Thermocouple device for polycrystal ingot furnace

A technology of polycrystalline ingots and thermocouples, applied in the direction of using electrical devices, measuring devices, polycrystalline material growth, etc., can solve the problems of high equipment maintenance costs and an average life span of only half a year, and achieve the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

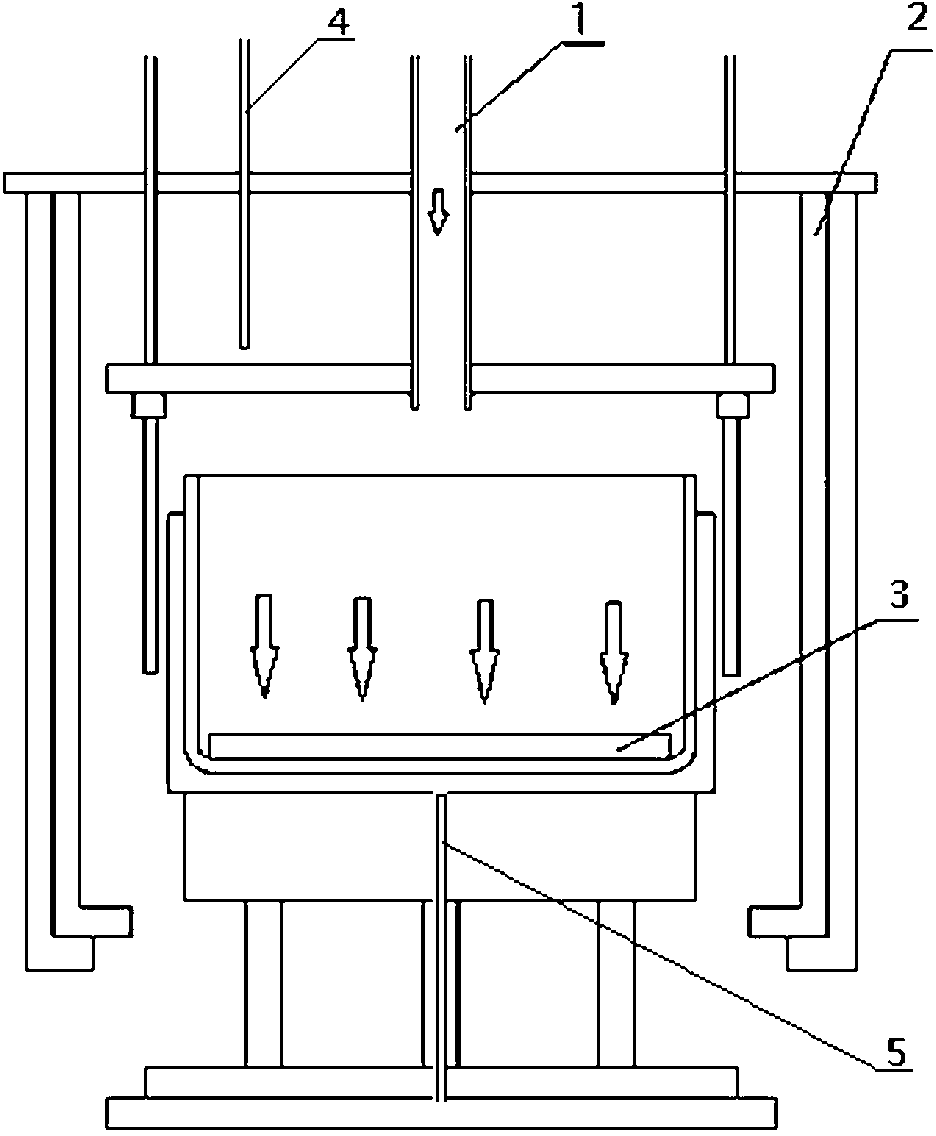

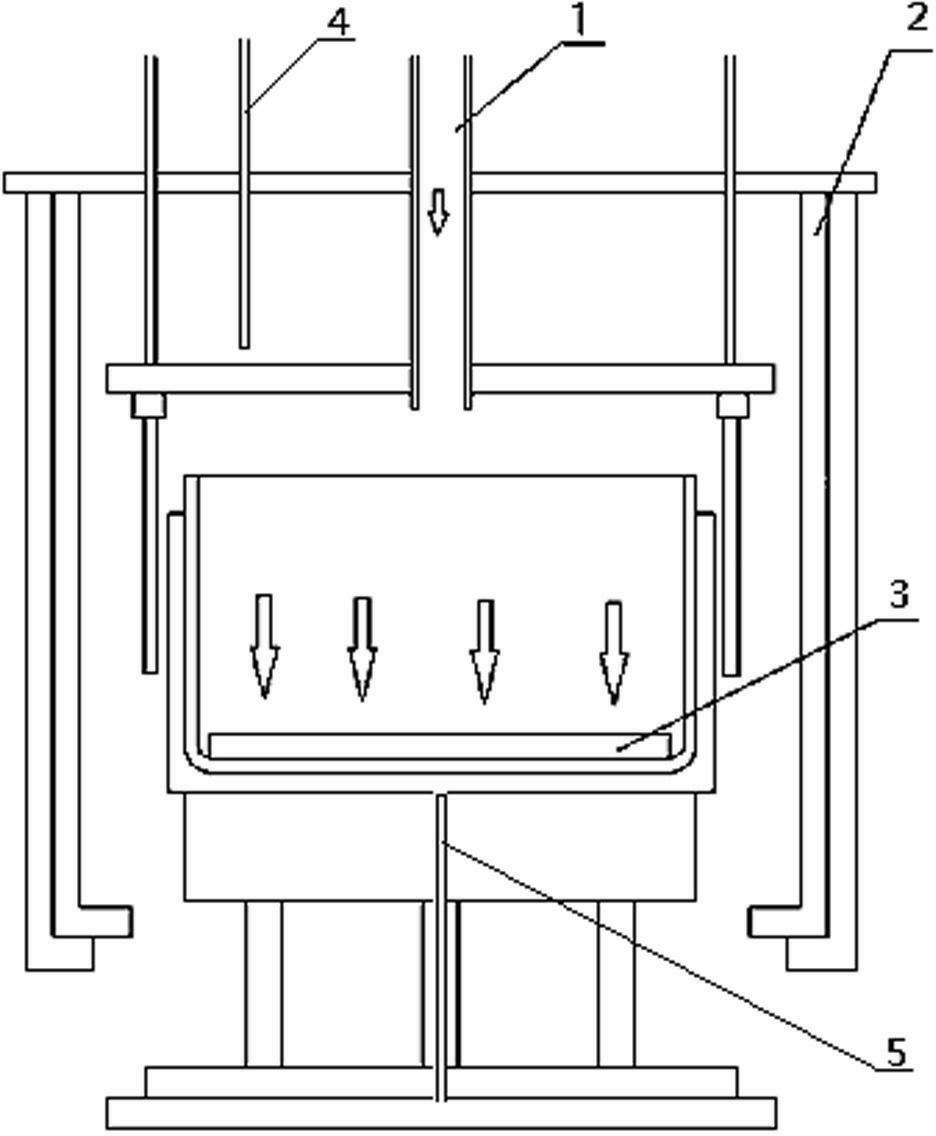

[0018] like figure 1 As shown, the thermocouple chamber includes a reducing tee 2, a thermocouple joint 1 sealed and fixed at one end of the reducing tee 2, and an alumina ceramic tube 6 fixed in the reducing tee 2 through a ceramic tube fixing seat 5 , the thermocouple 4 fixed in the alumina ceramic tube 6 through the thermocouple holder 3; wherein, the thermocouple 4 is connected to the thermocouple joint 1; the reducing tee 2 is connected to the pipeline branch fitting 8, and the pipeline branch The pipe fitting 8 is connected to the tee pipe 11 through the vacuum hose 10, the tee pipe 11 is connected to the vacuum shut-off valve 13, and the B interface of the vacuum shut-off valve 13 is connected to the vacuum unit; the branch pipe fitting 8 of the pipeline is connected with a vacuum deflation Valve 9; wherein, the pipeline branch fitting 8 is a four-way pipe, and the spare A interface on it is connected to another thermocouple chamber; the three-way pipe 11 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com