Vacuum stop valve under zero gravity

A zero-gravity, globe valve technology, used in lift valves, valve details, safety valves, etc., can solve problems such as small mass-to-volume ratio, small operating force, and inability to adapt to cyclic temperature changes, to ensure accurate positioning and release internal pressure. , the effect of preventing system damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

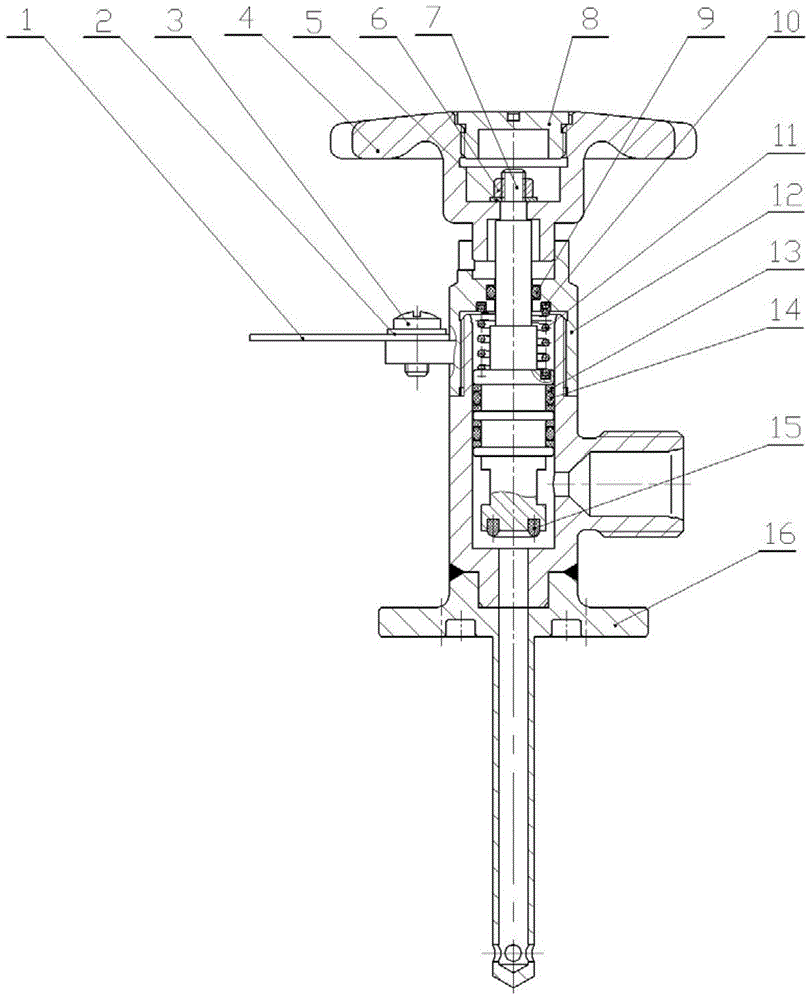

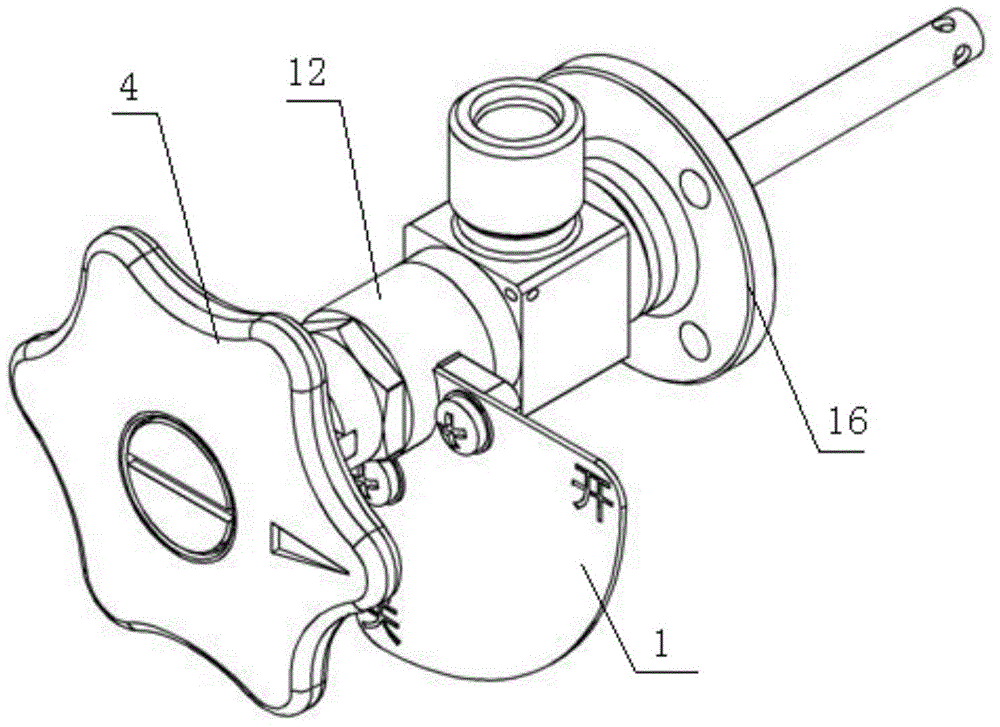

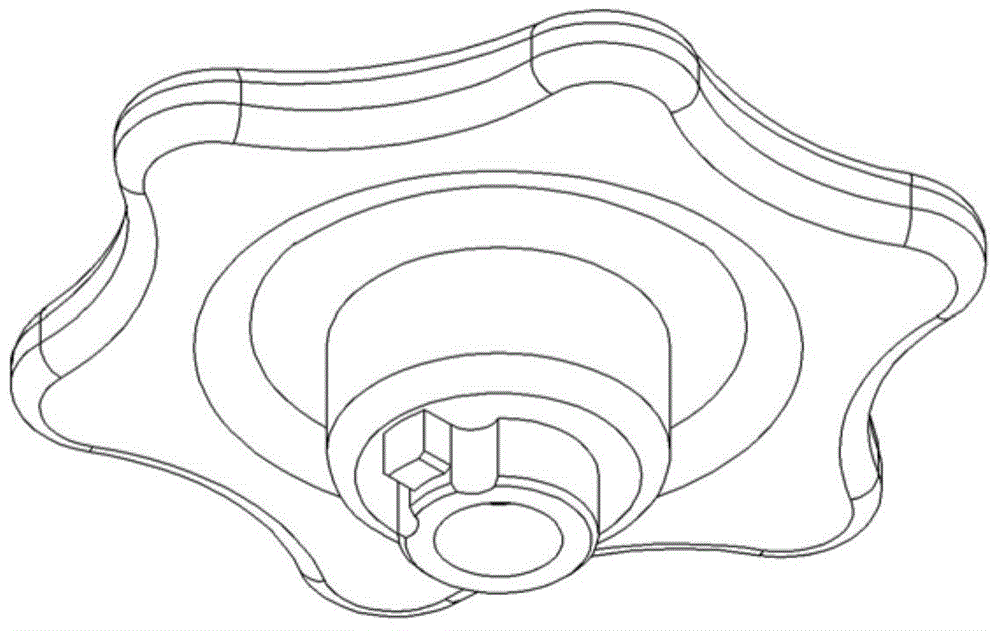

[0025] Such as figure 1 , 2 As shown, the present invention consists of identification plate 1, gasket 2, screw 3, handle 4, gasket 5, nut 6, valve core 7, upper cover 8, small radial sealing ring 9, antifriction plate 10, spring 11, valve cap 12. Seal retaining ring 13, large radial sealing ring 14, axial sealing ring 15, valve body 16, the right side is the inlet, and the lower side is the outlet.

[0026] The valve core 7 and the spring 11 are installed in the valve body 16 through the valve cap 12, and the valve cap 12 and the valve body 16 are connected by threads.

[0027] The handle 4 is connected to the valve core 7 through the gasket 5 and the nut 6, and transmits the operating force of the astronaut's handle to the valve core 7, so that the valve core 7 can move back and forth axially in the valve body 16, thereby realizing the switching action of the valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com