Superposed copper strip unreeling device

A technology of copper strip and lifting device, which is applied in the directions of transportation and packaging, winding strips, and thin material processing, etc. It can solve the problems of affecting product quality, affecting production efficiency, and no stacking, etc., and achieves stable control of unwinding tension , improve production efficiency and production quality, and ensure the effect of unwinding tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

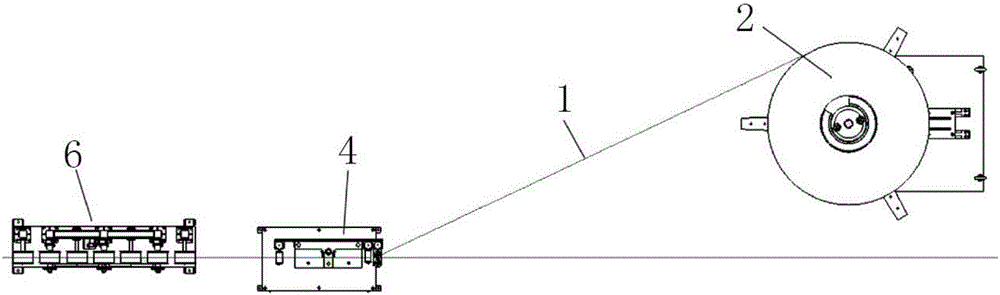

[0034] Such as figure 1 As shown, a stacked copper strip device is disclosed in this embodiment, which includes a tape release device 2, a copper tape lifting device 4 and a tape release dancer 6 arranged in sequence along the tape release direction. The specific structure of each part is as follows:

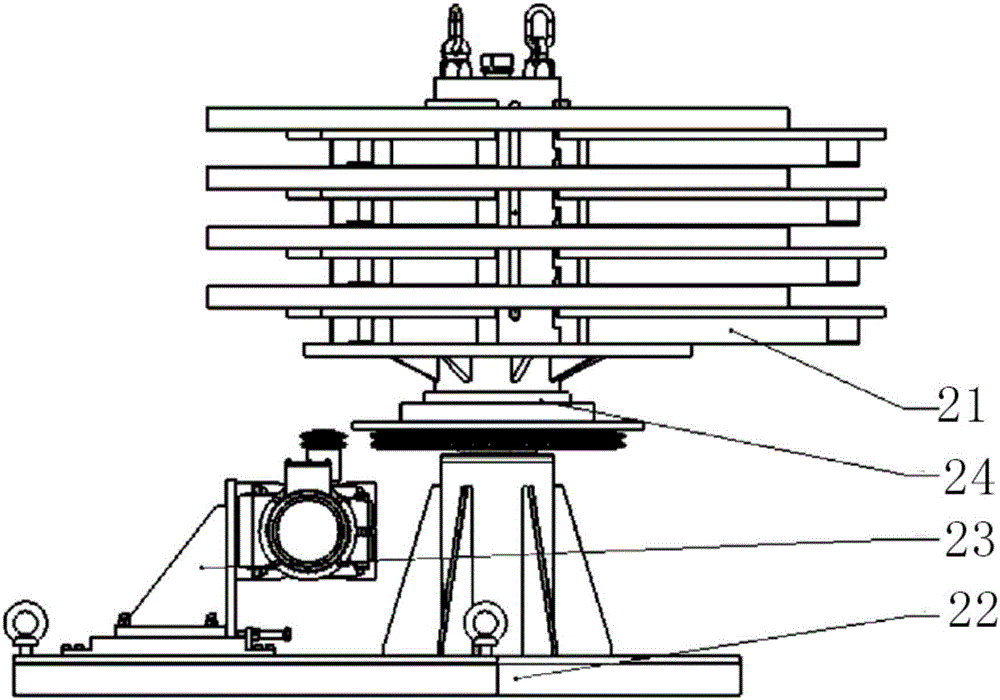

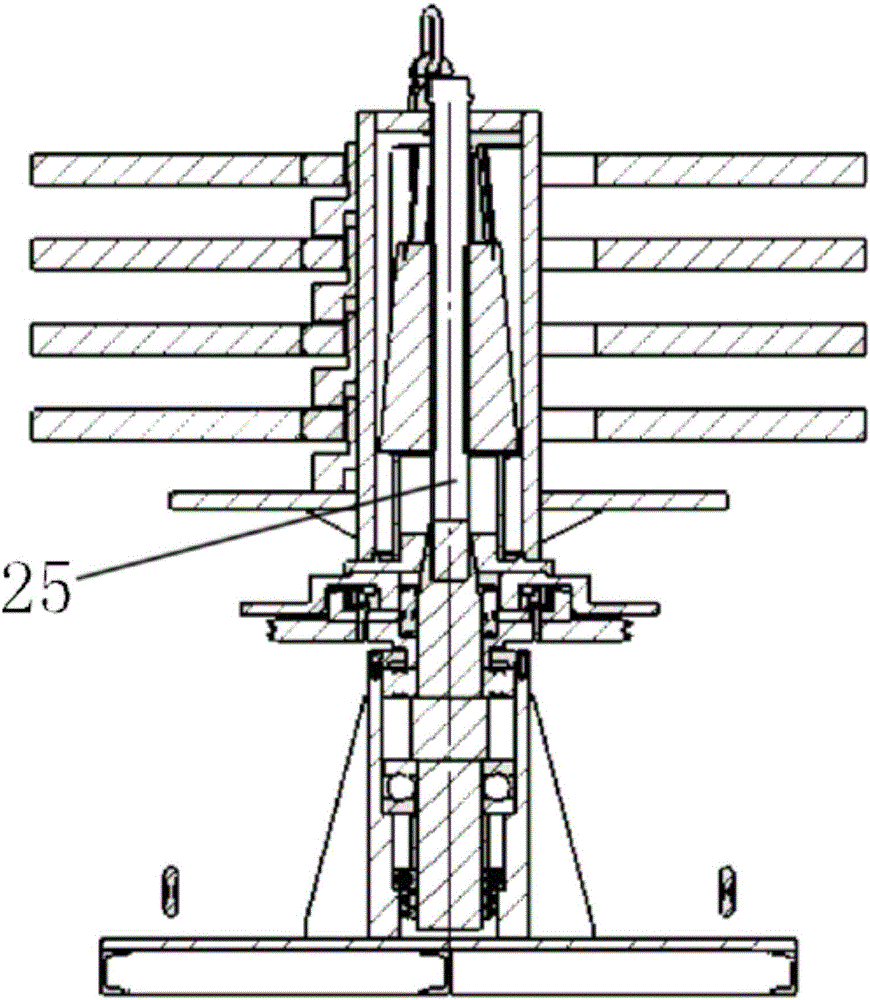

[0035] Such as figure 2 , 3 As shown, the tape unwinding device is provided with a plurality of copper tape reels 21. In this embodiment, four copper tape reels 21 are provided. The four copper tape reels 21 have the same specifications and are stacked sequentially from top to bottom, and The copper strips 1 on the adjacent copper strip reels 21 are connected end to end during loading.

[0036] Specifically, the tape unwinding device 2 also includes a fixed seat 22, a power part 23 and a tensioning part 24, and the four copper tape reels 21 stacked are installed on the tensioning part 24, and the tensioning part 24 is installed on On the fixed seat 22, the power part 23 is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com