a printing device

A technology of printing device and printing roller, which is applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve the problems of ink liquid throwing out, etc., and achieve the effects of preventing pollution, benefiting high-quality printing, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

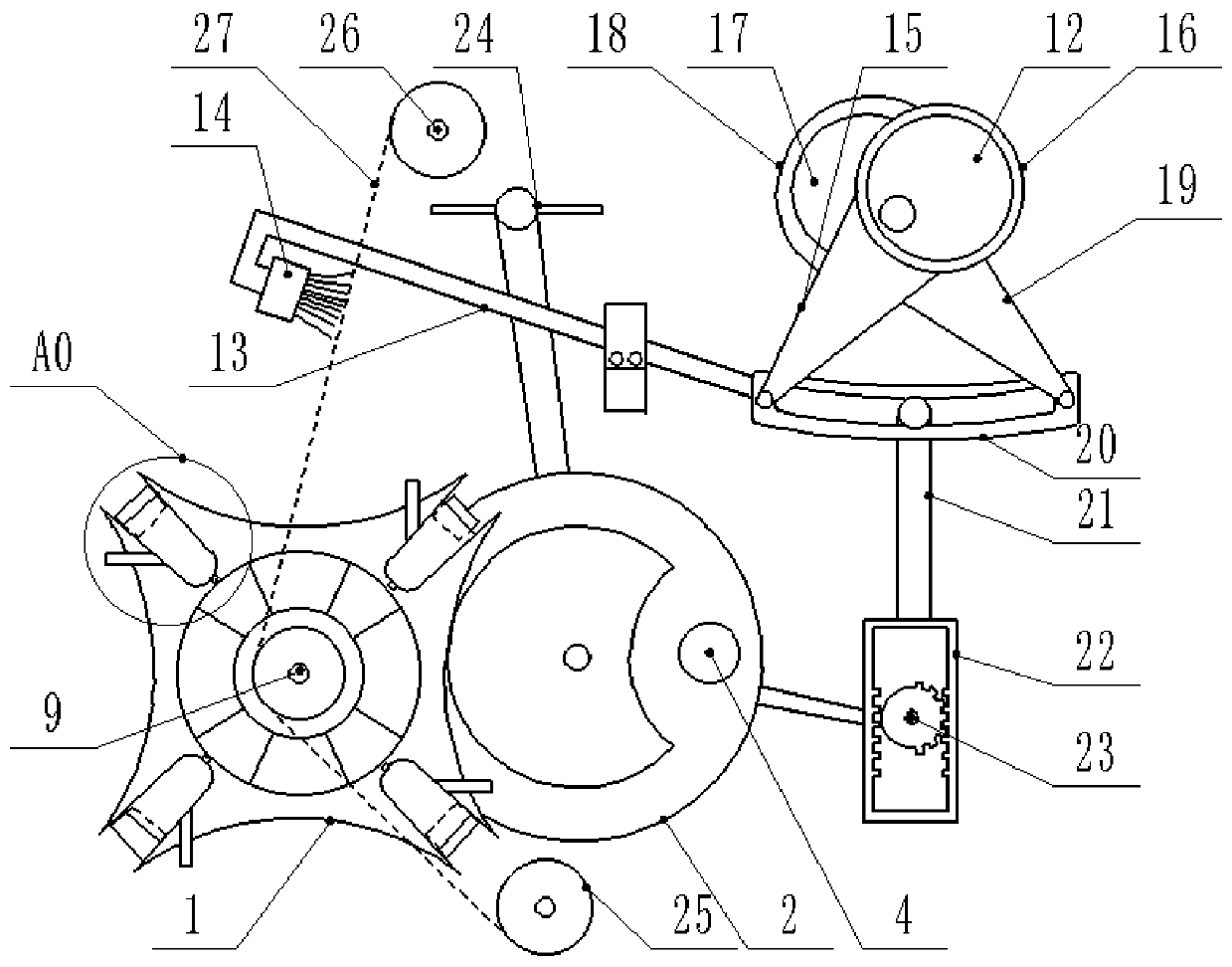

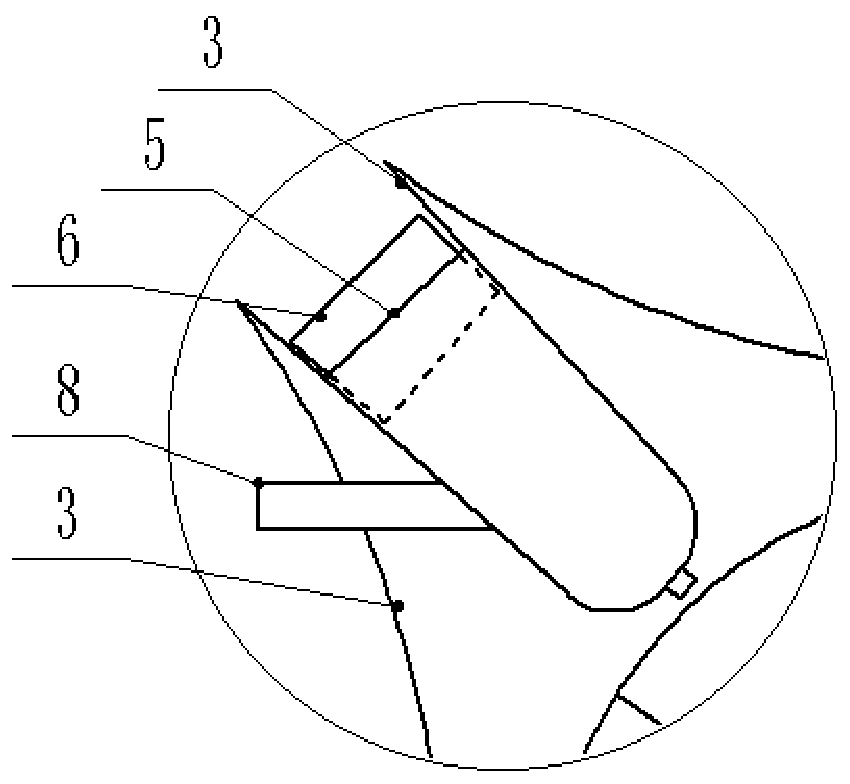

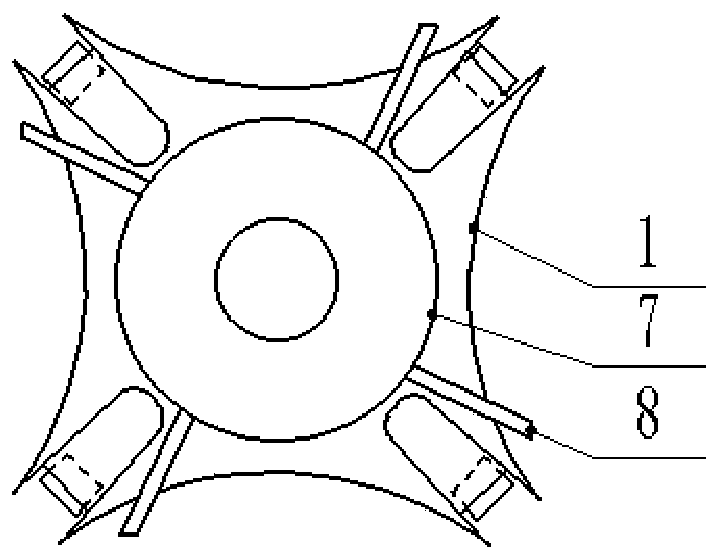

[0023] The reference signs in the drawings of the description include: grooved wheel 1, runner 2, card slot 3, card column 4, slide plate 5, piston 6, ink tank 7, ink inlet tube 8, printing roller 9, ink guide roller 10, Ink guide groove 11, first eccentric wheel 12, lever 13, hair brush 14, first swing arm 15, first ring 16, second eccentric wheel 17, second ring 18, second swing arm 19, swing rail 20, pendulum 21, rectangular frame 22, half gear 23, fan 24, put paper roll 25, roll paper roll 26, paper tape 27, axle bar 28.

[0024] Example figure 1 Shown: a printing device, including a sheave mechanism, and the sheave mechanism includes a sheave 1 and a runner 2 . combine Figure 4 with Figure 5 The front end of the sheave 1 is welded with a tapered ink guide roller 10, the front end of the ink guide roller 10 is welded and fixed with the printing roller 9 coaxial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com