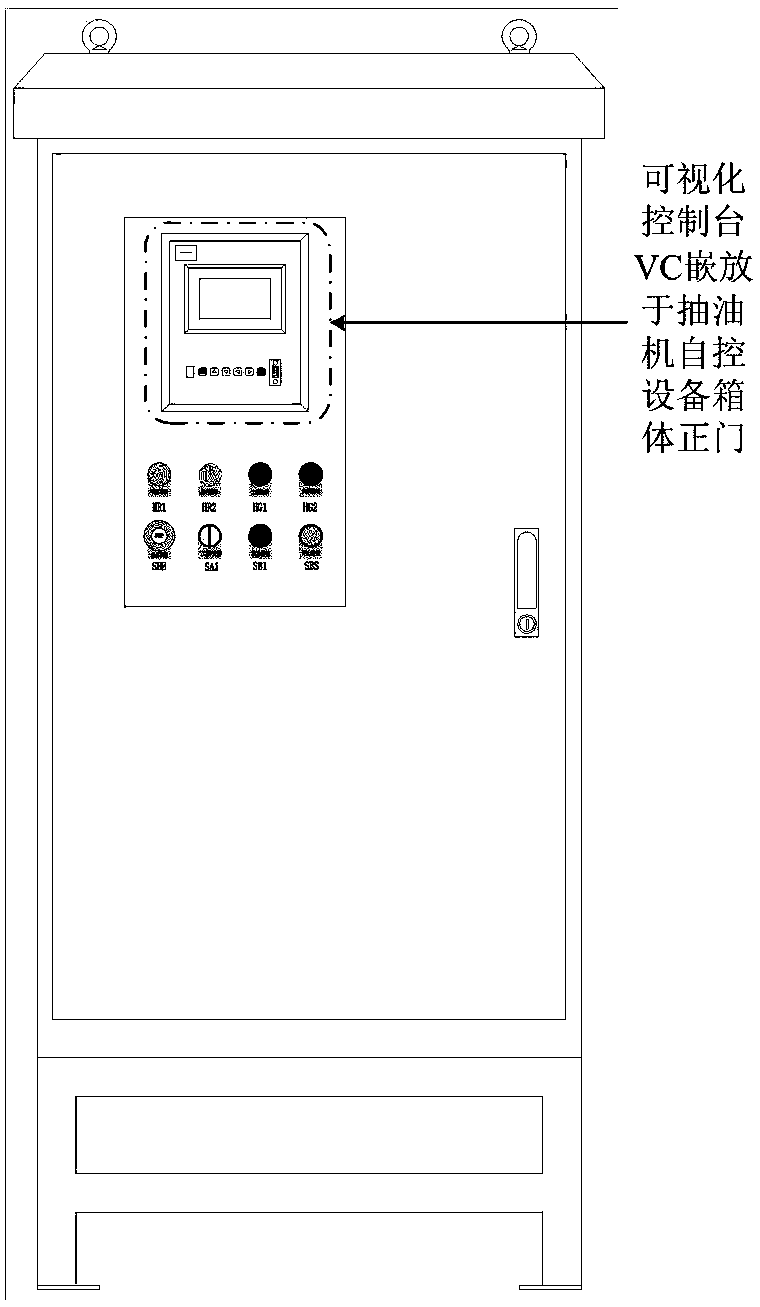

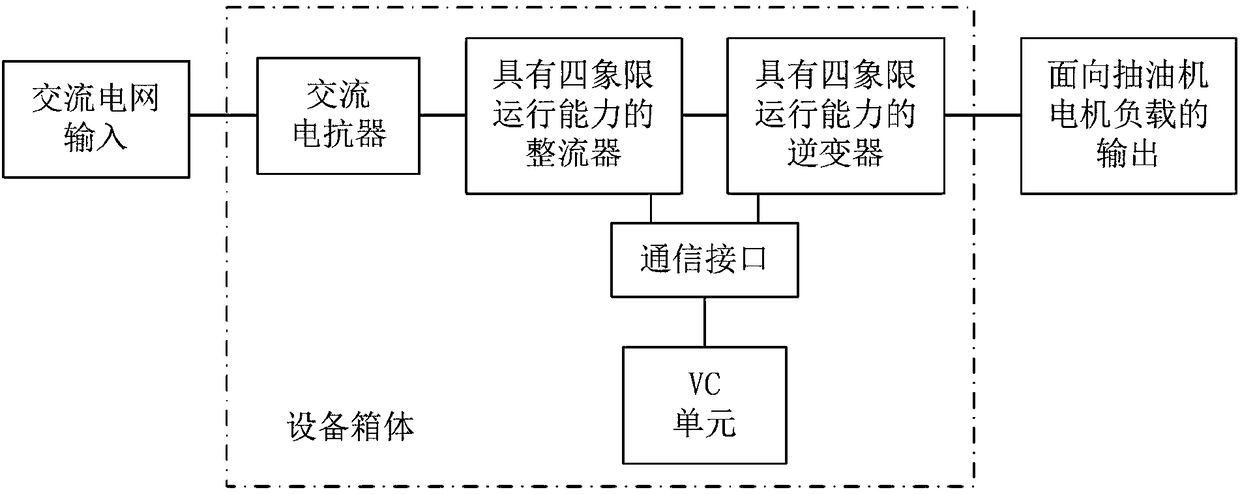

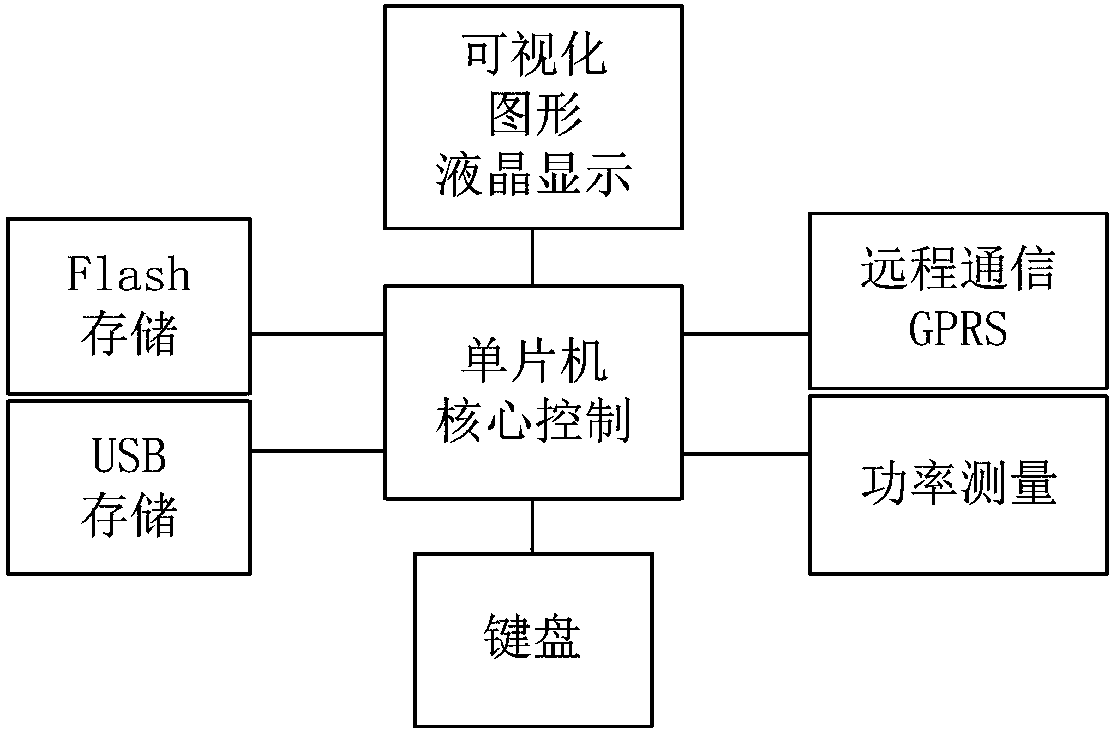

Local and remote dual-purpose oil pumping unit automatic control equipment based on visual control console

A console and pumping unit technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of disconnection in digital construction of oil fields, and achieve the effect of visual and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Such as Figure 4 As shown, it is the display of a set of operating status parameters by the visualization console VC, which mainly includes: from top to bottom, the first line is the operating mode of the automatic control equipment, the second line is the upstream current Uab and the upstream current Iab, and the third line is the downstream voltage Uab and downlink current Iab, uplink frequency and downlink frequency in the fourth line, alarm information in the fifth line, date and hash number in the sixth line.

Embodiment 2

[0037] Such as Figure 5 As shown, it is the display of a set of operating state parameters by the visualization console VC, which mainly includes: from top to bottom, the first line is the operating mode of the automatic control equipment, the second line is the uplink active power and downlink active power, and the third line is the uplink power factor simplification. The uplink power factor and downlink power factor are simply downlink power factor, the fourth line is the current balance degree, and the power balance degree is simply the power balance, the fifth line is the alarm information, and the sixth line is the date and number.

Embodiment 3

[0039] Such as Image 6 As shown, it is the display of a set of operating state parameters by the visualization console VC, which mainly includes: from top to bottom, the first line is the operating mode of the automatic control equipment, the second line is the stroke times and running time, and the third line is the uplink power factor simplification. The uplink power factor and downlink power factor are simply downlink power factor, the fourth line is the current balance degree, and the power balance degree is simply the power balance, the fifth line is the alarm information, and the sixth line is the date and number.

[0040] Display interface embodiment four

[0041] Such as Figure 7 As shown, it is the display of a set of operating status parameters by the visualization console VC, which mainly includes: from top to bottom, the first line is the operating mode of the automatic control equipment, the second line is the daily active energy, the third line is the monthly ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com