Organic metal compound supplying container

An organic metal and compound technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the increase of organic metal compounds, the reduction of the utilization rate of organic metal compounds, the inability to supply organic metal compounds to vapor phase growth devices, etc. problem, to achieve the effect of increasing the carrier gas flow and reducing the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

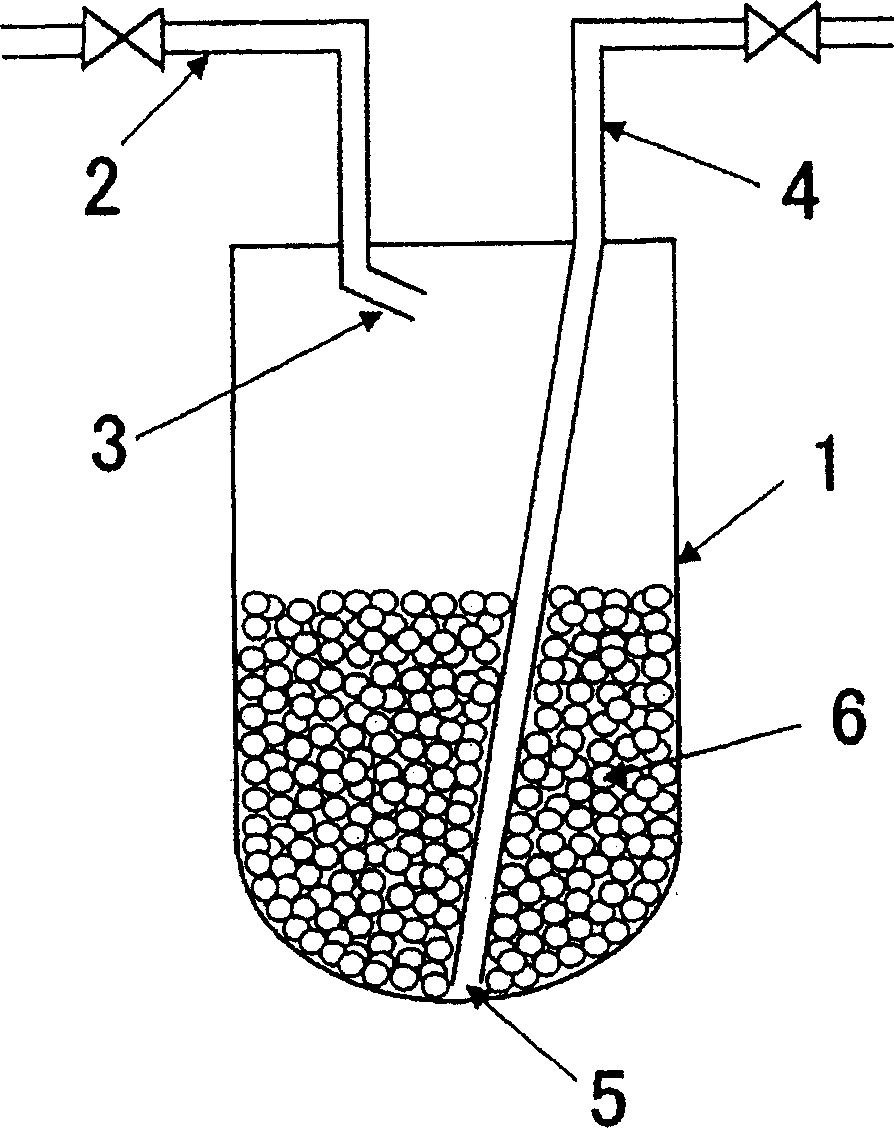

[0015] The organometallic compound of the present invention is solid at room temperature, and is used for vapor phase growth, etc. Specific examples include: trimethylindium, dimethylindium chloride, cyclopentadienyl indium, trimethylindium trimethyl Indium compounds such as arsine adducts, trimethylindium and trimethylphosphine adducts, zinc compounds such as ethylzinc iodide, ethylcyclopentadienylzinc, cyclopentadienylzinc, etc., methyl di Aluminum compounds such as aluminum chloride, gallium compounds such as methylgallium dichloride, dimethylgallium chloride, and dimethylgallium bromide, biscyclopentadienylmagnesium, and the like.

[0016] In addition, as a carrier inert to the organometallic compound on which these organometallic compounds are supported, alumina, silica, mullite, glassy carbon, graphite, potassium titanate, quartz, silicon nitride, etc. can be used. , boron nitride, silicon carbide and other ceramics, stainless steel, aluminum, nickel, tungsten and other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com