Isolated water bath type gasifier

A water-bath gasifier technology, which is applied in the field of isolated water-bath gasifiers, can solve the problems that the gasification efficiency of the gasifier is greatly affected by the ambient temperature, and it is difficult to control the gasification process, so as to avoid heat transfer medium Waste, improve heat exchange efficiency, and prevent backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below by means of the accompanying drawings and examples.

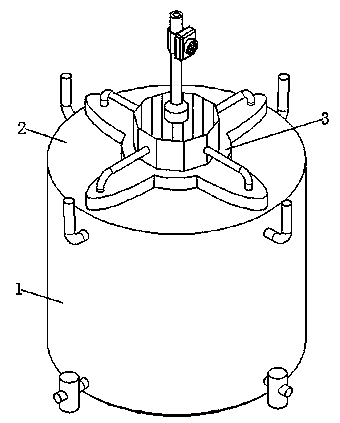

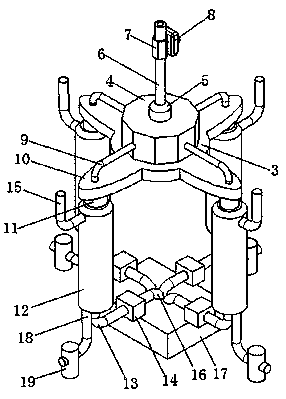

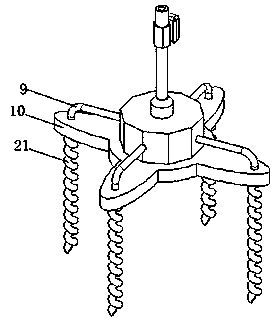

[0024] see Figure 1-5 , the embodiment of the present invention provides the following technical solutions: an isolated water-bath gasifier, comprising a shell 1, a top plate 2 is installed on the top of the shell 1, a fixing seat 3 is fixedly installed on the surface of the top plate 2, and the top of the fixing seat 3 is fixed A flow divider 4 is installed, and a fixed cap 5 is installed on the top of the flow divider 4. A medium conduit 6 is installed through the top of the fixed cap 5. The surface of the medium conduit 6 is provided with a fastening ring 7, and the surface of the fastening ring 7 is fixedly installed. There is a valve 8, a shunt pipe 9 is installed through the surface of the shunt 4, a wedge-shaped plate 10 is arranged on the side of the fixed seat 3, a sealing joint 11 is installed on the bottom of the wedge-shaped plate 10, and a heat exch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com