Large-flow low-pressure online gas supply system

A technology of gas supply system and large flow, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., which can solve the problems of equipment loss, lifespan and decline, and achieve large gasification capacity, low pressure, and gas supply pressure. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

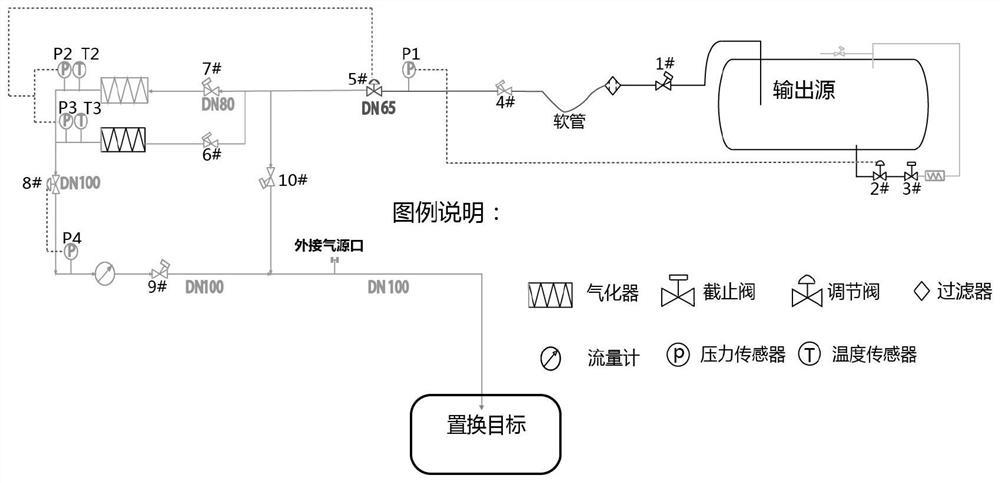

[0023] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] In order to avoid equipment loss and lifespan reduction caused by intermittent shutdown of industrial nitrogen production equipment, an online gasification system is designed in the pipeline to directly produce nitrogen at room temperature and low pressure through liquid nitrogen, eliminating the need for pressure adjustment equipment and improving economic efficiency.

[0025] The online gas supply system of the present invention includes liquid nitrogen output source, 1# vacuum shut-off valve, filter, 3# vacuum shut-off valve, 4# vacuum shut-off valve, P1 pressure sensor, and 7# vacuum shut-off valve, vaporizer, T2 Gasification channel composed of temperature sensor and P2 pressure sensor, gasification channel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com