High-power image dot coverage rate digital measuring method suitable for whole printing process

A technology of dot coverage and measurement method, which is applied in the field of digital measurement of dot coverage of high-magnification images, and can solve the problems of inaccuracy, affecting the accuracy of measurement values, too large or too small per unit area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

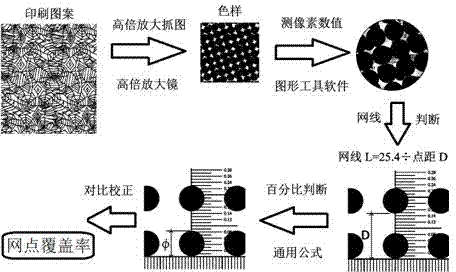

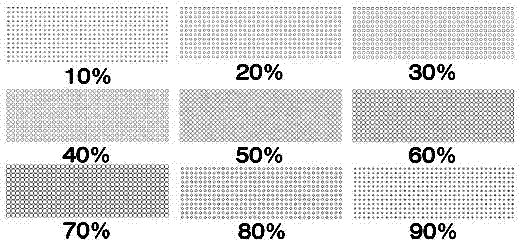

[0063] Embodiment 1: preferably use 300 times of 0.001 mm precision high-magnification magnifying glass, first measure the dot pitch to determine the number of screen lines, then measure the diameter of the dots, and compare the diameter and dot percentage value corresponding to the number of screen lines to obtain the dot percentage value.

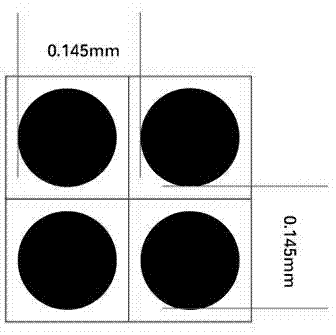

[0064] In the foregoing, as attached figure 2 As shown, taking the 175 line as an example, the amplitude modulation square and the dots are used to determine the data of the 175 line using a 0.145mm dot pitch; according to the RIP principle and the area formula, the 175 line dot 1-78.5% diameter formula is as follows:

[0065] =2r S= r 2 ≈3.14 1 inch =25.4 mm=175 lpi

[0066] = 2

[0067] =2

[0068] =2

[0069] =2

[0070] =2

[0071] in: :diameter S:area r:circle radius n:dot number per unit area m:dot percentage value.

[0072] In the above, if it is not 175 lines, use the formula: network line L=25.4÷dot pi...

Embodiment 2

[0087] Embodiment 2: In the case of dot enlargement, the above-mentioned method is still used for the dot measurement of the small-version copy proofing. When outputting a large format, there will be dot gain, and the dot gain is complicated. Before the matching correction "reduction" data is obtained, the existing technology usually uses the method of printing and adding time to ensure the printing of large format dots. CTP To add the corresponding curve to solve.

[0088] In the foregoing, there are two cases of network expansion:

[0089] 50% dots 150 lines 175 lines 200 lines Diameter (mm) 0.135 0.116 0.100 perimeter 0.424 0.364 0.314 Area (mm2) 0.0143 0.0106 0.0079 Area enlarged by 0.01mm 0.0189 0.0145 0.0113 Dot gain value (%) 32% 37% 43%

[0090] 175 line dots 25% outlets 50% outlets 75% outlets Diameter (mm) 0.082 0.116 0.142 Expanded Diameter (mm) 0.092 0.126 0.152 Expand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com