Device and method for closure construction of girder side span of cable-stayed bridge

A cable-stayed bridge and side span technology, applied in cable-stayed bridges, bridges, bridge forms, etc., can solve the problems of inability to achieve statically indeterminate locking, inability to overcome synchronous free expansion and contraction of cast-in-place sections, and high construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

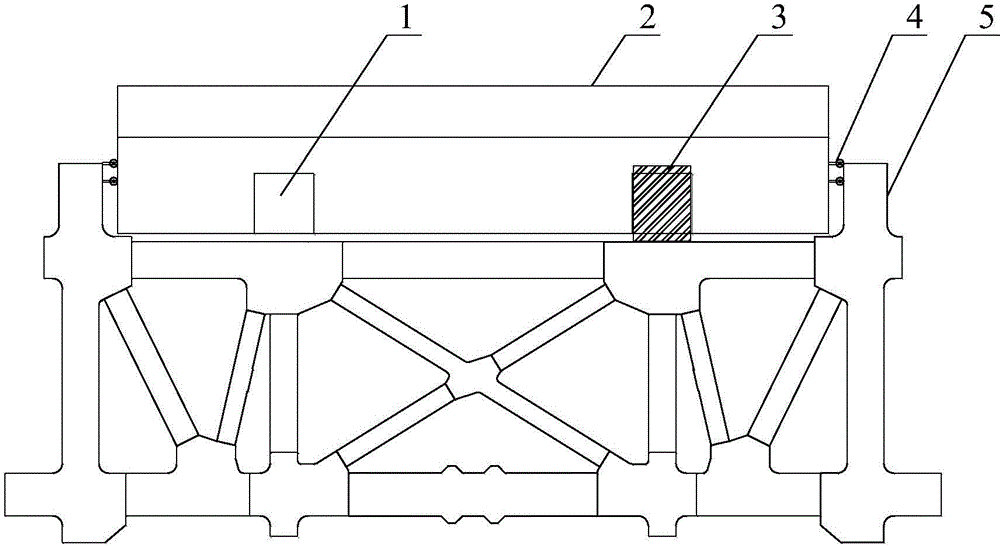

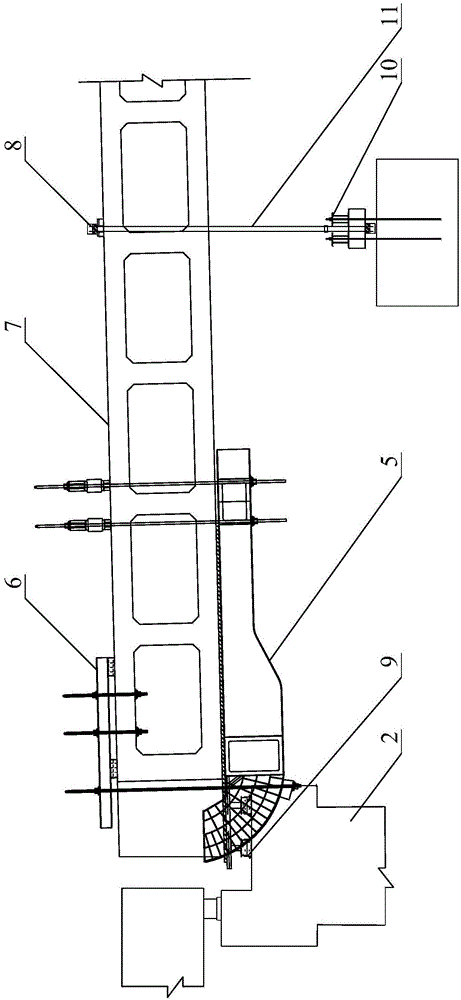

[0032] see figure 1 with figure 2 As shown, the embodiment of the present invention provides a device and method for closing the side spans of the main girder of a cable-stayed bridge. The cantilever beam 6 at the top of the beam 7, the stay cable hanging basket 5 arranged at the bottom of the poured main beam 7 and the down-down cable system arranged on the poured main beam 7, the side span closing section support pier 2 is located 7, the cantilever beam 6 is located above the pier top support system 9 and the guy rope hanging basket 5.

[0033] The lanyard hanging basket 5 comprises two arc heads, and the outside of each arc head is welded with a lateral positioning fixed pulley 4, and the lateral positioning fixed pulley 4 is fixed on the outside of the side span closing section buttress 2.

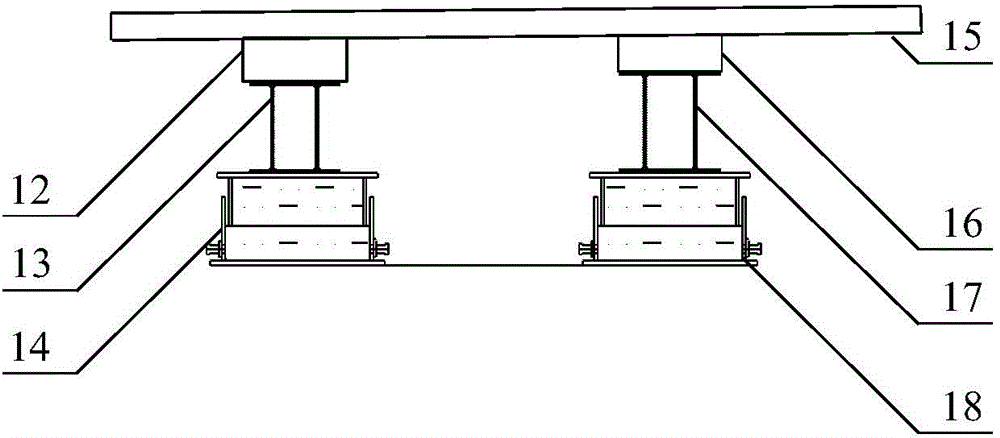

[0034] join image 3 with Figure 4 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com