Down-press crimping machine for staple fiber production line

A technology of production line and crimping machine, which is applied in the direction of non-polymer organic compound adhesives, textiles and papermaking, non-polymer adhesive additives, etc. It can solve the problem of short service life, increased production costs, and inability to meet fiber crimping process requirements, etc. problems, to achieve the effect of reducing maintenance costs, reducing cumulative installation errors, and not easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

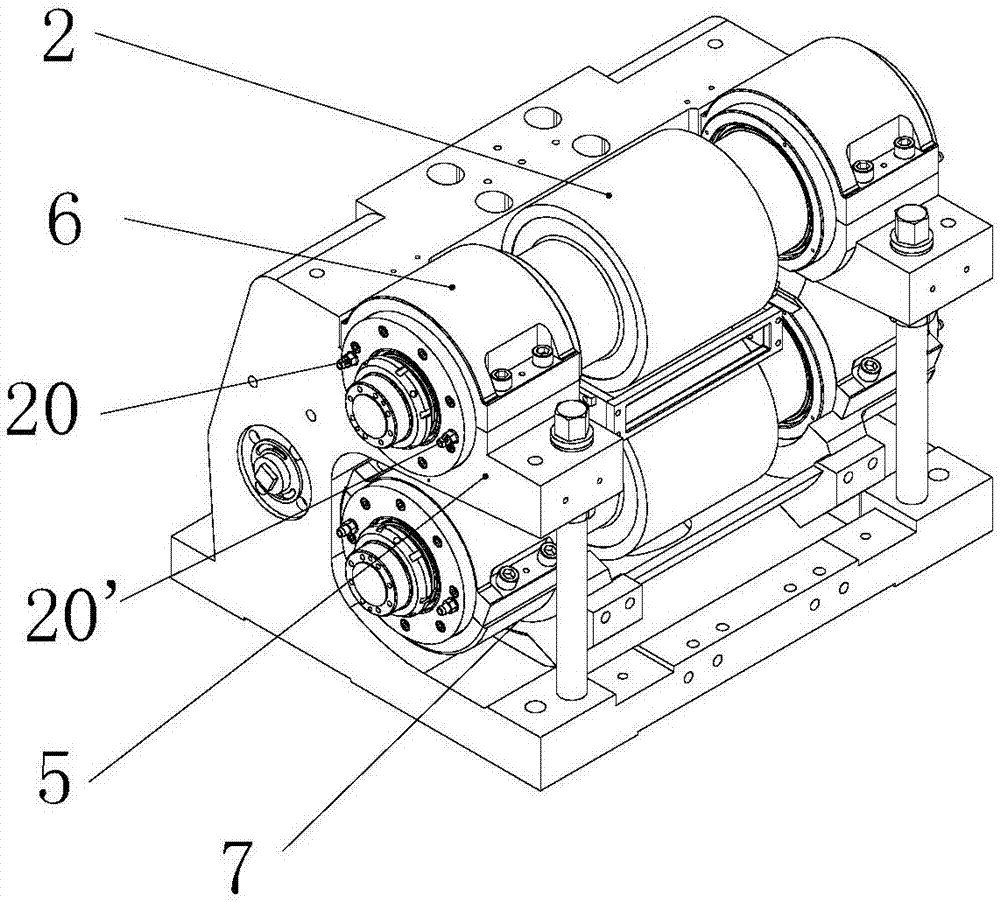

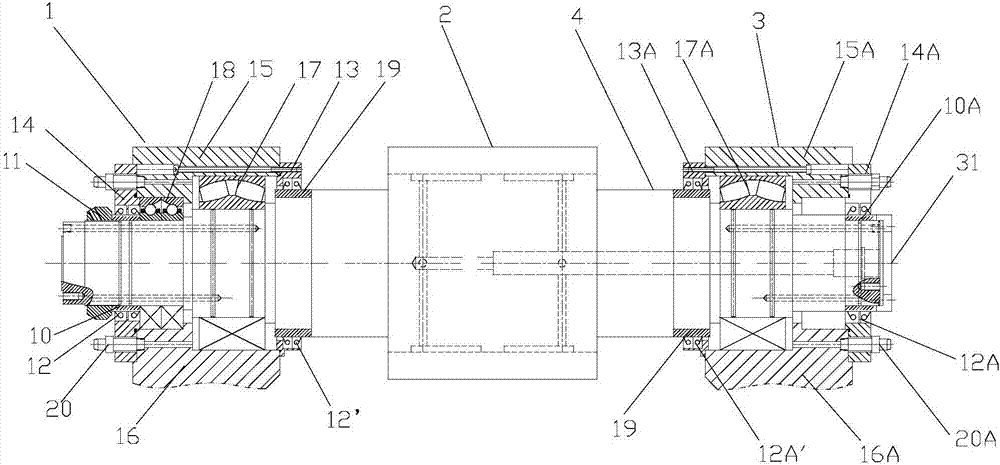

[0016] A kind of down-pressing crimping machine for staple fiber production line provided by this embodiment, the structure is as follows: figure 1 As shown, it includes a crimping roller, a machine base 5 and a lower rocker arm 7, and a pair of crimping rollers rotating together are installed on the machine base and the lower rocker arm. The roll includes a curling roller 2 and curling rollers 4 arranged on both sides of the curling roller. The curling rollers at both ends of the curling roller are connected with the base and the lower rocker arm through a rotating mechanism. The rotating mechanism is composed of a power input transmission mechanism 1 and a heating The transmission mechanism at the input end consists of 3; the transmission mechanism at the power input end includes an inner flange 13, an outer flange 14, a bearing bush cover 15, a frame bearing bush 16, a radial load bearing 17 and an axial load bearing arranged at the end of the curling roller shaft. 18. The ...

Embodiment 2

[0020] This example provides a down-pressing crimping machine for a staple fiber production line. On the basis of Example 1, this example can make the chemical fibers heated evenly and prevent the chemical fibers from sticking to the surface of the crimping roller. On the curling roller, it is wear-resistant and has a long service life.

[0021] The composite film includes a PTFE film, one side of the PTFE film is coated with a cross-linked adhesive, and the other side of the PTFE film is sprayed with a nano solution, and the composite film is bonded to the curling roller through the cross-linked adhesive;

[0022]The mass percentage components of the cross-linked adhesive are: 4-methylcyclohexyl isocyanate: 35%, urethane: 9%, α-linolenic acid: 6%, ethoxylated bisphenol A dimethacrylate: 7%, Trimethylolpropane Trimethacrylate: 2%, Benzoyl Peroxide: 3%, Butyl Acrylate: 4%, Crosslinked Acrylate Emulsion: 5%, 2-Hydroxy-1,2 - Diphenyl ethyl ketone: 0.7%, dimethylformamide: 1%, vi...

Embodiment 3

[0025] This example provides a down-pressing crimping machine for a staple fiber production line. On the basis of Example 1, a composite film is pasted on the surface of the crimping roller, so that the chemical fiber can be heated evenly and prevent the chemical fiber from sticking to the On the curling roller, it is wear-resistant and has a long service life.

[0026] The composite film includes a PTFE film, one side of the PTFE film is coated with a cross-linked adhesive, and the other side of the PTFE film is sprayed with a nano solution, and the composite film is bonded to the curling roller through the cross-linked adhesive;

[0027] The mass percent components of the cross-linked adhesive are: 4-methylcyclohexyl isocyanate: 36%, urethane: 10%, α-linolenic acid: 7%, ethoxylated bisphenol A dimethacrylate: 8%, Trimethylolpropane Trimethacrylate: 3%, Benzoyl Peroxide: 4%, Butyl Acrylate: 5%, Crosslinked Acrylate Emulsion: 6%, 2-Hydroxy-1,2 -Diphenyl ethyl ketone: 0.8%, di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com