Air intake and exhaust thermal control device and method for implementing HCCI (homogeneous charge compression ignition) combustion of gasoline engine

A thermal control, air intake and exhaust technology, applied in the direction of fuel heat treatment devices, exhaust devices, electrical control, etc., can solve the problems of airflow resistance increase, size increase, heat exchanger difficult to greatly improve heat exchange efficiency, etc., to achieve Reduce demand, rationally store or release, and achieve the effect of selective and appropriate utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in combination with specific embodiments.

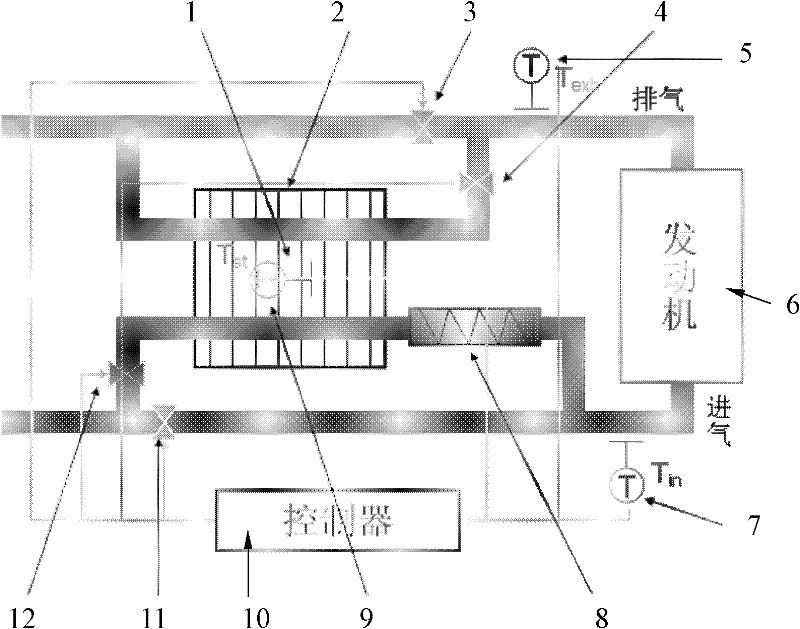

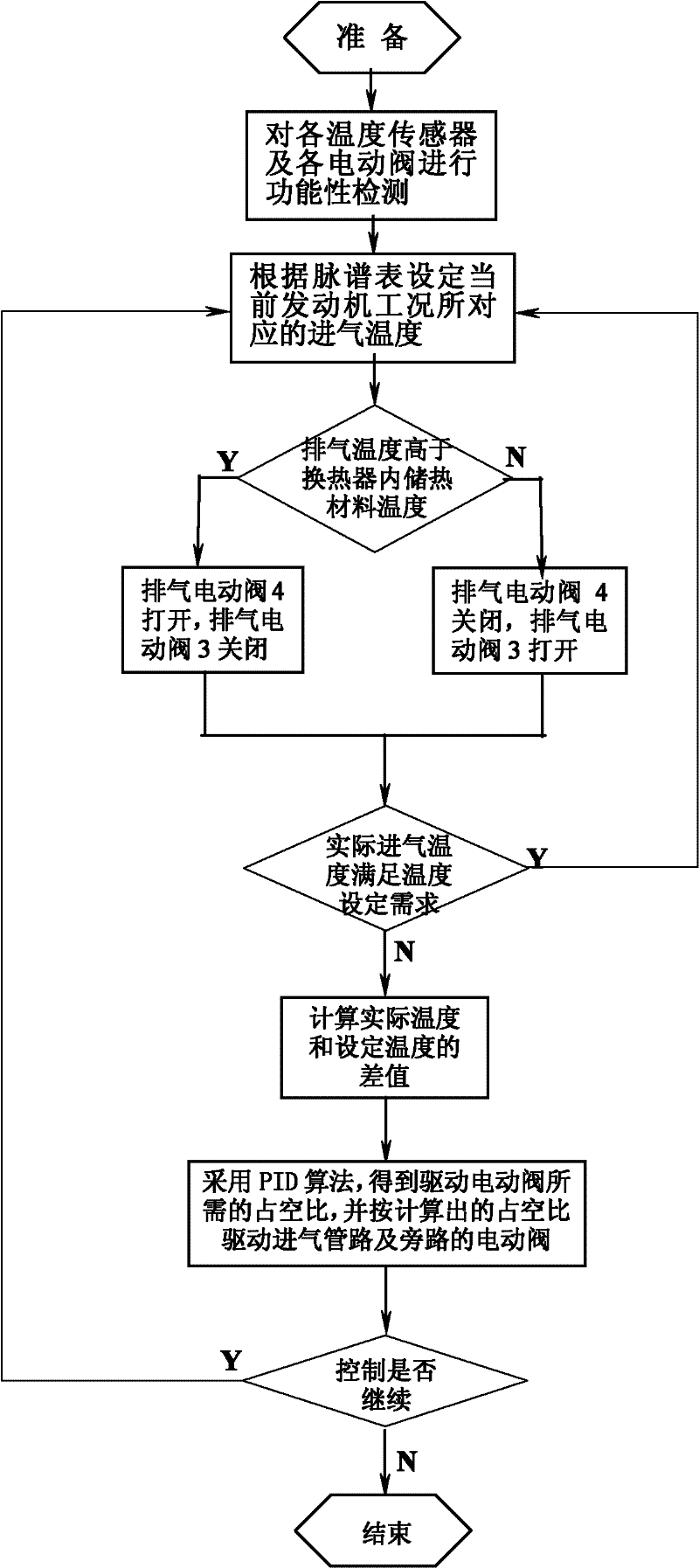

[0026] The basic idea of the present invention is to use an exhaust-intake heat exchanger containing heat storage materials, and to install electric valves on the exhaust and intake pipes, and realize the heat transfer in the exhaust by opening and closing the electric valves of the exhaust pipes. Accumulation and storage in the heat exchanger, at the same time, through the adjustment of the opening of the intake pipeline and the bypass electric valve, the intake air can use the heat in the heat exchanger in an appropriate amount.

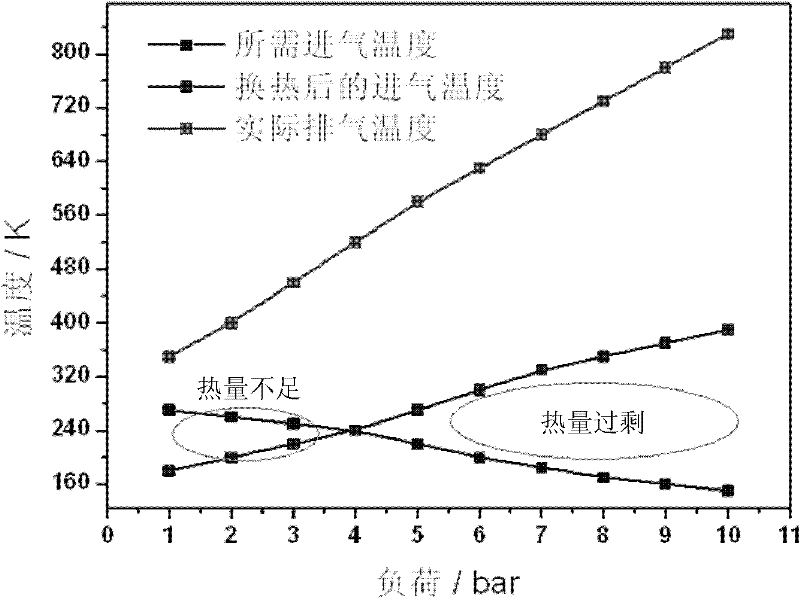

[0027] like figure 2As shown, the present invention realizes the intake and exhaust heat control device of gasoline engine HCCI combustion, including an exhaust pipeline, an intake pipeline and an exhaust-intake heat exchanger 2, and the exhaust pipeline is provided with a The exhaust bypass of the air-intake heat exchanger, the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com