A batch recovery process and equipment for membrane electrode catalyst slurry

A catalyst slurry and catalyst technology, applied in battery recycling, fuel cell disposal/recycling, recycling technology, etc., can solve the problems of high cost, waste of catalyst slurry, waste of energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

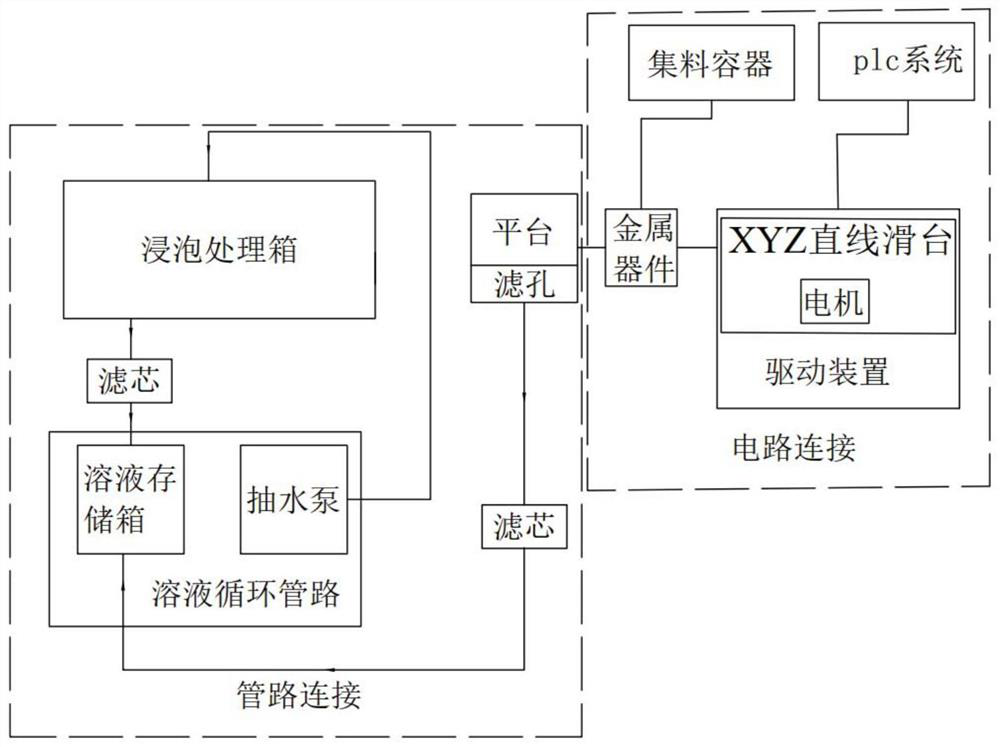

[0054] A fuel cell catalyst slurry batch recovery equipment, such as figure 1 As shown, include the following main institutions:

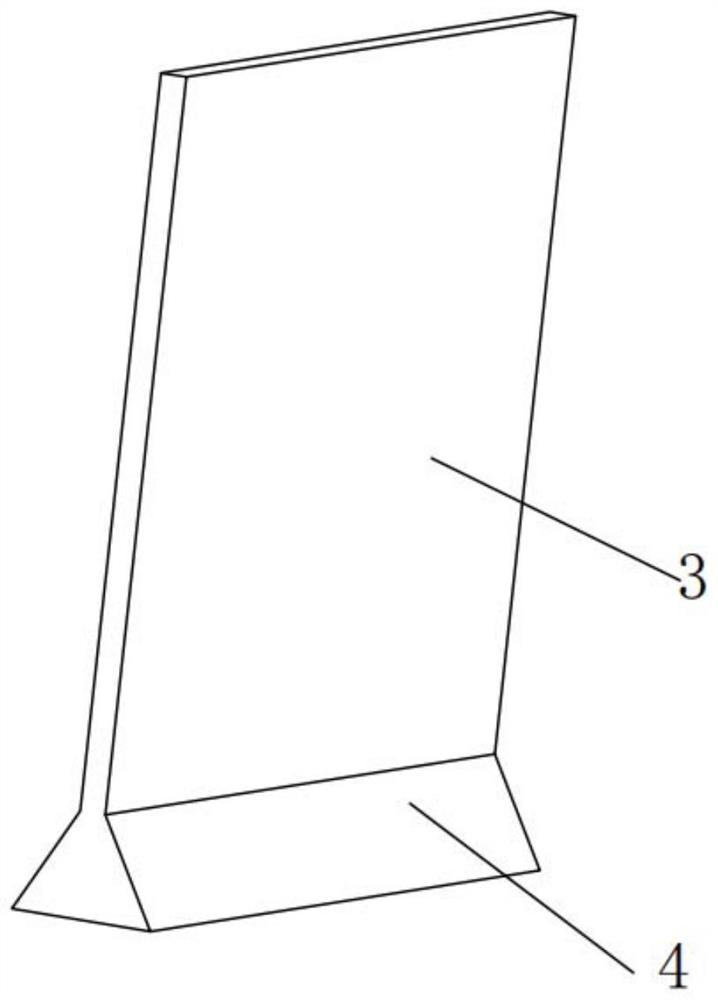

[0055] A. A soaking treatment box with a sealed cover;

[0056] B. Provide the solution circulation pipeline of the mixed solution in the soaking treatment tank. The solution circulation pipeline includes a solution storage tank, a water pump and a water pipe that is connected to the circuit between the soaking treatment tank and the solution storage tank. A filter element is provided on the return pipe where the solution flows into the solution storage tank;

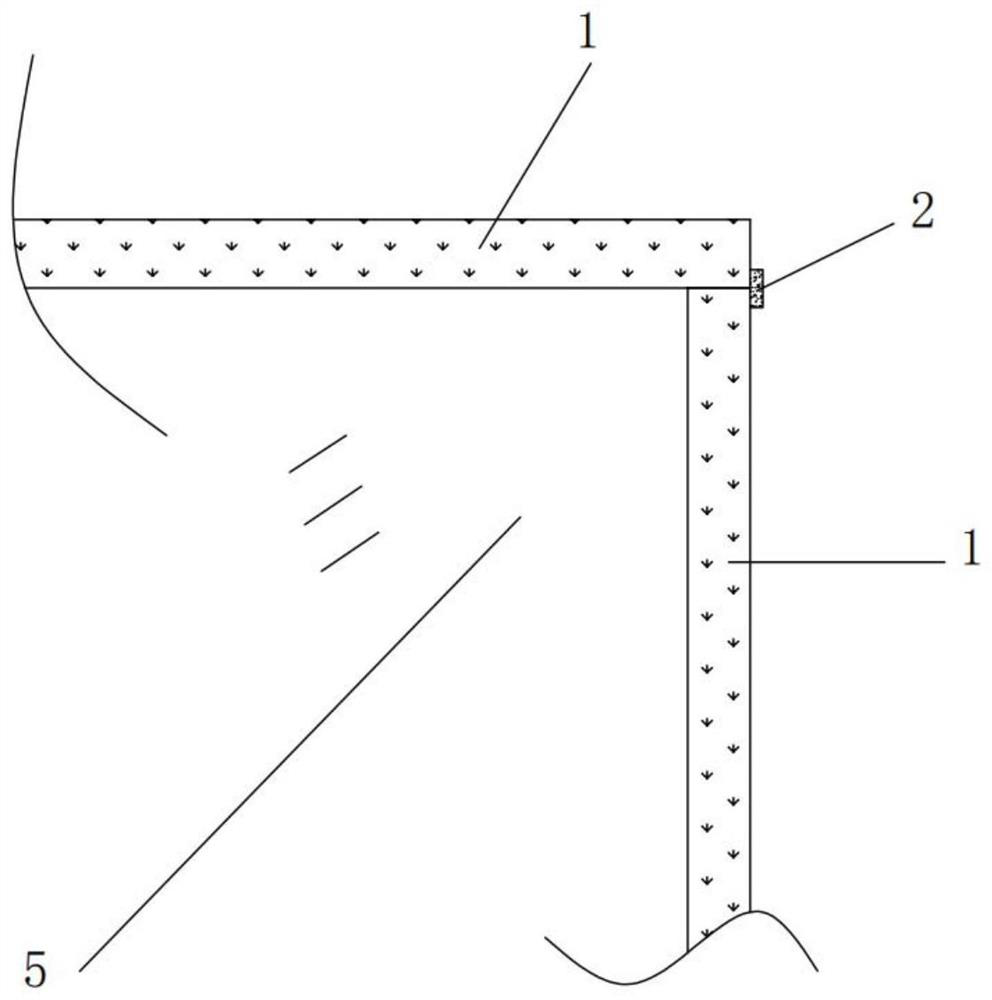

[0057] C. A placement platform with a filter hole, and the platform is connected to the solution storage tank in the solution circulation pipeline through a pipeline, and a filter element is also provided between the platform and the solution storage tank;

[0058] D. Driving device. There are metal devices on the driving device. The driving device can use the connection between the XYZ li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com