High-frequency torsional vibration viscosity reducing tool

A high-frequency, viscosity-reducing technology, which is applied to drilling equipment, earthwork drilling, driving devices for drilling in boreholes, etc., can solve the economic loss of the drill string system, reduce the service life of the drill string, and the failure of the PDC bit, etc., to achieve Improve drilling efficiency, eliminate drill string stick-slip, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

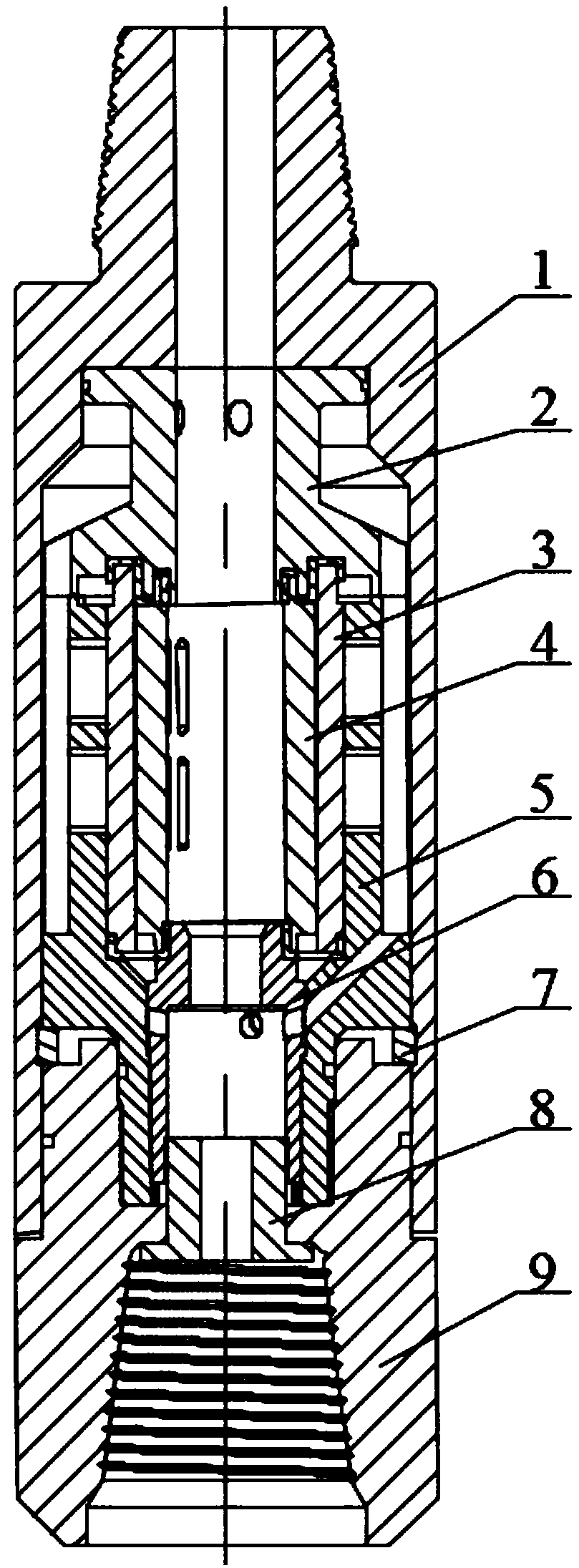

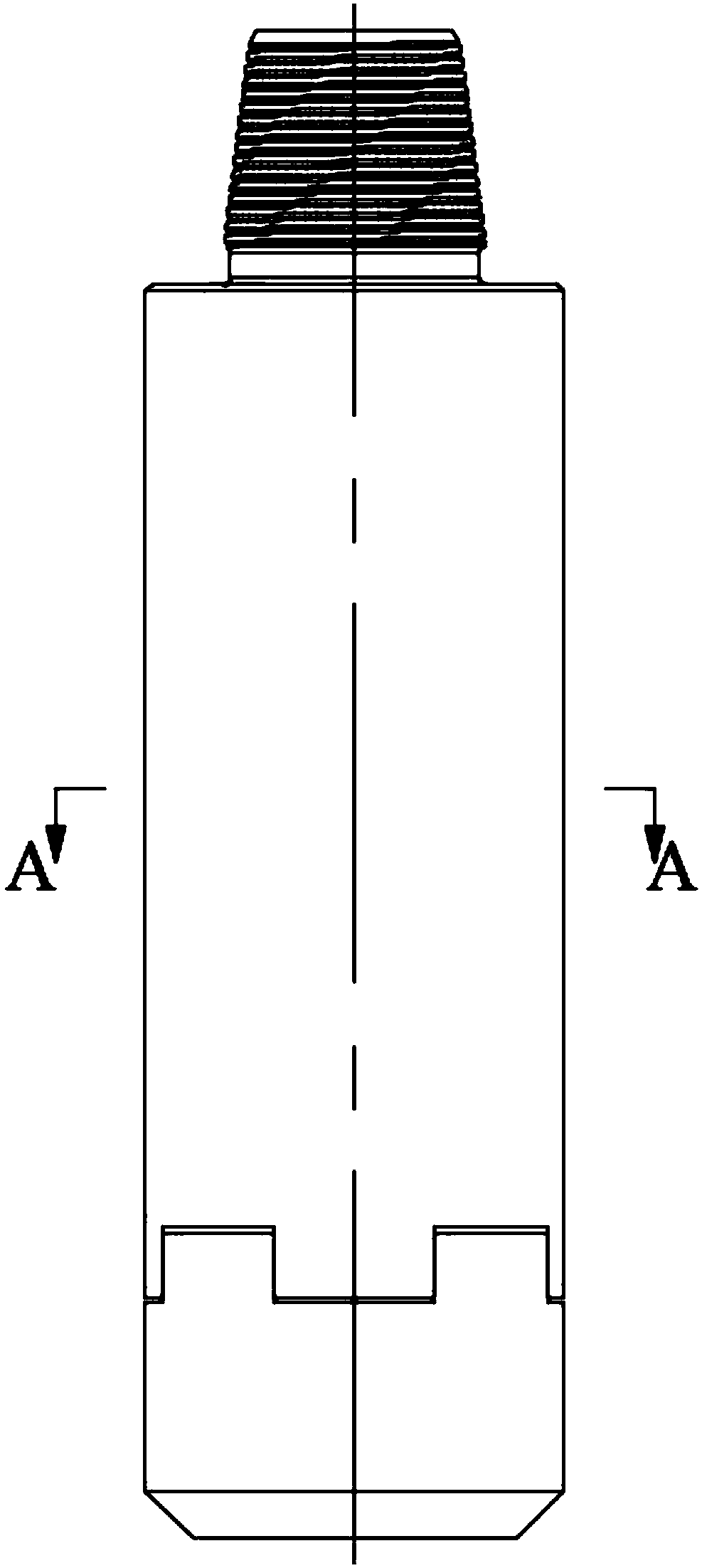

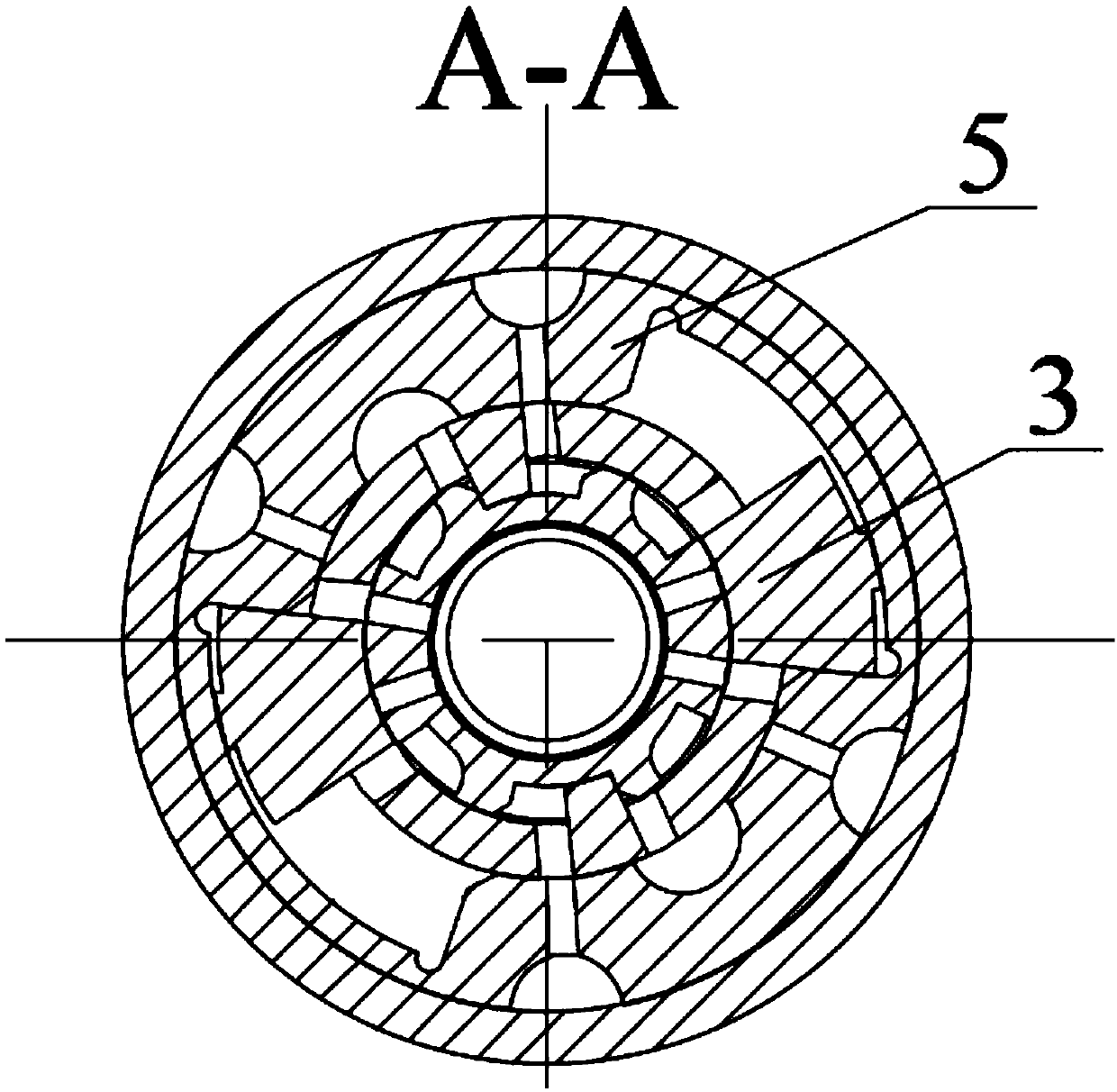

[0014] See attached figure 1 , the high-frequency torsional vibration viscosity reduction tool is mainly composed of the upper joint shell 1, the shunt sleeve 2, the impact hammer 3, the reversing fork 4, the impact valve body 5, the cage 6, the positioning snap ring 7, the jet nozzle 8 and the conversion joint 9 Composition, the shunt sleeve 2, the impact hammer 3, the reversing fork 4, the impact valve body 5, the cage 6, and the positioning snap ring 7 are all installed in the upper joint shell 1, and are carried out through the jet nozzle 8 and the conversion joint 9. Axial and circumferential positioning, the front end of shunt sleeve 2 is provided with an annular groove for installing impact hammer 3, reversing shift fork 4, and impact valve body 5. First install impact hammer 3 in impact valve body 5, and then replace the The shift fork 4 is installed in the impact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com