Damage-free preform conveyor

A non-damage, preform technology, applied in the field of non-damage embryo transfer machine, can solve the problems that affect product quality, preforms are easy to be scratched, and product appearance is affected, so as to ensure the overall quality, prevent lateral swing, and lift smoothly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

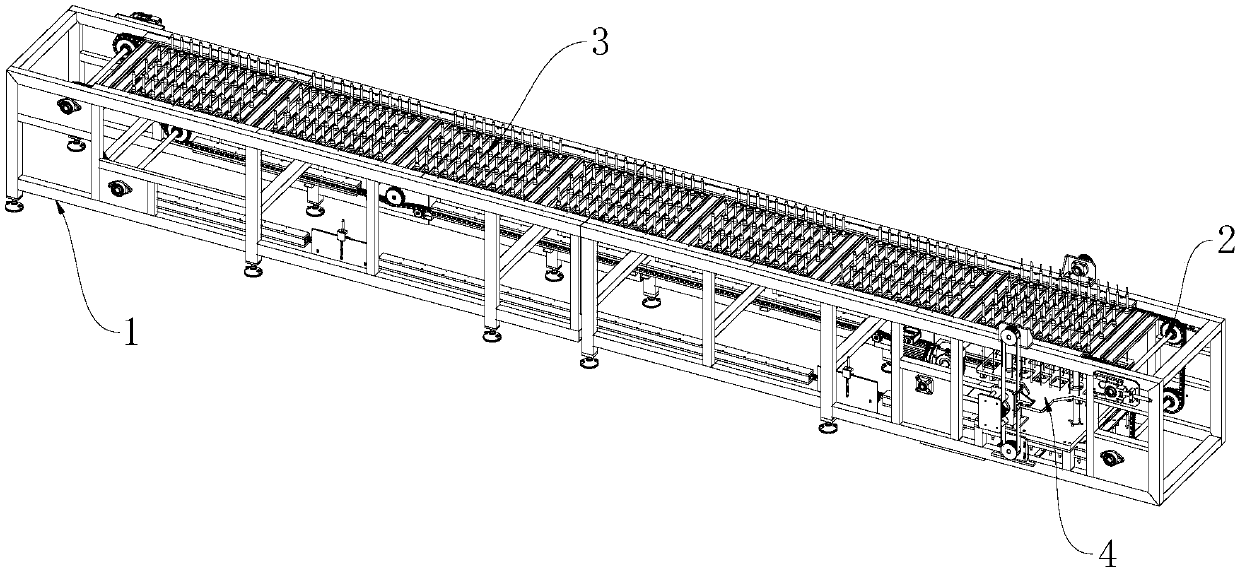

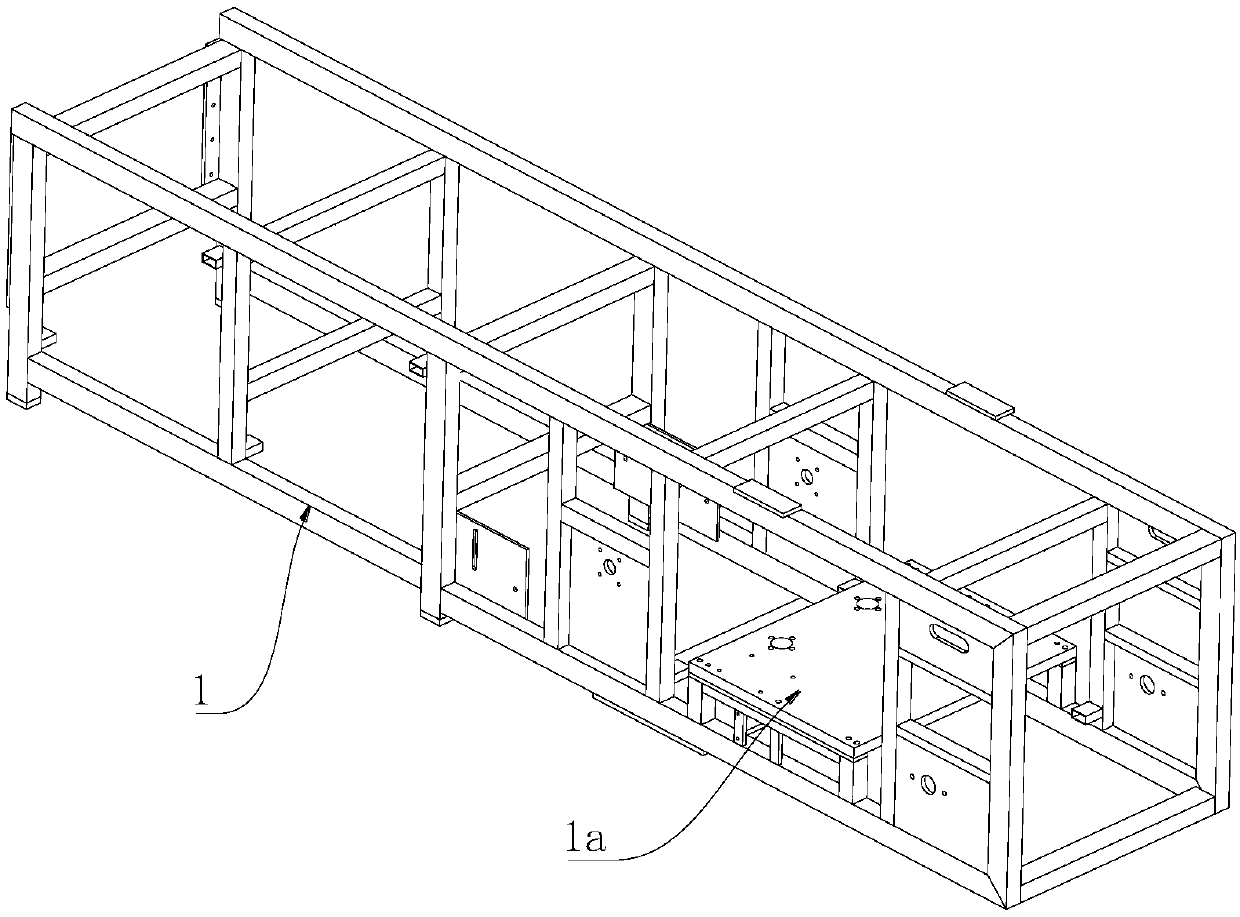

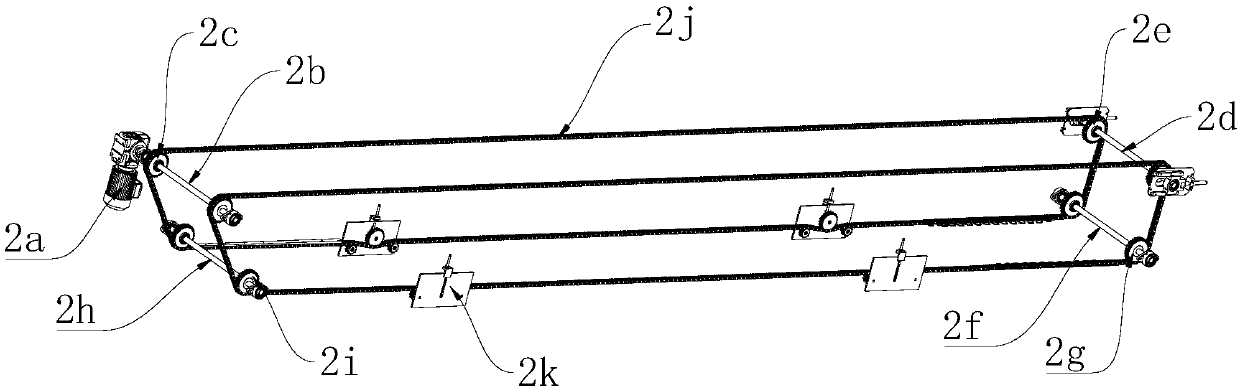

[0042] like figure 1 As shown, the non-damage embryo transfer machine includes a bracket 1, a chain transmission assembly 2, a embryo carrier assembly 3 and a embryo transfer assembly 4, the chain transmission assembly 2 is installed on the bracket 1, and the embryo carrier assembly 3 is installed on the chain transmission On the component 2, the preform receiving component 4 is installed on the front side of the support 1. When connecting the preforms, the preform connecting component 4 connects the preforms from the embryo ejection mechanism to the preform carrier assembly 3 located directly below the embryo ejection mechanism Then, the preform carrier assembly 3 carrying the preform is moved to the rear side of the support 1 by the chain transmission assembly 2 .

[0043]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com