Maintenance system and method for air blowing type level gauge

A technology for maintaining systems and liquid level gauges, applied in the direction of displaying liquid level indicators through pressure measurement, liquid/fluid solid measurement, and measuring devices. It can solve problems such as measuring tube blockage and liquid level abnormalities, and achieve safety risk control. Simple operation, thorough dredging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

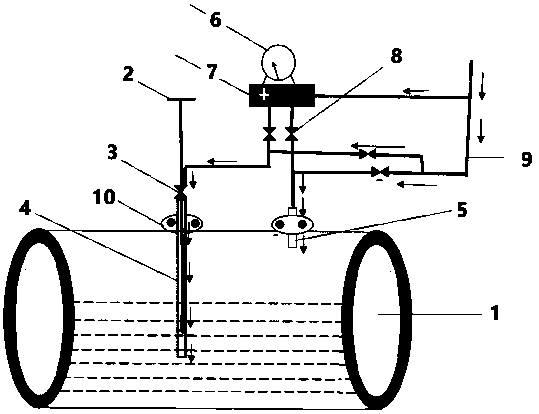

[0044] Combine below figure 1 The present invention is described in detail, it should be pointed out that the following examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention, those skilled in the art can make the present invention according to the above-mentioned content of the present invention Some non-essential improvements and tweaks.

[0045] The maintenance system of an air blowing liquid level gauge of the present invention comprises a reaction kettle (1), an air blowing liquid level gauge, a vacuum stop valve (8) and a nitrogen delivery pipe (9). The air blowing liquid level gauge The needle is pierced by the positive pressure measuring tube (2), the special valve for blowing air (3), the positive pressure measuring tube of the liquid level gauge (4), the negative pressure measuring tube of the liquid level gauge (5), the differential pressure transmitter (6), Composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com