Vacuum pumping system for die cavities of die-casting dies

A vacuum system and die-casting mold technology, applied in the field of mechanical equipment, can solve the problems of molten metal easily entering the vacuum pipeline, incomplete vacuuming, complex structure, etc., and achieve the effect of simple structure, low cost, and low difficulty in vacuuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

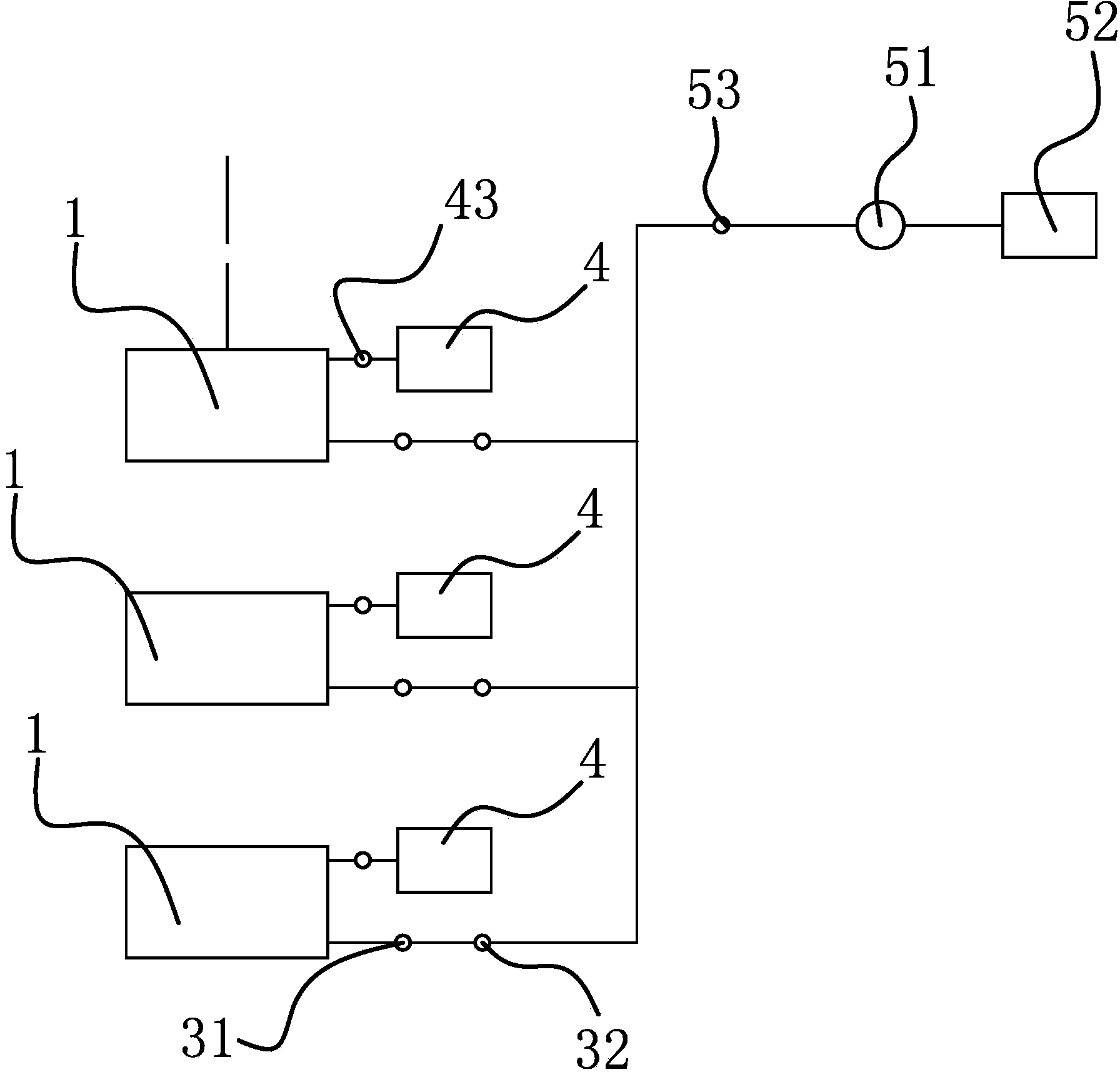

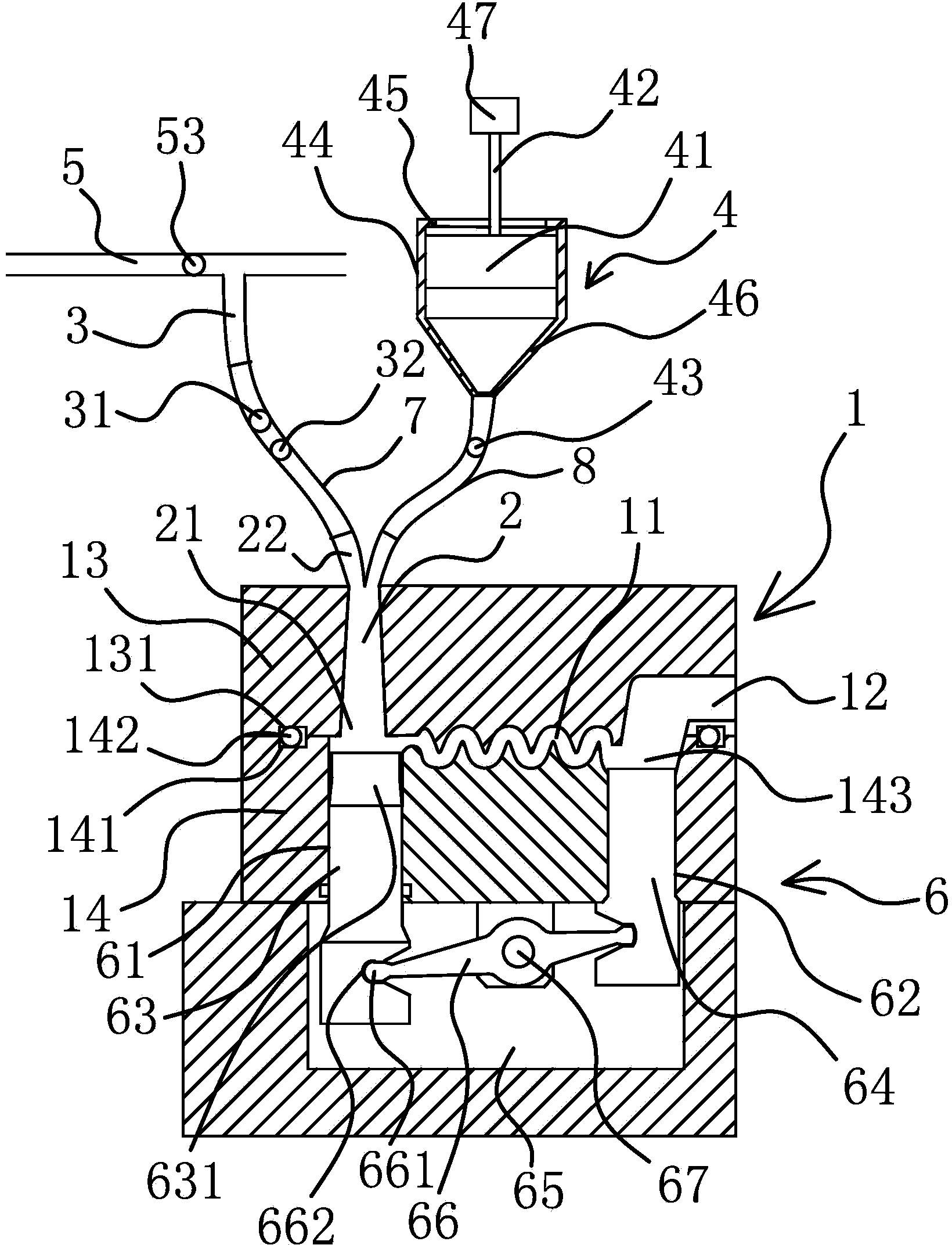

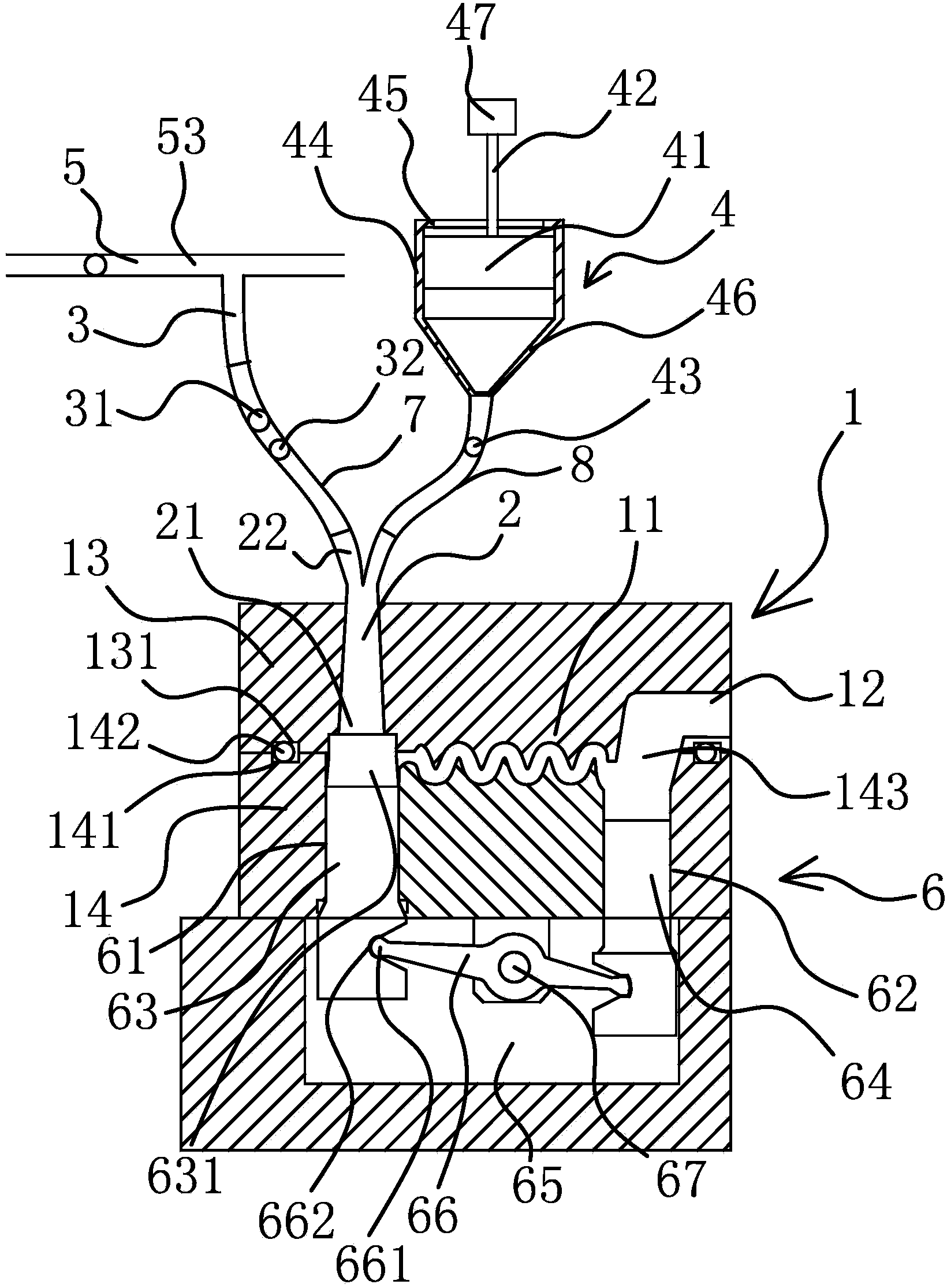

[0021] like Figure 1-3 As shown, this die-casting mold cavity vacuuming system includes a plurality of die-casting molds 1 with mold cavities 11 . There is a Y-shaped vacuuming channel 2 with one inner port 21 and two outer ports 22 respectively, the inner port 21 is connected with the mold cavity 11, and one outer port 22 of each die-casting mold 1 is respectively connected with a pipe 3, and the other is An external port 22 is respectively connected to a vacuum cylinder 4, each branch pipe 3 is connected in parallel with the main pipe 5 and communicated with one end of the main pipe 5, the other end of the main pipe 5 is communicated with the vacuum tank 51, and the vacuum tank 51 is connected with a vacuum pump. The vacuum device 52, the vacuum pumping device 52 is preferably a vacuum pump, and each vacuum pumping cylinder 4 is slidably provided with a piston body 41 that is mutually sealed with the circumferential inner wall of the vacuum pumping cylinder 4, and the pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com