Bracket carrier rear frame capable of quickly changing loading width and using method

A support truck and rapid change technology, applied in vehicle parts, transportation and packaging, substructure and other directions, can solve problems such as hidden safety hazards, large replacement workload, labor intensity of workers, etc., to prevent lateral swing, alleviate overload wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

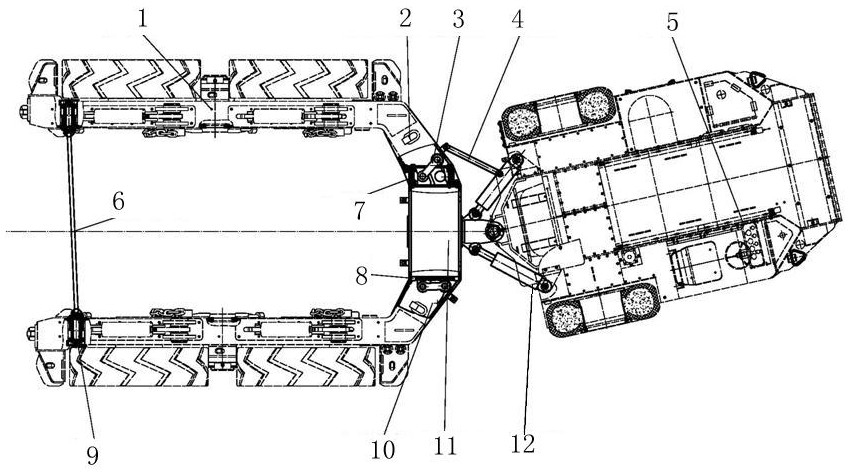

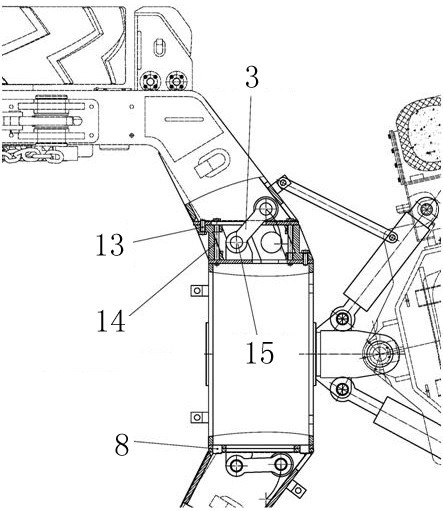

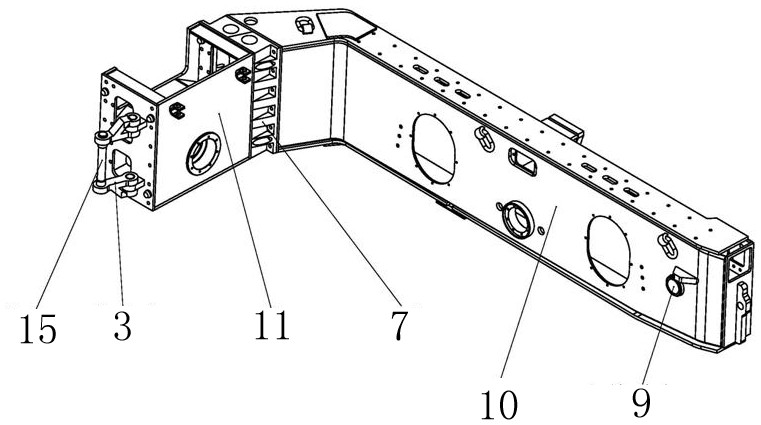

[0028] A rear frame of a support truck that can quickly change the loading width, including a front frame 5 and a rear frame 1, the front frame 5 and the rear frame 1 are hingedly connected, and two sets of steering cylinders 12 are respectively arranged on both sides of the hinged position , characterized in that: the rear frame 1 includes a middle box 11, a swivel frame 3, a left carrier 2 and a right carrier 10, the middle box 11 is hingedly connected with the front frame 5, and the two sides of the middle box 11 are respectively connected to the left The carrier frame 2 is connected to the right carrier frame 10, and the joint surface between the middle box body 11 and the left carrier frame 2 or the right carrier frame 10 is fixed by positioning pins 8 and short bolts 13, and a set of concave pads can be added in the middle of the joint surface 7. The left bearing frame 2 or the right bearing frame 10 and the concave spacer 7 are fixed by long bolts 14, and a rotating fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com