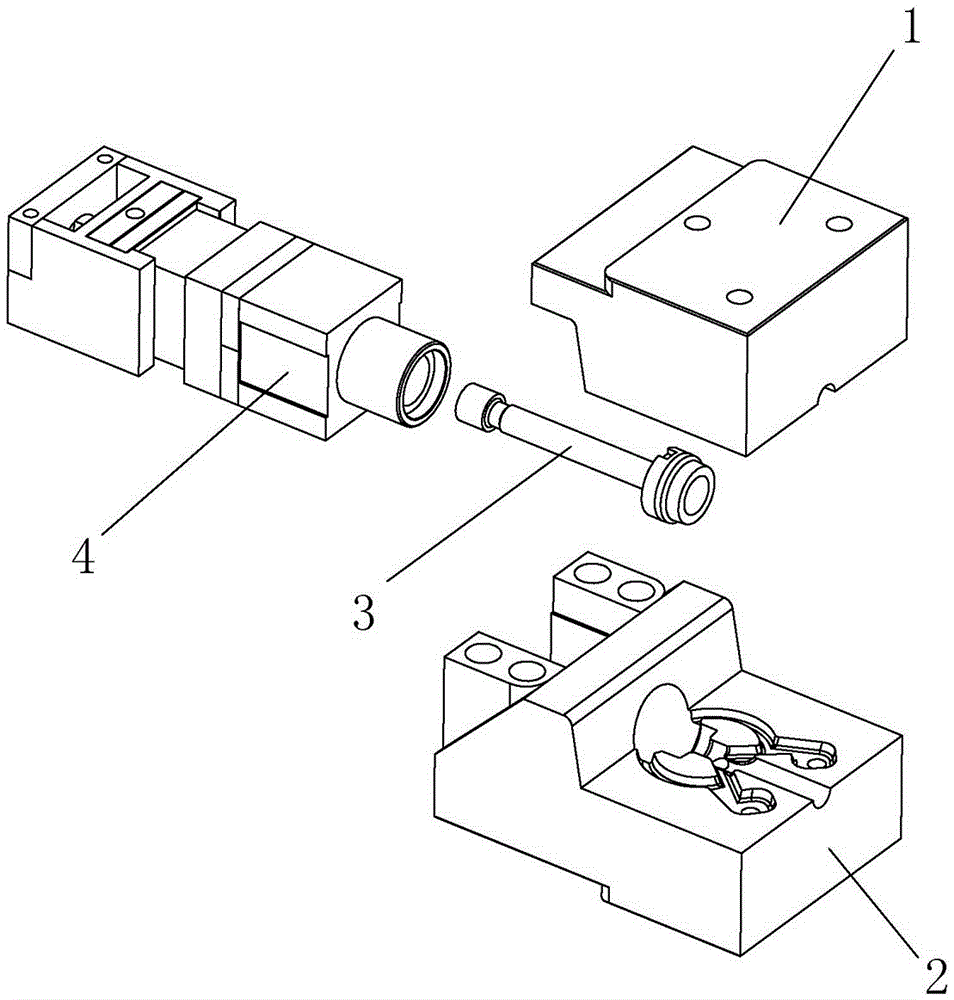

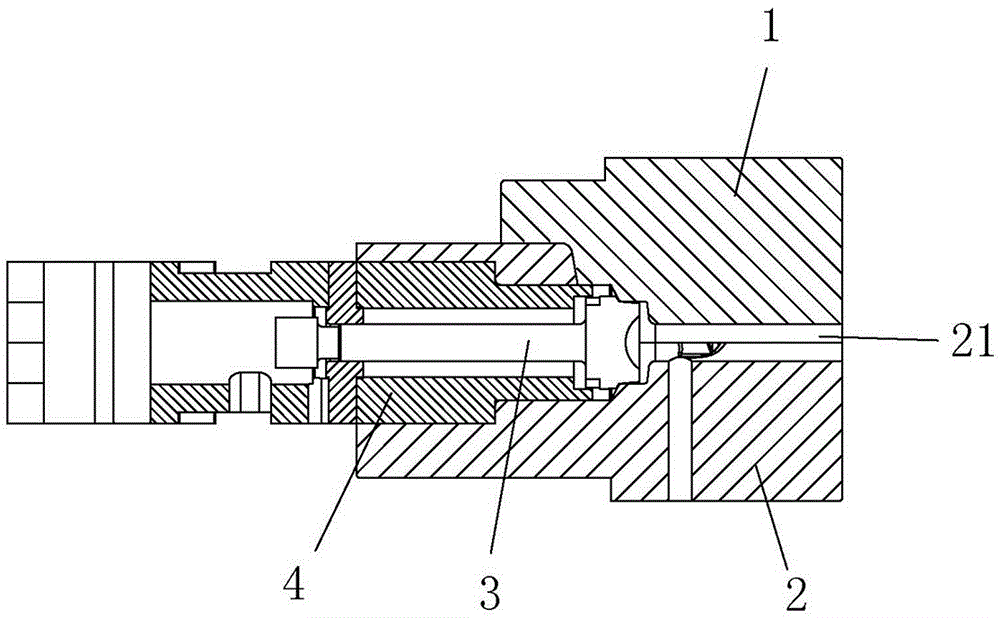

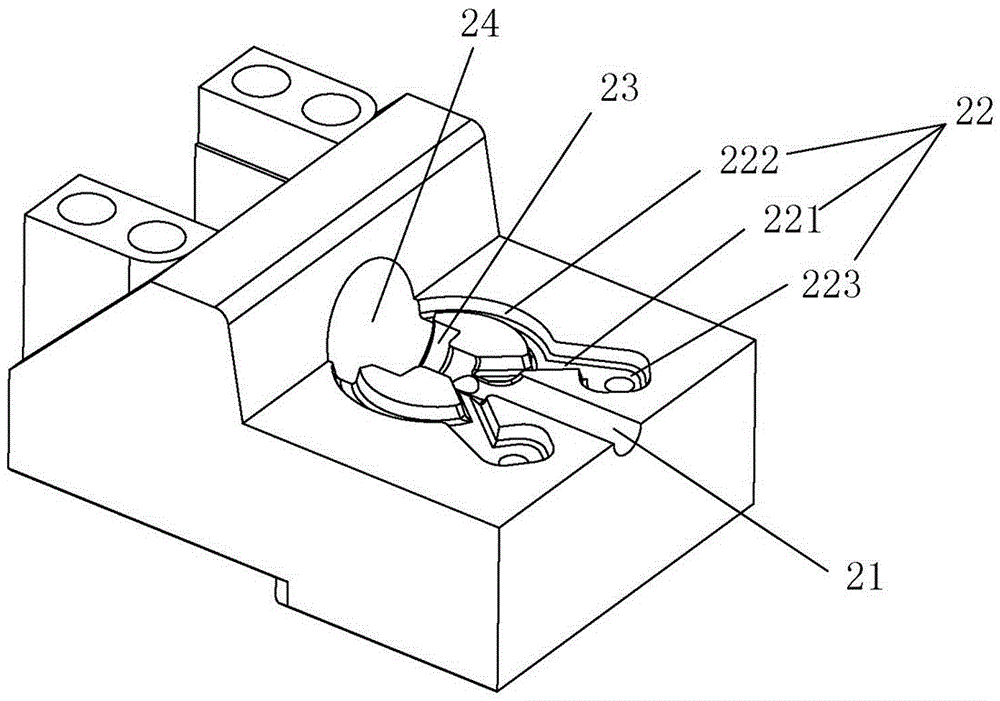

[0022] Examples such as figure 1 , figure 2 with image 3 As shown, a mold vacuum cut-off valve includes a valve body, a valve core 3 and a piston 4. The valve body includes a fixed valve body 2 and a moving valve body 1. A buffer circuit 22, an air inlet 21 and an exhaust passage 24, the intake passage 21 is arranged on the opposite side of the exhaust passage 24, and the buffer circuit 22 communicates with the intake passage 21 and the exhaust passage 24 respectively. The buffer circuit 22 and the exhaust channel 24 are arranged on the fixed valve body 2, and the intake channel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com