Back pressure turbine vacuum deaerator system and condensation water circulation method

A technology of back pressure units and deaerators, which is applied in chemical instruments and methods, separation methods, liquid degassing, etc. It can solve the problems of large water replenishment and inability to single-stage deaeration, so as to improve thermal efficiency and save medium pressure The effect of steam resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

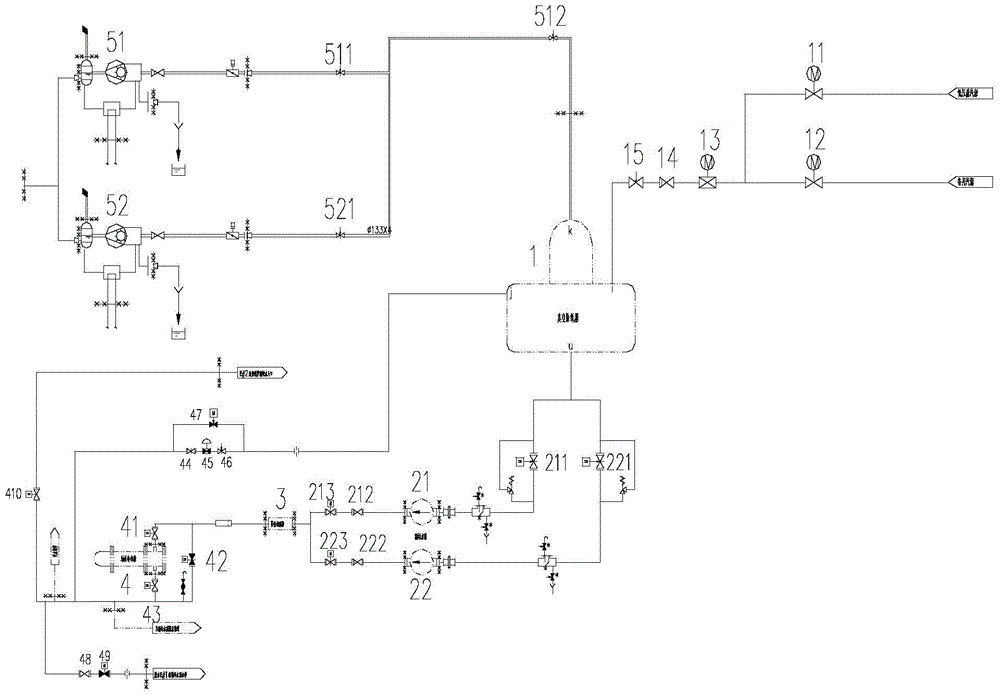

[0016] The invention will be described in detail below in conjunction with the drawings: figure 1 As shown, the vacuum deaerator system of a back pressure unit according to the present invention mainly includes: vacuum deaerator 1, condensate pumps 21, 22, iron removal filter 3, shaft seal cooler 4, vacuum pump 51 , 52, the low-pressure steam source as deoxygenated steam is connected to one end of the electric shut-off valves 11 and 12, and the other end merges into a way to connect to the electric regulating valve 13, and the other end of the electric regulating valve 13 is connected to the check valve 14. The other end of the valve 14 is connected to the vacuum cut-off valve 15, which is connected to the deaeration interface of the vacuum deaerator 1. One end of the vacuum electric gate valves 211, 221 is connected to the condensate outlet of the vacuum deaerator 1, and the other end Connected to the inlet side of the condensate pump 21, 22, one end of the check valve 212, 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com