Rolling bearing fault diagnosis method and system combining edge calculation and deep learning

An edge computing and rolling bearing technology, which is applied in computing, computer parts, machine/structural parts testing, etc., can solve problems that cannot meet the needs of real-time detection of industrial equipment, achieve efficient utilization, reduce system delay, and meet real-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The motor fan is taken as an example below to further describe the present invention in detail, but it is not used as a basis for any limitation on the invention.

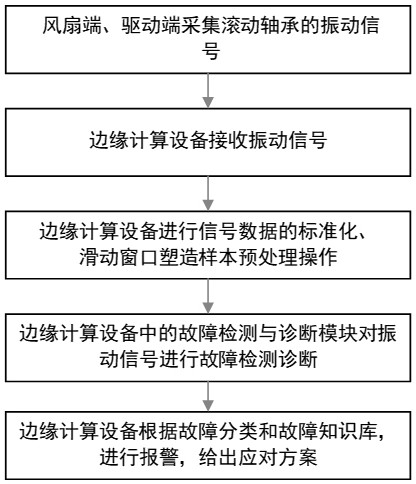

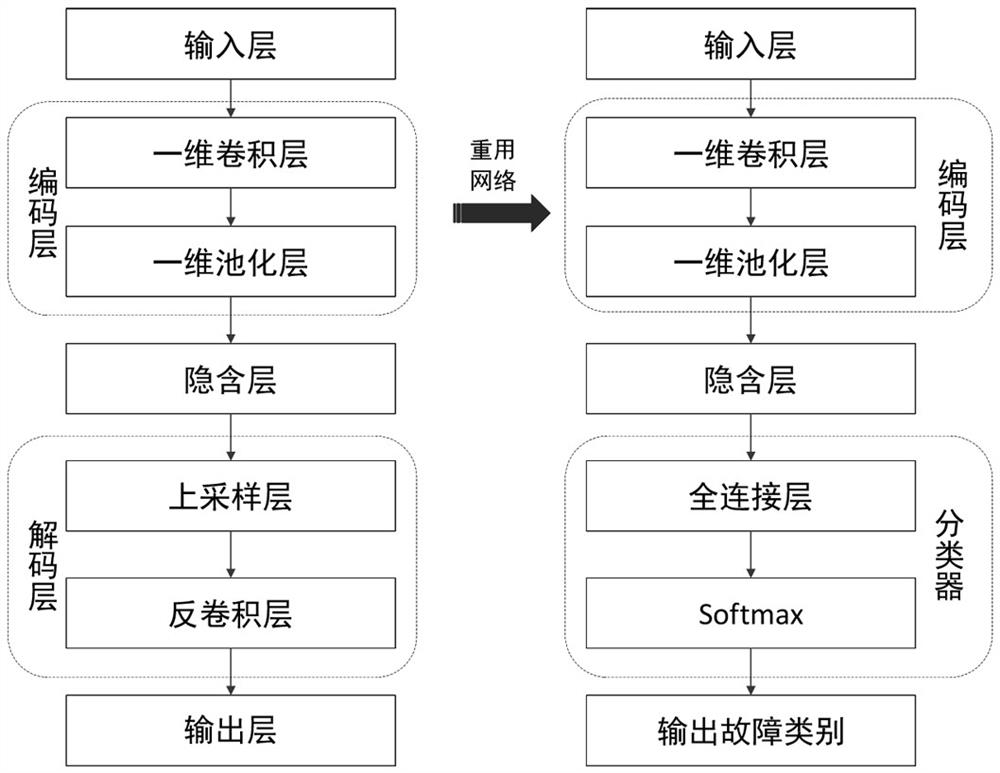

[0037] Such as figure 1 As shown, the rolling bearing fault diagnosis method combined with edge computing and deep learning includes the following steps:

[0038] Step 1, install an acceleration sensor on the bearing base of the fan end of the motor and the bearing base of the driving end to collect the real-time vibration signal of the corresponding bearing, and transmit it to the edge computing device through the signal transmission module;

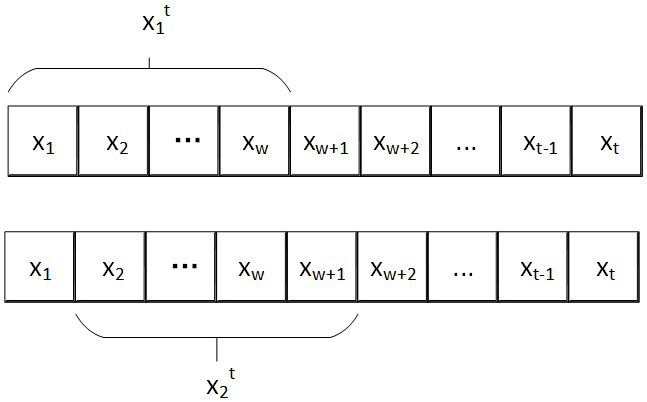

[0039] Step 2, the data preprocessing module in the edge computing device preprocesses the received real-time vibration signal, including standardizing signal data and shaping samples by using sliding window algorithm;

[0040] The standardized expression of the signal data is as follows:

[0041]

[0042]

[0043] x t =(x i -μ) / σ

[0044] where x i is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com