Gas distribution method and device for spacecraft leak rate detection

A spacecraft and leakage rate technology, applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree to measure the liquid tightness, and measuring the increase and deceleration rate of the fluid, etc., can solve the problems of occupying time, etc., to achieve Low vibration and noise, high degree of automation, and high pressure precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention are described in detail below: the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following implementation example.

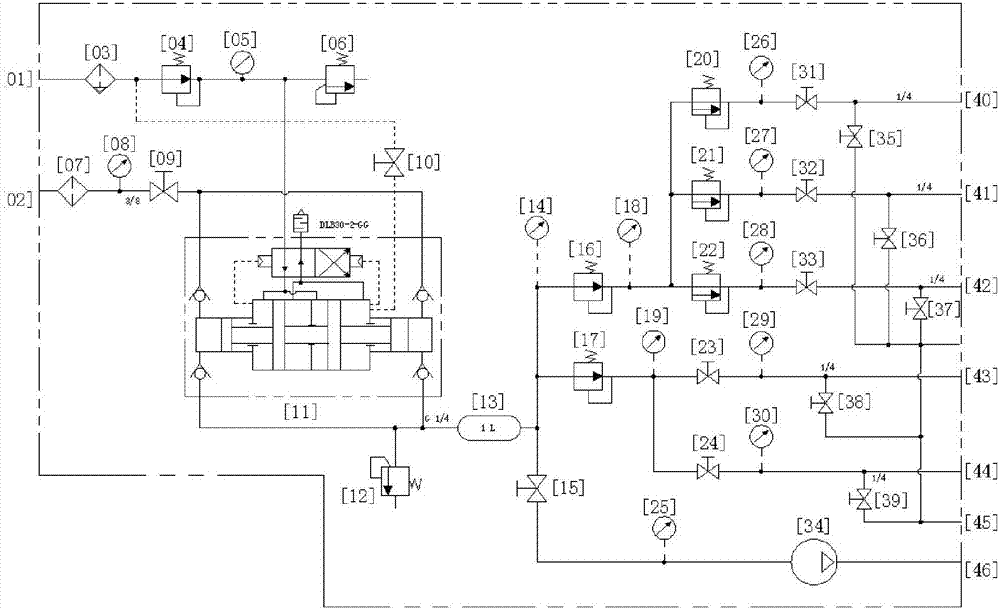

[0031] The gas distribution device schematic diagram of spacecraft leak rate detection of the present invention is as follows figure 1 As shown, the gas source inlet 02 of the device is connected to high-purity leakage gas with a purity ≥ 99.999%, the driver inlet 01 is connected to compressed air with a supply pressure of 0.7MPa as the driving power of the gas booster 11, and the gas output port is connected to the pre-filled workpiece , connect the gas output port to the workpiece, lead the unloading port out of the room with a hose, and ensure that the interface is clean and well sealed when connecting the pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com