Method of transferring and pouring aluminum liquid in process of preparation of electrician round aluminum rod

A technology for the preparation process and round aluminum rods, which is applied in the field of liquid aluminum transfer during the preparation process of electrical round aluminum rods. It can solve the problems of low efficiency and high energy consumption, and achieve the effects of high thermal efficiency, high transfer efficiency, and accelerated melting process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

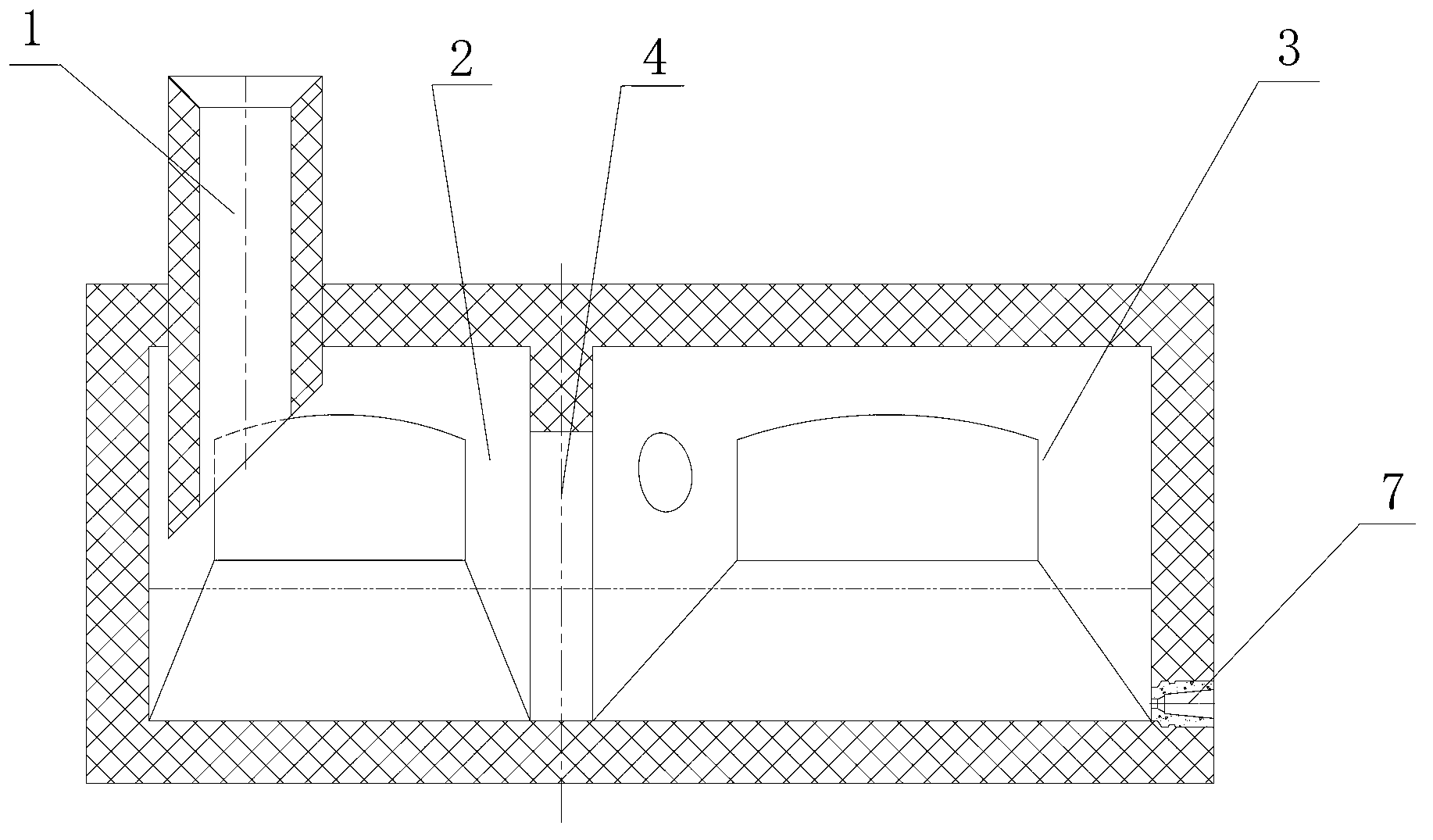

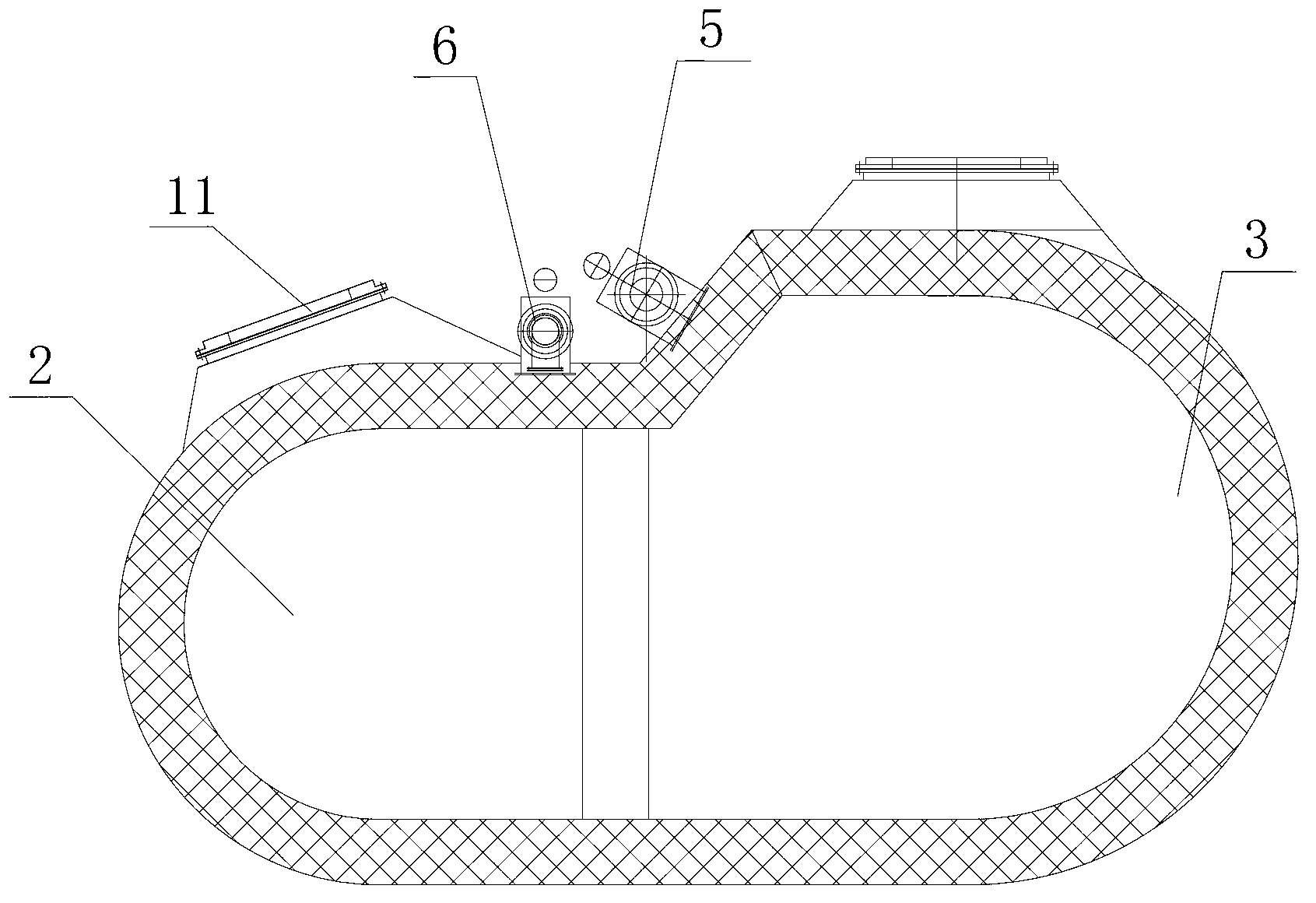

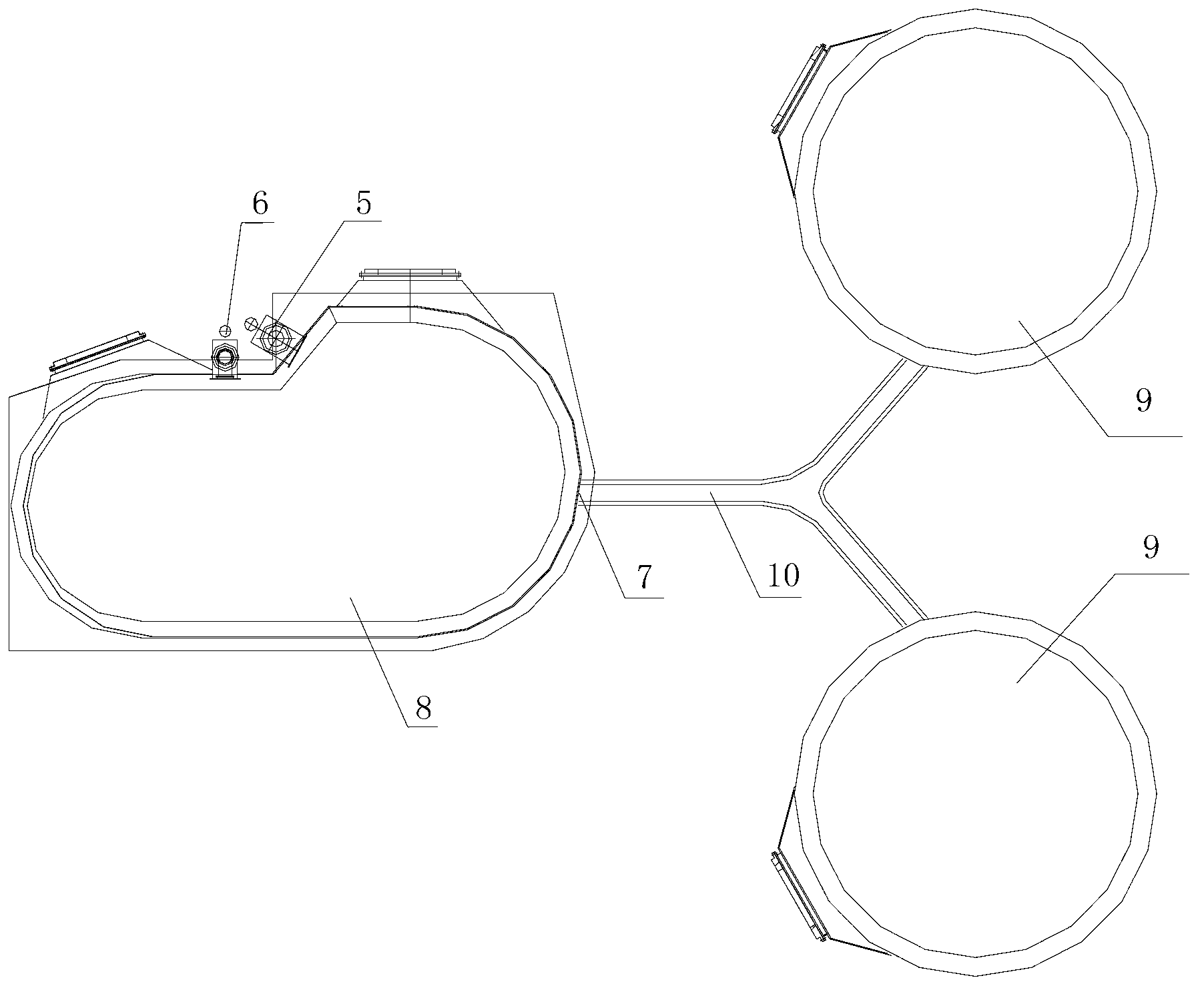

[0031] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

[0032] A method for transferring aluminum liquid during the preparation of electric round aluminum rods, comprising the following steps:

[0033] A. Monitor the amount of molten aluminum in the melting furnace, and the temperature of the molten aluminum is 720-760°C;

[0034] In this embodiment, the amount of molten aluminum in the melting furnace can be monitored through the observation hole or the liquid level detection device on the furnace door of the melting furnace.

[0035] The melting furnace has the ability to store and heat up molten aluminum, and closes the water outlet when it is not pouring, so that the furnace is well sealed, and the temperature of the molten aluminum can reach a high temperature that cannot be reached by the current cupola, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com