Novel PDC drill bit for improving rock-breaking efficiency based on impact effect

A technology of rock-breaking efficiency and impact effect, applied in the direction of drill bits, drilling tools, drilling equipment, etc., can solve problems such as drill sticking, low rock-breaking efficiency, and increased axial pressure of the drill bit, so as to solve mud bags and increase rock-breaking rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

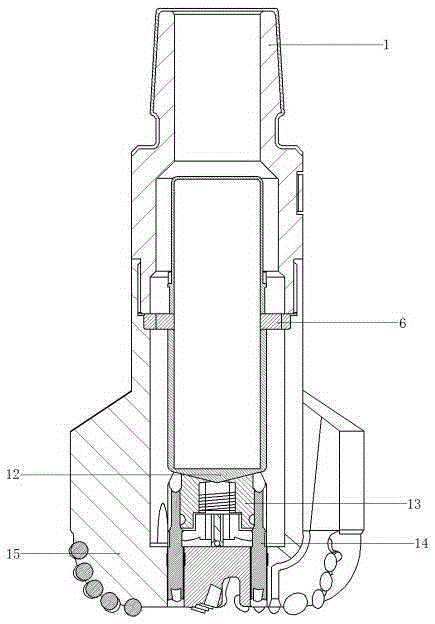

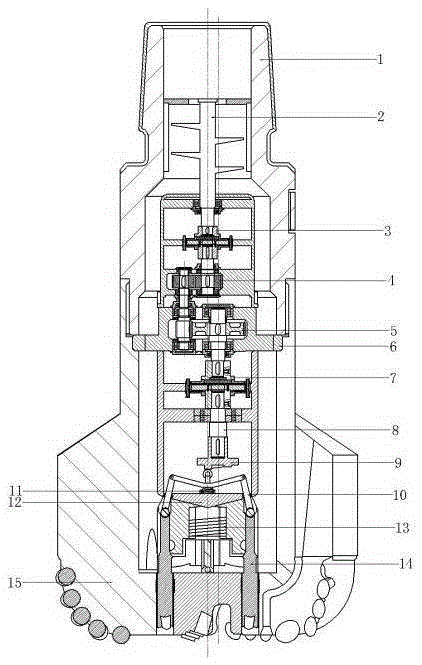

[0010] According to attached figure 1 As shown, a new type of PDC bit that uses impact to improve rock breaking efficiency is composed of a bit base 1 and an internal transmission device, wherein the drill base 1 consists of a carcass, a crown structure 15, a central tooth 14 with movable main blades, and an internal housing 12. And shock absorber 13 forms; Internal transmission device comprises power unit, transmission device, drive unit and impact device composition. Among them, the power device is composed of baffle plate, blade shaft 2, deep groove ball bearing and coupling 3; the transmission device is composed of transmission ratio transmission 4, primary reducer 5, and magnetic coupling 7; . It is characterized in that the blade shaft 2 is positioned by the upper port baffle of the drill bit, the lower end of the blade shaft 2 is connected with the coupling 3, there is a deep groove ball bearing between the blade shaft 2 and the inner casing 12, the bearing baffle is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com